Leaderboard

Popular Content

Showing content with the highest reputation on 08/09/24 in Posts

-

4 points

-

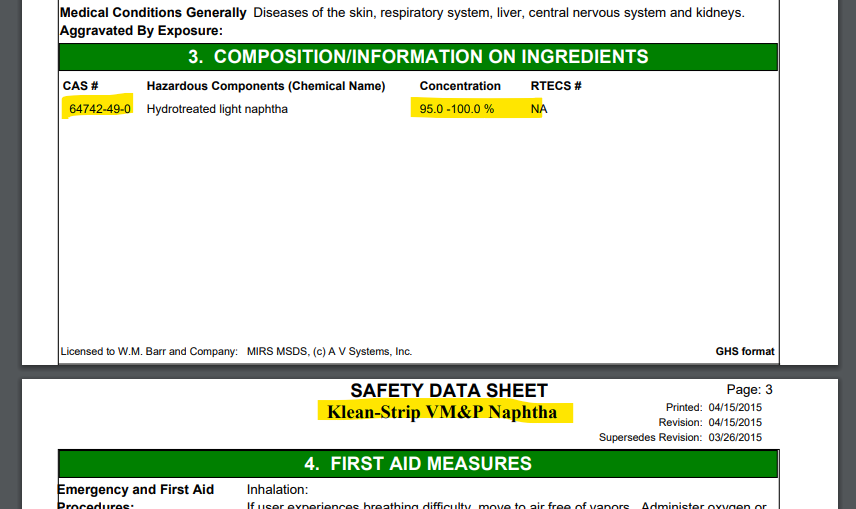

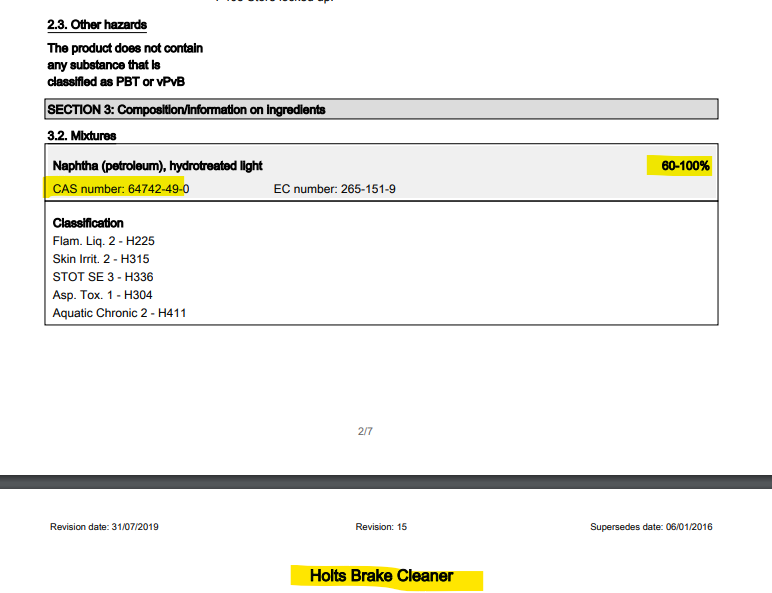

If you're not using water for cleaning then brake cleaner will work fine as an overall cleaning solution. The Kerosene will do a better job of lifting oil and grease then a quick rinse in brake cleaner to swill the Kerosene off. Both should be available just about anywhere, its just a heating oil and a car maintenance consumable. I'll do a mirror test later today to show you any residue left. On the parts there doesn't seem to be any. Theres an experiment i did a few months ago on 7 different solutions, will be somewhere in the archives, cant remember if it was my thread or i tagged it on to another. Found it, strangely enough i didn't test the brake cleaner ? https://www.watchrepairtalk.com/topic/29710-cleaning-tiny-springs/?do=findComment&comment=2521453 points

