Leaderboard

Popular Content

Showing content with the highest reputation on 08/05/24 in Posts

-

First of all I would like to thank the community here and Mark for providing a space to indulge our hobby and for some, profession. I feel very lucky to be able to enjoy learning and sharing. In no way do I want to come across as bragging or ungrateful. I have learned a lot over the past 20 months or so. I hope I can give back half as much as I have gained. That said this post is dedicated to @rossjackson01 whom I have seen recently state to the effect that he could not work on a mexhanical chronograph for at least 2 more years. I hope that he gets an oppurtunity sooner than that and there are still bargains out there if cost is a determing factor. I won't say how much I paid as you would not believe me, but this could be one of the best 404 club entrants ever, at least for me. One of the factors that led to this was a discussion with the seller that reiterated other similar discussions here and elsewhere to the fact that many independent watchmakers don't work on chronos due to cost and difficulty in finding parts. Add in Swatch owing eta/valjoux and restricting access to parts and so it is tough getting one serviced. Add in that Venus is a precursor to the Valjoux 7730 and ultimately 7750 and others, parts and service can be difficult to obtain unless we can maintain the right of servicing or DIY. Anyhow, here it is cleaned up case and new crystal with a new mainspring on the way (that is part of the story sourcing that part). I usually don't like to post things before I get them in the mail or finish the work to not jinx myself! I will post pictures as I get into the repair and cleaning, and hopefully no other parts will need replacement! I put a neat little strap on. Is about 35.7mm but is larger on the wrist with the pushers probably closer to 38mm. 44mm lug to lug and 18mm strap width. Works very well on my small wrist.4 points

-

Been awhile since I have posted anything--been crazy busy. So, I bought this for $70 from a lady in the hood. Missing a crystal with a broken mainspring. My friend in Dallas had a MS so today, I serviced the watch. I have never done one of these single plate pocket watches. It was QUITE the challenge. If there is a trick to getting all the wheels aligned, somebody let me know! I did it, but it took me the better part of an hour!!!! Anyway, it is together with a little over 1ms in BE and looks very accurate DU and DD (and over 300 deg in amplitude). Here is a picture of the finished watch, and a picture of the movement. Notice that the minute hand is wrong. Lucky me, today on ebay, somebody was selling a set of 940 hands. I won the bid at $43 total. A little steep, but the value of the watch is greatly increased with the correct hands. As an aside, I have been consumed with a big real estate transaction and pending move. I bought 47 acres in Bryan TX, adjacent to 20 I bought for my son. We will be making Bryan the center of gravity. A cool wrinkle is that I am going to expand my watch/clock hobby there by putting a large shop on the site. I am too cramped here. It is a work in progress, but next year I will post pictures!!4 points

-

That dial is so similar to my gramps Sekonda,.it must run through a lot of Russian brands. So anyway i dont always choose a watch for how it looks but whats inside and how it will perform. I have a thing for military watches DDs in particular, the grail DD being the rare guessimated production volume of 1000 made Grana. Unlikely i will ever own one but one can wish. So I cant have the watch but i can have a little taste of it and that comes in the form of this Certina which houses the same caliber. Granted it is a Certina signed movement and the spec may be slightly different but it is a Kurth Freres 320. Thats probably as close as i will get to the most rare DD3 points

-

Yes you definitely do not want to physically modify the mean time screws but they are movable. Plus you get some interesting combinations if you move both of them. In other words the one is heavy could go in a little bit and the one on the other side could go out a little bit.3 points

-

3 points

-

It worked perfectly ! I have a 1000 grit diamond sharpening stone which was ideal. Sliding the washer about 100mm 4 times took off about 0.01mm. I ended up taking 0.025mm off in total, which left it spinning perfectly with very little play. Good tip about using grease to hold those little balls in place.2 points

