Leaderboard

Popular Content

Showing content with the highest reputation on 08/08/24 in Posts

-

There should be a pinned post on alcohol. For many years my cleaning machine was a brilliant machine made by Greiner. First bath, water based cleaner, ultrasonic, fluid agitated by pump running through a filter (magnet in filter too!). Second bath is isopropyl alcohol. The way the "baskets" were set up the fork and balance were on their own set. They went in for 30s, then to hot air stream. The rest of the movement went in, 30s later push a button and the alcohol emptys into the built in distiller, and 6m later the bath is flowing (another circulating pump) with clean alcohol. Great setup. Sometimes I'd forget a fork in the alcohol for 30m or so, usually OK, sometimes it did strip the shellac. No biggie, reapply shellac. 99/100 or even more often the stones are a light friction fit so haven't moved. Most roller jewels younger than 60-70 years old are also frictioned, with a bit of shellac. In 15+ years one roller jewel came out of a 110+ year old watch, definitely because I left it in for at least an hour (and the alcohol is quite warm, coming from the distiller). The jewel was found in the filter for the distiller- yes another filter. Greiner made great stuff. Last century I learned very quickly that iso alcohol is sloooow to dissolve shellac. Ethanol, way quicker, and heated ethanol, way way quicker. Back then if I wanted to move pallet stones I usually stripped all the shellac, got them positioned, the reshellaced. Nowadays I do it with the original shellac in place. But if I was out of ethanol, it was a tedious process to remove with iso. I await 5 weeks from now when a new discussion on alcohol, the different types, and shellac comes up again. 2 weeks? As for French polish, most folks use some form of ethanol, either pure or denatured. It dissolves shellac so much better and faster. But I've read of folks using 99% iso too. There's probably woodworking forums with never ending discussion of this too. But as a pro, with 25+ years in, I can say isopropyl is crap at dissolving shellac, ethanol is great.5 points

-

Hi all. I'm from Teignmouth in the southwest of the U.K. and am a newbie to this fabulous hobby, around 10 months or so. I joined this group because when I googled my questions, this group consistently came up with the most interesting and friendliest comments. Really happy to be here and will definitely learn, but hope to perhaps also contribute to the conversation, even if it's with stupid questions! I have a passion for vintage Omega watches and decided that the only way I could afford to own them was to be able to service them myself, but since have found a deep appreciation for vintage watches of any brand.3 points

-

There are countless articles on here about how dangerous radium is : some would gladly sprinkle it on their breakfast cereals, and some would not want to go withing 100m of it. The truth is somewhere in the middle. If you are going to do it,take sensible precautions to prevent contamination. Loose flakes of radium are the danger, you don't want to inhale it. What I do, is cover the work surface with cling film, wear latex gloves and a mask. When finished, I wipe down all tools, surfaces, put gloves, clingfilm, wipes etc in a sealed bag and in the household waste.3 points

-

Welcome to the WRT forum. I am not afraid to ask stupid question, problem is I don't understand the answers.3 points

-

There are several isotopes of Raduim, whose half life differ greatly, ranging from 4 days to 1600 years, depending on which ones we had for breakfast today? we could be emitting radiations 1600 years after our body has turned to dust. Your breakfast might have contained Xenon 124 whose half life is only one trillion times longer than life of the universe. Radioactive elements like any other can chemically bond with other elements and enter our body hiding in food we eat. So I recommend buying many Geiger counters when on sale, one to incorporate into our pillow, one for every dish, one for the tooth paste ,.... We are the product of a supernova explosion, the entire universe is a nuclear reactor and will continue emitting radiations of all type until it ( the univers dies) . Did you like the story about the fate of universe? That ain't all, following its death the only force that remains is gravity and some kinetic energy of each mass, the fellow whose life is longer than universe will disintegrate too, gravity keeps pulling bits together, one such bit can be our galaxy, the more mass it pulls together the more massive it gets to generate stronger force of gravity thus pulls more mass till all mass is one big ball but not so fast forward , the bigger it gets the more it collapses into itself due to the force of it's own gravity, so there are opposing factors, one is growing gravity which grows with mass the other is collapsing due to stronger gravity of bigger mass, the new one ball the univers has become, keeps collapsing into a dimensionless point of unimaginable intensity, energy and zero entropy,.... Next may comes another big bang, oh no. That's how the theory of big bang in mankinds mind formed. Ever read the story that universe was a dimensionless intensely energised point. Stop redium ing your mind, and play with watches. Isn't a single moment of life too valuable to spend it worrying? Rgds2 points