-

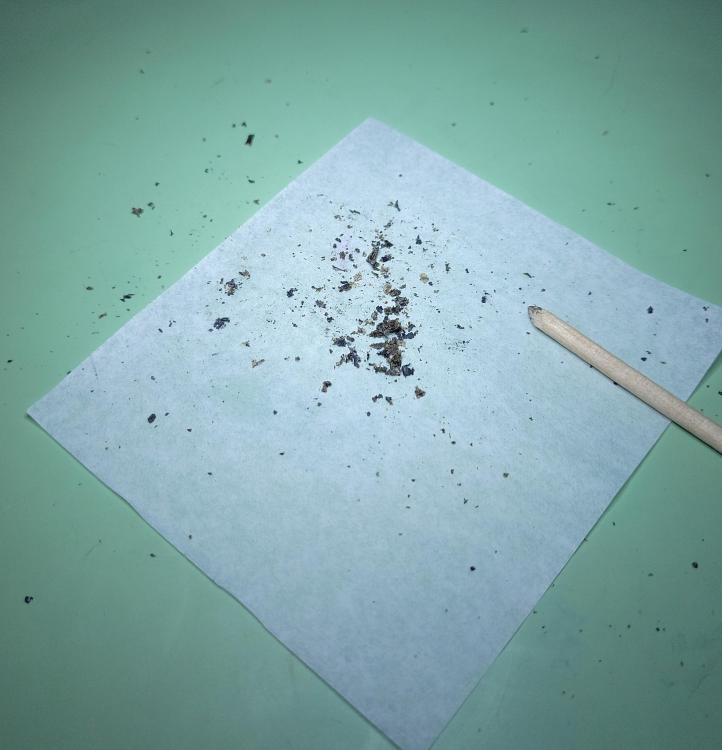

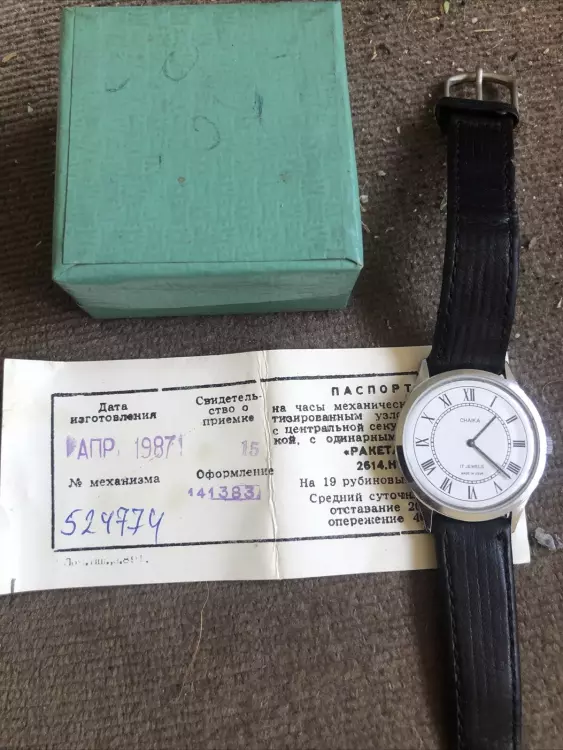

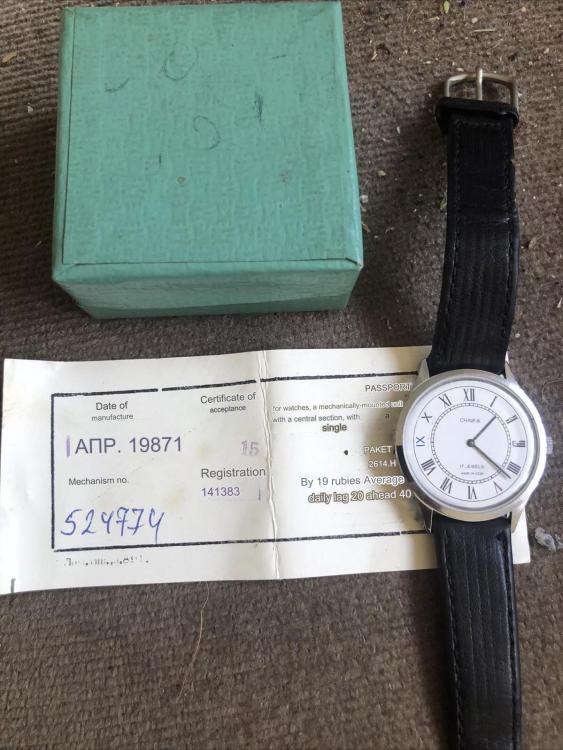

It could be magnetised but definitely needs a service. A watch needs to be running well before regulation.3 points

