Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/04/24 in all areas

-

4 points

-

The problem is likely the psu and cable are well underrated. 100W @12V is a bit over 8 amps, the psu and lead are designed for 5 amps Tom3 points

-

The only reason that I don't use your approach is the screw holes and threads can't be properly cleaned.2 points

-

I have a different approach to @RichardHarris123 and @oldhippy in that I return screws to their respective holes once the part that they were securing has been removed. This not only prevents losing screws but also helps to ensure that the screws all end up back in the right place, assuming of course that they were in the correct location to start with2 points

-

I would put them in ronsonol lighter fluid to clean them get a small pot with a screw lid then put them on some tissue paper and fold it over them to soak up the fluid. Very similar to what Richard has suggested.2 points

-

If the fan is not rotating in the correct direction, you have your fan leads swapped. The air should be flowing through the heater element. That is the other way that he can go. Keep the power supply and try a PTC heater that needs less power. The 100W ones are more common, but I do see at least one 50W heater on Amazon.2 points

-

Anyway, I think 100W is way too much power for the heaters. I use a 50W 220V PTC heater and I find that already too powerful. I think the original heater was only 15W or 30W.2 points

-

As Tom indicated, your power supply is not up to the task. With 12V and 5A, that makes only 60W while the heater it is supplying is rated at 100W. Try to find a power supply that provides at least 100W. This is the one that I have, which is a 120W unit. https://www.amazon.com/gp/product/B07PWZQ33N/2 points

-

I can't find any information in why IPA could shatter acrylic. Crazing is caused by the top layer being dissolved and resetting at a non uniform rate. I can only take an educated guess that the acrylic was already stressed.2 points

