Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/07/24 in all areas

-

I've spent quite a lot of time looking for chronographs for the 404 club, and for obvious reasons, they are rarer than unicorn poop, however no sooner had I spent the time needed to bring a Swatch Irony chrono back from the dead, than this popped up on fleabay. Its a Seiko CAL.VD57B based watch, and has the added bonus of having a blue dial, so it should scratch both the 404 club chronograph itch and the blue dial itch at the same time. It also allegedly works and has a fresh battery in it. I'm not sure why there were no other bidders, but I am certainly not complaining. It may not be the Zenith Chronomaster El Primero Blue Dial 42MM similar to this that I was tempted by the other day, but it does have the advantage of not making my bank manager nervous, and I suspect with a little TLC and perhaps a less boring strap, it should be quite a presentable piece. Two pounds eighty five plus shipping, before you ask. vd57bChrono.pdf2 points

-

So I asked my Grandmother and this is what she said “I started at unitime corp in 1965. We made movements from parts from Hattori trading company (they make the parts for seiko too). I didn’t make watches, but did get to handle and become fascinated by the parts and their functions. I also worked at Antilles industries which used the same parts to make watches for westclock. Grandpa went to work at Unitime at the beginning of 1968 - 1972. He did the same job I had had but he also learned how to put a watch together. Unitime made for : Waltham, carvelle, Dorset…. Well those were the names on the dials. I can remember the companies a little better: sears, Montgomery ward, top value stamps, Hamilton, oh my, Unitime also made a little rectangular movement for swank , they put them on cigarette cases, cufflinks and other “cool 60’s stuff”. Those parts came from France.” My goal is to find and acquire a watch that came from one of the factories when they worked there. We shall see one day if that comes to fruition!2 points