-

In old texts they always say to dry parts in warm boxwood sawdust, the sawdust absorbs the solvent quickly and keeps the bulk of air away while the rest dries. Depending on your climate and humidity level, the evaporation of solvent can cause moisture to condense on the part, and that can cause rust. In modern times one would use a warm air stream to dry parts. Puffing with a blower will blow off the solvent, and cause rapid evaporation and exacerbate the condensation issue- and if you want to really see condensation blow on the part with your mouth! In my climate condensation isn't a huge issue, but I do tend to use sawdust or warm air just to be sure.2 points

-

Since we are on the topic of exotic foods, here in Singapore, we have a fermented krill that is packed in a glass bottle with a crown top. It's similar to the Philippine bagoong. Several years ago, my mum asked asked for help to open a particularly stubborn cap. I don't know how long she was struggling with it but all that agitation built up pressure inside the bottle. So when I stupidly popped the cap off, I was sprayed with a stream of foul smelling, fermented shrimp juice. Even after showering twice, I could still smell it when I went to bed that night.2 points

-

Let's say it's not my favourite dish but for many Swedes, this is the height of culinary experience.2 points

-

Is the proper cooking technique to open the tin in a well ventilated area and then empty the contents into the bin? Hehe. Do you like it?2 points

-

2 points

-

Prepare to be extremely surprised. I can't claim to have the experience of a seasoned professional who's been at the bench for 40 years, but I have been practicing this wonderful craft as a hobbyist for about 20 years, averaging a couple of watches a month, so I have a sample size of more than just a handful of examples to go on. I can't say that I have ever come across.... I have encountered a few (I would say less than 10) grossly over oiled movements, but even on those, "dirt and grease laden threads" were not a feature. I find it hard to imagine a mechanism by which threads would even become so contaminated, unless someone actually purposefully oiled them (?????). Even excess lubrication migrating from places where there should be oil is unlikely to find its way into screw holes, let alone in sufficient quantities for the threads to become "laden". Still, we all have different experiences and I guess that I must be sourcing my victims from a cleaner and less oily source than some other folks. As I previously said if there is rust involved then it's a different matter. Note: I have actually come across a couple of examples of grossly contaminated threaded holes (dirt, not oil), but only in un-cased movements that have been rattling around unprotected in someones parts bin for a few decades.2 points

