Leaderboard

Popular Content

Showing content with the highest reputation on 08/01/24 in Posts

-

I closed the hole with my smallest round punches and it came out well. There is no visible evidence of the repair on top side unless examined under a loupe if you know what you're looking for. The underside has an indentation and I thought it might affect the end shake but that didn't change. It did take me three tries to broach it to the right size; I overdid it twice. But this was for practice, knowing I could still get a NOS replacement. Happily, the sideshake has been eliminated and the wheel spins free and true.4 points

-

You don‘t want to drill holes in the lugs here. Exactly what you can do, but originality will be lost a little bit. That is what I would do. But not at all soft solder - then you better do nothing - it will prevent any future proper repair. Use silver solder for repair. Frank3 points

-

3 points

-

It looks like the case and the bar are stainless? If so I would would use TIG with 316 filler. Once polished back it would be invisible. If it actually brass or nickel with the plating in excellent condition then I would use a silver alloy (technically a braze rather than a solder due to melting point). I usually use Silver Flo 55 which is relatively low temperature and cadmium free. If it is stainless then using a silver filler is possible but the fluxes are sufficiently nasty that I prefer to weld, plus it leaves a neater result in the end. If it is brass or nickel then the bar is likely to be brazed in. You can't tell whether the filler you are using is higher or lower melting point than that holding the bar in place, however with a fine enough flame you can get the heat into the ends of the bar before the lugs heat up. Some support and heat shielding by using clay would probably be how I went with it, unless I was feeling lucky. This also helps to avoid plating being damaged beyond the immediate region of the joint. Alec2 points

-

2 points

-

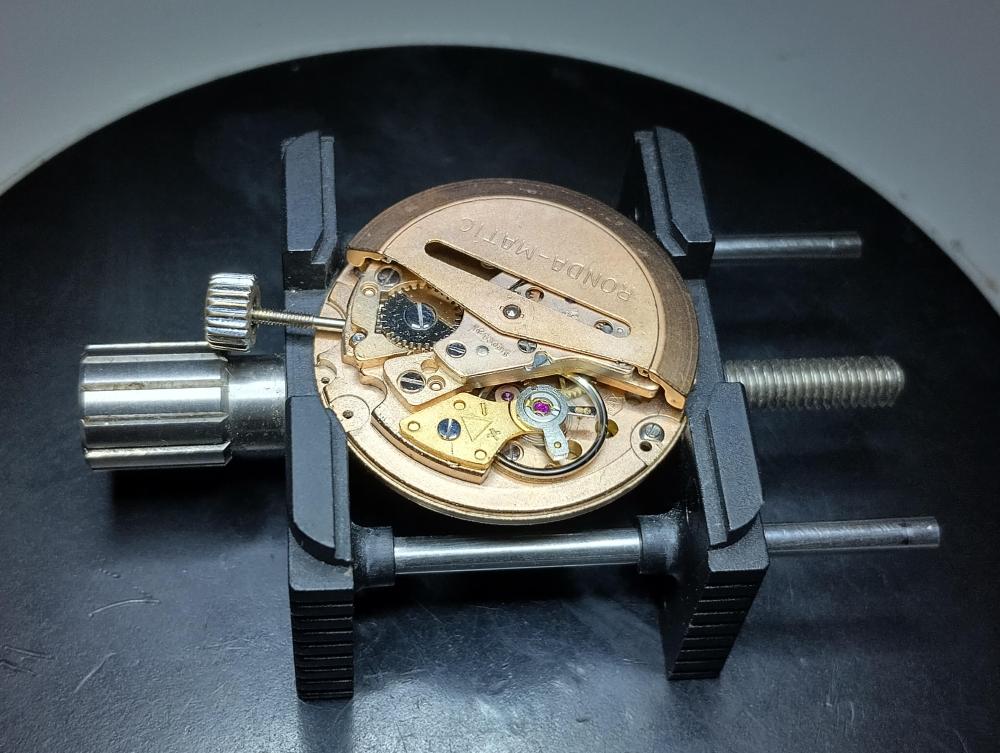

At what point does the winding become stiff, crunchy, resistant, etc? Does it feel like this when there is no power in the movement, or after you get to half way would, full wind? How doe the mainspring feel when it slips on the barrel wall? What breaking grease did you use? Did you try what it was like to wind before the automatic module was fitted? When you fitted the keyless work, did you observe the winding pinion, clutch and yoke? Was there any sloppy movement of those parts, especially the winding pinion that may have worn a larger slot, therefore it finds it hard to engage with the crown wheel because of the movement and it feels tight and crunchy, or close to fu7ll wind the clutch slips against the winding pinion because of the slop or an underpowered yoke spring. There are many thing that could be problematic. It's best to give us some pics and a more detailed background to the movement. what was it like before it was serviced, etc?2 points