-

Soldering skills would not be a big deal if you use low temp solder paste, apply like glue then heat the parts with a heat gun until it all flows together. As others have said clean thoroughly after, IPA should get rid of the flux residue, often used in the electronics world for this. Tom2 points

-

Yes indeed! In my experience, most often it only softens the shellac and makes it soggy, which in my opinion is undesirable even though it may not affect the performance of the movement. How much IPA affect shellac I believe depends on the type and age of the shellac. I tried to dissolve the shellac from a 60-year-old Omega 268 using pure IPA, which was basically impossible. It only softened it somewhat. I've had decent results removing shellac using acetone. I have methylated spirits from Cousins but I can't recall that it was more efficient than acetone, at least not at room temperature. Excellent advice (except for the "bloody" part)! Not being a pro, it takes me a long time to reset and shellac pallet stones. It's not just worth it if the locking depth is already perfect and the shellac is in good condition, and cleaning by hand is done in a few minutes.2 points

-

From the age of the watch, and the way the lume is turning from green to brown on the hands, I would guess radium. Shine a bright light (ideally UV) on to it. Radium is slow to glow, slow to fade. Later lumes like Luminova, Tritium, glow immediately. You can get the scratches out of the crystal with fine wet and dry, and Polywatch. But I can see cracks through the crystal.2 points

-

Been awhile since I have posted anything--been crazy busy. So, I bought this for $70 from a lady in the hood. Missing a crystal with a broken mainspring. My friend in Dallas had a MS so today, I serviced the watch. I have never done one of these single plate pocket watches. It was QUITE the challenge. If there is a trick to getting all the wheels aligned, somebody let me know! I did it, but it took me the better part of an hour!!!! Anyway, it is together with a little over 1ms in BE and looks very accurate DU and DD (and over 300 deg in amplitude). Here is a picture of the finished watch, and a picture of the movement. Notice that the minute hand is wrong. Lucky me, today on ebay, somebody was selling a set of 940 hands. I won the bid at $43 total. A little steep, but the value of the watch is greatly increased with the correct hands. As an aside, I have been consumed with a big real estate transaction and pending move. I bought 47 acres in Bryan TX, adjacent to 20 I bought for my son. We will be making Bryan the center of gravity. A cool wrinkle is that I am going to expand my watch/clock hobby there by putting a large shop on the site. I am too cramped here. It is a work in progress, but next year I will post pictures!!2 points

-

Very nice ! I have a 940 that is my "personal" favorite..in a display case. Yes..these full plate movements can be a challenge. To hold the pivot fork / potence in place...take a piece of the old M/S..and cut it down to about 2 inches. Then file a small notch on one end, and bend the piece in half. Slip the spring over the mainplate and adjust it as needed to get the notch to fit around the the upper pivot as it sits in the jewel. It will hold it in place as you do the assembly. Oldtimers called these Potence clips . Randy2 points