-

2 points

-

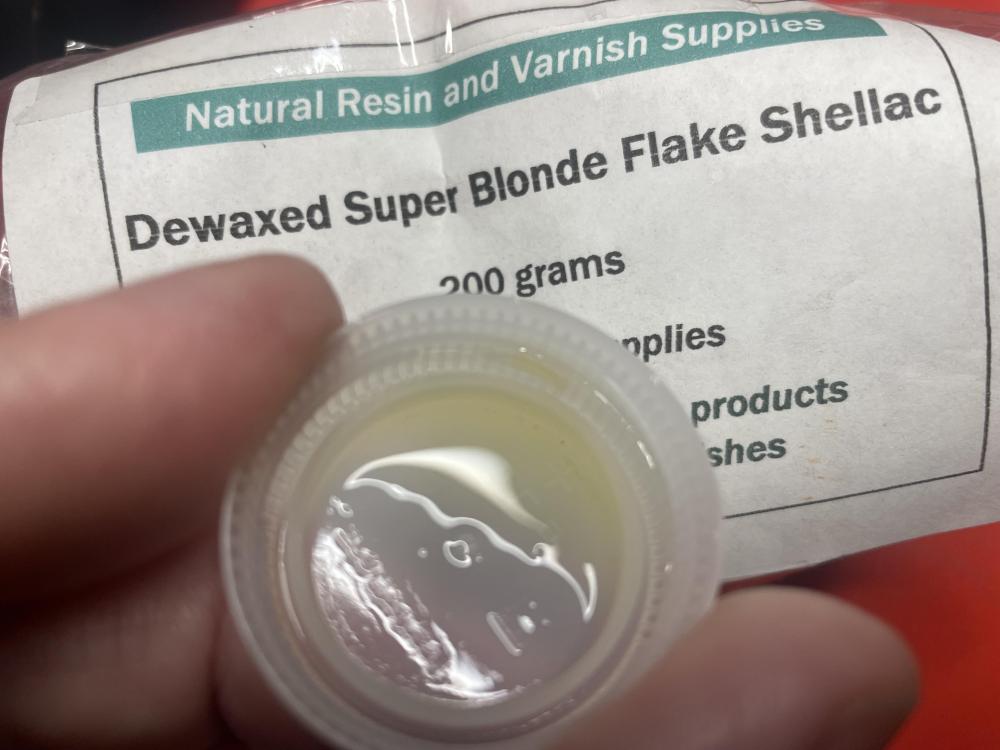

I've just tested the IPA again, in case I was confusing myself - I have tried different solvents at times to get away from the purple methylated spirit colour. (I now have industrial type, clear, denatured alcohol). This is dewaxed shellac in electronics cleaning grade 99.7% IPA; totally dissolved: It is slower dissolving than with denatured alcohol, but using IPA as a cleaner, it will be dissolving some amount of shellac with each wash. Re. the L&R 111 turning white, that happens if it is mixed with water, it forms a milky emulsion. I've seen that when the stuff has dripped in to the water outside the solvent pot, removing items from the ultrasonic cleaner. I've not seen the coating effect on things with watches, but I have seen a similar effect in machine tools, using emulsified oil coolant - which used watch cleaner may replicate, an emulsifiable solvent with oil dissolved in it? That stuff can dry and leave something similar to burned-on cooking oil, a thick gooey gel-like stuff that's near impossible to remove! The only thing that removes the stuff on machines is more, fresh, coolant emulsion.2 points

-

My mentor also puts everything through his cleaning machine with L&R cleaners and ending with IPA. He also says it's ok. He believes that those jewels that do come loose in the wash were not properly shellaced in the first place and it's good that they did come loose in the wash. I'm not proficient enough in resetting jewels yet to put everything through the wash.2 points

-

Pure IPA is commonly used to dissolve dewaxed flake shellac to make varnish, French polish and stains. It does not dissolve as fast as in ethanol, and IPA evaporates more slowly, but it categorically does dissolve - I use shellac flake for woodworking & refinishing. If the IPA has been open to the atmosphere for a long time & picked up water, or is lower grade containing water, then that may appear to not react with the shellac, though it will still have some effect. Another reference: https://sokolowskistudios.com/mixing-fresh-shellac-from-flakes/#:~:text=Solvents for Shellac,advantages outweigh this slight inconvenience.2 points

-

First of all I would like to thank the community here and Mark for providing a space to indulge our hobby and for some, profession. I feel very lucky to be able to enjoy learning and sharing. In no way do I want to come across as bragging or ungrateful. I have learned a lot over the past 20 months or so. I hope I can give back half as much as I have gained. That said this post is dedicated to @rossjackson01 whom I have seen recently state to the effect that he could not work on a mexhanical chronograph for at least 2 more years. I hope that he gets an oppurtunity sooner than that and there are still bargains out there if cost is a determing factor. I won't say how much I paid as you would not believe me, but this could be one of the best 404 club entrants ever, at least for me. One of the factors that led to this was a discussion with the seller that reiterated other similar discussions here and elsewhere to the fact that many independent watchmakers don't work on chronos due to cost and difficulty in finding parts. Add in Swatch owing eta/valjoux and restricting access to parts and so it is tough getting one serviced. Add in that Venus is a precursor to the Valjoux 7730 and ultimately 7750 and others, parts and service can be difficult to obtain unless we can maintain the right of servicing or DIY. Anyhow, here it is cleaned up case and new crystal with a new mainspring on the way (that is part of the story sourcing that part). I usually don't like to post things before I get them in the mail or finish the work to not jinx myself! I will post pictures as I get into the repair and cleaning, and hopefully no other parts will need replacement! I put a neat little strap on. Is about 35.7mm but is larger on the wrist with the pushers probably closer to 38mm. 44mm lug to lug and 18mm strap width. Works very well on my small wrist.1 point

-

After watching Alex Hamilton's video on improving ultrasonic cleaning, I decided to make a similar machine but using studier components. I first got a chemical stirrer almost identical to the one in the video. Then I got an Indian-made cleaning basket from eBay. After the parts arrived, I set about putting it together. I wanted it to be able to straddle my ultrasonic cleaner, so that the basket can be lowered into a glass jar containing the cleaning solutions. I wanted the basket to rotate slowly while the ultrasonic was on to avoid dead spots on the tank. I also wanted the basket to spin rapidly to spin dry the parts after each cleaning cycle. So this is what I came up with. The basket fits to a 8mm shaft but the chemical stirrer only accepts a 6mm rod. So I glued a 8mm stainless pipe over 6mm stainless tube. The rest was easy.1 point

-

Very nice ! I have a 940 that is my "personal" favorite..in a display case. Yes..these full plate movements can be a challenge. To hold the pivot fork / potence in place...take a piece of the old M/S..and cut it down to about 2 inches. Then file a small notch on one end, and bend the piece in half. Slip the spring over the mainplate and adjust it as needed to get the notch to fit around the the upper pivot as it sits in the jewel. It will hold it in place as you do the assembly. Oldtimers called these Potence clips . Randy1 point

