Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 07/31/24 in all areas

-

There are many things I've learned in the year or so I've been tinkering with clocks & watches, most of them courtesy of the helpful WRT community. By way of an attempt at giving something back - in the sense of 'paying it forward' for the possible benefit of others at an early stage in the hobby - I thought I'd mention one or two of the things I've assimilated & find generally useful. The first is Patience: not letting oneself get annoyed when parts won't sit the right way up for the tweezers to grab and/or won't slot easily into place. To help, I remind myself that with each attempt I'm improving my manual dexterity ("practice makes perfect") so the time spent should be looked on as an investment. This approach was reinforced by reading, in George Daniels 'Watchmaking', his advice to simply practice turning tweezers through 360 deg. while holding small objects to improve one's dexterity. The other aspects of Patience I've learned are knowing when to walk away; and not trying anything tricky if one isn't in the right frame of mind. In terms of techniques, I've learned to start small screws once seated by gently giving them - with a 'stroking' motion - a few turns with the tweezers so that, being then somewhat secured, I don't 'go down a snake' when applying the much heavier screwdriver. I find my oilers are also useful for starting screws more gently than I can with the screwdriver. Of course I've lost my share of springs & screws as I've been learning just how much/little pressure to apply to them and have spent much time on my hands & knees. Yes it's frustrating but when I do locate one of the little b----rs I find I'm feeling as I imagined the father of the prodigal Son felt rather than cursing it! Another aspect of Patience, I suppose!3 points

-

I am reminded of the saying, "If you have nothing good to say, then say nothing." Seems rather apt here. I did my time with other apprentice fitter and machinists. I have since worked with other fitter and machinists. How one turns out is directly related to how much one listens, learns and applies oneself. (from someone considering doing the DLC course via BHI)3 points

-

3 points

-

That is not a spring bar it is molded to the case. Open ended straps are for this type. Now it has been cut you will have to drill holes each end and fit a spring loaded bar, then you can fit a stitched strap or whatever floats your boat.2 points

-

You slightly bend a half of the bar, to fit the leather strap on the other half, then slightly bend the side with the strap to the same height as the one you bent before and manouver in the half bar into the tube of the strap, finish by bending back both halves of the bar to a straight bar as if one bar. You can drill out a hole in the lug, but might find the bar comes out as well , leaving a wide hole, too wide to fit in a spring bar.2 points

-

2 points

-

Are you sitting down Richard because you have got it right. Congratulations. Now for the info. The ways of telling it is the late period for Longcase clocks and in this case White dial longcase clocks, painted dials are known as white dial. You can see the dial is full full from the four corners early one you would have a break between corners, also the painting is not good gone are the finer detail of the pictures. The case late cases had very short doors and wide the cases were chunky without fine detail heavy looking again very wide. I've included a close up of the dial and can see what I mean about detail.2 points

-

Welcome to the forum. Would need to see photos of the movement but it could well be a stem problem.2 points

-

It took me the longest to understand that braking grease doesn't have a braking effect but helps the spring slip just enough. Then I heard someone say that too much braking grease, I believe it was Kluber, would actually put a brake on the slippage. I don't know what to think about that.2 points

-

Your clock is called a granddaughter and I would say it is German. It is a westminster chime with strike, the duration should be around 8 days. As for the pendulum what Kalanag has suggested is a good way of finding what you need.2 points

-

This is my "no more watches for me" watch. I hope. At least for a while. I've been very fond of all things Japanese lately, especially vintage LM and KS Seikos. And old Seiko tools. I just put together a complete set of S-220 crystal presss. Anyway here's the watch. KS 4502-7001. Manual wound and originally chronometer graded according to the serial stamped in the bridge. 36000 bph. I hope the parts are ok. The crown is a diver type so there's a little struggle to change the gasket.2 points

-

Hi Dmitry, First of all, not clear what it means "After 4-5 winds". If it means "movements of the fingers when turning the crown", then this should be probably about one turn of the barrel arbor, then the spring is definitely not slipping, but the internal end is not attached well to the arbor. If it means "revolutions of the ratchet wheel", then the revolutions should be about 6, the spring is slipping and another type of grease should be tried. But as 4-5 is not so far from 6, the watch will work and the power reserve will be at least 2/3 from the normal. Is it the case? For sure the internal end is damaged and it is not clear how long this spring will be able to work before breaking.2 points