-

2 points

-

This is kerosene from my earlier post https://www.amazon.se/-/en/Naphtha-500ml/dp/B0CRZ61G9J/ref=sr_1_2?crid=1ZQ3GE3QEZFYY&dib=eyJ2IjoiMSJ9.HcvQu_vyRj6s-6IsVrdsL1n_a1Mp8UIwUknfig59OcNb1iQXymjU4eNfyyty7TldX83MDY1FrMyvJ-AFsdT0c3LbTUSMVGcQa2Q4-Z1PbAumQMNRQfiUe_wRQ_hfsKy45xCFP53uGc2Q2VEzxpvDRx9qtBWs1XAw9c9766ui4HznSr1_dnMaWc34Xa5367aDVlGsibudbQlP9eRxGZpM3JhJvzL-D9V6clxpzdDsqmg7t3HUn98oscx0e6KTYXLZl0hXnMRAVDClefmG_s3d0Q.aLYsiKtIg0nWF9YI0DcLd_KYc00O_uhEYtfE0SMTcTM&dib_tag=se&keywords=naphtha&qid=1723200248&sprefix=naphtha%2Caps%2C66&sr=8-2 I thought that's what you meant but even with the high shipping it's still only works out as 60p a litre when diluted.2 points

-

2 points

-

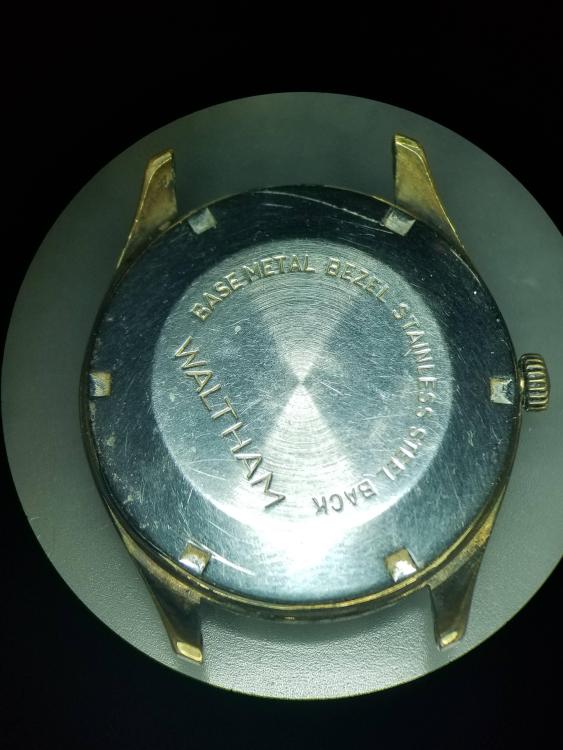

I guess these qualify as 404's. Freebies from a watchmaker friend of mine. I guess he doesn't think that I am busy enough. Waltham automatic with PUW 1463 movement. 17 jewels. It's a runner. I don't know the manufacturer of the "Time is Money" pocket watch. My first experience with a pin set movement. Pallet fork is all metal. A few jewels are evident. Time sets fine. Trying to wind the mainspring has no resistance, so maybe a broken mainspring. Balance seems good. Looks like a mucky mess around the ratchet wheel.2 points

-

Its probably more than that. Its a small 4oz jar I use, and its maybe a 1/4 full. So probably more like 30-60ml. I use the tiny baskets, that are 10-ish mm in diameter. they are small, but they go in, usually 4 at a time, then the larger pieces go in individually. Yes, no jar for the first clean. I will run the movements through first, then cases and bracelets after. Then swap the solution. I should mention, in particularly dirty movements with excess oil and grease, I will pre clean the plates and barrel in naptha.2 points

-

Sad Richard very sad . In UK we use Paraffin as a heating oil, as far as research shows its similar to Kerosene , one may be a little more processed. These and the ones you mentioned are varieties of processed petroleum, used for different things. What i look at is the carbon to hydrogen proportions, a more hydrogen percentage structure will evaporate faster, light distilled label will indicate that. Heavier carbon structured varieties are slow to dry, they sit and wet surfaces, Paraffin does this surprisingly quick, probably why it shifts oil and grease so well. I guess like food,maybe pure/raw is better, you want something with no added ingredients that do something other than dissolve.2 points