-

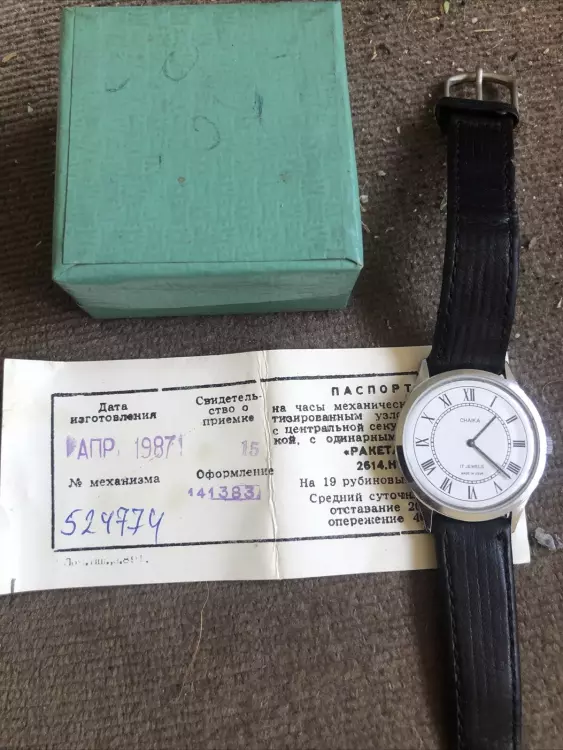

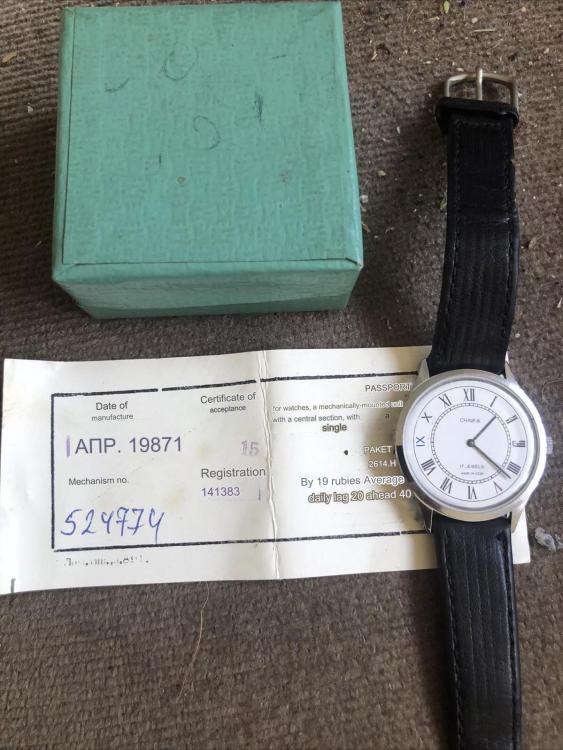

Advertised as 'Chaika 17 Jewels Men's Mechanical Watch USSR with Box & Papers - Not Working' - all of which is technically correct, however the box and papers seem to belong to a Raketa 2614.H based watch and I'm pretty certain this is Chaika 1601. Having said all that, the watch looks clean and the dial is perfect, and furthermore I have several USSR Raketa 2614.H watches from the correct period, that would most probably have started life in a box identical to this one. Obviously the 'Mechanism no' wont match the one on this "Certificate of Acceptance" but that is a minor detail. I wouldn't be trying to pass anything off as unauthentic, and its not as if this is a solid gold Rolex. Since the cost of the lot was well within the 404 club rules, I'll be pretty happy with whatever turns up in this fun little lot. Servicing it should be easy too as I have several spares 1601 movements. One interesting note. As you can see from the translated image, the 2614.H is specified to be accurate to -20 to + 40 seconds per day. Most of the ones I have serviced do considerably better than this. Edit: I wonder what '19 rubies Average' alludes to? "Maybe you get the full 19, maybe one or two fell out in production, maybe we slipped a few extra in just for good measure".2 points

-

Actually from time to time I would like to blow up the parts preferably in the assembled watch. Or specifically I was thinking of the can it be nice to make my problem go away in a spectacular fashion but for a variety of reasons Debbie very very bad in my location to do that. I'm always puzzled by why a different procedure for parts that have shellac? Because I run all of my parts through the cleaning machine and they come out nice and clean. Contrary to the YouTube gods to claim that ultrasonic alcohol cleaning fluids and probably just about everything else in the universe is bad for the shellac it seems to work just fine. Then there is a universal concern of Rust the way you describe by you didn't mention something? I've seen several references to using epilam can lead to rust. There used to be a website that had pictures and I was at a lecture once with a described the exact same concern. The solvent used with the earlier batches of epilam well basically think of it like Freon it wasn't Freon but it was something else. So what happened is as it was drying of that operating it would produce a chilling affect and depending upon your location humidity in the air you would get the moisture in the air to condense on the steel parts the pallet fork and escape wheel. Then ultimately that would lead to rust and on the website the person showed the rust damage and the damage it was doing. This is where I was at a lecture in some I was concerned about this so they had a hairdryer and yes you can hold the parts in your tweezers it works fine they would put it in The epilam and immediately warm air dry. The newer epilam is supposed to be less volatile so I don't think that's as much of an issue. I suppose it's conceivable though whatever your solvents is if you blow what sort of apparatus really fast could produce a chilling effect I think basically when anything evaporates it produces a chilling effect and if you have enough humidity in the area will have condensation1 point

-

I am Bulgarian and I live in Bulgaria. What I think of Russia... It is a long story, but we are frightened to be the next after Ukraina, together with the all Eastern Europe... I have many Russian friends and participate in the Russian watchmaker's forum, but this is different thing Glad to hear it worked well for You. When I was student (back in 1992) I was on student's brigade in UK (Wrockham, Norwich) picking strawberries. There, from a carboot sale, I bought my first Seiko 5 7009 (I think it was 3.5 pounds). It was my first not-russian watch. Of course, the bearing was badly worn. When I came home, I figured this decision how to repair the bearing. I wore the watch about 10 years after that with no problems, then replaced it with quartz.1 point