-

2 points

-

2 points

-

2 points

-

Here's some more details on the 2209 lift angle. https://17jewels.info/movements/w/wostok/wostok-2209/1 point

-

Hi @Neverenoughwatches I have one like that myself but never used on anger. The dies fit over the crystal and compress it from the sides I believe. Did you get no instructions at all.1 point

-

Looks like a fixed lug bar to me, which is why it didnt pop off, ahhh i see sarcasm Good way to spread the lugs as well, snipping the pin with nippers. I think Joe means a simple one piece leather strap to thread through. Common leather strap on ? not from around where i live matey, dont know bout you Rich i but I'm still old school . If it aint working pop a pill.1 point

-

Its likely a pin pallet, in which case you are straight welcomed to 404 club here. The date change complication includes several parts to make it jump. Hands and dial plate must be removed to get to date mech.1 point

-

If thats in their curriculum then there is no need for me to study that part, i can expect good marks here. Very true Michael, i take this stance and have spoken this phrase many times during an argument, its the perfect finisher, works every time and opens the door for you to leave without saying another word.1 point

-

I will now just observe on all questions about clocks and let you take the lead. I think I will enjoy this, I haven't had a holiday in years.1 point

-

1 point

-

Looks like it could be re-banking from too much amplitude. Are you sure you have the correct lift angle set ? Can you hear it making a galloping sound when it does it? I have a cal 2414 which has a 42° lift angle. It also has a high amplitude, but avoids re-banking. Does it do it if the movement is vertical ? If not re-banking, could be coils sticking together. Sometimes it can be really hard to get all the sticky gunk off hairsprings. I assume you have demagnetized ?1 point

-

1 point

-

I will open the case, when it arrives. It’s beat up, but it was cheap so could be fun to clean it, polish the crystal and make it run.1 point

-

It looks fine and a good price and it is all complete and having a glass dome. Koma didn't make all that many they were not one of the large factories producing these clocks. I would go for it and getting a key is easy. The base will need cleaning but Dell has a good video showing you what to do.1 point

-

Do some testing with different lubricants (as I did) and you get even more confused1 point

-

The co-efficient of steel on brass us 0.51 dry, 0.19 with grease (dimensionless). Thus grease must decrease the friction. I can only assume that braking grease does reduce friction but is formulated to do so at a predetermined torque.1 point

-

1 point

-

There's like 13 recent discussions on braking grease, including one proposing braking grease is like a cult belief. There are different ones for different cases, I actually remember the Moebius numbers: Glissalube A 8213 brass barrel Glissalube B 8212 aluminum barrels Glissalube 20 8217 general purpose Kluber P125 high end high performance high price Kluber has done the trick for me since I got some. Prior, used Glisslaube A or B as needed. One or two cases with smooth (unnotched) barrels required roughing up the barrel wall, long-term effect to be seen. When I started working on my own cars at 17yo, I quickly saw I had to sink some money in tools. In watchmaking it's very similar, and you can get by with some very basic lubes, but at some point you have to get the good stuff if you want a good result.1 point

-

I think your problem is related to the inner coils of the mainspring were it hooks onto the arbour. It looks damaged, did you have to manipulate it to fit the arbour because the new mainspring arbour hole was too big? I think what may be happening that as you start to put a wind in the way the mainspring inner coil is deformed it is releasing pressure on the bridle and causing premature slipping. Was it an genuine mainspring or after market ?1 point

-

1 point

-

1 point

-

Lol no , you have to sit exams and pass them to earn qualifications. Membership entitles you take their DLCs, at a cost obviously, free monthly magazines and i guess a few other perks.1 point

-

1 point

-

So did it fit OK at this point? As @mikepilk said the hairspring isn't right and have you done anything with the top jewel as the screws look obliterated?1 point

-

1 point

-

Run away Ross , run away and dont watch. Dont tell us OH, you're that impressed You're completely lost for words Definitely a special thing alright1 point

-

"What's more annoying is the people in the comments, they thing he's doing a very good special thing" "miraculously turned into a different spring Even as a novice I would never have considered such an action acceptable, or to try to con people. Going to continue running.1 point

