Leaderboard

Popular Content

Showing content with the highest reputation on 08/02/24 in all areas

-

I know a watchmaker that uses this method. He told me that it can only be done on fairly new watch movements that have been serviced within their service intervals, so there is no congealed lubricant to begin with. If there was, the jewel holes would need pegging clean. He also said that there s a higher return rate than if the movement were properly serviced. Personally, I would feel I was conning someone if the movement wasn't completely disassebled and checked before cleaning etc.4 points

-

Maybe I'll strap my whole collection of watches to my arms and legs, poor some of this stuff in the bath, and splash around a bit . Service the whole lot in one go3 points

-

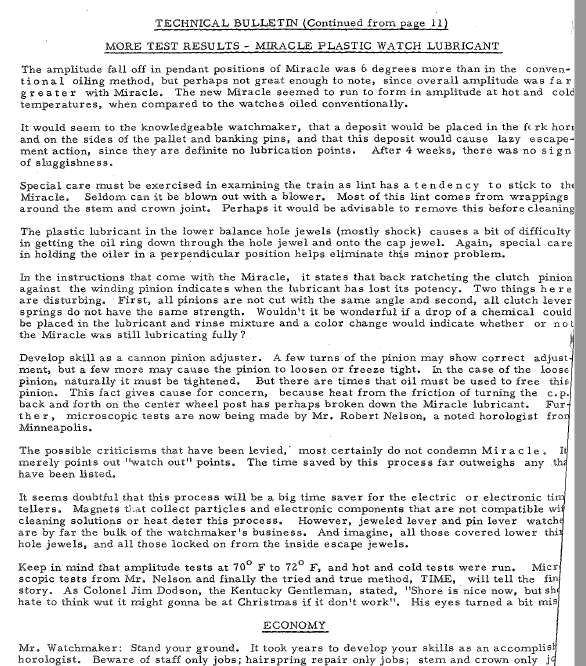

I like the wording of this what is it actually used for well that's a secret were not authorized to tell you. But seeing as how it's still being sold there must be a demand for the secret product. Now that we got that out of the way does it have a purpose well? Oh and you forgot one this one is still left most of the other ones appear to all be gone which is just as well this one is for the clock people so they don't feel left out You have a very good memory technically I worked into shops that used a variety of the miracle substances as I like to call them. The first shop the wife disassembled kind of in other words movement comes out of the case hands and dial calendar stuff comes off as placed in the cleaning machine holder where the entire movement was cleaned and even hold really do 20 watches at a time quite a volume of watches this shop would be the shop that the highest volume of watches I've ever worked in a shop that did and yes they did it at a bargain price. The second shop was a much smaller volume and something weird happened? Basically the three watchmakers not the shop owner had Swiss influence. Two of us had gone to wostep and there had better a school in Singapore someplace where somebody who had been towards step did the training so the three of us so enthusiastic about our work conveniently missed the last rinse of miracle substance and we lubricated the way you're supposed. The owner conveniently used his miracle substance. I was looking for an advertisement so I found this instead. Then there were a whole variety of substances like dual lube and here's an advertisement. Plus it tells you how to use it. Here's some more reading of the miracle substances. Unfortunately you cannot hear the tone of my voice the incredible lack of excitement I have regarding the miracle substances.3 points

-

I had that opener, it is for the seastar seven I never used it I found you easily remove the glass with the good old faithful Vigor Bergeon.3 points