-

2 points

-

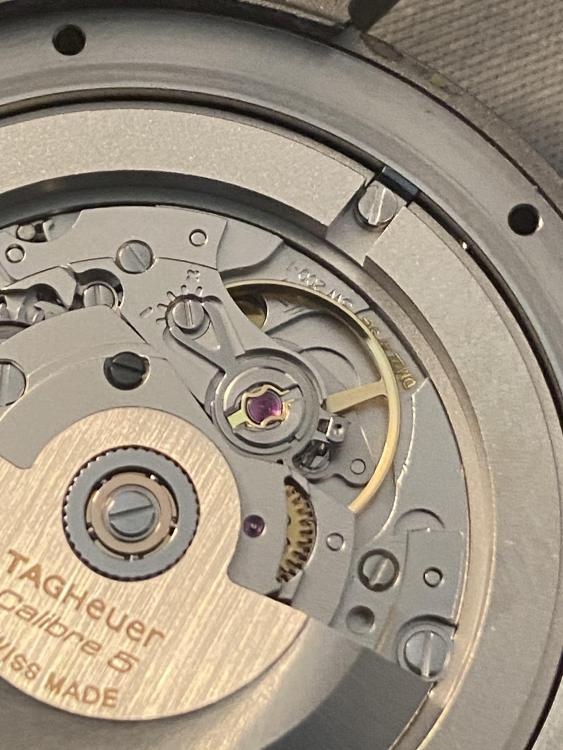

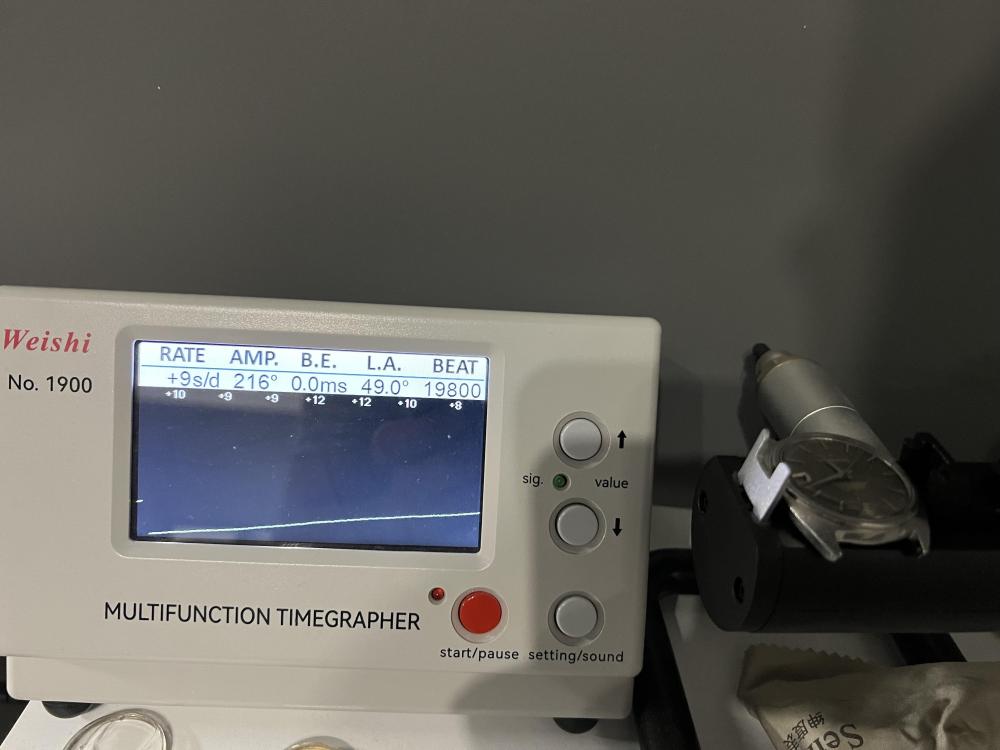

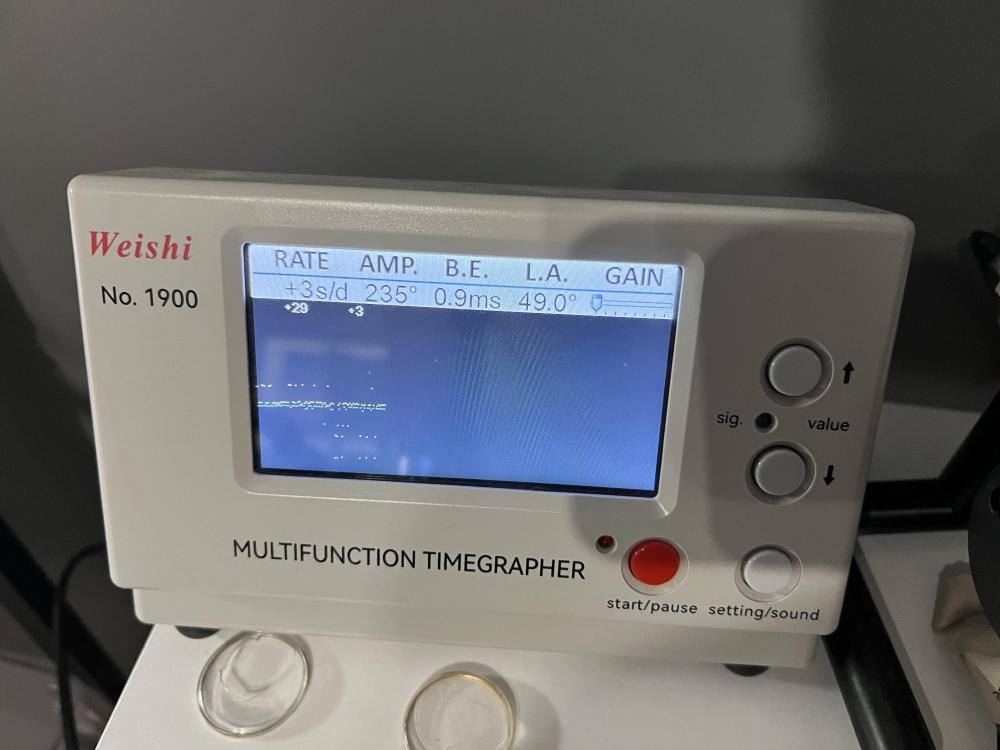

As I mentioned in some of my prior posts, I would probably work up the nerve to open the watch eventually. Well, this morning I woke up and decided to give it a go. In the intervening time, I bought a set of 10 watch screwdrivers, 5 brass pliers, a watch case vise/holder, and 4 loupes. They were all quite affordable around $10-20 for each set of tools. My wife had already bought me a time grapher some time ago, so I watched some YouTube videos on how to regulate an SW-200-1 and decided to try my luck opening the watch and turning the fine regulation screw a bit. The following posts will break down the steps of what I did. The image below shows the set of tools I used for the job. Here’s the watch in question. The images show the watch exterior front and back. The last one shows the dive bezel and the bezel spring removed, which reveals the six screws under the bezel holding the case back on. This is as far as I got during my last aborted attempt to open the watch. The next step was to remove the six screws under the dive bezel and spring that hold the case back on. At this point I thought I needed to unscrew the case back, so I put the watch in the vise and used the rubber ball method to try to unscrew the case back. I applied as much force as I could by hand, but it wouldn’t move the slightest bit. This left me quite confused, so I took the watch out of the vice and inspected it. As I was rotating the watch around and looking at it, the case back came loose and nearly fell off. Apparently those six screws are the only thing holding the case back on, so once they are removed, it comes off very easily. Then I inspected the movement. Tag Heuer calls this movement the Caliber 5 and gives very little information about it beyond that. However, through research on the internet, I surmised it was almost certainly a Sellita SW200-1. My suspicions were confirmed upon review of the movement. In the second picture below, you can see SW200-1 stamped into the baseplate near the top of the balance spring. In the third picture you can see the stamp saying 26 jewels. Another image zoomed in shows the 26 jewels a bit better At this point I wanted to regulate the watch. My previous post listed the performance in