-

No flimsy screw, robust and easy to tear down movement. Enicar sherpas Chrnongraph can be a bit pricey, but best of the crop, I think is Enicar Chronometer which I have been on the look out for one. Hard to find one for sale in my neck of the woods and ebay is not an option here. Guess you need a strong magnet looking for the spring. Not sure about balance complete , but all parts seem to be original in your watch, shame to replace any with after market ones. Some calibs were powered by valjoux 72 and are sought after. Good luck1 point

-

You probably didn’t get the deluxe version with lifetime support Col, a bargain at only 300% extra Tom1 point

-

1 point

-

1 point

-

See, this debate is silly and useless. Of course, alcohol and IPA will dissolve shellac. But it will take some time. First of all, I believe alcohol in watchmaking is used for getting rid of the water after rinsing the parts in distilled/dejonised water. This is when water based cleaning solutions are used. The procedure is: solution - water - alcohol - petrol. Pure Petrol (benzine, hexane) is the last instance. I know You call it 'naphta', but in my country we call this way the diesel... Rinsing in water is for 10 sec, and then alcohol - another 10 sec. What is the reason for using Petrol - IPA - IPA - IPA procedure? What is the logic? If You are frightened to loose the adjustment of the pallet fork, then first use peg wood stick to carefully clean the surfaces of the pallets and then soft brush the whole pallet fork with pure petrol. That's all. Don't put it in ultrasound at all. The correct thing is to learn to adjust the pallets, then one will never fear of destroying shellac. Now You try to keep on every price the shellac untouched , but if something is wrong with the pallets position, then You bravely will replace the entire pallet fork and believe this is OK. Then You will ask why the amplitude is decreased... But do You know how to check if the new pallet fork acts in this specific movement correctly???1 point

-

1 point

-

@mikepilk I just wanted to pop in and say thank you for your advice, I successfully opened, repaired and closed the watch1 point

-

This suggests as @mikepilk said. Maybe they had separated and you just pushed them back together? Once they're pushed together they can't be deformed any more no matter how hard you hit them.1 point

-

Minicraft do a range of DC motor rotary tools with some good attachments for drilling, cutting and sanding, the older stuff is German made so the quality is..... ok. No i wasn't suggesting you were Andy , just reinforcing Waggy's comment before someone tried it Lol you'd be surprised Andy. i think we are a better class here though than some of the muppets on YouTube. A better class of muppet at least1 point

-

1 point

-

Hello and welcome to the forum. No one judges anyone on here we just help where we can1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

Hello and welcome from Leeds, England. Do you know which watch manufacturer was on St Croix?1 point

-

Welcome to WRT and enjoy It's strange how things come full circle sometimes.1 point

-

If you need any parts it's a BFG 134 base https://www.emmywatch.com/db/movement/baumgartner--134/ https://www.cousinsuk.com/category/filter/bfg-movement-parts1 point

-

The hairsprings in contemporary watches practically doesn't get rusty. If You see rust on such hairspring, it probably is due rusty water that has dried on the hairspring, but the source of the rust is something else, made of steel. The old steel hairsprings (black or blued color) do get rusty, but... If you see real rust on such hairspring, then it is gone. The problem is that actually spring gets thinner in the rusted places and timekeeping is gone, the spring can 'breath' in strange manner.1 point

-

My question was, providing a solution de-rusts, say hairspring, would then that hairspring not restart rusting ? Is part of the reason that some watch cases are vacuumed not rust protection ? Are some hairsprings gold electroplated? Guess some springs are made of alloys that don't rust. I wouldn't want to reinstall a de-rusted hairspring specially not in a pricey watch.1 point

-

I also used perc but stopped for some reason, might have been this residue thing you're experiencing Col. or maybe it just didn't degrease very well, cant remember. Still variables to consider with the IPA , what sort of machine are different people using ? Alex Hamilton experimented with using an ultrasonic to clean pallet forks , his results were pretty conclusive that the cavitation bubbles removed the shellac from them and in most cases dislodged the pallet stones. Pallet fork and balance I've cleaned manually for ages now, this means i have more control over what happens to them. If the hairspring needs cleaning more so then i use a very simple vibrating macine that doesn't produce cavitation bubbles in the water it contains. If that isn't enough then i would pull the hairspring and clean it by itself in a small us machine . Same experience here exacly Jon.1 point