-

2 points

-

A Miyota GP11 based Accurist MB613 fresh from the healing bench. Not much of a repair as the original module was completely eaten up by a leaking alkaline cell. I rarely bother to change out failed quartz modules for relatively inexpensive watches such as this, since the cost of the replacement often outweighs the value of the watch. However I found a suitable brand new replacement for this one for a very reasonable price. The new battery is a silver oxide one, so there should be slightly less chance of a repeat of the carnage. I wasn't keen on the original strap colour, so I went with a navy blue with red stitching, which oddly photographs as almost black. I may give the crystal bezel a bit of a shine to remove those micro scratches, but since they are barely visible to the naked eye, perhaps not. Lets see how much they bother me while wearing it.2 points

-

I believe the expert opinion is vintage is greater than 50 years old but under 100 and antique older than 100 years. I have also seen 25 years and up touted as vintage too. I don’t think there is a definitive definition Richard. Tom2 points

-

T&T&T YouTube channel has a couple of videos for making and fitting second hand tubes, maybe worth a look. He has lots of interesting watchmaking videos there. Tom2 points

-

https://www.cousinsuk.com/product/female-0180mm-5mm-to-24mm-iso-swiss Cousins has female spring bars. I'm wondering if the fixed bar could be cut off in the middle, leaving 2 short projections on each end for the female spring bar to latch on.2 points

-

You get me!! I’ve seen a couple fixed lug mils like that Grana! I speak for everyone…pics please !! Yes, Ty…and I think those thick spring bars look clean in that type of repair…there’s still the other fixed lug which may be an issue with a spring bar/stitched style strap but a nato or pass thru isn’t going anywhere2 points

-

2 points

-

If anyone recognizes this part, then you understand the nightmare which is the Slava 2414. The date detent lever and spring are first installed to the underside of the date cover plate, then the plate is flipped over and screwed down to the mainplate. Sounds simple enough, right. But the slightest shake or bump could launch the lever and spring into orbit. I've watched several videos on YouTube and it looks like it's the only way to do it. You can't screw in the cover plate halfway and slip the spring in, like some of the early Seikos. I've done several using this method and have never enjoyed the experience. Then it hit me.... Why don't I just glue the blasted spring to the plate. So I used a hard setting UV glue and glued the short tail of the spring to the plate. And viola! Problem solved.1 point

-

The setting is at 30A but I am using pedal control so I would think around 10A. I am using a 0.8mm ceriated electrode. I have pulsed mode available but to be honest I don't find it useful at this sort of thickness. I use a zero downslope. I tend to strike the arc on the filler, raise the current enough to melt a bead and then hold it to wet out both sides, then power off. It doesn't give the neatest of edges compared with a longer downslope but it doesn't undercut either. I tend to aim for an oversized bead and file back, rather than keep close to size and risk being too low. Alec1 point

-

If the wheel is OK, then it always will turn true. It doesn't depend on the bearings position. But if the bearing is shifted, this will affect the depth of mesh with the neighbor wheels. Small shifting (this is the case here) has not that significant effect1 point

-

1 point

-

https://speedtimerkollektion.com/search?search=citizen+hands&sort=relevance%3Adesc Check these guys out. I've bought from them many times1 point

-

Yep! The broaches I use go down to 0.05 mm up to 0.3 mm. Perfect for the job. Bergeon 1896- G and 1896-H, cutting and smoothing broaches. Not cheap, but invaluable! Them coupled with a JKA Feintaster bench micrometer and you're go to go1 point

-

It's a piece of wood that says Constantinople. It has to be from 1930 backwards because it was changed to Istanbul. You never know Constantine the Great might have made this back in 330.1 point