various positions. I’m reposting that information here for reference. regarding the daily rate, it is very consistently +10spd measured on my wrist. Every 24hours I wear it, it gains about 10 seconds, and it gains about 70 seconds in 7 days. So the +10spd is the average daily rate when I wear it 24hrs/day. on the time grapher the rates are all over the place. Amplitude is around 290-300 in all positions. On a full wind the rates are: Dial up it’s +10spd 3 down it’s +18spd 12 down it’s +5spd 6 down it’s +20spd dial down its +13spd 9 down it’s +4spd Those rate numbers correspond to the fine regulation screw being at the position shown above. This is how the watch was when I opened it. I spent about an hour tweaking the position of that screw back and forth while watching the rate change on the time grapher. My sense is that when wearing the watch it runs +10spd and that is the roughly the rate for the dial up position. That indicated to me that I should regulate the watch mainly focused on that single position as that seems to be the effective rate of the watch given my wearing habits. After several adjustments and trail and error while watching the rate on the time grapher I ended up in the position shown below. It seems odd to me that the fine screw was not centered for yhe watch coming out of the box from the factory. In the end I just moved the screw back to its centered position which brought the daily rate onI the dial up position to 0 and the crown down to +10. I was happy with the new rates, so I reassembled the watch and checked it on the time grapher. The image below shows the rate for dial up. I’m not sure how the time grapher rates will translate to real world performance so I’ll wear the watch for a few weeks and see how it does. In any case, I’m happy I didn’t break the movement or case during this adventure. I’ll report back on how it performs in a week or two when I have enough data to assess it. Thanks for everyone’s help and advice here. I don’t think I would’ve know how to proceed through this process carefully enough to avoid destroying the watch without your suggestions.2 points

-

It needs to be reshaped correctly once removed from the watch. You need the correct size round bar and ideally soft nosed pliers, hammer, vice etc. Edit What's the strap reference as it may just be easier for you to get a new strap.1 point

