Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/17/24 in all areas

-

From my experience Silver / Conductive paints are only any good for small breaks in tracks and not suitable when large portions have been corroded. What's the movement and have you looked for a replacement circuit? My solution here would be to solder a replacement wire in place of the track.4 points

-

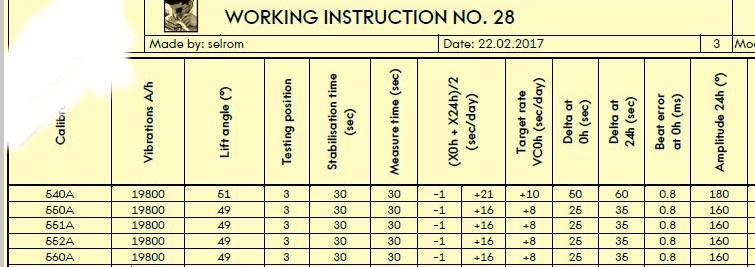

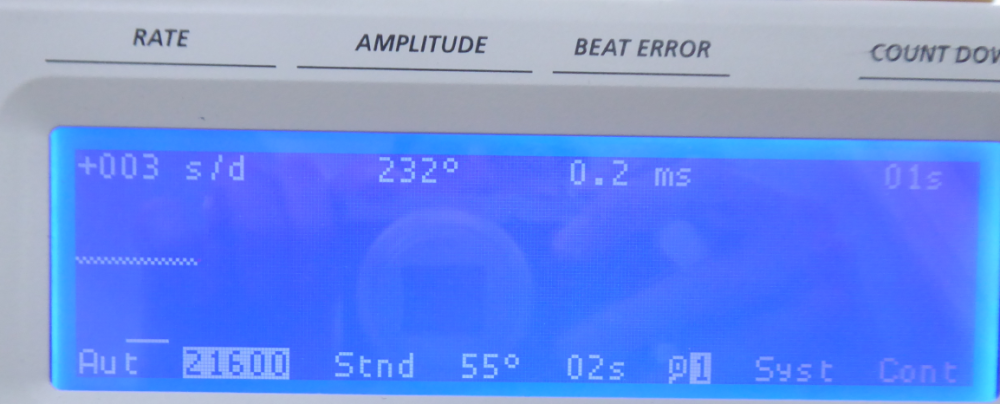

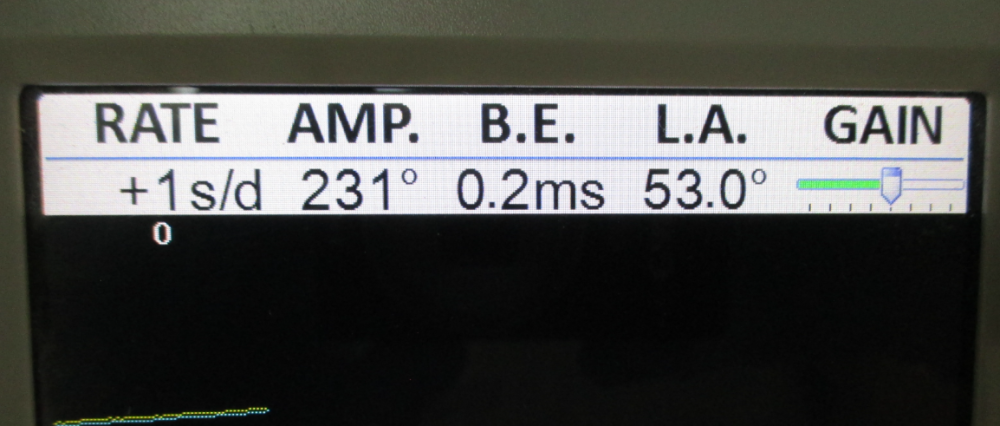

The fact that the amplitude seems to be jumping all over the place, suggests it could be endshake - with the wheels moving around and possible touching. The way I judge endshake, is to assume it's about the same as the thickness of the pivot. Too much and you get can get variable amplitudes like you are getting. If you can get a steady 240° and more than 180° after 24h, I would then wear it for a while to see how well it keeps time. I have some Seiko's where I have really struggled to get above 220-230°, and in the end decided it was OK. As @JohnR725 keeps pointing out, it's nice to have high amplitude, but not critical for good timekeeping. Look at the amplitude requirement for an Omega 560 (similar sized automatic) after 24h : 160° !! Interestingly, here are a couple of pics from the WatchGuy, who usually gets good amplitude when he services watches https://watchguy.co.uk/cgi-bin/library?action=show_brand&brand=Seiko For a 7s26A, 232° and a 7s26B 231°4 points