-

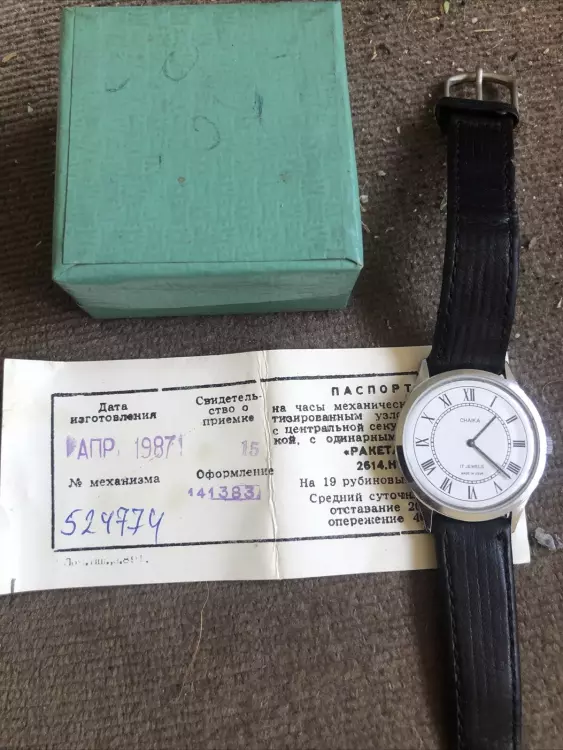

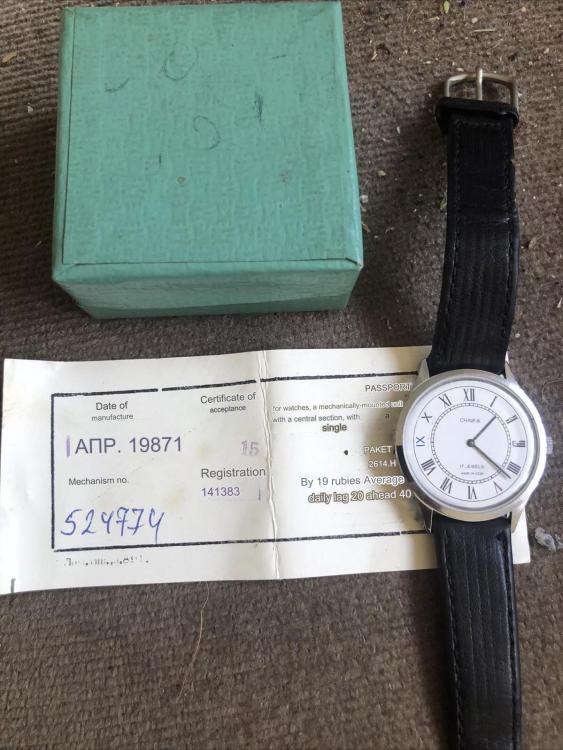

Advertised as 'Chaika 17 Jewels Men's Mechanical Watch USSR with Box & Papers - Not Working' - all of which is technically correct, however the box and papers seem to belong to a Raketa 2614.H based watch and I'm pretty certain this is Chaika 1601. Having said all that, the watch looks clean and the dial is perfect, and furthermore I have several USSR Raketa 2614.H watches from the correct period, that would most probably have started life in a box identical to this one. Obviously the 'Mechanism no' wont match the one on this "Certificate of Acceptance" but that is a minor detail. I wouldn't be trying to pass anything off as unauthentic, and its not as if this is a solid gold Rolex. Since the cost of the lot was well within the 404 club rules, I'll be pretty happy with whatever turns up in this fun little lot. Servicing it should be easy too as I have several spares 1601 movements. One interesting note. As you can see from the translated image, the 2614.H is specified to be accurate to -20 to + 40 seconds per day. Most of the ones I have serviced do considerably better than this. Edit: I wonder what '19 rubies Average' alludes to? "Maybe you get the full 19, maybe one or two fell out in production, maybe we slipped a few extra in just for good measure".2 points

-

2 points

-

With all the round dimples in it, I think someone used it to beat something in place without damaging it (crown tube??). Probably just a handy bit of wood they came across and kept around for this purpose. Hopefully Bergeon don't spot this post, they will start selling them for $150.2 points

