Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/16/24 in all areas

-

4 points

-

Welcome to the world of watch repair lol, it does get easier.4 points

-

4 points

-

You're having a tough time with this one Col, maybe take a break from it for a while. It ain't going anywhere its problems will still be there for you to solve another day. I find the harder i try the worse things become, i take a break come back and start from scratch sometimes months later, that isn't giving up , its coming back with a fresh head to a fresh problem with a different mindset, and hopefully a little bit wiser.3 points

-

That's quite a chunk to pay, I would go back to the seller and see what they have to say with a view to returning it for a full refund3 points

-

There's more that just a bit of spare poking through the stud as well, is that doing anything it shouldn't be. And no don't cut it back , you may need it yet. The non flat is likely caused by a twist but it could also be a vertical bend near the end raising the last coil up. Hopefully its a twist easier to deal with, as frank says back 180° from high point but you should be able to see where the twist begins. Anchor with one tweezer just before the twist , other tweezer leave open just after twist, angle tweezer in direction required and then nip together gently but with purpose, then examine and repeat as necessary. No its not beginner's stuff, practice on scrap springs, the vertical bend correction is more challenging and easier to overdo, lots and lots of practice. I finally , a year ago found a couple of mediums that i like to press the spring into, thick dense cardboard or hard pink dehydrated sponge, the sponge is good/gentle as it allows the spring to sink in as well. A uniform medium is easier to work with, i went off using timber there was too much variation in it to safely bend a spring's height profile.2 points

-

The last 90 to 180 deg to the stud is rising, it should be the same level as the rest. If you can see where rising starts, twist there with 2 tweezers. Else go back from stud max. 180 deg and twist. Not recommended for beginners. Frank2 points

-

I think the case back alone invalidates that this is an Omega case. There is a possibility of having a case back with no markings on the outside but the printing we see is not what you'd ever see for Omega. Then if there was nothing on the outside there would always be something on the inside at the very minimum the casing number. Because without a casing number we can't identify the watch parts Or even the watch. I don't think I've ever seen Omega that didn't have some casing numbers somewhere on the back. Then the movement does look like an Omega movement. So if you got it at a cheap enough price the movements okay but everything else is probably not. Than the crystal if it was a legitimate Omega crystal should have the Omega symbol stamped on the inside which and not seeing.2 points

-

Actually, this is a good point. Some of the main lessons I have had since beginning learning watchmaking is patience and tenacity. Don't lose your temper, don't give up - try it a different way. These are skills as well.2 points

-

We have all had days or weeks like that it's part of life.2 points

-

The photo is taken from an angle. So the logo might be positioned right. But yes, the indexes and hands are far from Omega quality.2 points

-

To identify your ladies watch, the dial needs to be removed, measure the mainplate's diameter and show us the parts of the keyless works.2 points

-

There seemed to be a different attitude back then to finger cots and gloves! I can't imagine being allowed to handle any of the exhibits of the Worshipful Company of Clockmakers without wearing gloves. BTW the collection is now in the Science Museum London. https://www.clockmakers.org/museum-archive Well worth a visit if you are in the area.1 point

-

I use reverse plating, with stripping solution from http://www.youplate.co.uk/stripping.html It works well, and quite quickly, but you have to keep checking and stop as soon as the plating is removed, to avoid too much pitting. There is then plenty of work to get it prepared for plating. Plating hides nothing - the finish you see on the brass is what you will get when plated.1 point

-

I always dried clock parts in sawdust. Many brass parts would be french chalked to prevent tarnish.1 point

-

With quartz movements , usually a new replacement is your best bet. As some of these quartz movement have plastic mainplate/ parts.1 point

-

Hi unless you made a bo bo and got the wrong version I would be inclined to follow Joes advice and get the one without the complication. If you buy direct from Sellita you should be able to get the technical sheets for all the versions and update bulletins.1 point

-

The manufacturer would be able to detail what is required to remove and replace. Do you buy direct from Sellita ? Simple answer to a simple answer problem Joe . You're the man1 point

