Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/06/24 in all areas

-

Maybe thats a joiner's thing ? Having a file rest in the bottom of the notch and removing material sideways just seems a safe option to prevent wander and to keep the cut perpendicular . Andy means file from the top into the notch. I took the ' if i aint on the ball i'll balls this up approach ' either way will work just depends how focused you are doing it. I like precaution these days the old eyes and hands aren't what they used to be lol.3 points

-

The caseback seems to be set into a channel, so there's no edge to get under. My photo doesn't really show that well. EDIT: I gave a razor blade a try and was able to find an edge to get under and was finally able to get the caseback off. Just a one jewel movement, as I expected. Balance spins freely, which is good. Just won't run for more than a few seconds.2 points

-

Dredging up some distant memories, I would widen the slot rather than go top down and risk damage to the bottom of the slot. Check the hand safe edge (proper term) cheaper files can have rough edges to this side and need stoned down to smooth it off and prevent marking. Tom2 points

-

Nothing more that a small needle file needed. Preferably with one non toothed edge so no risk of the depth being reduced at the same time. To remove the teeth marks, use a square degussit stone will smooth it off nicely or fine ally oxide paper/low grit lapping film glued to a matchstick.2 points

-

2 points

-

2 points

-

In some chronographs, this is what happens. The hammers are hard against both cams in a 7750, but in the 248, it's the jumper spring that gets the cam to the correct position. The hammer gets the minute runner to a certain point when the jumper spring snaps the counter into poisition. Both hammers or cams should be greased. Only the minute runner arbor isn't greased.2 points

-

The hairsprings in contemporary watches practically doesn't get rusty. If You see rust on such hairspring, it probably is due rusty water that has dried on the hairspring, but the source of the rust is something else, made of steel. The old steel hairsprings (black or blued color) do get rusty, but... If you see real rust on such hairspring, then it is gone. The problem is that actually spring gets thinner in the rusted places and timekeeping is gone, the spring can 'breath' in strange manner.1 point

-

Let us know how you get on, quite often sentimental value is way more important than quality.1 point

-

Yes you should use a barrette file. It has no side cutting teeth. Its one of my favorite files.1 point

-

Try a one sided razor blade and work around the case back.1 point

-

1 point

-

Yes, it's the same on a number of different movements with a number of alternatives. https://www.spareparts-watches.com/product/9834333/509-184-oscillating-weight-with-ball-bearing-substitute-509-004-509-080-509-074-509-069-for-seiko-7005-seiko-7006-seiko-7009-seiko-7019-seiko-7s26-seiko-7s361 point

-

1 point

-

I'm on round 4 of that haha. But this weird residue, this has to be it this time and this has exposed a hazard in my cleaning routine. I'm going to stop cleaning shellacked parts in perc, use ipa as my bench solvent just for jewels and clean my balance and pallet fork in my normal wash. Also gonna test the shellac vs ipa thing with a busted pallet fork i got and i'll share my results in another thread. I got all the people here saying yes, ipa destroys the stuff. All the people at my other place saying absolutely it doesn't destroy shellac unless you soak it in it for several days or basically boil the ipa. Now i'm curious.1 point

-

@clockboy Agreed! The air king that was used to compare, was with my watchmaker for a full service including axle replacement. I just did the non-scientific exercise to test a general principal. I have a new case and case-back on the way along with other auto module parts discussed above. I am determined to get to the bottom of this1 point

-

Strange how different people think but originally I would have gone from the top down but your idea of just expending it with a small flat safe edge file would probably work better.1 point

-

Depending how hard it is I'd be looking to take most of the material away with a standard square file and then finish with a diamond file.1 point

-

There are many types of needle files that you can use for this.1 point

-

There are variables which is why different folk have had different experiences . Experiments have been carried out here and through the world of ytube mostly coming to the conclusion that IPA does dissolve shellac....... but to what degree and in what manner does it affect shellac would vary in folks opinions. The cleaning and drying machine is probably a big factor in all of this, ultrasonic vs rotary, professional or basic use. Shellac age and type would be anoher variable. Period of contact, length of drying time etc. The views will be many and varied. I would try something trash first. I cant remember whats in evaporust. But vinegar is diluted acetic acid and turns steel grey, examined under a microscope looks to be etched. I've tried a couple of proprietary rust removers, had phosphoric acid in them and ate the steel quickly. If i remember the only solution that didn't seem to harm the steel was when i used lemon juice on a hairspring. The citric acid was mild, removed rust after a long soak but left a bit of a sticky mess between the coils which needed to be dissolved.1 point