-

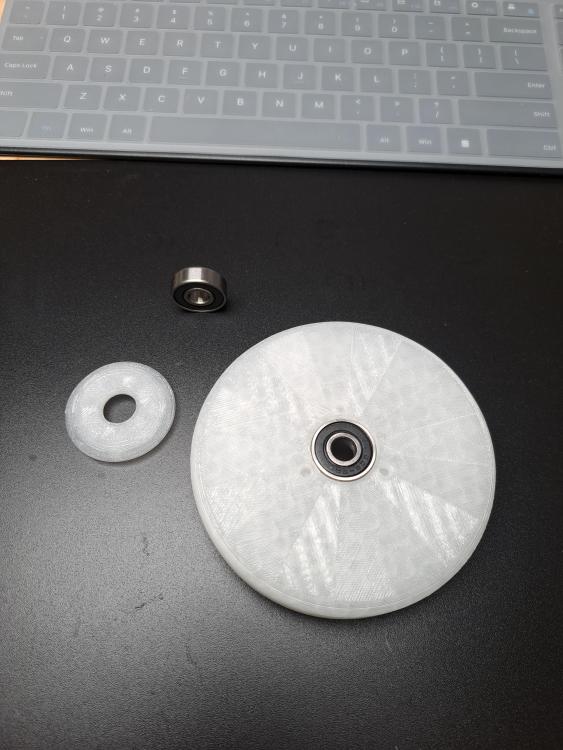

After reading a lot of you guys building an under budget cleaning machine made one myself. I bought the over head mixer thru amazon for less than $100 bucks, it has a timer bult in and can adjust the speed. I used 3D print to create the jar holders and the cover for the jars. The cover has a ball bearing to minimize the waggle in high speeds but also I cut the shaft short. The ebay indian baskets are hard to open and close, so I decided to buy the elma basket and luckily the Indian baskets fits in the elma basket. I'm still working in the drying station. Let me know what you guys think. All suggestions are welcome.2 points

