Leaderboard

Popular Content

Showing content with the highest reputation on 08/12/24 in Posts

-

When I first got into this hobby, I wanted to build myself a Seiko DressKX from parts. It was intended to be my 2nd watch project. The first being servicing an ETA 6497 clone that I turned into a pocket watch. Well, the order for most of these parts got lost in the mail (received only an empty envelope). Took me 2 months to get my money back from Cousins. Then I reordered those parts. Found out that I needed a different day wheel that will work with the crown at the 4 o'clock position. More time lost waiting for parts. Got distracted by other watch projects and life events. Finally got motivated to put this watch together and then managed to break the stem. More time lost waiting for parts. Over a year later from embarking on this project, it is finally done. Love the blue dial. It's become my daily wear watch.3 points

-

3 points

-

Mickey is all done. Turned out pretty nice. Buffed up the case, removed most of the crystal scratches and put a new band on it. I think my friend will be very happy. She's expecting the original vinyl band, which is too small for an adult. I'm surprising her with the new band so she can actually wear it once in awhile.3 points

-

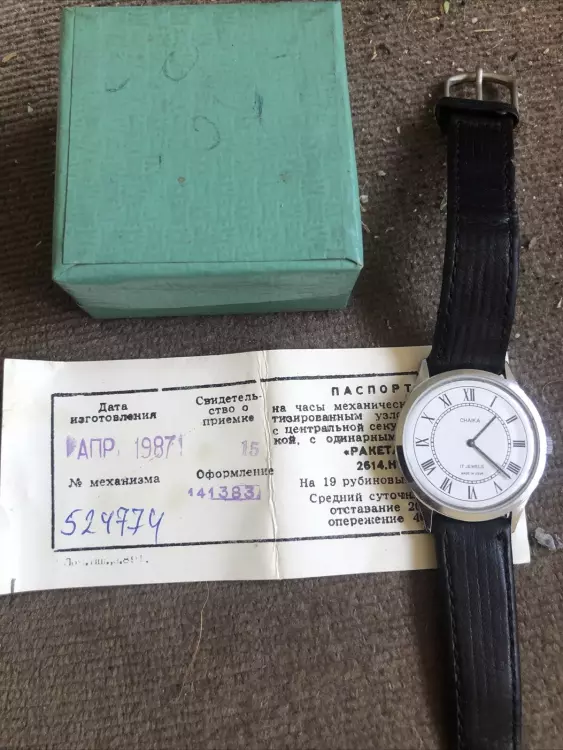

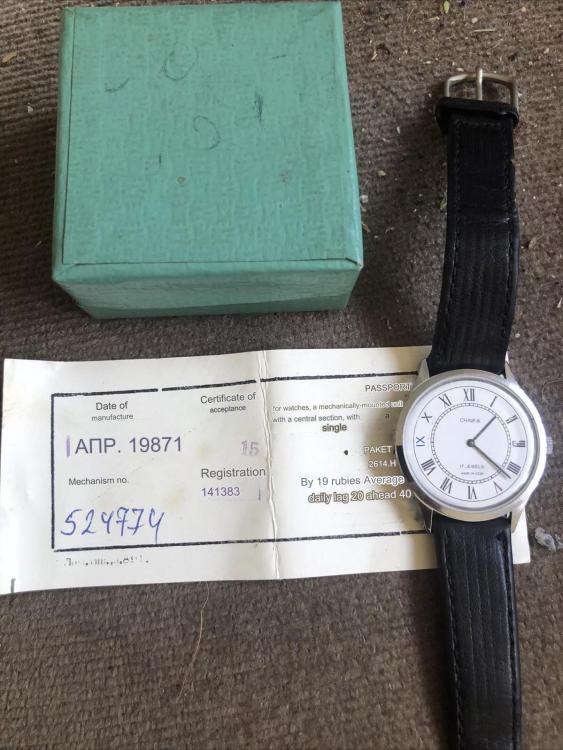

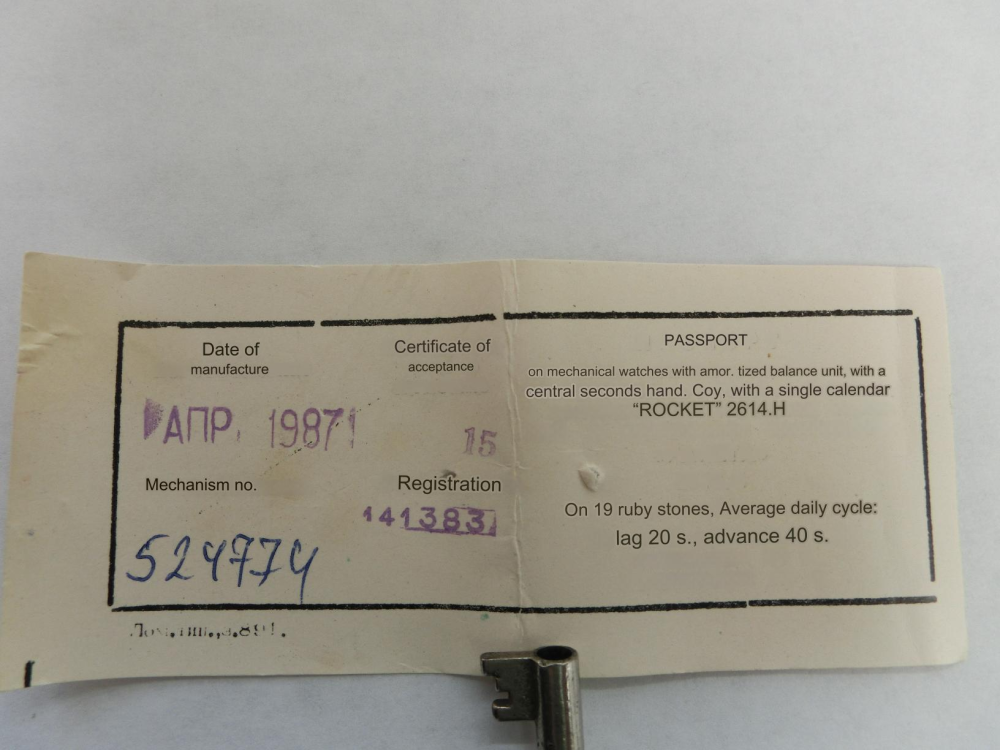

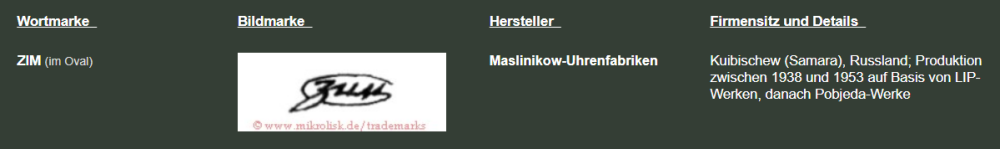

i bought a big pile of movements and after sorting i started trying to make working ones of the non working ones. i got 50 raketa 2603 movements among them and made one working one so far. it's a good way to get comfortable with working on watches while keeping the stresses of failing low. i have a couple of nice watches that i won't touch yet till i get a bit better.2 points

-

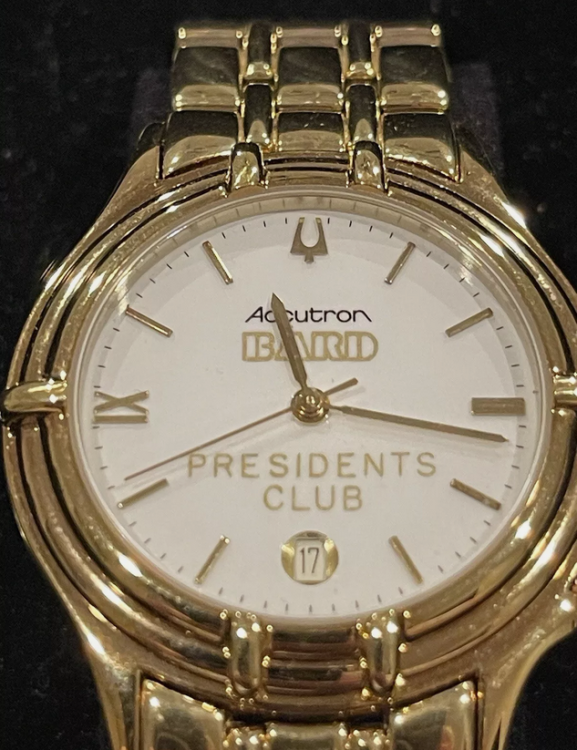

For some reason I thought it was tuning fork (probably placement of the crown), but on further research it's quartz. That's what I get for impulse bidding Still, for the price I'm not mad about it, if it's in the condition shown in the pictures.2 points