-

What's interesting with people on YouTube is they do all sorts of interesting things that perhaps the rest of us should not do. A lot of it depends upon the particular part. I think when I was in school the instructor would stick a little 9010 down inside. I remember once with an Omega or I cleaned it and did not lubricated at all and it came back. But that was the day of were days of where he could still buy Omega parts I just purchased a brand-new one the problem was solved. Then I went to work in a shop also in the days where individual shops were authorized service providers and I was looking forward to because he was Omega service provider I went to see the nifty tools for disassembling of the reverser. But he didn't disassemble he used dual lube. Somewhat recently were discussing miracle lube or one step and this is in the same category but it did apply a very thin coating of lubrication to the reverser wheels and apparently worked just fine. He was in a shop that was doing higher and watches and I suspect if it didn't work like the one I did he would hear about it really really fast so obviously it did work. But on the other hand if you can buy a commercial solution in a tiny bottle that's can take a long time to go through which by the way is exactly what were doing where I work there is a tiny bottle of the user for the reverser wheels.1 point

-

Hi guys, I wrote a set of five lessons for my second year students regarding the Landeron 248 chronograph watch, which incidentally we are meeting tonight. They are going to be polishing pivots and pinion leaves of their 248s, before putting the movements through the cleaning machines. This is number one of five. I posted number two of five the other day HERE There are seven eccentric studs on this movement, so understanding what the studs do, how to set them, their actions and interactions with other parts of the chronograph mechanism is vitally important. I found there is very little out there on the internet to help understand the principles of these eccentric studs, especially video content to show various faults and alleviations, so I put together quite detailed walkthroughs of various complicated movements usually consisting of 15 to 18 hours of learning/servicing in the workshop per movement/module With any watchmaking, especially with complicated work, only make one adjustment and measure the results, if any. Be methodical in your approach. The lesson was originally in PowerPoint and I had to convert it to PDF to post here, so a lot of the video content won't play, but the PowerPoint version is in my cloud storage here. https://docs.google.com/presentation/d/10KJJ58P0v2BglKZSilIv9o69xBsbrQPI/edit?usp=sharing&ouid=107902587627140904870&rtpof=true&sd=true You'll need quite a newer version of Microsoft Office (PowerPoint) so the video content will play, otherwise it won't. I hope you find this lesson useful and begin to get a better understanding of how to set eccentric studs. Sometimes you'll come across a stud that is too loose, or even too tight. Usually if one is problematic it will be because it is loose. This can't be left, as the stud will turn whilst the chronograph is stopped, started and reset, throwing the chrono mechanism setting off which could lead to the movement grinding to a halt. Don't fool yourself in thinking it will hold. Either a replacement stud is fabricated to suit the enlarged hole, or the hole can be closed up. In turning and setting the eccentric studs prior to disassembly of the movement, we are able to set the chronograph mechanism, especially the minute register mechanism correctly and test for any faults, such as a bent wheel over fourth arbor, or incorrect depth of the dart tooth with the sliding gear, or a mis-set minute runner jumper spring, to name a few possible faults and mis-settings. Also in turning these eccentric studs we can gain a 'feel' for how tight they are in the mainplate or bridge. The more they are turned the more the chance of the stud becoming looser increases. So once set correctly prior to cleaning, the less chance they will need setting once the chrono mechanism is assembled, only if a stud isn't tight enough in its setting in the first place. This is for setting Landeron 248 eccentric studs, but once an understanding of their uses and actions is gained through theoretical aspects together with practical application, then this skill and knowledge can be used in most vintage chronographs to set their eccentric studs and even in modern timepieces where you'll find very few eccentric studs, such as an Omega Speedmaster or Tag Heuer Calibre 01 chronographs Enjoy! Lesson 22. Landeron 248 Chronograph.pdf1 point