-

Some watches are just problem makers. I wouldn't get too hung up on amplitude. I know its an important number, but focusing solely on it and trying to crank out every bit of it will drive you mad, as you're experiencing. I will say, the 7S26 movement is a bit of a strange one compared to swiss movements that have the standard train of wheels, so its a bit more difficult to diagnose. But I have a few tricks. Is this part of the center wheel ok? try running the movement without the center wheel and see what your amplitude is. And also, this one is a bit strange, but its tripped me up on seikos before. Can you remove the magic lever and wheel and see if that improves amplitude? These have gotten out of mesh for me before and have caused me problems. I don't know if it will help, but worth a try!1 point

-

1 point

-

I literally just did this a few weeks ago with my own DD. You remove the associated parts, swap out the set lever spring to the two detent variety, then crack a beer cause you're done.1 point

-

Lol! Ouch! I was thinking more from the historical perspective. A lot of the watches that are lionized today were routinely handled quite crudely by today's standards. Finger cots, dedicated movement holders, timegraphers, spring winders with movement specific barrels, etc. Juxtapose all of that with pithwood and poking sticks! There's a high tech element to all this, but at the end of the day, nothing we do is all that new this side of the 17th century. Marketers have made mechanical watches out to be some esoteric thing, but it wasn't even that long ago they were just watches.1 point

-

What will be nice to see with all your springs would be out of the barrel laying on the table. In other words visually how do they look? We don't get specifications for the curvature the spring and a very interesting back curves and some of the Springs have can produce some really interesting power curves. Plus if any of the Springs were set and yes modern white Springs can be set that's going to produce a bad power curve One of the problems and watch repair is seeing things. In other words taking a break would be a good idea approach it a week or so later. Then with a fresh look maybe you'll see something You currently don't see because your brain isn't going to let you see it at all.1 point

-

1 point

-

Absolutely, if the universe thinks we need to learn a particular life lesson to continue growing, it will find a way to teach us it.1 point

-

The hour markers are set too close to the edge, simple fact that the swiss made lettering is obscured besides the markers look to be almost touching the chapter ring, also non differentiated from the 12 hour ( only dial i could find with markers anything like this was a Cosmic ) . Dont think I've ever seen a seamaster without a signed caseback maybe a very early one, if it was signed then its partway to being genuine but the crown could have been swapped out and replaced with a plain one, although with an auto you wouldn't expect that to be from wear if so its not an issue with a working self wind. Personally i wouldn't be happy knowing it was a fake regardless of price, probably chose the less common black dial to pick up more money. My policy is If theres a gut feeling that it isn't right then walk away because it probably isn't. Nope don't try to chamge them you'll crack the finish. You'd be adding more cost by buying a donor dial. My view is to return as the dial has been refinished and was unstated. But thats me , i can be harsh with ebay sellers1 point

-

This is a tough one, if I paid the going rate for an Omega Seamaster then I would probably try and return it, however if I got it at a rock bottom price then I may be happy enough to keep it as the movement (which is the important thing) seems to be good. I wouldn't be too hard on the seller as this my be an honest mistake, and they may not have realised that the dial/case/crown is not original. So it's down to you, are you going to feel that twinge of regret every time you put it on that it's not 100% correct, or can you live with it,and for me the price I paid would be a large part of this decision.1 point

-

I peg out my jewel holes before and after cleaning. I bought the watch new about 12 years ago. It ran perfect when i took it apart so it had never been serviced but yeah, was long overdue. Highly unlikely I only noticed the rust piled up by the pallet fork jewel as a fluke but it only ran for a little bit like that, maybe a few hours but I had 260 amplitude with this mainspring WITH the rusted parts. Thought i was done, cleaned it, relubricated it swapped out the parts and my amp cratered by 80 degrees. I forget the exact stats but it was running great. About 270 amplitude and a bit of a high delta but not out of spec for this movement. About what I expect from a factory 7s26 All the solvents have been replaced and i'm fairly certain that part is solved. New balance complete. UPDATE: I have some answers but those answers just create weird questions. I found an old very tired seiko mainspring, probably 20 years old that i just used to practice my mainspring winder and decided to prepare a barrel and throw it in. My amp jumped to 250 then quickly dropped down to 220 within an hour or two. What i don't get is why i was able to get 260 with these generic mainsprings but then they couldn't crank out more than 180 afterwards. I've always felt this issue was with the barrel, either the mainspring not putting out enough power or something but this seems to confirm that. I tried TWO of these 2377x mainsprings, i forget why i even switched over to another one but with one of them, at one point my amplitude was good. I'm so tired of dealing with this I'm going to just take a nearly new mainspring out of a 7s26c watch cuz you can still get barrel completes for them for fairly cheap and just transfer it into a barrel for this watch. I know @mikepilk Got up to 250 with one of these springs but I"m thinking for whatever reason they just aren't up to the task for this movement in my hands and i have no idea why. I'll report back.1 point