-

Agree with Richard regulation without a service is not good practice.. Pin lever watch’s are a bit rugged and not in the league of a jewelled Swiss movement. However when considering their low cost once serviced and regulated they are good reliable runners and great value.2 points

-

1 point

-

1 point

-

Hi John, there is a thumbs up like button on every post (except your own ), using this to like a particular useful post is what accrues onto the reputation score. Tom1 point

-

1 point

-

I will chime in again, but cleaning methods are just as divisive as oil conversations. I think there is a tendency to over complicate the cleaning methods, chemicals ect. in watchmaking. As someone who does this for a living, I will lay out my method below, and you can use it, or learn from it, or tell me I'm wrong, but its what I do everyday and I've had very little issues: Fill the ultrasonic cleaner with distilled water and I think 1-2% solution of Liquinox. Its a very small amount. Set the temp to 30C, and a time of 8 min. Be sure to do a degass cycle before hand. Then into a container of distilled water as a rinse. You can run it in the ultrasonic again. Then into IPA, then onto a cotton based card stock, with a small fan blowing across. Pallet forks and balance get a Naptha treatment by hand. Can be rinsed in distilled water, then into IPA, but this isn't always necessary. Liquinox is a very cheap water cleaning solution, and since switching from other cleaning methods that use different containers to contain cleaning solutions, this is much faster, easier, and cheaper. I can do 3 or 4 movements in a batch, and it will have used $0.18 of cleaning solution. I use a jar for distilled water rinse, as I change it after every movement. IPA gets changed often, as does Naptha, but these are in very small containers, maybe 30ml or so. People don't change solutions often enough, and if you see any buildup on the surface of your naptha, you're already too late. Its been contaminated.1 point

-

Thats what we do here Axel, help and support each other, banter and take the mick when we have developed a good repport with someone. We dont judge and have great moderators and regulars that dont stand any nonsense if anyone oversteps the mark. This is how all forums should be but sadly not. Not the rinse no caseback , only ever used IPA for rinsing, I would think it works in conjunction with Elma cleaners and better than IPA. The stubborn smudge might be an aspect of the ammonia in the cleaner and the rinse may neutralise that ? Still its something that is being added to the Elma rinse particularly if the baskets aren't spun off adequately, something a US user probably isn't doing.1 point

-

Yes, it's likely magnetized. A better and less expensive option is to download a metal detector app to your smartphone. There are many of those apps to select from so I can't recommend anyone in particular. Two popular timing machines are the Weishi 1000 and the Weishi 1900. I recommend the Weishi 1900 as it has a gain setting whereby you can adjust its sensitivity which sometimes needs to be increased and sometimes decreased. Also, when new, get yourself a watch that runs well. Then practice disassembling and reassembling several times until you've built some confidence. Then practice disassembling, cleaning, and oiling while assembling. This way you know if you've introduced some errors or not. I recommend a larger movement like an ETA/Unitas 6497 or an ETA/Unitas 6498, or a clone like the Chinese Seagull TY3600 which has Incabloc-like anti-shock springs which are a bit easier to handle when you're learning! Once finished practicing you can build your own watch using this movement. eBay is full of options for cases, dials, and hands. I've been an enthusiast for seven or eight years now and watches are by far one of the most intriguing and amazing machines I've come across after walking the planet Earth for 62 years. Good luck!1 point

-

1 point

-

Balance pivot should not jump out of the jewel hole by lifting one side of the balance rim, with moderately low force. No part of the balance complete be allowed to rub, Balance should be positioned to allow fork engage properly with impulse jewel. Fork pallets should be level with escape teeth. Show the setting on mainplate, is it movable? Ideally end shake on balance staff can be .01 mm , this reduces positional variation. Rgds1 point

-

You can get pretty far with IPA and manual cleaning and finishing with a cheap ultrasonic as I did before. I found cleaning pinion leaves the most challenging part. IPA is not a very good degreaser but it's relatively odourless and safe and evaporates fast without residue so I find it very user friendly. For shellaced parts I used Renata which is some kind of a hydrocarbon. I still sometimes soak balance and pallet fork in Renata.1 point