-

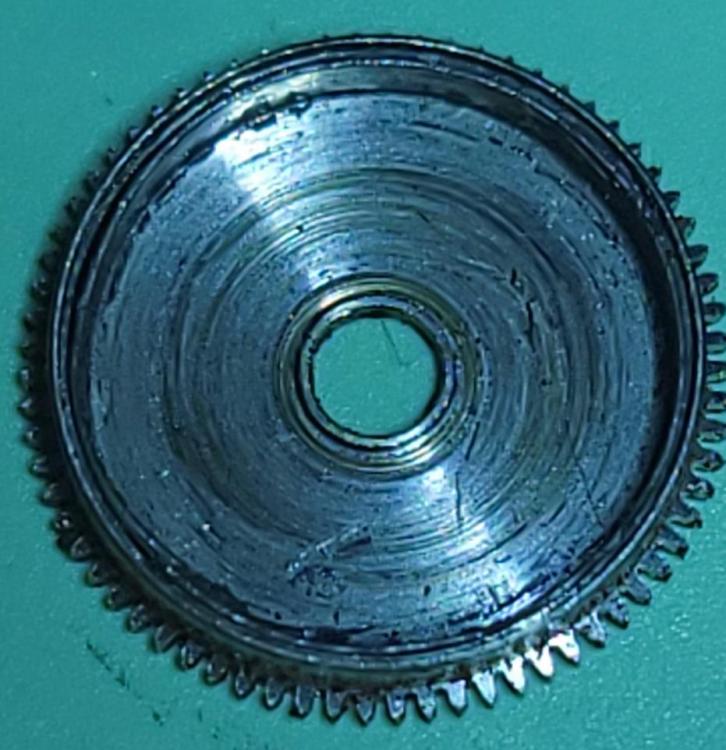

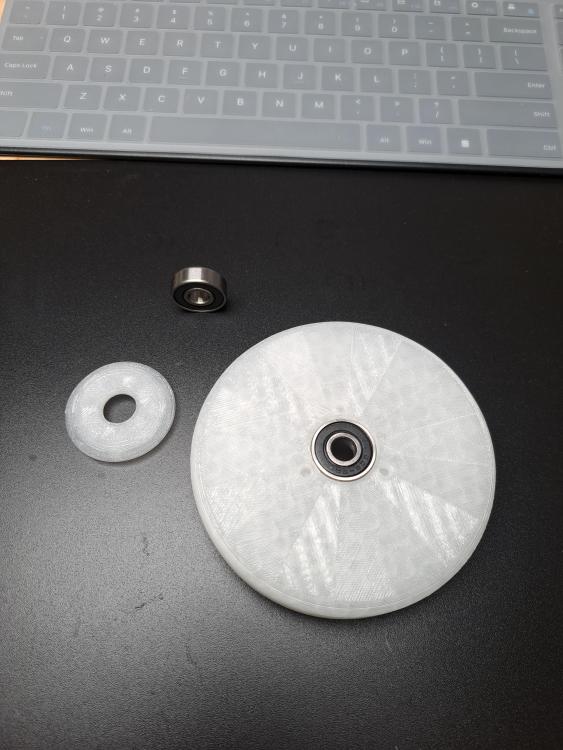

By "washer", do you mean the notched disc as the lower left of the photos? (That's the only item shown that seems to fit?) That is the part that functions as the bearing cage, it must rotate completely freely, separately from the inner race parts. Apologies if you meant something different.1 point

-

An interesting and valid observation. However, I first of all can't imagine how the threads might become dirty or contaminated in the first place, and secondly I can't see that it would matter much if they did. Obviously if there is rust involved then that would need to be addressed, as would any contamination that might cause the threads to bind or which could cause other damage in the watch. Other than rust though I have never come across threads that particularly needed cleaning. These are static, un-lubricated parts so it's hard to see how failing to clean them as individual pieces could be detremental to their function, and to me the pro's far outweigh the con's. None the less, this is watchmaking so is guaranteed to garner differences in approach and opinion, all equally valid1 point

-

I leave small screws and springs in the parts tray, leave it soak in cleaning solution, wipe the try afterwards thus keeping the tray clean.1 point

