Leaderboard

Popular Content

Showing content with the highest reputation on 08/03/24 in Posts

-

Seiko 11-0630 from July 1977 I think. White gold plated case and bracelet. Condition is amazing for 47 years old and running with great amplitude without even touching it. This one is for my wife. Nice charity shop find for just £4. I always look for watches in those shops but most of them seem to only sell modern quartz. You have to be really lucky to find something nice.3 points

-

Jeambrun? https://watch-movements-archive.com/watch-movement/jeambrun-217/ https://www.emmywatch.com/db/movement/jeambrun--217/3 points

-

That is good news and congratulations. Would you like me to just pop over and repair it for you. I can supply my own tools.3 points

-

Yes, exactly. You can take off material from there but in the end the separator must still rotate free. Be careful - not to grind to much. 3-4 movements on the file and try the end shake, and if still big - again. Assembling is easy, but use some grease to 'glue' the balls. When assembled, wash the bearing from the grease in petrol.2 points

-

The hole is actually a thread. The slots on top are to screw the bearing on. I just found a scrap one from an old 7s26 movement. The bearing is different but similar construction. I'll try to disassemble it ... Well it came apart The are just pushed together. I cannot see any shoulder, so the play just depends on how far the bottom is pushed on. Those balls are incredibly small ! Correction - I was forgetting the washer. The top and bottom do push together solidly. There is no more adjustment available. The play is from wear on the sloped edges where the ball bearings run. So to answer my own question - no you cannot reduce the play.2 points

-

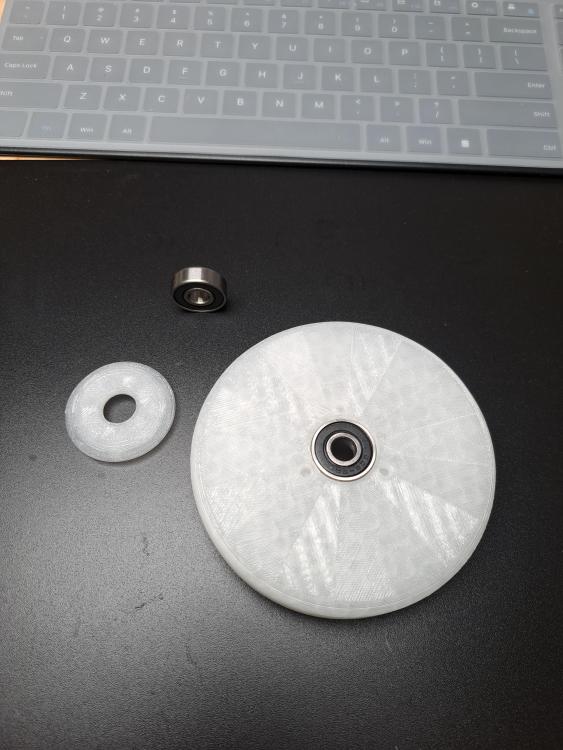

This is the one I made. I am still tryi.g to figure out how to add the drying station. I shorten the shaft to minimize the wobble in high speeds and on the jar cover I used a ball bearing which helps with the wobble. 3d printed the cover and jar holders. Jars and baskets bought in ebay. Any suggestions are welcomed.2 points

-

2 points

-

Spent more time in the workshop today. Organiser drawers installed, lighting up on the ceiling. Siliconed the screw, spring, part catcher bench backstop. Have worked out what I can do with my clock rig to get it out of the way. Joe Collins spring winder completed. Just have to work out some clips to hold the ratchet when I am not using it. I'll probably hit it with some black paint to tidy it up as well.2 points

-

Not sure if they have whale sharks in Lake Garda but if they do make sure to swim with them. I'm in the Philippines with the family and we did swim with whale sharks a few days ago. I panicked (slightly) on one occasion but the experienced guides helped me out. Happy Holidays Richard!2 points

-

Hello all. We are going to Verona, visiting Lake garda and Venice, other than the usual, any suggestions?1 point