-

1 point

-

You will love it . 9Stayed there 12 years ago, food was awful in hotel but the view was incredible, one night a raging lightening storm over the lake , never saw or seen anything like it since.1 point

-

1 point

-

I've done reverse electro plating in the past with mixed results. I think a lot depends on the overall quality of the case but the key is to take it slowly and keep watching it.1 point

-

Reverse electroplating is the best? / easiest method by far. Still plenty of preparation work required before replating.1 point

-

Funny how one can make it sound like a simple affair and then someone else can.............kind of not. Lol After reading joe's and geotex's comments, it makes more financial and reputable sense to just save those for date watches and buy the appropriate non-date version movements required. Makes no sense to cause yourself a headache now and a potentially bigger one further in the future. It may actually be a recognised and acceptable modification but why take chances. My trade is different but the same principles apply, make it right first time and you only make it once. Happy customer means happy business I'm not a watchmaker and never will be in the true sense of the word. I think I'd make a good apprentice and with luck one day be a good amateur maybe even part-time professional with the odd qualification. At 57 i am a pro in my trade with 40 years of experience of it and a businessman with 37 years experience with past success but winding down now, trademen with physical jobs can only last so long. To build a reputable business you need principles and methodology that you stand by while working. It takes time and a lot of effort to build a reputation, stick to good principles that you set for yourself af the start and your reputation will grow. There's a saying here in Yorkshire " you're only as good as your last job " and its absolutely true. People risk their own character when recommending , for some it can be like recommending themselves. I rarely do it for others. So that follows that good reputations take time to grow. Those same people that are slow to recommend only need to blink to generate critism, that follows that criticism can dent and destroy a reputation. Get it right , get it right and keep getting it right. Rich.1 point

-

SW200-1b has no date complication, perhaps best would be to buy one, it will answer all your question. Rgds1 point

-

I keep fast-forwarding through this to get to the part where George Daniels starts obsessing about 270° amplitude on his aliexpress timegrapher.1 point

-

I uncase the movement, and check it for running, as you remove each suspect like police does.1 point

-

Hi the movement may be Omega but the case and dial look decidedly odd. The caseback has no logo as does the crown. The indexes look far too crude and the Swiss made logo is not centered around the six baton it’s off center. The fact it’s been shimmed to fit the case. Looks like a cobbled job.1 point

-

I can confirm what Hector said- copper is the way to go. I tried German silver, didn't work. Brass, kind of worked but burnt the other side when the solder finally flowed. Copper- almost like magic.1 point