-

Not at all, the first version of a sweep second. Maybe the pinion wants an upper pivot?1 point

-

I picked up a Swatch chronograph which I thought might make it in to the 404 club a while back. I know, a chrono for four quid, seems pretty unlikely until you consider its condition. The crystal looked like it had been dragged across a rockface, and it wasn't possible to even tell what model of chronograph it was. It was also missing the battery cover and a strap. When it arrived, I got buyers remorse as the crystal looked too badly damaged to save, so it went in to the parts bin, and there it sat for ages. Yesterday I was looking through the junk for something else, and I gave it another quick look. I popped a battery in it, and it appeared to work. And so it was that an hour or so later I grabbed some 80 grit sandpaper, stuck it down on a heavy slate I use as a polishing bed, and had at it. The 80 grit would probably have worn clean through the crystal in quick time, so I stopped when all but one major ding had been polished out, then moved on to the finer grits. I'm still working on it, but I'm pleasantly surprised by the results so far. It will never be perfect, but it was saveable. Time to dig through the junk again and find a battery cover. I'm pretty sure I have one that will fit. The original band was black, so I've ordered a black with red stitching from AliExpress. I'll post the completed results when it arrives. For those who want to know it is apparently a "Swatch V8 Quartz Chronograph model YCS109" from some time around 2005.1 point

-

1 point

-

I have to disagree with DELL this time (sorry dell) I found the beat setting tool incredible good with its long handle you can make such fine adjustments in my days when repairing these clocks for me it was a must have. When it comes to the book if you don't want to get the new one it is expensive look on ebay for an old edition.1 point

-

One night, we were bringing a pot of water to boil on our cooktop and the tempered glass portion of our vent hood shattered rather spectacularly. Threw glass shards up to 20 ft away. Dinner was ruined and we had quite a mess to clean up. Luckily none of us were at cooktop at the time. I am rather surprised that IPA would have that affect on acrylic.1 point

-

1 point

-

Looks like a good setup. I like how you put the stirring motor post through the center of the turntable. What's the specs for the heater you are using? Specs for the power supply? How long are you running the heater?1 point

-

If I definitely don't want the old spring, I staple one end to some wood, roll it out and staple the end. Some staples in-between, then measure.1 point

-

Very nice. I must confess to trawling round charity shops for bargains too. I was down in Milngavie the other day doing just this while my wife was visiting the dentist. Nothing but cheap quartz stuff on that occasion, but sometimes you do get lucky. It might be advisable to at least take the hands off. The dial will probably survive, but I did manage to remove the paint from a set of hands in the ultrasonic a while back. Not sure why since they appear to be painted with battleship grade enamel paints, but once bitten as they say. Taking the dial off is a little risky as the metal tabs tend to fail. Generally I do remove the dial and the hands, but not always. I also generally don't put Timexes in the ultrasonic, I just go for the slunge.1 point

-

I got a great tip from someone on Facebook. I just gave it a try and it worked like a charm. No damage to the part while removing that driving pinion. Here's their message to me: Take two bladed punches for tightening cannon pinions in your staking set and put them in the staking tool. Place the new wheel with the two pinions between the stakes blades. Take a presto tool and using the blades as support for the presto tools feet just pop that pinion right off. Add a dab of of 9504 and use a flat stake with center hole to just press the pinion back on. Now the part will go through a full cleaning cycle, get fresh lube, and reassembled. It might not have been necessary, I'm not entirely sure. At least I'll have a bit of peace-of-mind about the work being done though.1 point

-

Agreed. My 10BPAC movements were the same and confused the heck out of me at first. If you look in the barrel, you should see a bridle that slightly overlaps, and has a hook on it to catch the tail of the mainspring. You can just see it in this picture, but check out this excellent post by Jon including much better pictures.1 point

-

Seiko 11-0630 from July 1977 I think. White gold plated case and bracelet. Condition is amazing for 47 years old and running with great amplitude without even touching it. This one is for my wife. Nice charity shop find for just £4. I always look for watches in those shops but most of them seem to only sell modern quartz. You have to be really lucky to find something nice.1 point