-

2 points

-

The watchmakers in Switzerland only use IPA as a final rinse to remove the oil based solvents. And their IPA is not 99.9% Real lab reagent grade IPA is very expensive, usually over $100 per gallon. I doubt you're not using that. @nickelsilver, a watchmaker in Switzerland, says he had a Greiner watch cleaning machine that had a built in distiller to clean up and reuse the last stage IPA solution. A simple distillation process can only produce a 91% IPA concentration. I believe all Swiss watchmakers use a rotary type cleaning machine and some have an additional ultrasonic bath in the 1st stage cleaning tank. Rotary machines have a spin cycle after every stage to remove all the solution that may be trapped in gear pinions and jewel holes and other nook and crannies. And after the last stage IPA rinse, it is spun dry and immediately goes into a heated dryer. So the contact time with IPA is never more than 3 mins. The shellaced parts are never ultrasound in IPA, just swirled vigorously for 3 minutes and dried immediately.2 points

-

2 points

-

I had a similar problem with a Bulova. I accidentally lost the original capstone and replaced it with one which was a little too big and not sitting properly in the chaton.1 point

-

I mostly oil as you do by placing chaton on top of the capstone but I used to set the chaton in the housing then place the capstone which just saves moving the chaton afterwards. The difference being that the tweezers are holding the cap fully, there is no lip to help the alignment as with the chaton placement. I agree it is a little more awkward this way but it just takes practice to place the cap perfect. The oil is catching your tweezer once you've mis-placed at the end. Nothing in particular i can see you are doing wrong Guy and your hand looks really steady. Just that final placement maybe slow it down a touch, it needs to drop perfect use you left hand to steady your tweezer hand further if you think it will help. I cant see a reason why the cap wont hold to the chaton though, maybe its a loose fit ? Under size ? for the chaton.1 point

-

Today's blue dial is being sported by a SII Cal. VD57B based "Prime Time" chronometer. It looks good, but could easily look much better. It is obviously engineered to a price, but the designer missed a few tricks that might have made this watch a little more interesting. It has lume, on the hands only. It could do with at least one lume pip on the dial for orientation, but better still would be lume at each hour. All of the hands are silver. It wouldn't cost more than a few cents to have fitted coloured chrono hands, and/or a coloured sweep seconds. Red or orange would probably look pretty good, maybe both, red chrono and an orange or yellow sweep. There were a few other issues. The seller had fitted it to a pretty awful "rolled sheet metal" band, which was held in by two broken spring bars. The crown and stem had not been fitted correctly and promptly pulled out when I went to set it. The chrono had not been correctly reset when the battery was changed, but fortunately the manual for the module is available online, so these little annoyances were all easily addressed except the strap, as I only had a 19mm NATO in the stash. Something more interesting in the correct 20mm size is on its way from the depths of China, which I may show when it appears. I may also have a crack at jazzing up the hands too, I'll see how I am placed for time. Having said all that, this is a 404 club watch, one of only two chronographs in the collection. The other, a Swatch is by far the superior of the two in terms of quality.1 point

-

So, gasket was indeed the right one - bonus on that front; I'll be buying some spares... Fitted the new crystal, more because I'd have spent a load of money on it not to use it... It's nice - sits higher than the original one and as a result the champfer is a little different/possibly less steep. Looks great though, same some, same effect on the distortion on the dial. Whether I keep it this way remains to be seen... Pics:1 point

-

1 point

-

Sort by calib and members of its family, Go on to Dr ranfft site to familiarize with base calib & members of their family and ultimtely the entire generation. Helps systemic understanding of interchangability. Good luck.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

I once soaked rusty oilers in Evaporust. I forgot them and left them for a couple of weeks. Now I have some nice plastic oiler handles! I've been searching for the best way to clean case parts from rust. Maybe I'll try Evaporust quickly after some more manual scrubbing. There's also some crap left in the bracelet after US bath.1 point

-

Hi welcome to the forum, you have plenty to keep you going there. Attached a couple of documents that may help you. TZIllustratedGlossary.pdf TM 9-1575.pdf Hi 4328_Raketa 2603.pdf1 point

-

Maybe and maybe not. The arm scratches on the hairspring side will be from removing the collet. Scratches on the table side could have been picked up from sitting in a rough bench block or roller table removal that wasn't associated with a staff change. Any scratches made by replacing a staff if done correctly would be minimal just outside of the staff opening, note i said done correctly, on a staking stump punched out ? Haha I'm afraid to comment any further . Could this be the start of the next installment of " PUNCHED OUT STAFF OR CUT OUT STAFF " . Looks straight to me. The table is meant to be pushed home until it stops. I look for the impulse pin being midway or close to between the gaurd pin and the top of the fork horn with equal minimal endshake of both the balance and the pallet fork that keep the pin's position constant . Gaurd pin center height of the safety roller notch. Straight up and down, looks nice when it is positioned between 2 balance arms, apparently that isn't a critical feature.1 point