-

Several weeks ago I waiting for a puncture repair, guess what I spent my time doing? Looking at cleaning products, solvents, polishes etc.1 point

-

As promised after finally getting round to tackling the watch repair here is an update of how I got on. The new movement arrived and all looked okay and matched up with the existing works. I had problems separating the works from the plastic cage and face. The new works came with some miniature screws and a couple of small plates I eventually spotted these and figured they clamped the works to the plastic. I still couldn't remove the works or face. After sometime I managed to loosen the face and found it was clamped to the works via a prong running down from the face. Unfortunately there were 2 prongs and I managed to snap one off. I attempted to glue the hour markers back onto the face from the back but when reassembling the watch some came loose and I had to superglue them from the front using a very fine wire strand to apply a very small amount. The watch hands came off using a set of levers from Amazon for £5. I came up with a method for holding the miniature screws so I could get them into position. I made a loop in a strand of fine electrical wire and used this to hold the screw. I would never have managed without doing this. The watch hands took me a while to put back on and after watching a YouTube video several times and purchasing hand pressers from Amazon for £5. I finally managed to get them back on. The seconds hand was by far the most challenging due to its small size and delicacy. The watch has been running a few days now and keeping good time. Once again many thanks for your help. I don't think I would have got started without your help1 point

-

If you can get odorless kerosene, that is even nicer. Almost no odor at all. I'm thinking of swiching to IPA for my final rinse as benzine really stinks. I'm also switching to hexane for cleaning hairsprings.1 point

-

A little update on this - all seems to be behaving since refitting the subdial hand. It hasn't had too much wear as I've been away, but in the few days prior to leaving I had no issues and it's behaved while away. Think I'm calling this one done!1 point

-

All youngsters, 80 plus medical problems after Covid but still operating.. two French clocks done a Viennese regulator on the bench a barometer to do and a schatz 400 day, So quite busy. I am inclined to agree wirh Rob, I have come across bases repaired the same way and when polished up the crack is almost invisible.1 point

-

1 point

-

For the cost and convenience, I'd suggest having one of these assortments in your parts collection - one got me out of trouble with an old Soviet watch recently: https://www.ebay.co.uk/itm/325594816875 There are obviously no guarantees of finding the exact one for any particular watch, but always a possibility & the cost per spring is next to nothing.1 point

-

I used an ultrasonic cleaner for well over a year, and used jars to contain the solvents (detergent, naphtha and IPA) all in all I had good results, the only issue was the time it takes to go through each of the cycles. I still use the same ultrasonic for cases and bracelets. Mine is the same as this one and I got it from Amazon: I know there are much more expensive ones out there, which do sweeps and degassing etc, but in my humble opinion this one will do you fine1 point

-

1 point

-

You don't always need a mainspring winder or a jeweling tool but you always need good cleaning.1 point

-

I just got a couple printed in the sizes I was interested in. I got the files to print here https://github.com/vishnu350/rs-mainspring-winder, along with all the instructions on how to print them etc. You'll find the STL files for the various parts of the winder in the rs-winder.zip file. I think the recommendation is to go for a size about 5% smaller than the diameter of your mainspring barrel. I got a 9.5 and a 10 for a 10mm and 10.5 mm barrels. For an axle I found a broken drill bit does the trick. I happen to have a few in various diameters. I'd recommend reading up on them a bit first, and watching some of the videos. I bookmarked this discussion at the time I got mine. It's got information on their development, printing and, if memory serves, how people use them.1 point

-

It looks like someone has tried to press the edge down as a fix. If you don't have Loctite, I seen no reason why you shouldn't glue it.1 point

-

There are countless articles on here about how dangerous radium is : some would gladly sprinkle it on their breakfast cereals, and some would not want to go withing 100m of it. The truth is somewhere in the middle. If you are going to do it,take sensible precautions to prevent contamination. Loose flakes of radium are the danger, you don't want to inhale it. What I do, is cover the work surface with cling film, wear latex gloves and a mask. When finished, I wipe down all tools, surfaces, put gloves, clingfilm, wipes etc in a sealed bag and in the household waste.1 point

