Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/14/24 in all areas

-

Personally i think too much emphasis is placed on getting high amplitude. Dependency of it varies between different watches. An example i have is a 60 year old Raketa that produces around 220 -240 ° at full wind 180-200° after 24 hours depending on watch position. Keeps very good time, a minute or so deviation per week, winding once per day and stays within one hour of the specified power reserve when i don't wind it.4 points

-

Hi I have used a few and had no bother. We are always hung up on amplitude, if the watch works as it should and keeps good time as is I would just service the watch as normal but if when removing the mainspring it looks set or damaged it will require changing . If ok reuse.4 points

-

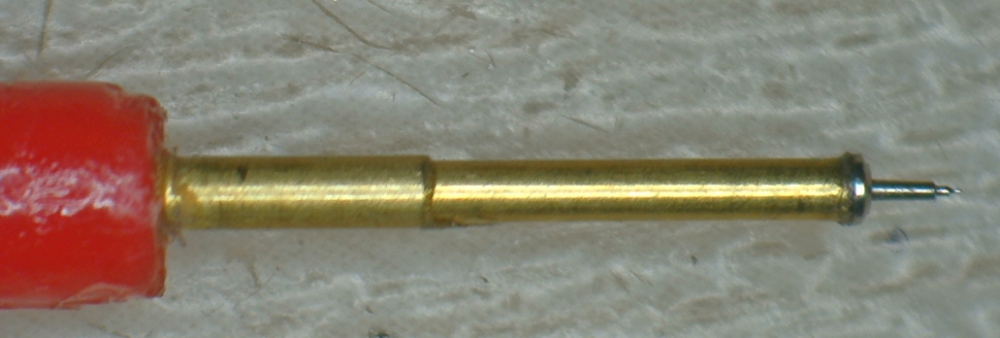

This is one of those tasks which starts as a real nuisance, but once you have the technique, becomes quite easy. I have a ground down oiler which works well, but you have to keep the tip really sharp. I also made a copy of the Horotec Incabloc oiler (which is designed for this task) by gluing an old balance staff in to some brass tubing (which was stuck on an old oiler). I put a blob of oil on the jewel, push the oiler through the hole and wait for a few seconds, then turn the jewel over to check the size of the oil circle. Repeat until enough oil gets through.4 points

-

The cheap, simple demagnetisers do not automatically "fade out" the magnetic field, which is an essential part of degaussing. With those, you need to start with the tool or part against the device, press the button then move the item slowly away from it, out to a couple of feet or more away, before releasing the button. If you just press and release the button, the residual field will depend on what point in the AC cycle the button was released; it could be small, or it could be strong.4 points

-

If you don’t know your options…present it back? Seriously, the top of the list is replace the balance or staff and there’s the low probability of success bending with a seitz pivot tool but with that amount of bend would it even fit in a jewel? …and just because the watch is no name doesn’t mean the movement is anonymous. Maybe there’s a replacement out there?3 points

-

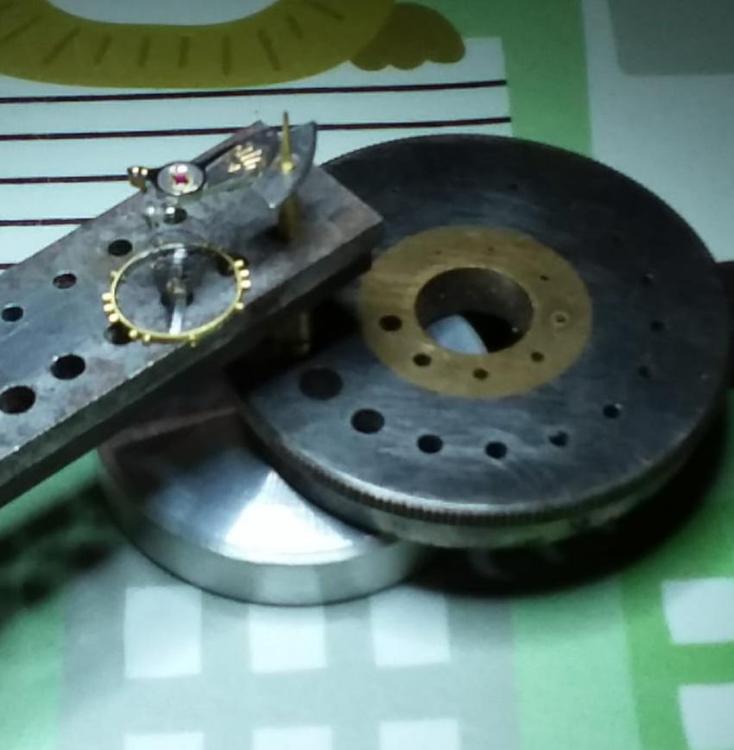

Any good sized staking block by itself can be used with a simple tapered pin set in one of it's hole to hold the cock.3 points