-

If anyone recognizes this part, then you understand the nightmare which is the Slava 2414. The date detent lever and spring are first installed to the underside of the date cover plate, then the plate is flipped over and screwed down to the mainplate. Sounds simple enough, right. But the slightest shake or bump could launch the lever and spring into orbit. I've watched several videos on YouTube and it looks like it's the only way to do it. You can't screw in the cover plate halfway and slip the spring in, like some of the early Seikos. I've done several using this method and have never enjoyed the experience. Then it hit me.... Why don't I just glue the blasted spring to the plate. So I used a hard setting UV glue and glued the short tail of the spring to the plate. And viola! Problem solved.1 point

-

Get a day ticket for the vaporetto, and ride line 1 down the Canal Grande to Arsenale and back ( or over to the Lido if you have time).1 point

-

1 point

-

The 10csc should have a separate bridle.1 point

-

I can't believe people have so much difficulty getting hold of Seiko Parts. I know some parts are getting rarer but I've never had any problems.1 point

-

1 point

-

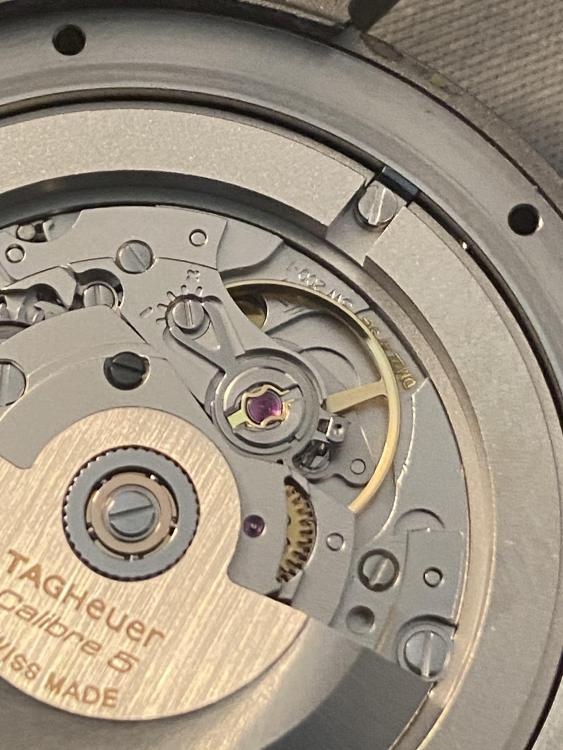

As I mentioned in some of my prior posts, I would probably work up the nerve to open the watch eventually. Well, this morning I woke up and decided to give it a go. In the intervening time, I bought a set of 10 watch screwdrivers, 5 brass pliers, a watch case vise/holder, and 4 loupes. They were all quite affordable around $10-20 for each set of tools. My wife had already bought me a time grapher some time ago, so I watched some YouTube videos on how to regulate an SW-200-1 and decided to try my luck opening the watch and turning the fine regulation screw a bit. The following posts will break down the steps of what I did. The image below shows the set of tools I used for the job. Here’s the watch in question. The images show the watch exterior front and back. The last one shows the dive bezel and the bezel spring removed, which reveals the six screws under the bezel holding the case back on. This is as far as I got during my last aborted attempt to open the watch. The next step was to remove the six screws under the dive bezel and spring that hold the case back on. At this point I thought I needed to unscrew the case back, so I put the watch in the vise and used the rubber ball method to try to unscrew the case back. I applied as much force as I could by hand, but it wouldn’t move the slightest bit. This left me quite confused, so I took the watch out of the vice and inspected it. As I was rotating the watch around and looking at it, the case back came loose and nearly fell off. Apparently those six screws are the only thing holding the case back on, so once they are removed, it comes off very easily. Then I inspected the movement. Tag Heuer calls this movement the Caliber 5 and gives very little information about it beyond that. However, through research on the internet, I surmised it was almost certainly a Sellita SW200-1. My suspicions were confirmed upon review of the movement. In the second picture below, you can see SW200-1 stamped into the baseplate near the top of the balance spring. In the third picture you can see the stamp saying 26 jewels. Another image zoomed in shows the 26 jewels a bit better At this point I wanted to regulate the watch. My previous post listed the performance in various positions. I’m reposting that information here for reference. regarding the daily rate, it is very consistently +10spd measured on my wrist. Every 24hours I wear it, it gains about 10 seconds, and