-

A wooden stamp, those departing constatinople got stamped on the wrist with this , for free re-entery , or vice versa.1 point

-

Are you sure the problem isn't with the arbor? Edit 2nd thought is are you winding the spring in the correct direction?1 point

-

See, the 3th wheel has the one table riveted to the pinion, but the other must turn free. If not, this is the problem with the original wheel. Check it and clean the wheel well and ensure that the table rotates free. A little oil where the the free table is on the pinion will not be useless @nickelsilver has explained well the purpose of this train system in another thread, don't remember where, but try and search. The russians got it from Zenith 135 calibre, which they produced as Восток/Волна 2809 and used it in Poljot 2209 and 2615 and then in this Wostok2209. I will only say that this system actually looses power and in some degree tends to stabilze (equalize) the torque of the main spring in the train. The main idea is to solve the problem with the additional seconds "free" pinion, which would make the second hand jump 2-3 seconds in the limits of the free play of the engagement of the pinion with the 3th wheel. Now the pinion is not free, as the riveted table is engaged with the pinion, then the pinion transmits the movement to the free rotating table and it then transmits to the 4th wheel pinion. It is not normal that reducing the amplitude (due to drop of torque) leads to such significant increasing of the rate. I would check the depth of the escapement. You may try to replace the pallet fork from donor to see the difference.. The amplitude on the video is about 275.1 point

-

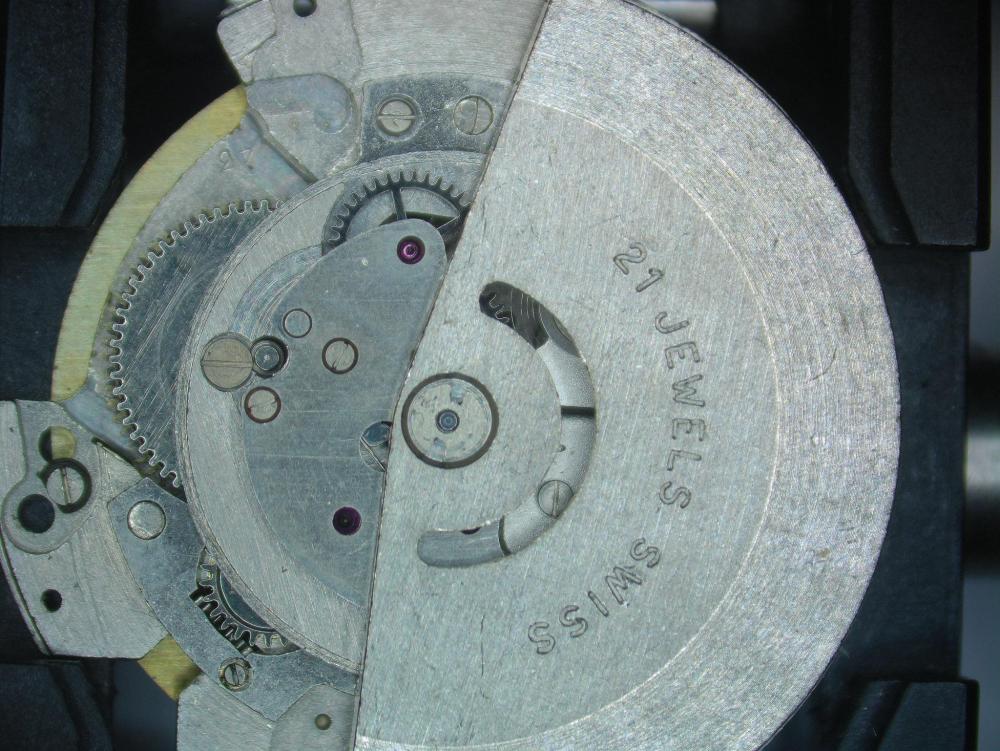

HWGIKE#4 EB8127 Full service. Roskopf, 21 jewels, automatic. Don't forget to put the click back into place because it is in the middle of the sandwich, cannot be easily accessed. My first ever Rolex... oh wait .. Raflex! HWGIKE#5 AS1916 Full service, swiss lever, 25 jewels, automatic, calendar. It was full with some green grease covering everything, maybe old lubrication?1 point