-

Yes, sadly. On the last hole. That's why I thought a longer clasp might be good. It feels like it is already the 'standard' length clasp (I guess the width of a typical wrist), so I question whether there is a slightly longer one that would space it out. Bang on Andy! That is probably exactly what I am looking for. I had a look around Cousins site but I didn't see anything (must have been looking in the wrong section). Need to measure it up and put it on the next order of crystals and mainsprings. This is a great site! Anyway, here are some gratuitous wrist shots. Look how thick it is! I love it's lug-less puck shape. It's fitted with an ESA 9154 Dynotron electronic movement. I bought it off eBay for $50 AUD and it came as 'running well, new battery '. When I opened it up, it had a broken battery bridge, the wrong size battery and a chunk of aluminium foil wedged in to pack the battery out. It was barely running, with the balance not moving enough to drive the 'click lever' (pallet fork). Tested it as per the technical guide (balance dampening) and found the balance only oscillated for about 10 seconds - seriously needed a service. Electrical tests were all OK (coils, insulation test etc). Easy strip down, clean and rebuild. Put the 'wrong battery' back with the broken battery bridge and aluminium foil and it fired up. It performs well on the timegrapher with minimal variation between the positions and (I think) good amplitude. Not sure what the correct lift angle would be because it isn't a conventional escapement but getting about 270 degrees DU and DD, dropping to about 250 in the vertical positions with a 52 degree LA I have ordered a new battery bridge and correct Renata battery and will sort that out (along with the bracelet) before I put it into my rotation. I have a Citizen Cosmotron from a similar era and I really like these 'electronic' watches which are a hybrid between a mechanical watch and something solid state like a quartz. A horological ugly cousin - evolutionary oddity!1 point

-

1 point

-

To answer the problem folk need to know and understand what the actual issue is. What is not functioning correctly ? Its a bit like saying when i start my car a noise comes from the engine. Do you mean the time setting train ? The clutch isn't disengaging from the crown wheel ?1 point

-

Not sure where in the world you are but there are a number of different types. https://www.cousinsuk.com/search?searchTerm=strap extender1 point

-

My experience with a Rolex 3135 was that the automatic system is delicate and does not work correctly unless in perfect condition. Ie the mistake I made with my first service of a 3135 is I did not treat the auto parts with Epilame. Initially it worked fine but after a couple of weeks it did not self wind efficiently and the watch would stop on overnight.. The rotor should have no wear or play and the the rotor shaft on the 3135 is known to wear and must be replaced1 point

-

If evaporust is like pure vinegar it should not affect the shellac. I don't follow how you do it but the following story might be helpful. When I was new, I used an ultrasonic cleaner. I placed the parts in glass jars partly filled with a degreaser and lowered them into the ultrasonic cleaner partly filled with warm water. The glass jars had lids that were not completely tight. When I put the lid on the ultrasonic cleaner to reduce the noise from the motors, condensation formed on the inside of the ultrasonic cleaner and penetrated the glass jars. As water is heavier than petrol products, the water fell to the bottom of the glass jars and the parts were bathed in water, causing them to rust. These days I use a 72-year-old antiquated ELMA cleaning machine (still going strong) with a heater and it has solved these problems.1 point

-

Well, that's as good as it will ever get. Over long periods of time it may come to fluctuate a bit but that's normal and is to be expected. Congrats! That's what @Tudor was indicating but using a different wording. When regulating a watch you always first adjust the beat error if needed and then the rate. The reason is that adjusting the beat will also affect the rate but not the other way around. In your case the beat error was fine so no need to touch it.1 point

-

One good way to prevent parts blown by hairdryer is to hold the part in tweezers. Why to be concerned about the shellac??? Save the part from the rust, then apply shellac. But my advice is not to use chemical way for rust removing, as this will for sure destroy the part. As this is only surface rust, use wooden stick and polishing paste1 point

-

This unfortunately is the classic problem of poising. Ideally the balance wheel left the factory reasonably poised over time interesting but not always good things have happened to a balance wheel. It would actually be nice before static poising to figure out where you stand so you know as to whether you going to be adding weight or the consequences of removing more weight. But at least you know where you stand now and you can add timing washers. Then you can still use the mean time screws to fine tune things at the very end.1 point