-

Hi Both @tomh207 and @rehajm have given you sterling advice, easiest way out of the hole is as said return the watch the alternative you already know. Try to identify the watch. Post pictures of the watch on the site. I may just identifiable through the resources of the members.2 points

-

A lot depends on the movement and your skill level and of course tools. You could try getting a pair of pinion straightening tweezers and heat them up to try and massage the pivot straight. I do have those but never used them, with the amount of bend you have there I would expect the pivot to break off during the attempt. next option is to identify the movement and search for a balance complete. Failing that is making a balance staff on a lathe. Tom2 points

-

Oh dear this won't do it all? We're going to have to find you a different discussion group to be on because this is the group that 300° or death is the only acceptable answer. Yes of course this is always my amusement the watch companies if they published specifications they don't care about amplitude either they only care about timekeeping what a weird concept. Then if they even publish their amplitude specifications it depends upon the company for instance Seiko does not although they now publish a lift angle maybe someday they'll give us an amplitude. But the other companies only care about amplitude at 24 hours and of course the watch still has to keep time. Typically it's 200° thoughts some of the watches will go West I've seen some ETA watches at 190° and Omega it depends on the caliber will go down to 160°. So yes until customers have timing machines the watch companies only care about timekeeping because that's all the consumer cares about. Unless a course Huron discussion group and anything less than 300 considered yourself a failure and maybe should take up another hobby.2 points

-

I'm curious as to where you're going to buy replacement components for this watch from? As it's a Swatch group proprietary movement I don't think there's any replacement parts anywhere unless you're working a Swatch group service center where they have an endless supply of spare parts. The problem with things based off of is what exactly has been changed and because parts are no longer available parts cross references to figure out exactly what is been changed become nonexistent. It depends upon how far you want to go into this. A lot of times students that go to the modern school of watch repair where they spend or at least used to spend a lot of time making things. I think they dropped the making part because are having a problem. The problem was that when they spent all his time teaching the students how to make things then they didn't want to go work in the service centers instead they would launch their own watch company making and/or modifying things. So very common watch to start with is the 6497 or 6498 and they would modify the plates. So you'd make use the wheels modify the plates end up with a really pretty looking pocket watch. Then the problem with modifying the balance wheel is you would need a hairspring and that would be a challenge to get at least today unless you want to buy a few thousand of them than that's not a problem.2 points

-

2 points

-

I have used generic mainsprings in a few Seiko watches and to be honest I don't see any a smoking gun when looking at amplitude which seems the same as using the Seiko original. However, there are sooooo many factors that can influence amplitude it is hard to blame the mainspring, or conclude that it makes no difference (as something else may be the limiting factor, so the effect [good or bad] of the spring is masked). I will continue to use the generic springs as I have yet to see a problem with them. Probably not the definitive answer you were looking for, but it is difficult to pin down one component in a multi-component mechanism.2 points

-

2 points

-

They are considered an upgrade on a movement, sometimes the end pieces are missing and the holed jewel is traditional with an oil sink on the outside of the plate with a matching pivot shape for that jewel manufactured as such. They do serve a purpose and that is to reduce train friction, more significantly in the smaller wheels and lever. Remove, oil and replace, the installed wheel's pivot will reach and ride in the oil, the cap sets the endshake, do not mix up the endpieces as they may differ in depth set .2 points

-

Wrap the whole thing in tissue paper, constricting the spring as much as possible, and try again.2 points

-

I presume you're referring to identifying the movement? Most movements are marked but if you post photos there's a chance we can identify it and advise on what spares are available.1 point

-

So now I know you mean the disc then the problem could be that the star on the back of the disc has become loose. Edit Check out this video.1 point

-

There are a few different tools that hold and seperate the balance and the cock that help to make the adjustment with more safety than a free hand adjustment. Try a googly of hairspring collet adjusting tools. Some attempt free handing with the use of a balance tack some by sitting the balance in a staking block and lifting the cock to one side. I like this kind of staking block for the lifting aside method1 point

-

Welcome onboard. Check that it is not a tapered pin. Cousinsuk stock tapered and solid pins. You may be able to get away with using a normal cotter/split pin for bracelets. Tom1 point