-

I know, right? I can only imagine they thought the spring bar was stuck. their surprise when they learned the mistake1 point

-

Personally, I would repair it as it is rather than drill holes for spring bars. I have done three fixed lug repairs in the past couple of months and am probably doing another one in the next few weeks, although the owner has not yet decided whether they would rather keep the originality of the fixed lug or have more choice of straps. The OP's example is a very straightforward one to repair, in practice a lot less work than drilling out spring bar holes well at both ends. Alec1 point

-

Given a Sellita220/ETA2824 I‘d say the hand slips on its pivot.1 point

-

1 point

-

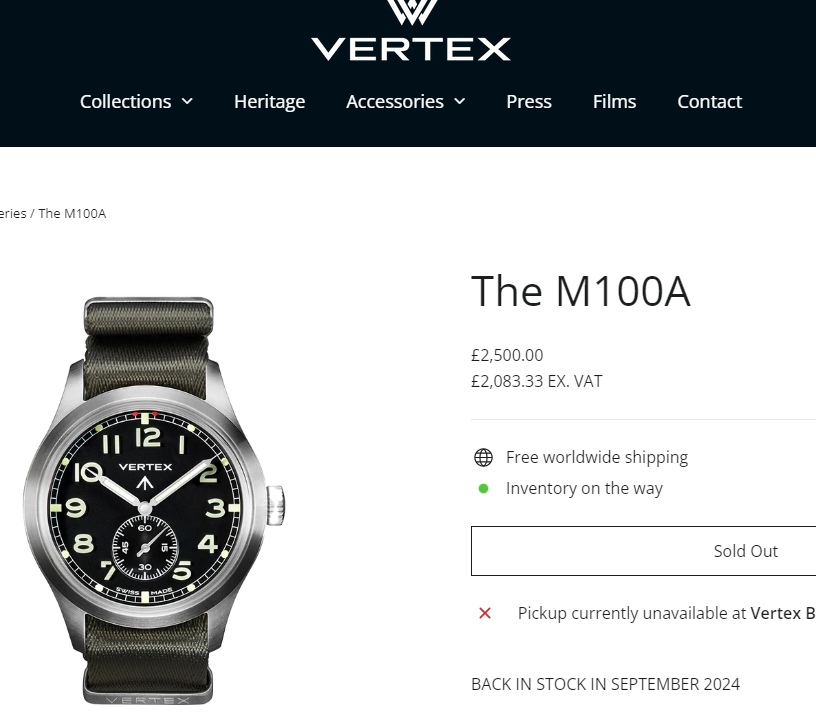

Haha, i did say " ahh sarcasm " . You gotta get up early to catch me out with that style of humour. Recently re-established if I'm not mistaken , by the grandson of the original importer in the UK. I have something special coming, its not in a military case but this watch does house the KF 320 .1 point

-

Hi. The bestfit books were up loaded by old hippy using the term. Mediafire. If you look that up in the search box you will find them . You will need to scroll through the list. If not I am sure old hippy would oblige again.1 point