-

The movement, dial and hands move as one unit within the suspension. There will be a restriction in the build as to how close the hands and dial side get to the crystal. Tom1 point

-

What's more annoying is the people in the comments, they thing he's doing a very good special thing1 point

-

First spring was trashed again after softening the coil next to the broken one with the bloody huge blowtorch. Then miraculously turned into a different spring. Shame the camera didn't pan back so we could see him wearing his top hat and tails and waving a wand. The sexy magician's assistant might have been the only one worth watching here Haha, I'm close behind and catching you up Ross A few therapy sessions and you'll be back to normal Ammer, i say normal.........1 point

-

It'd never work, the spring is mangled beyond belief, the release of power would be random and inconsistent and the watch rate would be sporadic at best . I do not think you can even fit the spring in the barrel without breaking it again anyway, this guy is either absolutely clueless or the biggest troll the humanity ever known, I lean towards the first option tbh.1 point

-

@nevenbekriev @Neverenoughwatches @rjenkinsgb It is indeed a pressed in bush. I pushed one out of my donor's train bridge. There's a decent chance I will be able to find a direct NOS replacement, since the American watch companies produced spare parts in huge numbers. Furthermore, I was just looking over other Waltham 12s movements and they do use pressed-in jewel settings on the train. Unlike Elgin & Illinois I'm more experienced with, who used the non-friction fit settings fixed down with screws. So theoretically I could replace this with a jewel from another donor, but then I'd want to upgrade the whole thing to 15 or 17 jewels and I might as well just restore the jeweled donors instead.1 point

-

Looking at thre picture, I doubt there is bushing there at all. Seems like it is just stamped. If there is a bush, then the best decision is to replace it. Another simple option is to mark the bush position, to press it out and then return in place but rotated to 180 degr. Thus the wheel position will be restored. Oil retention then may suffer, but using grease like 8200 will solve the problem. Punching to close the holle is possible, but it will change the wheel position and will spoil the look. Actually, spoiling the look here is the main danger in such repairs. One option is to fit thinny bush wit only slight enlarging the hole. The hole is to be elarged and blunted with tappered pin from the down side, then the pin cut and made flush with down surface, then new hole drilled in correct place. Then the upper, visible side of the pin has to be trimmed by slightly bigger drill bit or turned on the lathe with face plate and finally slightly punched with polished round tipped punch to form the top side and in the same time riveting the bush. Then final opening of the hole with smoothing broach... This technic alows to make the bush almost invisible. The other option is to drill the whole thing and fit new pressed bush, but keeping the center unshifted can be a chalenge. I1 point

-

You,l love its TG print out, some escapement on these look as if a Grand Seiko. Wear it in good health.1 point

-

1 point

-

Placed a lowball Best Offer and to my surprise it is heading my may. Ok, not the 404 price. But I thought practicing on a Swiss wind up without complications might be a useful and rewarding exercise for a newb. I gather Belforte was a lower price point Benrus. Screw on back so it is not one of "those" I read about. More for practice, learning than for wearing.1 point