-

Enicar Star Jewels MRO (AR 165D) A while back I won this watch at an auction here in Norway. I’d never heard about Enicar before, but a Google search made me stay up until too late. What a charming brand and history! If you ask, they had some killer design going on for a while and all their movements are inhouse. And It was so cool to find that this brand also had a little community going online! From the guy who made a nice book about the brand; enicar.org to a youtube favourite of mine HorologyBiology who has vintageenicar.com. And also enicar101.com deserves a mention for sure. It’s cool to discover a brand like this and learn about its history. I’ve never been so into vintage watches before, but discovering this brand opened the door for me on what’s out there. So on to this project: This will be my very first watch service/reparation ever(!). I have disassembled a Seiko before, that’s it This design is so 70s its funny! A strange way to design a watch with a sort of inlay between the dail and plexy. Unfortunately, this inlay had come loose on this watch, and as a result, scratched the dial very badly. This watch has an AR 165D movement which was launched (and I think mostly used) in 1975. Making this watch about 50 years old. Does anyone know what MRO stands for? I guess I have to find a original Enicar dial that fits. I found some on ebay that will match the calibre, but maybe not the design with the inlay. In hindsight, this movement is probably not the best to start out with. They seem to do stuff a bit different, and this movement has A LOT of parts. A cool feature is a quick set date that changes one day when you press in the crown. 29 jewels and a nice design. Well, it's no way back now. I couldn’t find too many guides online, but I got some quality expertise from these ones; Vwatchie made an excellent guide for a similar calibre although a bit less complex: https://www.watchrepairtalk.com/topic/22036-enicar-calibre-161-service-walkthrough/ But there is a lot of solid information here, and I will also use it when reassembling the movement. On youtube I found French Watch Collector who has a good video about a very similar movement. Also some good information about the Brand etc: https://www.youtube.com/watch?v=Ea0fwnsspk8 But the only one I could find who is working on this specific movement was Horology Biology who made an excellent video. Unfortunately, it isn’t real-time and It can be hard to copy at times. Not everything is shown. https://www.youtube.com/watch?v=rJpucnLHbB8&t But with all this expertise thrown together, I think I have enough to get this watch assembled again. I have done a complete disassembly now, even the mainspring! And so far I only know one major mistake I made. I should have used some rodico to hold down every spring when removing. I didn’t, and one tiny spring flew into another timeline or dimension. So not only do I need to buy a new dial, I probably will end up buying a backup movement as well. I have some concerns regarding the balance wheel also. Even though this watch did ok on the timegrapher. Luckily they aren’t too expensive. In the meantime my plan is to do a DIY cleaning, rinse and drying without a proper machine. And then try to polish the case. Im not sure how it will turn out, but im sure I will learn a lot. All feedback and tips are very welcoming! It's my very first project, so some more mistakes are probably expected1 point

-

You can also go a very long way without a staking set unless you intend to spend a lot of time on vintage pocket watches or other very old timepieces. You won't need it often if you're mostly working on wristwatches from the 1950's onward.1 point

-

You don't always need a mainspring winder or a jeweling tool but you always need good cleaning.1 point

-

Many of us use a 3 jar ultrasonic regimen, preferably not the $10 jewlery cleaning devices, (they are not ultrasonic). There are many discussions here on that subject too. some cannot afford or find a watch cleaning machine, some just do this for fun and there is no reason you can’t be successful cleaning by hand. Tom1 point

-

I just set a timer on my phone. Not sure that my stirrer controller has an audible alarm or not, but even if so, with my cleaning machine down in my basement, I won't hear it from the main floor. I'm not impressed with the speed control on my unit as there is no RPM indication. I wonder how good the speed control is on @Martin89's setup.1 point

-

Have a search on here for DIY cleaning machines, lots of ideas and innovative solutions. Tom1 point

-

Mickey has a heart beat. Got oil applied to two escape teeth and it just took off. That was last night. Still running this morning.1 point

-

Indeed, as Joni Mitchell sang : "We are stardust, we are golden*" *It's amazing to think that all the gold on earth is produced either in supernovas or colliding neutron stars.1 point