-

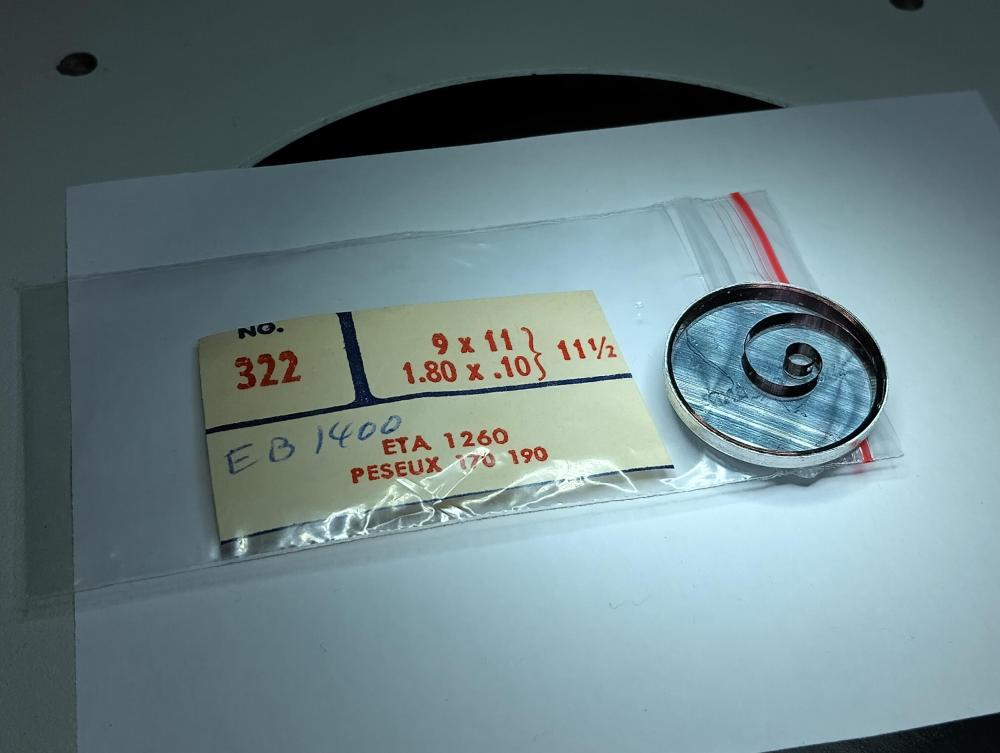

HWGIKE#6 FHF 96 ST (standard). Full service, needed a new setting lever spring. Swiss lever, 17 jewels. MAJOR mistake is made. I checked the train for free running before screwing the bridge down, but one of the lower pivot jumped out and chipped / broke the jewel. Had to source one from one of my Seitz set, and had to use my Seitz jeweling tool. Not happy about the mistake but i am happy that I could sort it. HWGIKE#7 ETA 1260 Full service, swiss lever, 17 jewels. New setting lever spring and blue main spring. HWGIKE#8 AS 984 Full service, swiss lever, 7 jewels. HWGIKE#9 Ebosa 65 Full service, Roskopf, 21 jewels - 4 of them helping sales department only Service was event-less, I had a little helper. HWGIKE#10 AS 1931 Full service, two worn parts are replaced. Swiss lever, 17 jewels, calendar and alarm. Home painted dial. Two new crowns, unfortunately they are higher than the original so it looks like a rabbit now. These were the only ones I could find with Cousins. Hands are re-lumed. Not very attractive but the movement is running happily with a nice performance.2 points

-

Also include Rolex in this process. In a variety of service centers and watchmakers will practice something called free cleaning. This is where similar to the process described above watch is only partially disassembled and run through the cleaning machine into hack and usually it's a special machine for the process shorter cycle. Then at the nice clean watch they can proceed to evaluate disassemble repair whatever before complete disassembly and basically proper servicing. The pre-cleaned method is frowned upon by some watchmakers as it basically obliterates the scene of the crime. It makes it a lot harder to look for things like metal filings if there now gone. But it does make it easier for looking for broken jewels cracked jewels where Rolexes obsessed with and shake adjustments having everything clean is nice. I doubt any of the high-end watch companies would advocate any of these substances at all. For the most part they're entirely gone anyway which tells you the miracle of the miracle substances didn't last very long. But as I saw in the advertisements of the 70s there were quite a few products Basically the first shop as I said my first job or he did this bizarre practice. I don't actually remember doing any repair? In other words the repair was only cleaning and miracle lubrication and finally regulation. So basically you are dealing with watches that cleaning fixes the problem anything that's going to need a serious repair isn't going to work with this method of all. A lot of questions unanswered. Do you think about this like I thought in one of the instructions you are not supposed to clean the entire balance because you get it all over the hairspring etc. but you rinse it off so I guess well I remember we did lots of watches so I guess it worked. But if everything is coated with a microscopic film of lubrication Lubricating the pallet fork for instance would be totally insane because the oil will be whisked away because the thin film of oil. Although on the higher frequency like higher frequency lady Seiko watches. This shop was doing a lot of Seiko watches because these were the early days where the shops could be authorized this shop was authorized Seiko service agent. So on the lady Seiko high-frequency the pallet fork came out it was rinsed off and the entire pallet fork was epilam. But the other watches I just have to wonder Now we end up with an interesting problem? As I said this was my first job out of school so was extremely long time ago I believe I got one third of whatever they got. It's basically what I would call a percentage you get a percentage of whatever they get. A percentage shop is extremely bad if there's a problem and you of a problem with the watch now you're not going to get paid to do the repair. The only way to make money is by being really really fast and no I wasn't really that fast so one of our biggest problems is is to relate the cost of this to the cost today. Plus my memory in those early days was that the jewelry store brought in the work or the people who set it from their stores nobody cared about quality all they cared about was price. So if you set up shop as a watchmaker and nobody's willing to pay the price to do a quality repair and you starve to death versus this miracle substance what would you do? As I said it's a unfair comparison because in the second shop we did service the watch is properly we did disassemble them we did wail them at least three watchmakers did the owner still used his miracle lube which left the last rinse a really pretty blue colored they had tinted the miracle substance. It's like I remember one day an entire box of safe clocks came in and I wondered? So apparently we had a contract with a company servicing safe clocks these were all modern Swiss not the pretty old ones. By the Monday they're all gone again as just think how fast it would be to and I always wondered because? I used to know somebody who worked for a security company and occasionally the bigger the banks and stuff they would have more of the clocks all he need is one to release the mechanism so you can unlock your safe so a banker something would typically have three or four clocks something smaller and cheaper might have one too would be much better. But here you have something to be extremely expensive if all four stopped which apparently on occasions they did and then there lubricated with this miracle substance fortunately other than explaining in this message I don't have to ever again think about this insanity I guess what we have would have to stop and think about this for placing a modern view of things on this time so in other words is nobody was not pay the watchmaker service the watches basically watch repair was considered at the time a dying field anyway because remember the newfangled electric watch it come into existence in the late 50s and I think this might abound about the time of the digital watch and the watchmakers all felt this was the end of them anyway and if no one's going to pay for your servicing because you have to go back and look at the last two magazines I was looking at I couldn't believe the number of ads in a professional watchmaker's magazine to the must of been a definite need for cheap servicing? Oh and of course there is the other amusement nobody sees what's inside their watch they don't know if their watches disintegrating or not all they know is that? And we cannot entirely say it was cheap because typically the wholesale shop we charge a price jewelry stores would typically double that cost and occasionally some shops would wear stores would cripple price. So the customer still paying a reasonable sum of money in 1970 but the watchmakers only making a fraction of. I decided to go back and look at the magazines I was looking at and it must've been cost must've been the prime factor some reason that this stuff came out because literally everybody had cents.just one or two products but lots of products like here's one that I didn't even know about Notice how there's a reference of long-term testing instills so much confidence in a they've tested for almost one whole year. And now the nifty product is on the market. Then yes I really do like the word miracle.1 point