-

1 point

-

1 point

-

Hi. Blue spring steel hairsprings are best wrapped as per nicklesilvers advice to constrict any movement. This advice is also given in De Carles book..1 point

-

1 point

-

A blue spring that has lost its elasticity ? Looks like its been overstretched. Visit youtube and search for "hairsprings 101" Fried the old master demonstrates restoring a spring of this shape by pulling it through on itself.1 point

-

1 point

-

It is, and while its still hot from slicing cooked pizzas you can weld a dial foot with it1 point

-

So you'll probably have to get a 1.5mm Hour Hand and reamer it out to the required 1.75mm. Then you'll need a 1.2mm Minute Hand which are standard. As my response to your other post you'll need a 0.21mm Seconds Hand but may get way with a 0.20mm which are more readily available. https://www.cousinsuk.com/category/hands-watch1 point

-

One way to avoid hairsprings getting tangled by a demagnitizer is to have them submerged in a jar of one dip while doing so. I must say I've never seen a hairspring looking like this. It appears that the spring is deformed/damaged evenly along its length. Usually, when it's bent out of flat, you can locate one or more individual points where it is deformed, but not a gradual deformation like this. Even when you stretch it by pulling on it, you would think that there is a weakest point where it bends first, not gradually.. Are you really really really sure it's not magnetized anymore?1 point

-

Your hairspring looks like it has become coned. It needs to be flattened or it won't be able to run properly.1 point

-

Can you confirm what actual part you got as the ID is on the Main Plate not the Main Bridge?1 point

-

1 point

-

I can confirm what Hector said- copper is the way to go. I tried German silver, didn't work. Brass, kind of worked but burnt the other side when the solder finally flowed. Copper- almost like magic.1 point

-

Timex indigo electroluminescent backlight watch with a unidirectional bezel (with a bright lume pip and a very satisfying click) and a nautical themed dial. It is water resistant, apparently, but there is absolutely no indication whatsoever of exactly *how* water resistant, so I would assume "not very" would probably cover that. This was floating about in the junk box, as part of a job lot and seems to have appreciated a little TLC. It is actually not a bad little watch. Perhaps not something I would wear very often, but in essence it was free, since I bought the lot for some other piece and since it is the only EL backlight watch I have, its actually quite a neat addition to the 404 club. If anybody knows the significance of the pennant flag on the dial, I would love to know.1 point

-

Maybe and maybe not. The arm scratches on the hairspring side will be from removing the collet. Scratches on the table side could have been picked up from sitting in a rough bench block or roller table removal that wasn't associated with a staff change. Any scratches made by replacing a staff if done correctly would be minimal just outside of the staff opening, note i said done correctly, on a staking stump punched out ? Haha I'm afraid to comment any further . Could this be the start of the next installment of " PUNCHED OUT STAFF OR CUT OUT STAFF " . Looks straight to me. The table is meant to be pushed home until it stops. I look for the impulse pin being midway or close to between the gaurd pin and the top of the fork horn with equal minimal endshake of both the balance and the pallet fork that keep the pin's position constant . Gaurd pin center height of the safety roller notch. Straight up and down, looks nice when it is positioned between 2 balance arms, apparently that isn't a critical feature.1 point

-

Mickey is all done. Turned out pretty nice. Buffed up the case, removed most of the crystal scratches and put a new band on it. I think my friend will be very happy. She's expecting the original vinyl band, which is too small for an adult. I'm surprising her with the new band so she can actually wear it once in awhile.1 point

-

At the top right of your post are 3 dots, click on them and edit should be an option. Tom1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

1 point

-

I've been running the brand for more than 5 years. The biggest mistakes brand owners do when they start is to overthink complications, and technical specifications. What I have learnt is that the first question anyone should be asking is - Who is your target customer? What do they want from a new watch brand that other brands today don't offer? And proceed from there. This is easier said than done. Most brand owners are discovering answers to these questions only after 1-2 projects and then course correct. If you get this right in your first project then kudos to you! Thank you! Indeed! Thank you! Yes, Swatch (ETA) will not supply movements to us. We have been sourcing Sellita for a few years and it has worked out quite well.1 point

-

I assume you are nickel plating ? Reverse electroplating can cause some pitting, which you then have to remove. But it's easier doing it that way than trying to remove existing plating. Removing nickel plating using abrasives is hard work. Unless you remove all the existing plating, it's not easy to get new plating to adhere consistently. But then I never really bother about the inside, as you don't see it.1 point

-

1 point

.thumb.jpg.855ec4d2c6a843b0981b824425517bf8.jpg)