-

How about cleaning the edge and groove, once the parts are separated, then adding a trace of solder paste in the groove before re-assembling it? I'm not sure how safe it is to heat it to ~350'C though. Alternative would be low melting point solder paste, eg. https://www.ebay.co.uk/itm/385050331282 Or, solder for white metal - 70'C melting point! Use that with acid flux, then wash it very thoroughly. https://www.ebay.co.uk/itm/2564518118441 point

-

My first thought from the visual is that I would treat it as radium. If it is radium then you shouldn't have removed the back without precautions in place as there was more than likely a build up of gas which has now been released and potentially inhaled. Unless it has some sentimental value I'd leave well alone.1 point

-

What oil is good for that? I usually use 9415 for pallet fork jewels. Maybe 9010 instead? EDIT: Checking around, 9010 looks to be the recommendation.1 point

-

A piece of USED fine sand paper works to take these scratches out, then smear some tooth paste on a piece of cloth to polish this crystal with. Rgds1 point

-

Hi, Good idea a whole movement as a donor is best option. Back in the days, spare parts were made by Renata which is good quality, I don't know who else did, if any. The idea is to keep integrity of the piece, specially vintage collectables and antiques. In case you haven't yet bought a timegrapher, WATCH ACCURACY METER app is good for start, easy to download off the web and works with your smart phone, , it will at least give the beat error, daily rate and an idea of the escapement's health. Let us work with you every step of the way please. Good luck1 point

-

I’ve done a half dozen of these. WRT professional educator Jon has extensive information on servicing these pin pallets. See this below and look for my other posts on servicing…1 point

-

Is that even possible? If you don’t have one of the inexpensive counters assume that it is…. A nice looking dial with potential…1 point

-

So I was overly concerned about damaging the threads. I spent less than 5 minutes with a barette file and sized the notch roughly where it needs to be and later I will finish it more to flatten the bottom and square up the side with a fine grit diamond file. But my cut is on the following side of the thread gap so there is no issue with the bezel missing a damaged thread after it crosses the gap.1 point

-

1 point

-

I'm really confused by this discussion. What kind of oil did you put inside the oiler in the first place?9010 does not gum up. Did you use your oiler on an uncleaned jewel and got dirt into the tip? Is the needle tip bent? Naptha does not destroy plastic. Ronsonol now comes in plastic bottles. Just rinse out the reservoir with naptha and soak it for a few minutes.1 point

-

See, this debate is silly and useless. Of course, alcohol and IPA will dissolve shellac. But it will take some time. First of all, I believe alcohol in watchmaking is used for getting rid of the water after rinsing the parts in distilled/dejonised water. This is when water based cleaning solutions are used. The procedure is: solution - water - alcohol - petrol. Pure Petrol (benzine, hexane) is the last instance. I know You call it 'naphta', but in my country we call this way the diesel... Rinsing in water is for 10 sec, and then alcohol - another 10 sec. What is the reason for using Petrol - IPA - IPA - IPA procedure? What is the logic? If You are frightened to loose the adjustment of the pallet fork, then first use peg wood stick to carefully clean the surfaces of the pallets and then soft brush the whole pallet fork with pure petrol. That's all. Don't put it in ultrasound at all. The correct thing is to learn to adjust the pallets, then one will never fear of destroying shellac. Now You try to keep on every price the shellac untouched , but if something is wrong with the pallets position, then You bravely will replace the entire pallet fork and believe this is OK. Then You will ask why the amplitude is decreased... But do You know how to check if the new pallet fork acts in this specific movement correctly???1 point