it gains about 70 seconds in 7 days. So the +10spd is the average daily rate when I wear it 24hrs/day. on the time grapher the rates are all over the place. Amplitude is around 290-300 in all positions. On a full wind the rates are: Dial up it’s +10spd 3 down it’s +18spd 12 down it’s +5spd 6 down it’s +20spd dial down its +13spd 9 down it’s +4spd Those rate numbers correspond to the fine regulation screw being at the position shown above. This is how the watch was when I opened it. I spent about an hour tweaking the position of that screw back and forth while watching the rate change on the time grapher. My sense is that when wearing the watch it runs +10spd and that is the roughly the rate for the dial up position. That indicated to me that I should regulate the watch mainly focused on that single position as that seems to be the effective rate of the watch given my wearing habits. After several adjustments and trail and error while watching the rate on the time grapher I ended up in the position shown below. It seems odd to me that the fine screw was not centered for yhe watch coming out of the box from the factory. In the end I just moved the screw back to its centered position which brought the daily rate onI the dial up position to 0 and the crown down to +10. I was happy with the new rates, so I reassembled the watch and checked it on the time grapher. The image below shows the rate for dial up. I’m not sure how the time grapher rates will translate to real world performance so I’ll wear the watch for a few weeks and see how it does. In any case, I’m happy I didn’t break the movement or case during this adventure. I’ll report back on how it performs in a week or two when I have enough data to assess it. Thanks for everyone’s help and advice here. I don’t think I would’ve know how to proceed through this process carefully enough to avoid destroying the watch without your suggestions.1 point

-

Sorry I have forgotten to add the link to the thread. Now it is there. No lathe needed, just fine diamond disk or file.1 point

-

What part no are looking for as there are numerous ones that will work. https://www.spareparts-watches.com/product/9834333/509-184-oscillating-weight-with-ball-bearing-substitute-509-004-509-080-509-074-509-069-for-seiko-7005-seiko-7006-seiko-7009-seiko-7019-seiko-7s26-seiko-7s36 https://www.cousinsuk.com/product/seiko-part-number-from-500?code=SEI5091841 point

-

Yes, I did, and they are not the same. Even so, the feeling of the springs is completely different. The Seiko/Orient springs feel considerably softer and the Swiss springs much stiffer. Seiko/Orient springs easily deform if you don't handle them carefully. This is another reason, except for the super tiny Diashock springs for the escape wheel and the third wheel, why I avoid Seiko/Orient movements. Anyway, the next time I service a Seiko I'll try Alex's method. He demonstrated it on a balance Diashock spring (not too challenging) but told me in a comment that his method should be working on the other Diashock springs as well. It remains to be investigated.1 point

-

I was expecting to do that, but if it's possible to reduce the play, I may as well give it a go1 point

-

1 point

-

1 point

-

Well I now own an Anniversary clock. <insert happy bunny icon here> I will have to get hold of the Horolovar book now and the tool for adjusting the beat. Another thing that I cannot find in Australia. There are times I wonder how our country ever moved forward. Picking it up tomorrow. 5 hour round trip, which with stopping to collect and then dropping into my son's in Heidelberg, that will probably be all I will do tomorrow.1 point