-

I think your translate didn't work too well. It just says 19 Rubies and then something along the lines of Average Day which I presume relates to the accuracy.1 point

-

Wow you have been busy, love the Bentima Star, i have one also. outstanding work , you've given me a great idea to create a new thread, lets call it " Classic Mistakes " . Haha at least you can laugh about it Rambo, i think I'll keep my big cock-ups to myself. Everything else looks" bloomin marvellous " matey1 point

-

1 point

-

HWGIKE#11 Felsa 390 Full service haha, 15 jewels, swiss lever. MAJOR, MAJOR MISTAKE WAS MADE! We could call it as the train of mistakes. Benny Hill would be proud of me. Realized that there was a broken jewel, so I pushed it out... did not mark the jewel hole... only silly ppl do so, you obviously do remember what jewel hole is missing a jewel dont you? So I selected a jewel for a wheel which was incorrectly selected and tried to push it in into the setting lever spring threaded hole. (i did not know this that time). I could not... so i used some excessive force... so I smashed the jewel into dust with my seitz jeweling tool... not to worry... in the factory they did not align the hole size to my seitz set, it must be just a bit off... so I thought, so I reamed it out... placed the jewel... happiness... ohh... its upside down.. lets push it out and flip it... done... happiness.... train wheel re-assembly.... ohh dear, one of the wheel has only a hole.. no jewel.... all right lets select a correct jewel this time... (the seitz jewel set had no jewel which had 1mm OD and hole size above 19 so i had to use one size bigger in OD and consequently i had to ream the hole out to the next size, the correct hole this time), jewel placed, good end shake, free run.. happiness.... lets put together the keyless work... for some reason the screw for the setting lever spring did not want to catch.... ohh dear.... I am a happy owner of a Chinese 1.1 mm tap now! Hahahaha... Will continue this in September.1 point

-

Interesting reading. It worked well for a year. I wonder what happened long term? For 'lower value' watches, like Seiko 5, a service is many times the price of the watch. So maybe this would be a solution? * (*sorry about the pun)1 point

-

Ah, ok. That doesn‘t really matter, easy will be strong enough. But also harder flowing will be no problem, the bar is thin and solder point far from the lugs, little danger of melting the lug/bar joint.1 point

-

I believe but forgive me if I'm wrong but @JohnR725 stated that he worked somewhere that dunked the whole movement for a quick turnaround.1 point

-

Hi @Neverenoughwatches good to hear your Mum is doing well and getting out and about, The true Yorkshire grit. All the best.1 point

-

Normally for such small diameters, I'd use my dental pulse arc welder. For pieces bigger than my dental welder can handle, I use an add-on pulse timer with my 100A unit. But after my retirement, my welding machines are gathering dust in my front yard. I should really do something about them.1 point

-

The setting is at 30A but I am using pedal control so I would think around 10A. I am using a 0.8mm ceriated electrode. I have pulsed mode available but to be honest I don't find it useful at this sort of thickness. I use a zero downslope. I tend to strike the arc on the filler, raise the current enough to melt a bead and then hold it to wet out both sides, then power off. It doesn't give the neatest of edges compared with a longer downslope but it doesn't undercut either. I tend to aim for an oversized bead and file back, rather than keep close to size and risk being too low. Alec1 point