-

1 point

-

Not really, it's fermented herring and properly cooked and served, it's a delicacy. Unfortunately, you need a few per cent of genuine Viking blood in your veins to appreciate this national dish. Something the Germans in the video below sadly lack.1 point

-

I expect it does just need a good clean and service. Can you confirm what battery you've fitted? Edit Case clamps shouldn't make a difference but would be advisable to get some if you get it working.1 point

-

The screw you mentioned is to remove the stem but do not loosen it too much or you'll have to strip the dial.1 point

-

I believe this style of ladies watch is called a wristlet which would have a textile based strap. Tom1 point

-

1 point

-

1 point

-

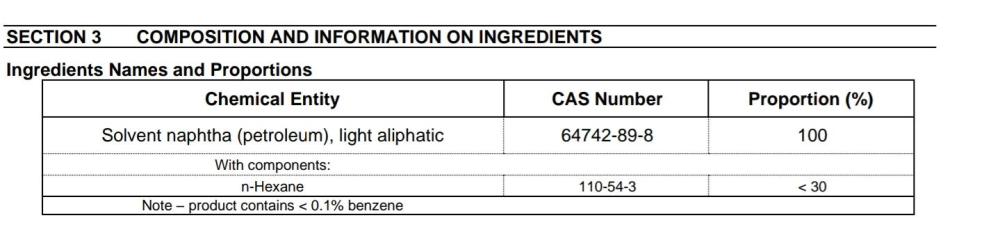

Actually, ten quid is not too bad - maybe I will just put some on my next Cousin's order. I was thinking about the cost of buying 33ml of 9010! The Shellite (as opposed to Naphtha, lighter fluid, Coleman fluid etc) doesn't seem to leave a residue. Looking at its constituents on the MSDS, it's not clear what would be a residue. I use it for cleaning (ultrasonic and pre-cleaning) but I usually use IPA to rinse after the Shellite. Thinking about changing my MO to use Essence of Renata for dip type cleaning (balances, shock settings, pallet forks) and maybe use some dedicated watch cleaning solutions available in Australia (that all seem to be Naphtha based) in the Ultrasonic. I thought I saw Alex Hamilton make some using IPA on a YouTube video (I could definitely be wrong here). Maybe he used Hexane (which would probably be a better solvent, I just can't get hold of that). I have seen people just apply a bit of neat 9010 to a few of the rollers, or even leave them un-oiled. Not sure which would be the best compromise if you had no Lubeta type lubricant at all.1 point

-

I used to make my own with naphtha. The Omega guide just says Benzine - which could mean anything. Wiki : We all know that Naphtha leaves a sticky residure and several times I had watches which were very hard to wind after cleaning and lubricating the reversers. I wonder if the naphtha residue is too sticky? So I decided to buy some Lubeta V105, and I haven't had any more problems. You don't need to be either @Simeon, you can buy 10ml bottles for just £10 (at least here in the UK)1 point

-

Haha yes you are right marc I'm surprised, maybe I've been rather unlucky in my finds lol1 point

-

Ah yes it was Rich you're right , i think it was discussed what we looked like, he mentioned my profile pic was epic . Shame its not me , well kind of me 30 years ago, its my lad.1 point

-

I think it was @Jonvideo which showed his workshop and students. He said it showed a little of who he was and his ethos.1 point

-

I think most of us here are opinionated Rich, this hobby calls for a logic brain developed through experience .When we have that or think we have that we dont wish to see our logic flawed by other folk , that it turn can make us quickly more opinionated than we would normally be. Its not a bad thing as long as it remains within the bounds of civilised back and forth discussion . We learn from our experiences and others can also learn from our experiences through that discussion. What was the previous "who are you" post ? I'm struggling to understand that Marc? I have seen it often, before any cleaning process while inspecting for faults, taking bridges off putting them back on dirt is pushed through threads ending up on the plate. Its possible that cleaning solutions will wash through the threads to clean them to some degree but wouldn't you want to keep solution jars less contaminated as in mechanical precleaning ways ?1 point