-

1 point

-

1 point

-

Visit Sirmione. The town will be packed, but the ruins of the Roman villa on the peninsula are worth seeing. Verona has much more to offer than just the arena (impressive) and Juliet's balcony (underwhelming). If you are staying there, you can easily explore the old town on foot. The river makes a loop around two thirds of the old town and is a nice stroll in the evening. In Venice, everywhere you look is spectacular and beautiful. Get away from St. Mark's a short distance and the tourists fall away. Get lost in the smaller canals and alleyways. If you see a bridge, cross it. There's always something worth seeing around the next corner! On Dorsoduro there is an outdoor gondola workshop where they build the boats. You can watch them working from across the canal. If you are there for more than one day I will ask my wife this evening for more tips. Burano, Murano, St. Michele etc.1 point

-

The only times I've had problems with the mainspring slipping way too early have been with Seiko and Orient springs when I've tried to replace them with Swiss Generale Ressorts generic springs. Very long story short my conclusion was that the alloys aren't compatible. For this reason, I always keep the original spring when doing a Seiko or Orient unless it is completely shot. Sourcing new springs for Seiko and Orient watches seems nearly impossible.1 point

-

1 point

-

Definitely go on a gondola though Venice city. Did this 20 years ago, at the mouth of the canal the river was a bit choppy all the boats were bumping into each other , the gondoliers starting swearing at each other and shoving , so funny . Stayed at lake Garda it was beautiful .1 point