-

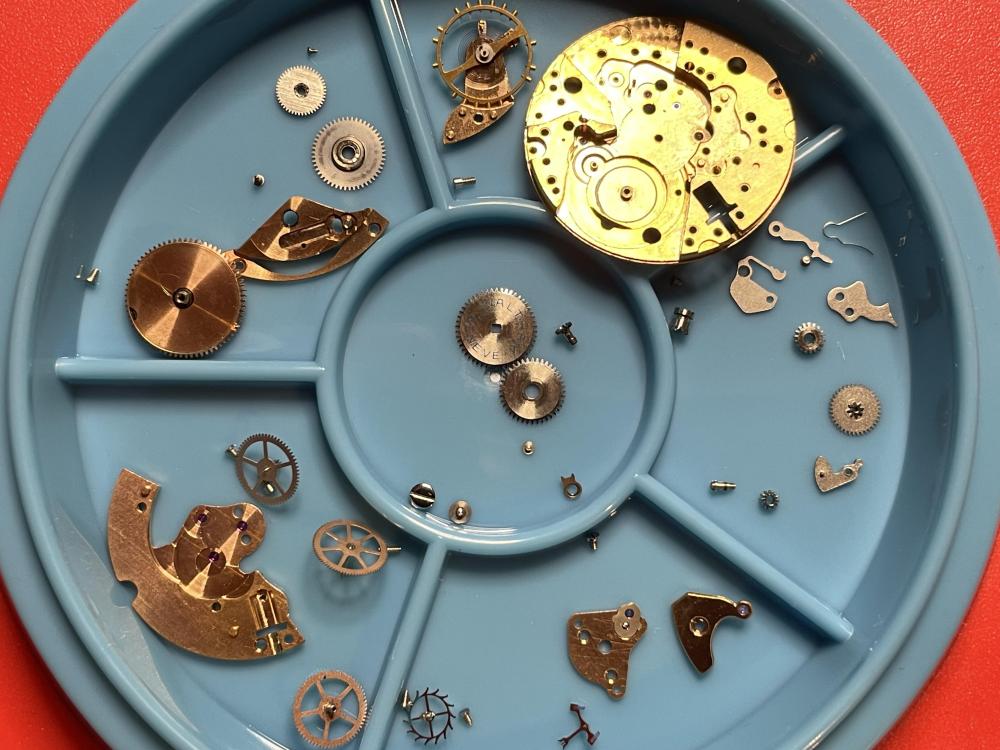

Although it's obviously a bit of a gimmick having so many jewels in the rotor, I don't see how it can be claimed that they have no function - they limit the end float or twist on the rotor. I think it's safe to say it will never get the wear and scarring seen on some auto movement mainplates as the rotor bearing wears over time! OK, I have to confess, it got to me - I stripped it down yesterday evening.... The mainplate is marked AS1700, which according to the 17jewels site is pretty much the same as the AS1580 mentioned in another article on this watch. (The movement itself is a seventeen jewel type). It has an unusual auto wind system, at least from my experience so far. That feeds a gear train to a wheel below the barrel, containing a centre ratchet which engages the underside of the barrel. Main movement parts, with the mainplate there just for the photo. Auto section parts (+ misc bits):1 point

-

It all depends what the actual OD of the opening is compared to the Cousins generic ones.1 point

-

1 point

-

The Best Fit books are on this site I uploaded them both a long time age. If you can't find them just ask and I can upload them again1 point

-

That is not a spring bar it is molded to the case. Open ended straps are for this type. Now it has been cut you will have to drill holes each end and fit a spring loaded bar, then you can fit a stitched strap or whatever floats your boat.1 point

-

That sounds like a risky manoeuvre that could bend the lug as well if its not supported. Then trying to re-align the pins with the strap fitted sounds fun. I'd prefer altering the strap, unpick the stitching and re-sew it.1 point

-

You slightly bend a half of the bar, to fit the leather strap on the other half, then slightly bend the side with the strap to the same height as the one you bent before and manouver in the half bar into the tube of the strap, finish by bending back both halves of the bar to a straight bar as if one bar. You can drill out a hole in the lug, but might find the bar comes out as well , leaving a wide hole, too wide to fit in a spring bar.1 point

-

1 point

-

Geez, 65 jewels. Hadn't seen that type of jewel arrangement before on the rotor.1 point

-

To improve my skills and to try things I have not done before I started a challenge: "Here we go, I know everything 100". The rules are simple: I must repair/service 100 different movements and there must be at least one successful balance staff replacement done. I have already completed 11 of them and 3 more are already on the bench waiting for parts to arrive / shellac to dry / waiting for me to get the practical knowledge on the lathe or buying a molfres. I am away from my bench till September and until then I am going to add the pics I took about the finished watches. HWGIKE#1 Ronda Matic 1239-21 Full service, there was an excessive amount of oil in it. Spent hours looking for parts on my carpet with my reading glasses and a torch. Swiss lever, 17 jewels, automatic. HWGIKE#2 BFG158 Full service. 25 Jewels, Roskopf, automatic. Very loud on the bedside table. HWGIKE#3 Felsa 4007N 21 jewels, swiss lever, automatic. Crown is not original as far as I can tell, and its a bit difficult to turn it, as it is a bit too tight on the tube.1 point

-

Braking grease like P125 is gritty to the touch. I’ve always assumed it was increasing friction or at least maintaining friction once the spring begins to slip, so the spring slips and catches smoothly and also reducing wear. The problem is calling it ‘grease’1 point