-

1 point

-

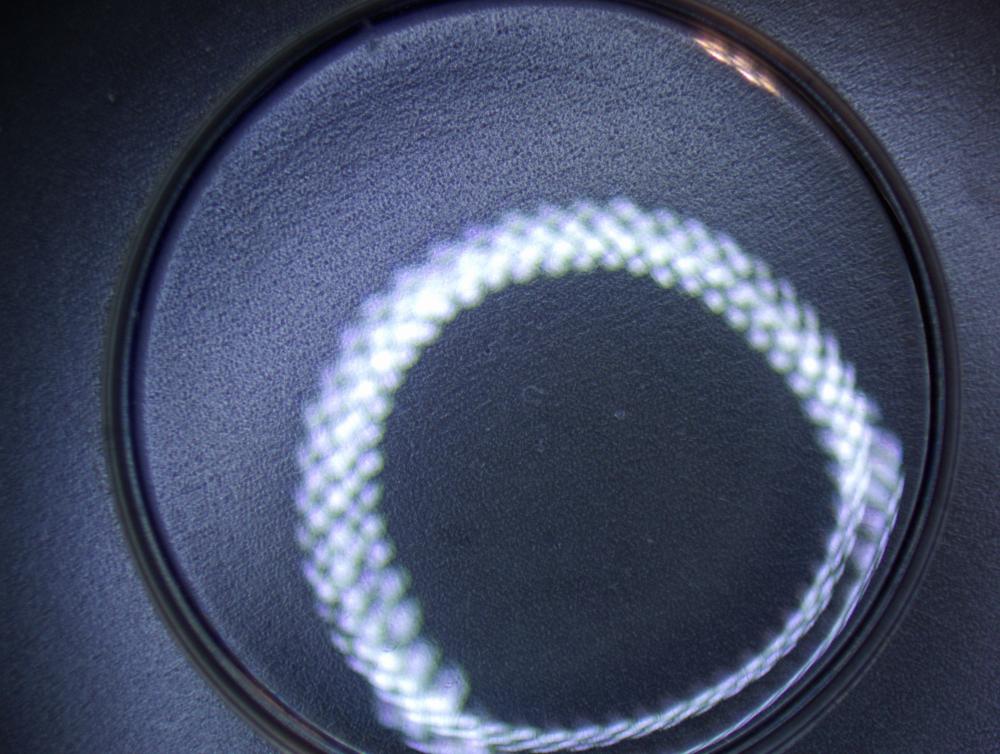

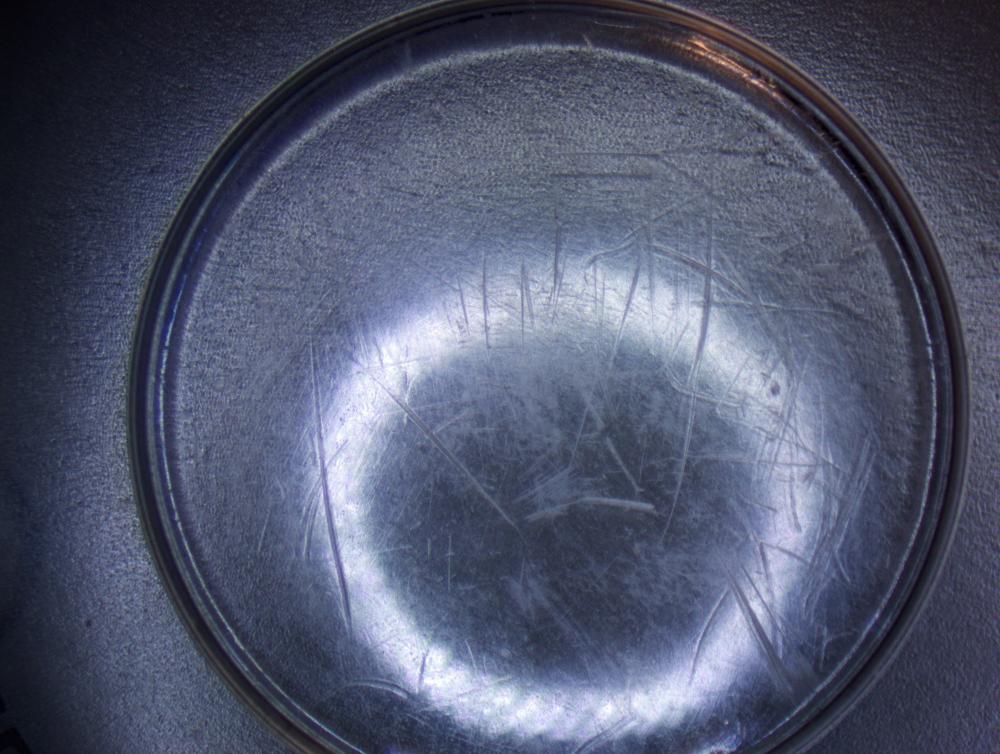

Just a little update. The movement is back together and running nicely after lots of fighting with me. Tonight was case prep. Wet sanded the crystal with 400 through 1500 grit, ran in on a polishing wheel with red rouge, then finished with automotive headlight polish. It's my first time working out scratches this deep, and I have to say it was a lot easier than I expected it to be. Edit to note that what I thought was a tiny blemish I missed in the center is actually an Omega symbol! ENHANCE1 point