-

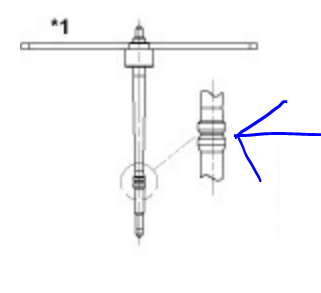

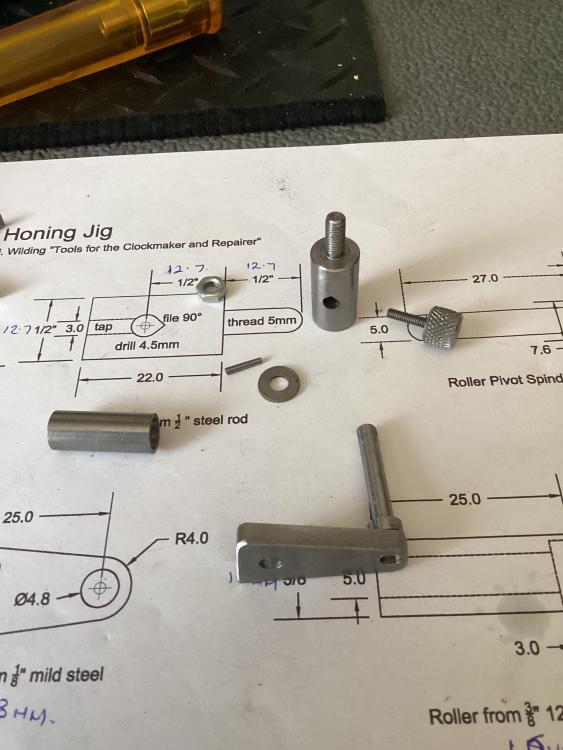

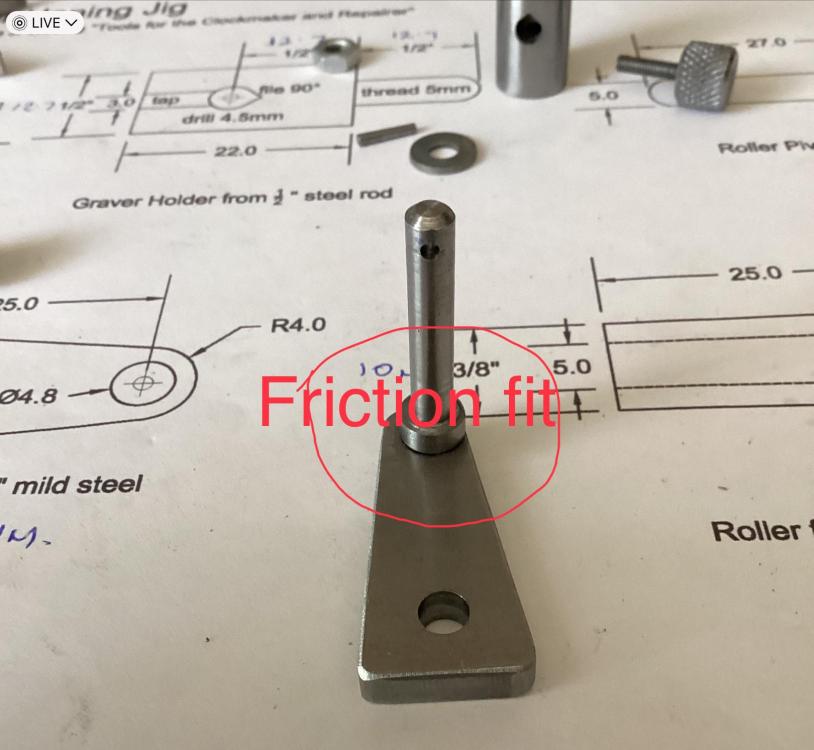

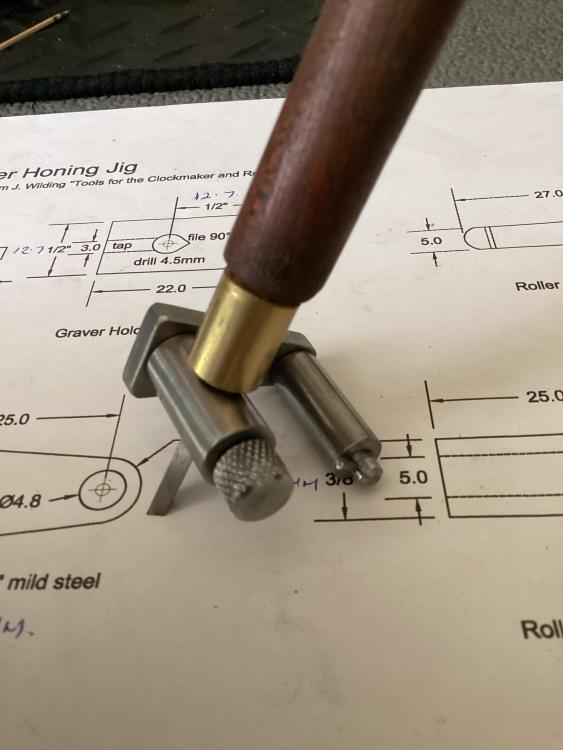

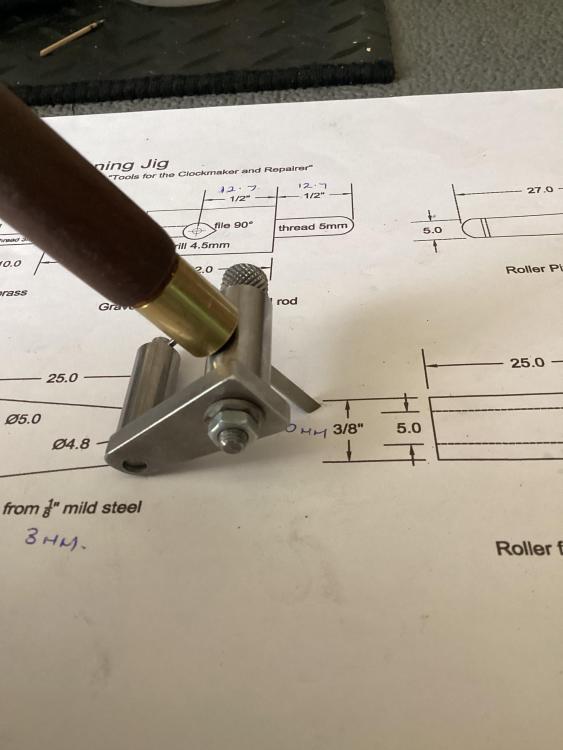

It may be my age but I can’t get on with the Crocker style jig for honing my gravers , I would have liked the Bergeon one but there is no way I am paying £120 just to sharpen gravers , I used to do it free hand but having gout in both hand has made it difficult, I chanced upon a set of drawings from John Wildings book tools for the clockmaker & repairer so today I made it and I must say it does a good job, not sure if legal to post drawing so if anyone interested then PM me . Dell1 point

-

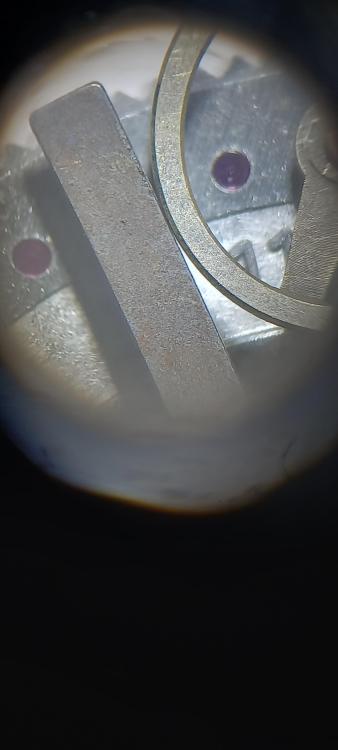

It was suggested that i do a little review so for anyone interested this is the Seitz 30350 "Tool for straightening the pivots". Now i have no instructions for this just bits and pieces that @JohnR725 could tell me, i know he has one. So these are just my findings and what i thought worked for me. It is by no means cheap for a little gadget but if it does the job then it does the job, cost is irrelevant. Ive seen about half a dozen of these come up in the last two years, always way above what i wanted to pay, but good things come to those that wait so they say. Its construction is very simple, the best inventions usually are. A metal base with 33 pressed in flat pivot jewels, ranging in size from 0.07mm to 0.15mm in increments of 25 microns ( correct me anyone if my maths is wrong ) . So 0.07, 0.0725, 0.0750, 0.0775, 0.08 and so on. Mounted on the base is a spring loaded register arm that swivels so it can be positioned above any one jewel and height