-

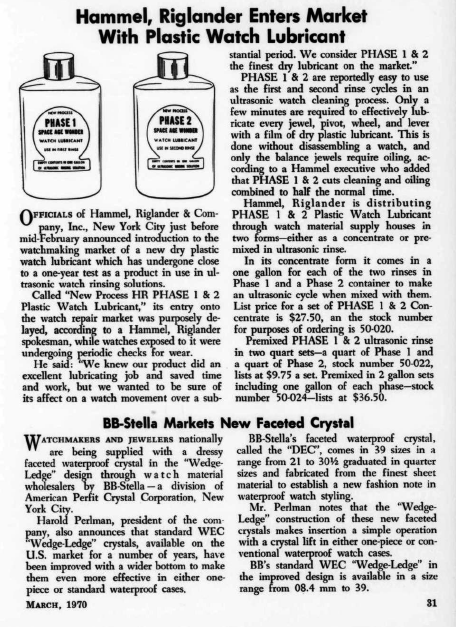

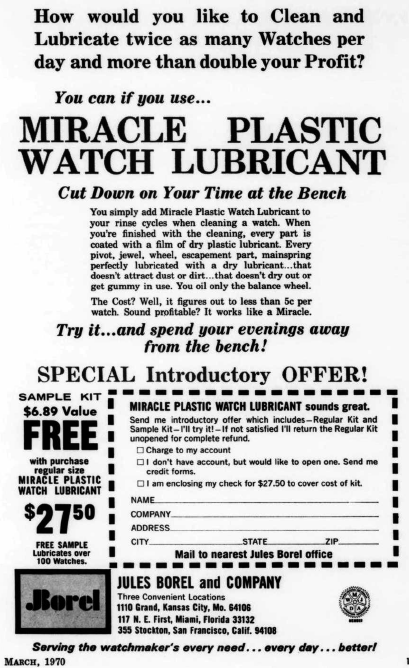

Also include Rolex in this process. In a variety of service centers and watchmakers will practice something called free cleaning. This is where similar to the process described above watch is only partially disassembled and run through the cleaning machine into hack and usually it's a special machine for the process shorter cycle. Then at the nice clean watch they can proceed to evaluate disassemble repair whatever before complete disassembly and basically proper servicing. The pre-cleaned method is frowned upon by some watchmakers as it basically obliterates the scene of the crime. It makes it a lot harder to look for things like metal filings if there now gone. But it does make it easier for looking for broken jewels cracked jewels where Rolexes obsessed with and shake adjustments having everything clean is nice. I doubt any of the high-end watch companies would advocate any of these substances at all. For the most part they're entirely gone anyway which tells you the miracle of the miracle substances didn't last very long. But as I saw in the advertisements of the 70s there were quite a few products Basically the first shop as I said my first job or he did this bizarre practice. I don't actually remember doing any repair? In other words the repair was only cleaning and miracle lubrication and finally regulation. So basically you are dealing with watches that cleaning fixes the problem anything that's going to need a serious repair isn't going to work with this method of all. A lot of questions unanswered. Do you think about this like I thought in one of the instructions you are not supposed to clean the entire balance because you get it all over the hairspring etc. but you rinse it off so I guess well I remember we did lots of watches so I guess it worked. But if everything is coated with a microscopic film of lubrication Lubricating the pallet fork for instance would be totally insane because the oil will be whisked away because the thin film of oil. Although on the higher frequency like higher frequency lady Seiko watches. This shop was doing a lot of Seiko watches because these were the early days where the shops could be authorized this shop was authorized Seiko service agent. So on the lady Seiko high-frequency the pallet fork came out it was rinsed off and the entire pallet fork was epilam. But the other watches I just have to wonder Now we end up with an interesting problem? As I said this was my first job out of school so was extremely long time ago I believe I got one third of whatever they got. It's basically what I would call a percentage you get a percentage of whatever they get. A percentage shop is extremely bad if there's a problem and you of a problem with the watch now you're not going to get paid to do the repair. The only way to make money is by being really really fast and no I wasn't really that fast so one of our biggest problems is is to relate the cost of this to the cost today. Plus my memory in those early days was that the jewelry store brought in the work or the people who set it from their stores nobody cared about quality all they cared about was price. So if you set up shop as a watchmaker and nobody's willing to pay the price to do a quality repair and you starve to death versus this miracle substance what would you do? As I said it's a unfair comparison because in the second shop we did service the watch is properly we did disassemble them we did wail them at least three watchmakers did the owner still used his miracle lube which left the last rinse a really pretty blue colored they had tinted the miracle substance. It's like I remember one day an entire box of safe clocks came in and I wondered? So apparently we had a contract with a company servicing safe clocks these were all modern Swiss not the pretty old ones. By the Monday they're all gone again as just think how fast it would be to and I always wondered because? I used to know somebody who worked for a security company and occasionally the bigger the banks and stuff they would have more of the clocks all he need is one to release the mechanism so you can unlock your safe so a banker something would typically have three or four clocks something smaller and cheaper might have one too would be much better. But here you have something to be extremely expensive if all four stopped which apparently on occasions they did and then there lubricated with this miracle substance fortunately other than explaining in this message I don't have to ever again think about this insanity I guess what we have would have to stop and think about this for placing a modern view of things on this time so in other words is nobody was not pay the watchmaker service the watches basically watch repair was considered at the time a dying field anyway because remember the newfangled electric watch it come into existence in the late 50s and I think this might abound about the time of the digital watch and the watchmakers all felt this was the end of them anyway and if no one's going to pay for your servicing because you have to go back and look at the last two magazines I was looking at I couldn't believe the number of ads in a professional watchmaker's magazine to the must of been a definite need for cheap servicing? Oh and of course there is the other amusement nobody sees what's inside their watch they don't know if their watches disintegrating or not all they know is that? And we cannot entirely say it was cheap because typically the wholesale shop we charge a price jewelry stores would typically double that cost and occasionally some shops would wear stores would cripple price. So the customer still paying a reasonable sum of money in 1970 but the watchmakers only making a fraction of. I decided to go back and look at the magazines I was looking at and it must've been cost must've been the prime factor some reason that this stuff came out because literally everybody had cents.just one or two products but lots of products like here's one that I didn't even know about Notice how there's a reference of long-term testing instills so much confidence in a they've tested for almost one whole year. And now the nifty product is on the market. Then yes I really do like the word miracle.1 point