-

I've spent quite a lot of time looking for chronographs for the 404 club, and for obvious reasons, they are rarer than unicorn poop, however no sooner had I spent the time needed to bring a Swatch Irony chrono back from the dead, than this popped up on fleabay. Its a Seiko CAL.VD57B based watch, and has the added bonus of having a blue dial, so it should scratch both the 404 club chronograph itch and the blue dial itch at the same time. It also allegedly works and has a fresh battery in it. I'm not sure why there were no other bidders, but I am certainly not complaining. It may not be the Zenith Chronomaster El Primero Blue Dial 42MM similar to this that I was tempted by the other day, but it does have the advantage of not making my bank manager nervous, and I suspect with a little TLC and perhaps a less boring strap, it should be quite a presentable piece. Two pounds eighty five plus shipping, before you ask. vd57bChrono.pdf1 point

-

1 point

-

So keep in mind this was my bench solvent i I washed these in and not part of my normal naphtha>Ipa>Ipa>Ipa wash routine. I used the perchloroethylene bench solvent for shellacked parts due to the insistence that ipa will destroy my shellacked parts. The only thing that i can think that could have gotten into it is moisture from the air. Basically I took a break from watchmaking my nearly nearly airtight benzine jar for months and months, maybe only half a centimeter evaporated off and i didnt' think much of it and just topped it off to work on this watch. Not only did it rust two parts but i've been having a comedy of errors with this watch i'm working on and low amp. It rusted my original balance and pallet fork, but now i'm seeing it also deposited a thick but nearly invisible waxy residue that neither fresh perc or naphtha and a q tip could get off, so that's on my balance cock and probably new pallet fork, hence the amplitude issue. At the recommendation of my other watchmaking place that has their professionals, iv'e been told to put the balance on the mainplate and put it and my pallet fork through my normal 4 stage wash/rinse cycle. The rust makes sense to me if moisture got in and settled in the bottom or contaminated my perc bench solvent jar...this waxy residue...i have no clue what this is. Does perc spoil? Is it a reaction between the water, the trace oils in it and the perc? This is something i'd love to know. So both here and my other space have seasoned professional watchmakers. Not a single person there believes ipa unless heated to very hot damages shellac and not a single person here believes it doesn't I'm gonna get to the bottom of this and see for myself.1 point