-

I think it depends how you wish to term it H, braking and slipping seem like they are the two opposite ends of the scale and they are when they are at their extremes also but a fine line between them when nearing the point of slip. The correct moment of slip is what counts. Maybe " friction grease " would be a better name, so greases have different gripping properties. I suppose also to consider would be how much the spring will slip until is grips the barrel wall again so minimal amplitude is lost. Maybe there is a specification for this within the grease ? there should be considering how much some braking greases cost. " slip distance " ? " braking reaction " ?1 point

-

1 point

-

Do you mean to say you measure closed pipe seconds & chrono hands with a broach too? In that tiny pipe?1 point

-

I think I left it for several minutes. Like you, I will still give a swift wipe of an acrylic with a splash of IPA.1 point

-

My personal favorites is at four minutes and 54 seconds. The machine with how many parts? All before CNC on the other hand if they Needed to change the tooling to a new watch plate how long would that take? Then if you like the movie there is a book different watch company few years before but still it talks about the tools or some of them https://archive.org/details/evolutionofautom00mars_01 point

-

I will have to find time to watch all of this. 5min in and I am floored by the automated milling and the "ten plates at once damaskeening rig"1 point

-

One is staked to the pinion, one is free. They both engage the sweep pinion, but only the free one engages the 4th pinion. The result is the sweep pinion leaf engaged gets sandwiched; the staked wheel pushes, the free one must turn too, but it is stopped by the 4th pinion. It’s a great system that gives a perfectly stable sweep and doesn't suck amplitude like friction springs.1 point