-

1 point

-

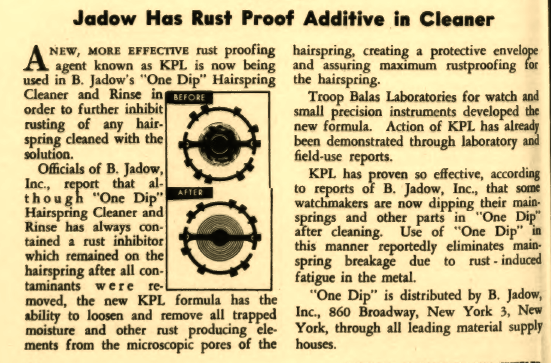

The problem is we end up with way too many variables here. For instance how is or was the original one dip marketed in other words what is its true purpose if anything? So advertisement from 1957 the basically has two purposes one to prevent rust and clean things like your hairspring. So in other words if you're cleaning machine didn't do a good job of cleaning in the first place this would be something you would use. YouTube is always interesting I've seen two separate videos on ultrasonic is evil and bad it will destroy your watches. Yet both of the schools I went to had ultrasonic cleaning machines. The cleaning machines were cleaning all day long watches. It seems like we might and noticed the destruction of the evil ultrasonic but I guess we weren't paying attention. Then if the shellac was disintegrating I think we would've noticed that too. I think all the shops I've worked in except one had ultrasonic cleaning machines. So my experience in real world differs from YouTube. Then the ongoing and listed debate of how can you dissolves shellac is probably just about everything in the universe if you leave it in their long can. That does appear to be that alcohol will dissolves shellac so it is forbidden under penalty of death of ever using alcohol except variables again. As I said I used alcohol that will dissolves shellac the can was very clearly labeled that it will dissolve in sin shellac and yet it never was a problem because I didn't leave it in there all day long I only used it for the final final rinse. As I said the cleaning machine at work at the recommendation of Elma you would think they would understand about cleaning machines after all they make them their recommendation was ipa once again as the final rinse. Then as I said too many variables and too many stories. For instance the Chinese 6497 clone I think I cleaned it twice in commercial watch cleaning products and Of course the evil alcohol rinse and they hairspring cam free from the stud. So let's see the conclusion would be don't use ultrasonic cleaning machines don't use commercial watch products and definitely don't use alcohol as poorly glued Chinese studs will disintegrate. We also don't know in your chronograph example which chronograph it was how long did it stay in the solution and whether was any other solutions involved at all too many variables. Now we get to the peculiar problem of chemistry the formulas of course have changed. Then I suspect that probably all solvents that evaporate which is a nice characteristic unless we like wet parts probably are bad for our health. I know one of my coworkers was using of the one dip for cleaning off glue on a display case and it was definitely not good for her system at all. Although it she does seem to react way more to chemicals and things than most people. But definitely having it on a cloth breathing in the vapors and this would be the newest stuff was not good at all.1 point

-

No clue, i sorta doubt it. Yeah for all my normal parts they're still in the basket and i blowdry them. For balances though I"m not entirely sure what to do as at least i've been told you have to hold up the balance wheel with your tweezers while you dry and hitting that with a blowdryer would be a disaster....maybe this step isn't necessary...or maybe i could just put it on a mainplate and then blowdry. Never really thought of this. So, perhaps i've been mislead but i was ALWAYS told ipa will destroy shellac, this is why onedip exists and why people use a bench solvent for those parts. My other watchmaking space told me the other day that it's only denatured alcohol that does it, and that ipa does not. But i also specifically remember a guy here who ruined a brand new chronograph with ipa and the hairspring came unglued from the stud. Can anybody confirm or deny this? So i'm going to toss that pallet fork into some evaporust and i'll report back. Your story about the water ingress into your solvent, i'm actually fairly confident that's whats happened. So i took a long break from watchmaking and my benzine jar just sat there for months, a bit of it evaporated off so i just topped it off. It never occurred to me there could be moisture ingress into it but i think that's probably what happened. Cautionary tale, lesson learned. I cleaned the jar and refilled it and i'll be more mindful of that in the future. Thank you for sharing that!1 point