-

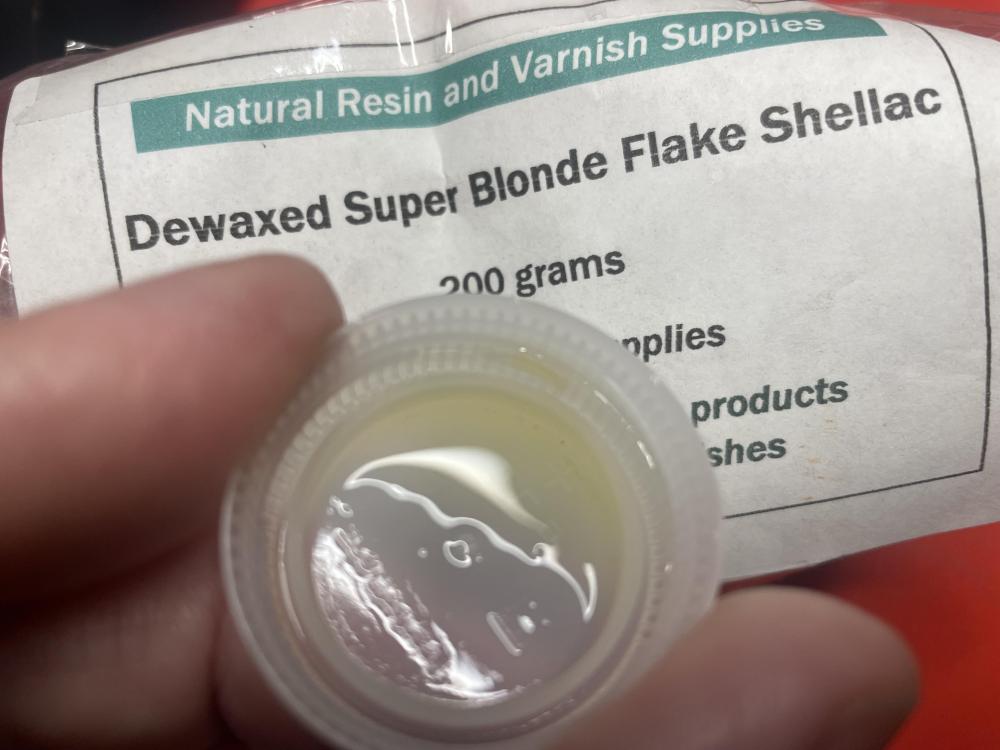

I've just tested the IPA again, in case I was confusing myself - I have tried different solvents at times to get away from the purple methylated spirit colour. (I now have industrial type, clear, denatured alcohol). This is dewaxed shellac in electronics cleaning grade 99.7% IPA; totally dissolved: It is slower dissolving than with denatured alcohol, but using IPA as a cleaner, it will be dissolving some amount of shellac with each wash. Re. the L&R 111 turning white, that happens if it is mixed with water, it forms a milky emulsion. I've seen that when the stuff has dripped in to the water outside the solvent pot, removing items from the ultrasonic cleaner. I've not seen the coating effect on things with watches, but I have seen a similar effect in machine tools, using emulsified oil coolant - which used watch cleaner may replicate, an emulsifiable solvent with oil dissolved in it? That stuff can dry and leave something similar to burned-on cooking oil, a thick gooey gel-like stuff that's near impossible to remove! The only thing that removes the stuff on machines is more, fresh, coolant emulsion.1 point

-

Try a one sided razor blade and work around the case back.1 point

-

In old texts they always say to dry parts in warm boxwood sawdust, the sawdust absorbs the solvent quickly and keeps the bulk of air away while the rest dries. Depending on your climate and humidity level, the evaporation of solvent can cause moisture to condense on the part, and that can cause rust. In modern times one would use a warm air stream to dry parts. Puffing with a blower will blow off the solvent, and cause rapid evaporation and exacerbate the condensation issue- and if you want to really see condensation blow on the part with your mouth! In my climate condensation isn't a huge issue, but I do tend to use sawdust or warm air just to be sure.1 point

-

1 point

-

So do I and it works well enough that I haven't made it a priority to get a bow. Anyway, if any of you have a bow that you do not need please get in touch with me. Learning how to use the Jacot takes some practice but it is an invaluable tool to get those pivots in near-perfect condition and it can improve amplitude quite a bit. Especially if the pivots have been deformed by some microrust. The most difficult bit is to learn not to press your face into the tool but to work with it from a distance. @nickelsilver was instrumental in teaching me this and I found it so useful that I recorded a video about it which you can see and read about in the following thread:1 point

-

I have a couple of whale bone bows around here, but have used the Bergeon wire bow for most of the last couple decades. I use monofilament fishing line, don't know the "test" strength, but it's 0.30mm diameter. I might change it once a decade. Otherwise the key/ID card setup Mike mentioned works great. Still have to get some fishing line. If you can't find a retractable key thingy, I had a teacher who used elastic cord you would find in a sewing shop. A piece of that, with fishing line fastened to it, keyring at the end of that. He kept it fixed at the back of the bench, and it'd get whipped out anytime the Jacot got used. I tried it and it works great too. Bergeon has discontinued their bow, #2045, but Horia sells one for a cool 85 bucks.1 point

-

Horse hair was used for the old bows. I think you can get that in good music shops. The bow fits in the box so you can get the length of the cane by the length of the box. The old ones were made of ivory, you can make one out of wood or wire. I don't know if bergeon still supply them ask at your suppliers. As to using the tool there are plenty of videos on Youtube.1 point

-

Can't you just rotate the Jacot tool 180° (work on the other side of it) and get yourself a burnisher for left-handed people, for example, the Bergeon 2933D? Perhaps that is what is different or am I missing something? In the video, I do mention there are two types of burnishers for those who are either left-handed or right-handed.1 point

-

1 point