adjusted. The idea is to place the bent balance pivot in the first hole it will enter with no resistance then bring the register arm up against the balance wheel ( or possibly the staff itself, i thought that was more awkward and risked scratching it ) I actually lowered the arm onto the top edge rim of the wheel which helped to stabilise it and pull the bend out. Turn the wheel a few times then move the arm away and position the balance pivot into the next smaller hole and then repeat this process. The first few pivot holes nothing much seems to happen maybe the hole i chose to start with was too big. The later steps shows more noticable straightening , the last few is where the magic takes place. I used 0.13 down to 0.1075 ten steps in total. The final step didnt quite finish the job off for me, i wasn't totally happy as i could still see some wheel wobble acting up from the bent pivot. The next step felt risky and is probably not recommended and very unlikely in the instructions. I looked for a midway point of trueness between the wheel and the register arm, brought the arm up to that midway point and then gently teased the wheel towards the arm and check for true Voilà job done, the arm stops you pushing too far over and breaking off the pivot. Now to do this properly you need good magnification , i used x25 and x40 , you must be able to see what you are doing. Being very careful wins the day, slow and controlled movements, i would almost compare it to hairspring manipulation. This attempt was on an escape wheel so i guess more delicate and tricky not to damage the teeth, a balance should be easier. Is the pivot weakened undergoing 2 bends maybe but its still a repair, time will tell.1 point