-

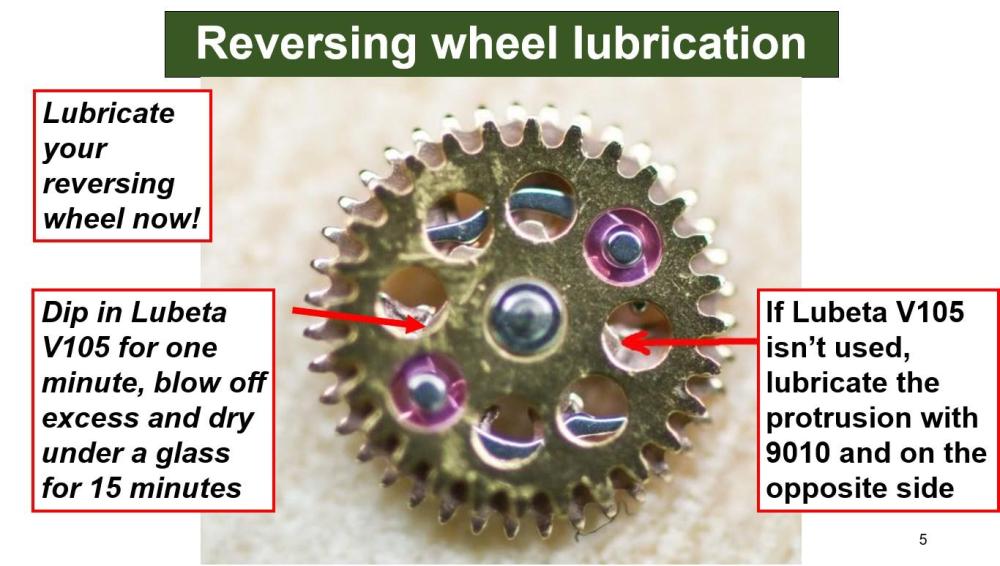

The typical reason for stiff winding (when no wear or defects of the parts) is not proper lubrication of the reverse wheels1 point

-

Otomans kicked Constantine the great in the A... and renamed the city to Islambul , Islam + bul, where bul means city in Turkish. Then some reason unknown to humans the name became Istanbul. Had noticed, thats how it must be engraved on a stamp. Rumor has it when constanty got kicked, Sh.t went the opposite direction.1 point

-

1 point

-

1 point

-

At what point does the winding become stiff, crunchy, resistant, etc? Does it feel like this when there is no power in the movement, or after you get to half way would, full wind? How doe the mainspring feel when it slips on the barrel wall? What breaking grease did you use? Did you try what it was like to wind before the automatic module was fitted? When you fitted the keyless work, did you observe the winding pinion, clutch and yoke? Was there any sloppy movement of those parts, especially the winding pinion that may have worn a larger slot, therefore it finds it hard to engage with the crown wheel because of the movement and it feels tight and crunchy, or close to fu7ll wind the clutch slips against the winding pinion because of the slop or an underpowered yoke spring. There are many thing that could be problematic. It's best to give us some pics and a more detailed background to the movement. what was it like before it was serviced, etc?1 point

-

1 point

-

It's a piece of wood that says Constantinople. It has to be from 1930 backwards because it was changed to Istanbul. You never know Constantine the Great might have made this back in 330.1 point

-

A wooden stamp, those departing constatinople got stamped on the wrist with this , for free re-entery , or vice versa.1 point

-

1 point

-

1 point

-

Hard to tell without seeing the black part in other views. I would suspect that Niko made this for a specific purpose to help in his work. To be fair it has given me an idea of making something similar for opening battery hatches. Is the black part maybe the thickness of a common coin? If soo… Tom1 point

-

I remembered that explanation. And found the thread. I've come across a few watches with the double wheel and couldn't figure out the reason. Thanks nickelsilver1 point

-

Looks to me like it's just a piece of wood with words on it. Expect it would have been a tourist gift at the time so still probably best part of 100 years old.1 point