-

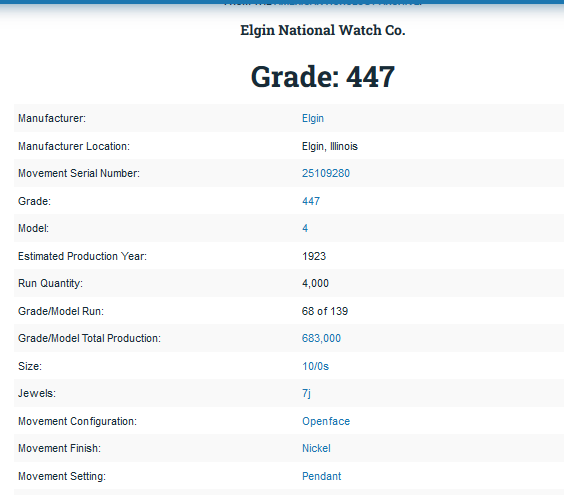

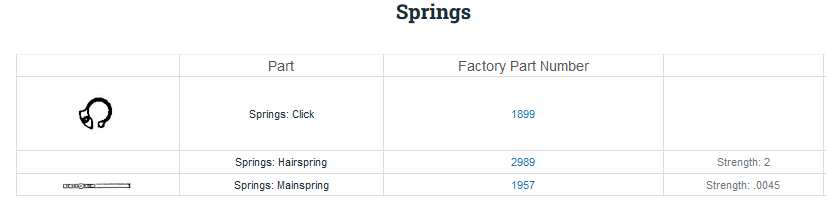

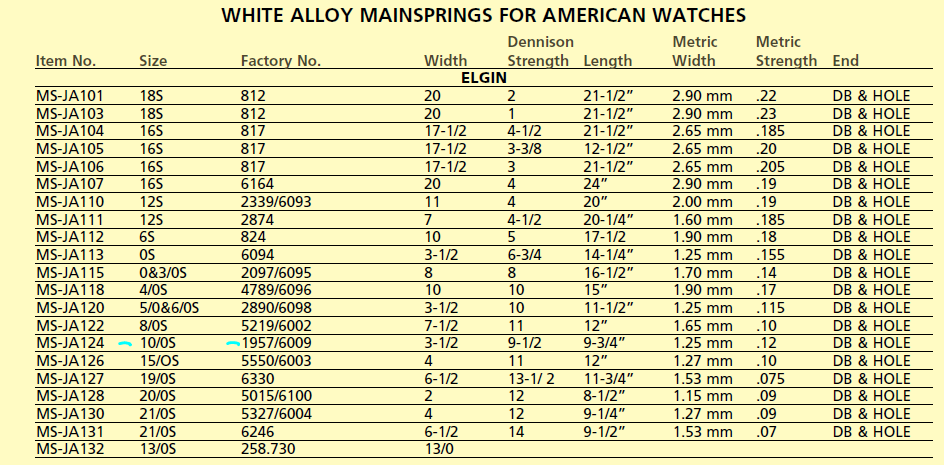

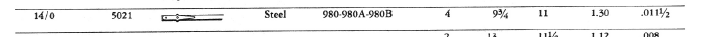

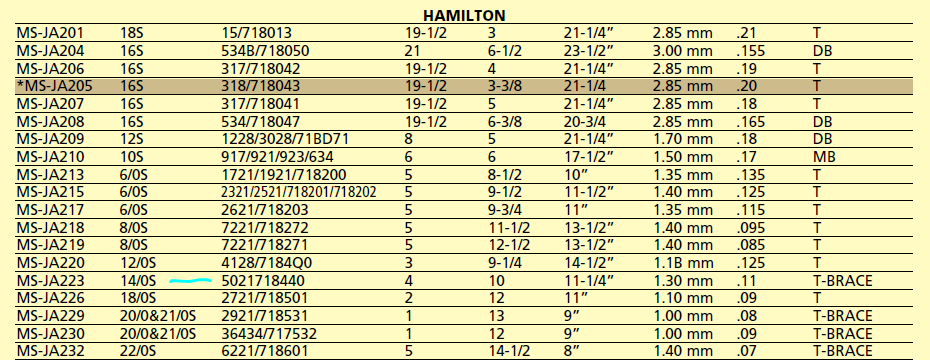

did you look at your picture of your Elgin? I circled something for you it has letters as because it's an American-made watch if you look at pocket watch database you'll see Elgin national watch company.. Then your grade numbe is 447 not the number that you quoted is really important to get the numbers right if you want to get the right parts tthen when you're on the pocket watch database side if you look on the left-hand side one of the categories is parts.. Then from the parts section llego Springs and also about the image we see the mainspring. then notice in the bottom of the image there is your mainspring part number 1957 strength .0045. the. But it looks like that's going to be a problem because well mainsprings are always going to be a problem. Which is why the other way always do this is take the mainspring out and measure what it is and then we can look on the listings and verify the spring in the watch is the same size and we think it is. Looks like it's been upgraded to a new part number and as usual you're only going to find one spring if you go with the modern as they don't make all the springs they once did but looks like this is your spring I'm confused here as this is not a 12 size watch? proper diagnostics I think is needed. In addition typically changing escapement components in vintage watches is a bad idea because they were adjusted to each watch. Plus I see your watch has movable banking pins I wonder if anyone's ever move those? We really need better pictures to see what were looking at.. Then look at the parts list another problem typical with vintage watches looks like there were two separate pallet forks for this watch. in other words it was made by the Hamilton watch companyanother US watch company. then I just can't do a couple of quick copy of pace and not inform you where all this came from as it's way past my bedtime and I don't have time to explain. Other than typically with mainsprings take out the old spring and measure it as things work out a lot better if we can compare the old with whatever we think were finding oftentimes especially with a vintage there could be possibly validity of variations. Then with both Elgin Hamilton they had the original steel Springs and often times they had newer alloy Springs with different part numbers and of course aftermarket would have different numbers tthen I'm assuming this is the correct spring then we discussed this somewhere on the group because the type of end of spring is this or both of these have you will be extremely unlikely to dish of the spring and you're going to have to the hand wind it in or get some mainspring wagers which would be preferred and then there is a procedure.. Simplistically wind most of the spring into the wind your belief a little bit out the end dish of the whole thing in the barrel which is actually quite easy to do if you're holding a Winder and observe what you're doing it like the end in place into its slot hold it down and pop it out and as I said we have pictures somewhere to explain this when you get your springs. Because otherwise if you try to shove the spring in the end is never going to catch and that will be a problem tthen you go to eBay and search for both springs you might be lucky and find the original Elgin or Hamilton spring and yes even though their vintage usually the originals are much better than the aftermarket especially lately where the aftermarket's seem to not be there best.1 point

-

1 point