-

Hi guys, I wrote a set of five lessons for my second year students regarding the Landeron 248 chronograph watch, which incidentally we are meeting tonight. They are going to be polishing pivots and pinion leaves of their 248s, before putting the movements through the cleaning machines. This is number one of five. I posted number two of five the other day HERE There are seven eccentric studs on this movement, so understanding what the studs do, how to set them, their actions and interactions with other parts of the chronograph mechanism is vitally important. I found there is very little out there on the internet to help understand the principles of these eccentric studs, especially video content to show various faults and alleviations, so I put together quite detailed walkthroughs of various complicated movements usually consisting of 15 to 18 hours of learning/servicing in the workshop per movement/module With any watchmaking, especially with complicated work, only make one adjustment and measure the results, if any. Be methodical in your approach. The lesson was originally in PowerPoint and I had to convert it to PDF to post here, so a lot of the video content won't play, but the PowerPoint version is in my cloud storage here. https://docs.google.com/presentation/d/10KJJ58P0v2BglKZSilIv9o69xBsbrQPI/edit?usp=sharing&ouid=107902587627140904870&rtpof=true&sd=true You'll need quite a newer version of Microsoft Office (PowerPoint) so the video content will play, otherwise it won't. I hope you find this lesson useful and begin to get a better understanding of how to set eccentric studs. Sometimes you'll come across a stud that is too loose, or even too tight. Usually if one is problematic it will be because it is loose. This can't be left, as the stud will turn whilst the chronograph is stopped, started and reset, throwing the chrono mechanism setting off which could lead to the movement grinding to a halt. Don't fool yourself in thinking it will hold. Either a replacement stud is fabricated to suit the enlarged hole, or the hole can be closed up. In turning and setting the eccentric studs prior to disassembly of the movement, we are able to set the chronograph mechanism, especially the minute register mechanism correctly and test for any faults, such as a bent wheel over fourth arbor, or incorrect depth of the dart tooth with the sliding gear, or a mis-set minute runner jumper spring, to name a few possible faults and mis-settings. Also in turning these eccentric studs we can gain a 'feel' for how tight they are in the mainplate or bridge. The more they are turned the more the chance of the stud becoming looser increases. So once set correctly prior to cleaning, the less chance they will need setting once the chrono mechanism is assembled, only if a stud isn't tight enough in its setting in the first place. This is for setting Landeron 248 eccentric studs, but once an understanding of their uses and actions is gained through theoretical aspects together with practical application, then this skill and knowledge can be used in most vintage chronographs to set their eccentric studs and even in modern timepieces where you'll find very few eccentric studs, such as an Omega Speedmaster or Tag Heuer Calibre 01 chronographs Enjoy! Lesson 22. Landeron 248 Chronograph.pdf1 point

-

@HectorLooi The post was in Bulgarian and not Russian. Which my browser did an excellent job of translating. I'm not sure of @nevenbekriev's nationality - his profile says Bulgaria, a country with a long and proud history and member of NATO. I'm not sure what Neven thinks about Russia, but we're not allowed to discuss that here1 point

-

I tried once and had little success. I ended up replacing the reservoir.1 point

-

It worked perfectly ! I have a 1000 grit diamond sharpening stone which was ideal. Sliding the washer about 100mm 4 times took off about 0.01mm. I ended up taking 0.025mm off in total, which left it spinning perfectly with very little play. Good tip about using grease to hold those little balls in place.1 point

-

That dial is so similar to my gramps Sekonda,.it must run through a lot of Russian brands. So anyway i dont always choose a watch for how it looks but whats inside and how it will perform. I have a thing for military watches DDs in particular, the grail DD being the rare guessimated production volume of 1000 made Grana. Unlikely i will ever own one but one can wish. So I cant have the watch but i can have a little taste of it and that comes in the form of this Certina which houses the same caliber. Granted it is a Certina signed movement and the spec may be slightly different but it is a Kurth Freres 320. Thats probably as close as i will get to the most rare DD1 point

-

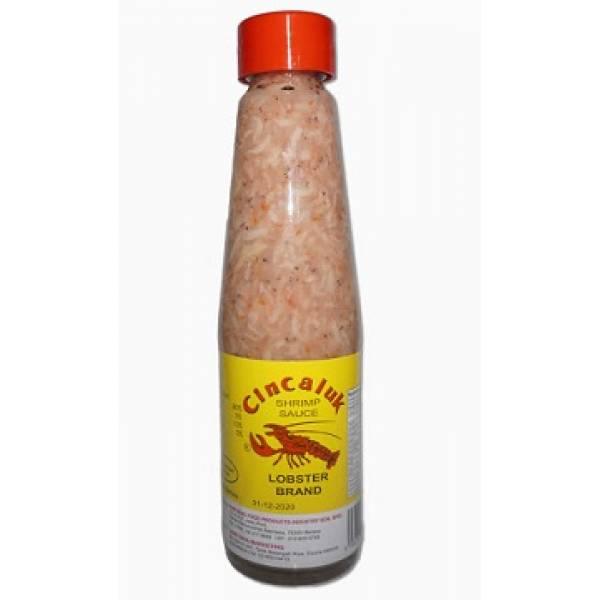

Since we are on the topic of exotic foods, here in Singapore, we have a fermented krill that is packed in a glass bottle with a crown top. It's similar to the Philippine bagoong. Several years ago, my mum asked asked for help to open a particularly stubborn cap. I don't know how long she was struggling with it but all that agitation built up pressure inside the bottle. So when I stupidly popped the cap off, I was sprayed with a stream of foul smelling, fermented shrimp juice. Even after showering twice, I could still smell it when I went to bed that night.1 point

-

1 point

-

There doesn't appear to be very much detail around on that movement so think you'll have to just measure the pinion.1 point

-

@Waggy - many thanks for measuring those dimensions. Exactly what I needed to know. I’ve ordered a set from Cousins, along with a Horia clone from Ali with 4mm top and bottom. Looks like they’ll work together. Cheers, John1 point

-

Yes, the old like 7009 are just pressed and and only pushing of the downside part thru the hole of top part, untill the rotor is supported above proper hole is needed. The newer are riveted, so first some drilling of the riveted part is needed. No riveting is needed after all is done, as the screw holds the both parts together well pressed1 point