-

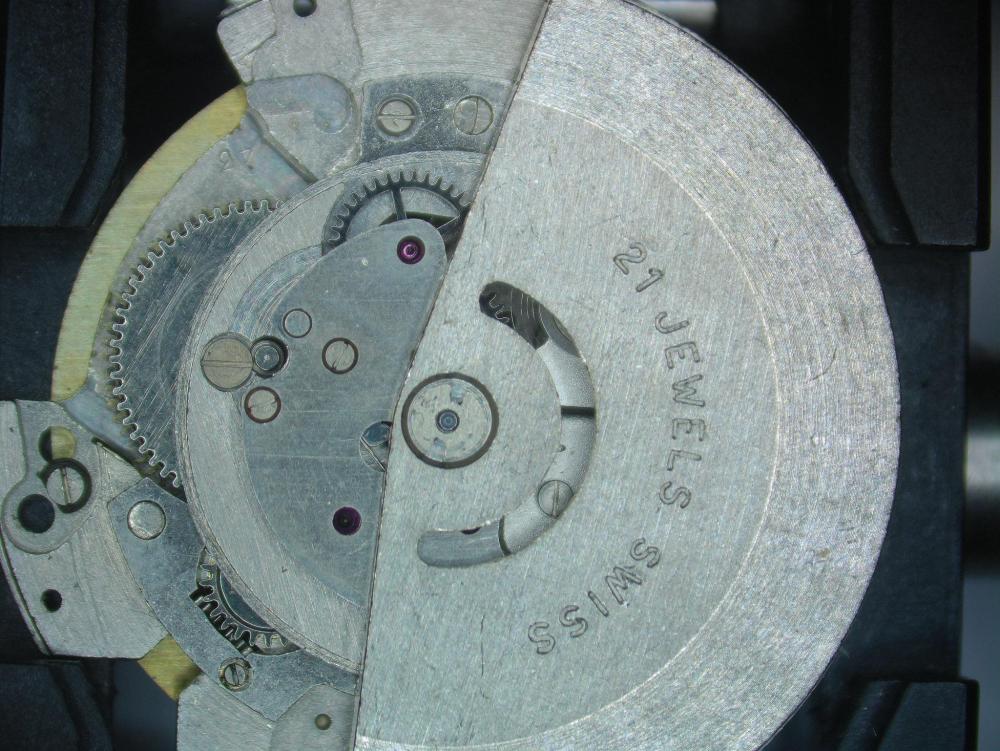

HWGIKE#4 EB8127 Full service. Roskopf, 21 jewels, automatic. Don't forget to put the click back into place because it is in the middle of the sandwich, cannot be easily accessed. My first ever Rolex... oh wait .. Raflex! HWGIKE#5 AS1916 Full service, swiss lever, 25 jewels, automatic, calendar. It was full with some green grease covering everything, maybe old lubrication?1 point

-

I closed the hole with my smallest round punches and it came out well. There is no visible evidence of the repair on top side unless examined under a loupe if you know what you're looking for. The underside has an indentation and I thought it might affect the end shake but that didn't change. It did take me three tries to broach it to the right size; I overdid it twice. But this was for practice, knowing I could still get a NOS replacement. Happily, the sideshake has been eliminated and the wheel spins free and true.1 point

-

T&T&T YouTube channel has a couple of videos for making and fitting second hand tubes, maybe worth a look. He has lots of interesting watchmaking videos there. Tom1 point

-

Looks like it could be re-banking from too much amplitude. Are you sure you have the correct lift angle set ? Can you hear it making a galloping sound when it does it? I have a cal 2414 which has a 42° lift angle. It also has a high amplitude, but avoids re-banking. Does it do it if the movement is vertical ? If not re-banking, could be coils sticking together. Sometimes it can be really hard to get all the sticky gunk off hairsprings. I assume you have demagnetized ?1 point

-

ABS has more resistance to chemicals and heat than some of the other printable filaments. I do have to zip up my enclosure when printing ABS to retain the heat and often print with a brim to keep the part from warping.1 point

-

I am sure that I read somewhere that someone like Tissot (or even Omega) were advising that the whole movement be placed in the cleaner, fully assembled.0 points