-

1 point

-

Anything is indeed possible, but considering the safety features put in place on this quality movement to precisely combat overbanking, it is not one of the more likely scenarios. Indeed! Better bring out the Sherlock magnifying glass and take it apart. Yes, as there could be many other reasons or a combination of reasons. That would be very interesting. Thanks! As far as I can tell it's equipped with the KIF anti-shock system. It is the very same system used in millions of Rolex movements. These days, Rolex has its patented anti-shock system named Paraflex but that's a different story. Anyway, if KIF was good enough for Rolex, it's good enough for LJP. So yes, no problem there. That is highly unlikely as it's been designed and thoroughly tested to combat overbanking. No, they are generally speaking very rugged. Still, it's a fine balance between making a movement precise (Swiss) and rugged. If you want a movement that can take a beating like no other I'd suggest a Russian Vostok movement calibre 2415 or 2416B. Those movements are on the other hand not very precisely built so that's a trade-off and the watch would no longer be Swiss. My 15-year-old son (who can be pretty wild) has been abusing my Helson skin diver watch (built like a hockey puck) for six months now (Miyota cal. 9015) and put quite a few dents on the case (soon time to repolish) but it's still working perfectly.1 point

-

1 point

-

You can get spares from AliExpress. Watchmaker Tools Professional Welding Dial Feet Machine Accessories (Carbon)5 pcs https://a.aliexpress.com/_mMdzcRK If you have a lathe, you could make your own from graphite rod blanks.1 point

-

Just FYI, the one you linked has $140 shipping charge. The one I have works well, you can also use it to spot weld bridles on mainsprings too. I think the biggest knock on the device (other than the cost) are the carbon (?) holders for the dial feet. There are different sized holders for each of the dial feet sizes. One of mine broke when removing it from the unit and without it you cannot solder any dial feet of that size. I was able to get them to send me a new one but I don't think you can buy them and if they don't want to send it to you then I'm not sure what recourse you would have. Also, there is a bit of slop in the foot holder such that when you press it down, it has a tiny bit of wiggle to the left/right/front/back. Unfortunately, even a fraction of a mm off and the foot doesn't go into the hole on the dial. I'm going to need to figure out a way to shim it so that there is not wiggle.1 point

-

1 point

-

From: https://www.vintagewatchstraps.com/casemarks.php Sterling silver import marks After 1 June 1907 all gold and silver watches imported into Britain were required to be assayed and hallmarked in a British assay office. They were stamped with new hallmarks that were intended to show that the item was imported and not of British manufacture. The picture here shows a set of London import hallmarks for silver. NB: For clarity this picture shows only the three assay office marks, the town mark, standard mark and date letter. It does not include the sponsor's mark, but a British hallmark must have all four marks, it is not complete and legal without a sponsor's mark …the accompanying photo shows three of your marks- the sterling indicator, the London assay mark (though yours looks inverted) and the date letter. the fourth is a ‘sponsor’ mark… …your sponsor mark looks like ‘GS’, likely a mark for Stockwell & Company, according to the same site…1 point

-

I can varify without doubt that the root cause was a rather hard knock on the edge of a table ( I definitely have it right this time ) As to the remaining issue please let us know what your watch guy finds. Its ok you can just tell me i can keep secrets.1 point

-

1 point

-

Haha I'm pleased that you noticed how hard i was trying . Note to myself - regain full consciousness before offering advice . You learned 2 new watch terms , one way or another i feel i accomplished my mission1 point

-

in normal running circumstances H, but the impact may have damaged a safety feature allowing an overbank to occur. Without a gaurd pin tracking the safety roller to bump off, a quick flick of the wrist can trigger an overbank. Caught halfway might be the only overbank scenario to explain a restart without intervention The impulse pin could have been caught right at the tip of the horn, its not forced to jump completely to the opposite side, releasing tension on the lever after unwinding the mainspring may have been enough to reposition the pin back in the fork slot . Waaayyy too much speculation, time to move on . A disney song from Frozen now springs to my mind "Let it go, let it go"1 point

-

1 point

-

I'm really confused by this discussion. What kind of oil did you put inside the oiler in the first place?9010 does not gum up. Did you use your oiler on an uncleaned jewel and got dirt into the tip? Is the needle tip bent? Naptha does not destroy plastic. Ronsonol now comes in plastic bottles. Just rinse out the reservoir with naptha and soak it for a few minutes.1 point

-

You probably didn’t get the deluxe version with lifetime support Col, a bargain at only 300% extra Tom0 points

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)