-

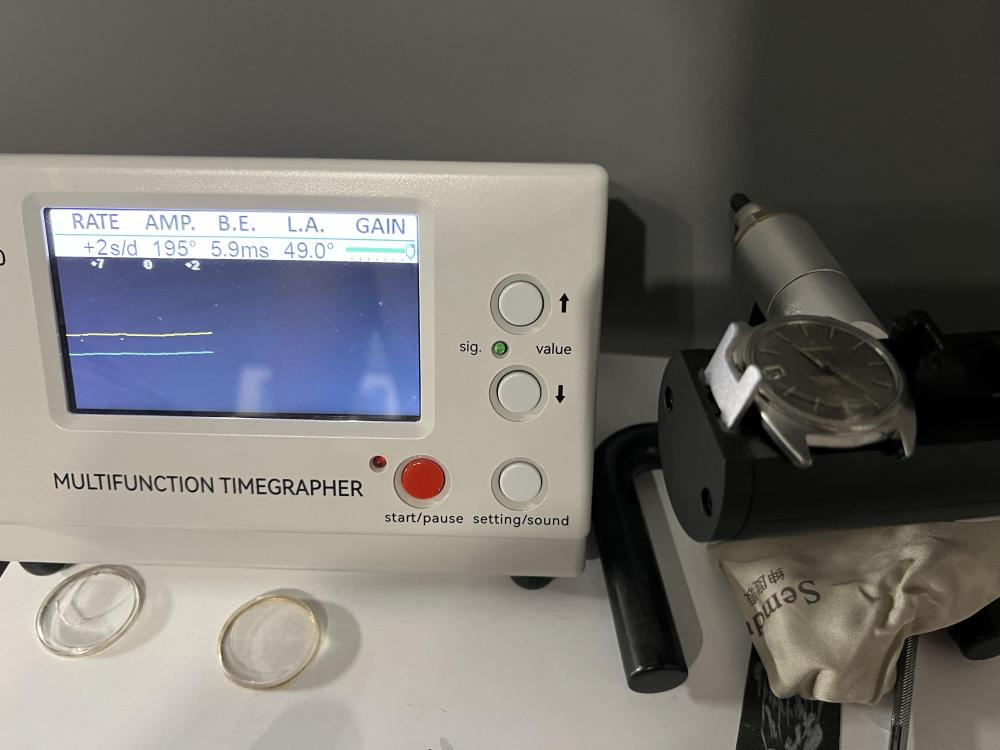

I have 3 jars with steel mesh in them, all jars filled with clear lighter fluid sold for machine cleaning, I separate parts by size and dirt level and ultrasonic clean the 3 jars inside water for 8-60 minutes depending on the watch. I also do a manual cleaning with wooden pegs if the watch is really dirty, and retry as needed For the pallet fork I use 9415 on the tips, for the rest of the train I just oil the jewels with 9010 After replacing the pallet fork with a problematic one from another watch: (In that watch this pallet fork was stiff, but visually seemed flawless with pivots not bent) After this I concluded that the high beat error high gain reading was the correct one and readjusted the balance ^ After the readjustment both high and low gains read the watch as above So low amplitude but consistent time keeping, I will settle It's also important to note that the previous guy likely had the same dilemma but ended up picking the high beat error reading, assumably, or just coincidence1 point

-

Guys, the spring gets in place after assembling of the whole thing - thru the big hole in the plate1 point

-

This is the one I made. I am still tryi.g to figure out how to add the drying station. I shorten the shaft to minimize the wobble in high speeds and on the jar cover I used a ball bearing which helps with the wobble. 3d printed the cover and jar holders. Jars and baskets bought in ebay. Any suggestions are welcomed.1 point

-

1 point

-

1 point

-

1 point

-

https://speedtimerkollektion.com/search?search=citizen+hands&sort=relevance%3Adesc Check these guys out. I've bought from them many times1 point