-

There are a few complete as the eBay listings below but not sure what delivery would be to Canada especially from the european ones. https://www.ebay.com/itm/364745874240?ff3=2&toolid=10044&customid=&lgeo=1&vectorid=229508&item=364745874240&ufes_redirect=true https://www.ebay.com/itm/313044979567?ff3=2&toolid=10044&customid=&lgeo=1&vectorid=229508&item=313044979567&ufes_redirect=true1 point

-

Interesting reading. It worked well for a year. I wonder what happened long term? For 'lower value' watches, like Seiko 5, a service is many times the price of the watch. So maybe this would be a solution? * (*sorry about the pun)1 point

-

With all the round dimples in it, I think someone used it to beat something in place without damaging it (crown tube??). Probably just a handy bit of wood they came across and kept around for this purpose. Hopefully Bergeon don't spot this post, they will start selling them for $150.1 point

-

I closed the hole with my smallest round punches and it came out well. There is no visible evidence of the repair on top side unless examined under a loupe if you know what you're looking for. The underside has an indentation and I thought it might affect the end shake but that didn't change. It did take me three tries to broach it to the right size; I overdid it twice. But this was for practice, knowing I could still get a NOS replacement. Happily, the sideshake has been eliminated and the wheel spins free and true.1 point

-

1 point

-

Looking at thre picture, I doubt there is bushing there at all. Seems like it is just stamped. If there is a bush, then the best decision is to replace it. Another simple option is to mark the bush position, to press it out and then return in place but rotated to 180 degr. Thus the wheel position will be restored. Oil retention then may suffer, but using grease like 8200 will solve the problem. Punching to close the holle is possible, but it will change the wheel position and will spoil the look. Actually, spoiling the look here is the main danger in such repairs. One option is to fit thinny bush wit only slight enlarging the hole. The hole is to be elarged and blunted with tappered pin from the down side, then the pin cut and made flush with down surface, then new hole drilled in correct place. Then the upper, visible side of the pin has to be trimmed by slightly bigger drill bit or turned on the lathe with face plate and finally slightly punched with polished round tipped punch to form the top side and in the same time riveting the bush. Then final opening of the hole with smoothing broach... This technic alows to make the bush almost invisible. The other option is to drill the whole thing and fit new pressed bush, but keeping the center unshifted can be a chalenge. I1 point

-

In another thread I mentioned sometimes making bushings to repair a watch with a broken or missing rubbed in jewel, and as I had one to do today I thought I'd show the process. There are tools for opening and closing the settings, but they don't always work as sometimes the metal just doesn't want to be flexed back an forth like that; on this piece, a LeCoultre 409, the bridge is quite thin where the jewel sets (0.30mm), and is german silver, and the walls of the setting just crumbled when trying to close and looked horrible. I determined the outermost diameter of the original setting was 1.30mm and had a jewel with the correct hole size and an outside diameter of 0.90. The plate was glued to a support and centered on a faceplate. My setup is pretty "fancy" but it's the same as a regular watch lathe faceplace, just bigger, and I have the advantage of using a scope in the little jig borer to check the centering rather than the old school wobble stick technique. Once centered, the bridge with the bad setting was installed, and it gets put on the lathe. I bored the hole to 1.29mm, then made a bushing with an outside diameter of 1.30, and hole of 0.89. This was done with a cross slide in the watchmaker's lathe, the hole being bored not drilled, to ensure exact size and concentricity. The wheels in this caliber have very very short pinions, so any error in alignment between the jewels could easily tilt a wheel enough to crash somewhere. A rather large bevel was cut on the bushing to simulate the rubbed over area of the original, everything pressed together like it should, and is pretty much invisible. While perhaps a bit invasive if working on a museum piece by Berthoud, it's a solid way to approach this sort of repair, and down the road if there's ever a problem with that jewel again, easy for the next guy to replace.1 point

-

rogart63 thank you for your reply. I figured it out...I think. The ring is a spring which holds the lever in place. The ring has a cut (small opening). The other end of the lever is the bit that holds the rotor. Now it's a matter of coaxing the ring back over the lever. Charlie Maryland1 point