-

1 point

-

Actually from time to time I would like to blow up the parts preferably in the assembled watch. Or specifically I was thinking of the can it be nice to make my problem go away in a spectacular fashion but for a variety of reasons Debbie very very bad in my location to do that. I'm always puzzled by why a different procedure for parts that have shellac? Because I run all of my parts through the cleaning machine and they come out nice and clean. Contrary to the YouTube gods to claim that ultrasonic alcohol cleaning fluids and probably just about everything else in the universe is bad for the shellac it seems to work just fine. Then there is a universal concern of Rust the way you describe by you didn't mention something? I've seen several references to using epilam can lead to rust. There used to be a website that had pictures and I was at a lecture once with a described the exact same concern. The solvent used with the earlier batches of epilam well basically think of it like Freon it wasn't Freon but it was something else. So what happened is as it was drying of that operating it would produce a chilling affect and depending upon your location humidity in the air you would get the moisture in the air to condense on the steel parts the pallet fork and escape wheel. Then ultimately that would lead to rust and on the website the person showed the rust damage and the damage it was doing. This is where I was at a lecture in some I was concerned about this so they had a hairdryer and yes you can hold the parts in your tweezers it works fine they would put it in The epilam and immediately warm air dry. The newer epilam is supposed to be less volatile so I don't think that's as much of an issue. I suppose it's conceivable though whatever your solvents is if you blow what sort of apparatus really fast could produce a chilling effect I think basically when anything evaporates it produces a chilling effect and if you have enough humidity in the area will have condensation1 point

-

One good way to prevent parts blown by hairdryer is to hold the part in tweezers. Why to be concerned about the shellac??? Save the part from the rust, then apply shellac. But my advice is not to use chemical way for rust removing, as this will for sure destroy the part. As this is only surface rust, use wooden stick and polishing paste1 point

-

That dial is so similar to my gramps Sekonda,.it must run through a lot of Russian brands. So anyway i dont always choose a watch for how it looks but whats inside and how it will perform. I have a thing for military watches DDs in particular, the grail DD being the rare guessimated production volume of 1000 made Grana. Unlikely i will ever own one but one can wish. So I cant have the watch but i can have a little taste of it and that comes in the form of this Certina which houses the same caliber. Granted it is a Certina signed movement and the spec may be slightly different but it is a Kurth Freres 320. Thats probably as close as i will get to the most rare DD1 point

-

1 point

-

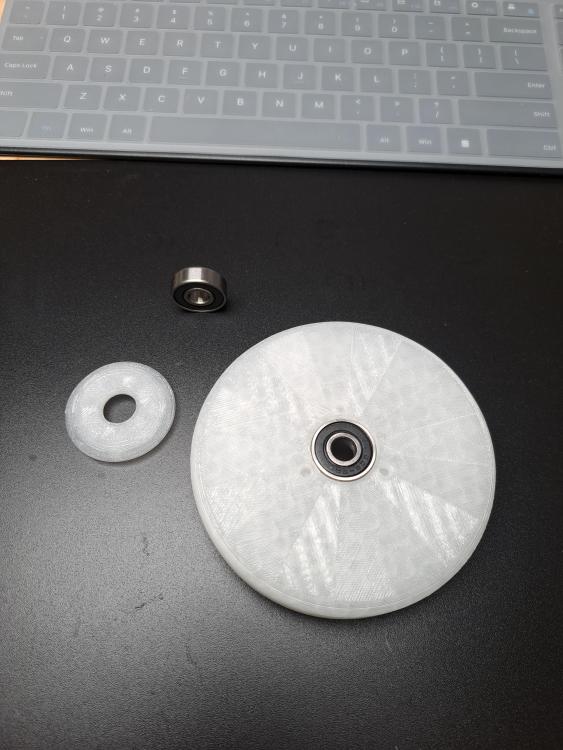

After reading a lot of you guys building an under budget cleaning machine made one myself. I bought the over head mixer thru amazon for less than $100 bucks, it has a timer bult in and can adjust the speed. I used 3D print to create the jar holders and the cover for the jars. The cover has a ball bearing to minimize the waggle in high speeds but also I cut the shaft short. The ebay indian baskets are hard to open and close, so I decided to buy the elma basket and luckily the Indian baskets fits in the elma basket. I'm still working in the drying station. Let me know what you guys think. All suggestions are welcome.1 point

-

I was also looking at the Indian basket but several reviewers had trouble with the wobble so I ordered an Elma basket. Pretty expensive but precise manufacture.1 point

-

1 point

-

Well the other "Waltham 65" that I posted the ebay photo of a few days ago (26th July) has just arrived. This was advertised as in running order. The seller needs a serious lesson in packing such things! This is all the packing in the box; the watch itself was loose already: And the rattling about it endured was bad enough to knock two of the hands off! I've sent the same photos to the seller, to show how it was received. I have not looked inside it yet; possibly later today.0 points