-

There should be a pinned post on alcohol. For many years my cleaning machine was a brilliant machine made by Greiner. First bath, water based cleaner, ultrasonic, fluid agitated by pump running through a filter (magnet in filter too!). Second bath is isopropyl alcohol. The way the "baskets" were set up the fork and balance were on their own set. They went in for 30s, then to hot air stream. The rest of the movement went in, 30s later push a button and the alcohol emptys into the built in distiller, and 6m later the bath is flowing (another circulating pump) with clean alcohol. Great setup. Sometimes I'd forget a fork in the alcohol for 30m or so, usually OK, sometimes it did strip the shellac. No biggie, reapply shellac. 99/100 or even more often the stones are a light friction fit so haven't moved. Most roller jewels younger than 60-70 years old are also frictioned, with a bit of shellac. In 15+ years one roller jewel came out of a 110+ year old watch, definitely because I left it in for at least an hour (and the alcohol is quite warm, coming from the distiller). The jewel was found in the filter for the distiller- yes another filter. Greiner made great stuff. Last century I learned very quickly that iso alcohol is sloooow to dissolve shellac. Ethanol, way quicker, and heated ethanol, way way quicker. Back then if I wanted to move pallet stones I usually stripped all the shellac, got them positioned, the reshellaced. Nowadays I do it with the original shellac in place. But if I was out of ethanol, it was a tedious process to remove with iso. I await 5 weeks from now when a new discussion on alcohol, the different types, and shellac comes up again. 2 weeks? As for French polish, most folks use some form of ethanol, either pure or denatured. It dissolves shellac so much better and faster. But I've read of folks using 99% iso too. There's probably woodworking forums with never ending discussion of this too. But as a pro, with 25+ years in, I can say isopropyl is crap at dissolving shellac, ethanol is great.1 point

-

See, this debate is silly and useless. Of course, alcohol and IPA will dissolve shellac. But it will take some time. First of all, I believe alcohol in watchmaking is used for getting rid of the water after rinsing the parts in distilled/dejonised water. This is when water based cleaning solutions are used. The procedure is: solution - water - alcohol - petrol. Pure Petrol (benzine, hexane) is the last instance. I know You call it 'naphta', but in my country we call this way the diesel... Rinsing in water is for 10 sec, and then alcohol - another 10 sec. What is the reason for using Petrol - IPA - IPA - IPA procedure? What is the logic? If You are frightened to loose the adjustment of the pallet fork, then first use peg wood stick to carefully clean the surfaces of the pallets and then soft brush the whole pallet fork with pure petrol. That's all. Don't put it in ultrasound at all. The correct thing is to learn to adjust the pallets, then one will never fear of destroying shellac. Now You try to keep on every price the shellac untouched , but if something is wrong with the pallets position, then You bravely will replace the entire pallet fork and believe this is OK. Then You will ask why the amplitude is decreased... But do You know how to check if the new pallet fork acts in this specific movement correctly???1 point

-

Seiko Kinetic that I picked up at a local jewelry shop on a whim. I occasionally walk in to ask if they have any broken old watches, so I like to buy a few every now and then even if they're not my favorite. After replacing the capacitor and cleaning the atrociously filthy case and bracelet, I have to say it's grown on me and I wear it a lot.1 point

-

1 point

-

1 point

-

one of things helpful to do with screws is to arrange them in groups of identical screws. Usually once you have them all together ill become apparent what at least most of them are for. A lot of the components like the pallet fork bridge will either have one or two screws and those screws will be different etc. so you usually have the bigger category the plates screws and it makes it a lot easier if things are in categories.1 point

-

If you've got his "Parts List" - there should be no difficulties identifying which screw goes where: https://www.cousinsuk.com/PDF/categories/645_as2060,1,2,6,4,6.pdf Each screw has the part number and description.1 point

-

You should remove the roller and continue riveting the staff. Use pin wice to hold the staff where the hairspring seat and test if the rim can be easuly turned.1 point

-

Hi this book contains a lot of useful material apertaining to clocks and watches. chapter 18 ( page 134 for chiming clocks.) If what you have quoted is one continious chime its not locking and the first quarter is a round of one round 2nd is two rounds 3rd is three hour is four followed by the hour strike as per OH's chart handbook_of_watch_and_clock_repairsa.pdf1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)