-

1 point

-

1 point

-

Beat error looks good on the Timegrapher so you’re good. but you always get beat error as good as possible before attempting rate adjustments. And I personally regulate dial up and crown down. These two positions simulate wear and rest positions. The others are good to get but those two are key for me.1 point

-

On a previous post the question was asked " who are you?" Impossible to answer as most of us are a myriad of things. One of my few (many) faults is being opinionated when I think I'm correct, so try really hard to temper my opinion because I don't want to upset anyone. In this case, I have seen grease and dirt both on threads and in the screw hole So who am ? Impossibletoanswer but a small snippet, I'll go out of my way to help anyone, try really hard not to hurt anyone, cross me, poor you.1 point

-

Sorry it's not a cheap or easy strap to get hold of and the only one I know available is also mangled. https://www.ebay.com/itm/293734767699 The problem you may also have is the pin on that end link could be bent or worn which would involve even more tools and work.1 point

-

Oops, washer would be the one on upper right, the looks of it is what I call it by. Can't just call it a bad design , rather one that sells, possibly with every seven years service. Thanks for bringing this up, gave me a chance to explain to be clear to understand. Since the rotor is not balanced , there is always a force exerted on the heavy side which tends to tilt the rotor and create the free play in the long run. Rgds1 point

-

1 point

-

1 point

-

Yes, exactly. You can take off material from there but in the end the separator must still rotate free. Be careful - not to grind to much. 3-4 movements on the file and try the end shake, and if still big - again. Assembling is easy, but use some grease to 'glue' the balls. When assembled, wash the bearing from the grease in petrol.1 point

-

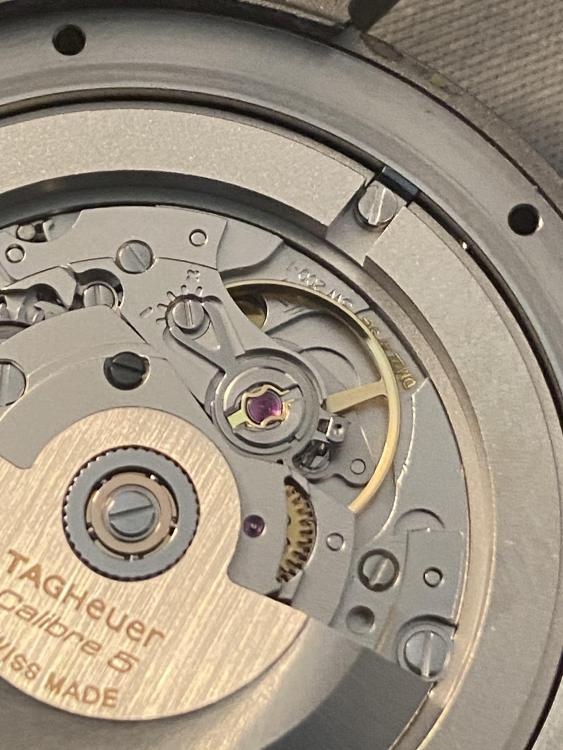

As I mentioned in some of my prior posts, I would probably work up the nerve to open the watch eventually. Well, this morning I woke up and decided to give it a go. In the intervening time, I bought a set of 10 watch screwdrivers, 5 brass pliers, a watch case vise/holder, and 4 loupes. They were all quite affordable around $10-20 for each set of tools. My wife had already bought me a time grapher some time ago, so I watched some YouTube videos on how to regulate an SW-200-1 and decided to try my luck opening the watch and turning the fine regulation screw a bit. The following posts will break down the steps of what I did. The image below shows the set of tools I used for the job. Here’s the watch in question. The images show the watch exterior front and back. The last one shows the dive bezel and the bezel spring removed, which reveals the six screws under the bezel holding the case back on. This is as far as I got during my last aborted attempt to open the watch. The next step was to remove the six screws under the dive bezel and spring that hold the case back on. At this point I thought I needed to unscrew the case back, so I put the watch in the vise and used the rubber ball method to try to unscrew the case back. I applied as much force as I could by hand, but it wouldn’t move the slightest bit. This left me quite confused, so I took the watch out of the vice and inspected it. As I was rotating the watch around and looking at it, the case back came loose and nearly fell off. Apparently those six screws are the only thing holding the case back on, so once they are removed, it comes off very easily. Then I inspected the movement. Tag Heuer calls this movement the Caliber 5 and gives very little information about it beyond that. However, through research on the internet, I surmised it was almost certainly a Sellita SW200-1. My suspicions were confirmed upon review of the movement. In the second picture below, you can see SW200-1 stamped into the baseplate near the top of the balance spring. In the third picture you can see the stamp saying 26 jewels. Another image zoomed in shows the 26 jewels a bit better At this point I wanted to regulate the watch. My previous post listed the performance in various positions. I’m reposting that information here for reference. regarding the daily rate, it is very consistently +10spd measured on my wrist. Every 24hours I wear it, it gains about 10 seconds, and it gains about 70 seconds in 7 days. So the +10spd is the average daily rate when I wear it 24hrs/day. on the time grapher the rates are all over the place. Amplitude is around 290-300 in all positions. On a full wind the rates are: Dial up it’s +10spd 3 down it’s +18spd 12 down it’s +5spd 6 down it’s +20spd dial down its +13spd 9 down it’s +4spd Those rate numbers correspond to the fine regulation screw being at the position shown above. This is how the watch was when I opened it. I spent about an hour tweaking the position of that screw back and forth while watching the rate change on the time grapher. My sense is that when wearing the watch it runs +10spd and that is the roughly the rate for the dial up position. That indicated to me that I should regulate the watch mainly focused on that single position as that seems to be the effective rate of the watch given my wearing habits. After several adjustments and trail and error while watching the rate on the time grapher I ended up in the position shown below. It seems odd to me that the fine screw was not centered for yhe watch coming out of the box from the factory. In the end I just moved the screw back to its centered position which brought the daily rate onI the dial up position to 0 and the crown down to +10. I was happy with the new rates, so I reassembled the watch and checked it on the time grapher. The image below shows the rate for dial up. I’m not sure how the time grapher rates will translate to real world performance so I’ll wear the watch for a few weeks and see how it does. In any case, I’m happy I didn’t break the movement or case during this adventure. I’ll report back on how it performs in a week or two when I have enough data to assess it. Thanks for everyone’s help and advice here. I don’t think I would’ve know how to proceed through this process carefully enough to avoid destroying the watch without your suggestions.1 point

-

1 point

-

1 point

-

Visit Sirmione. The town will be packed, but the ruins of the Roman villa on the peninsula are worth seeing. Verona has much more to offer than just the arena (impressive) and Juliet's balcony (underwhelming). If you are staying there, you can easily explore the old town on foot. The river makes a loop around two thirds of the old town and is a nice stroll in the evening. In Venice, everywhere you look is spectacular and beautiful. Get away from St. Mark's a short distance and the tourists fall away. Get lost in the smaller canals and alleyways. If you see a bridge, cross it. There's always something worth seeing around the next corner! On Dorsoduro there is an outdoor gondola workshop where they build the boats. You can watch them working from across the canal. If you are there for more than one day I will ask my wife this evening for more tips. Burano, Murano, St. Michele etc.1 point

-

Maybe I'll strap my whole collection of watches to my arms and legs, poor some of this stuff in the bath, and splash around a bit . Service the whole lot in one go1 point

-

Hello, thanks for the response. I used Moebius 8217 for the barrel wall and Lubeta for the reverse wheels. The winding pinion and clutch where oké. I re-used the mainspring because it looked oké to. After three or four days in the watchwinder the watch runs nice. I'll try the winding without the automatic module.1 point

-

Looks like my gamble paid off again. I haven't opened the caseback yet (still at work) but it arrived ticking at a ridiculous rate, the second hand sweeps, the day, date, and time all set. There's a little ding in the dial, but I was expecting that. The back is slightly dented in, but we can fix that too. For the price I paid, I am extremely happy. I took a video to try capturing how the dial shimmers. It's like a butterfly's wing.1 point

-

1 point