-

So if the spring is bad and you don't know if it's even the correct one then is there any point in continuing with it?2 points

-

HI. I get your drift, this is a development phase to gauge reaction to the model without complication. So sooner than shell out for the non complication version you are wanting to use what you have already. Sensible. If you are a registered company using Sellita movements it would make sense to open an account , as it seems that once done you have full access to parts and data hopefully the full blown technical documents, ie Exploded diagrams, oiling sheets , parts sheets. Etc. Hi @Neverenoughwatches that’s what I was alluding to in the previous post.2 points

-

I don't know part numbers or anything like that off the top of my head, but I happen to have the baggie of takeoffs in the drawer under my right elbow. Look at the way the energy is transferred from the date wheel backward. I'm sure there are plenty of tutorials out there, but at the end of the day, just follow the energy pathway, and make sure you're not affecting any other subsystem. The plate with the attached wheel (and its screw to the top left) holds, IIRC, the larger wheel down, which is what reduces from the hour wheel probably. The top piece is the jumper spring that holds the date wheel in place until it's time to flip over. The smaller wheel is what actually flips the date wheel over a notch. The big washed out spring at the bottom is the 3-position that gets removed and replace with a 2-position spring to eliminate the middle date set position. The dial side of the movement isn't especially busy, so this should hopefully make it pretty clear. @Microbrandowner, As a fellow startup guy and entrepreneur, these guys aren't wrong about sourcing the dateless movement... once you are actually in production. Prototype phases and all sorts of other things can necessitate something like this activity all manner of different ways. I get that. Sometimes it's just part of the thinking process too, and you gotta work through things. Hope this helps.2 points

-

2 points

-

I haven't done lots, but I have no trouble changing staffs. I punch them out with a Kendrick and Davis tool. Once you have selected the correct punches, it only takes a minute or two to rivet the new staff in. You do avoid some rebalancing if you straighten the pivot.2 points

-

It helps to have the right tweezers and the right procedure with tweezers. Yes like everything in the world there's procedures like if the tweezers a heated up not red hot but they have to be hot hot enough you can't actually hold the tweezers. When I was in school the instructor had the tweezers with strips of wood to keep you from burning your fingers. Then it hit it with an alcohol lamp and that's how he would do that. Plus of course the right shape of the tweezers conveniently I don't remember what they're called I'd have to get a picture.2 points

-

Not too rare though and not too expensive for an old one tbh, i found two on ebay just now. You take your chances on if a jewel or two might be broken . I was very lucky at £120 in perfect condition, i wouldn't have paid much more and the seller was kind enough to drop it from 150 to 120 my cheeky offer, so i figured it was a bargain. I see an attempt at straightening a pivot as nothing to lose and everything to gain. Out of 3 i broke 1 and that was complacency, too confident that i had success with 2, i didn't give the 3rd enough time in each jewel, i wasn't progressive enough so my bad. The upside is a potentially if not a high probability of a straight pivot. No risk of clumsy staff removal / rivetting up, potential damage etc. The straightening up i would say is faster and damage limiting for me anyway as staff replacement for me isn't my fortè, I'm ok but haven't done enough to be super confident and i haven't managed to cut a staff out cleanly yet. So in my experience the pivot straightener gets a if you can aquire one cheap enough.2 points

-

I'm a bit puzzled here as you can move the stud and put the watch better in beat? Then this is a four arm balance wheel views of the roller jewel corresponds to one of the arms so visually putting it in beat is usually very simple. You can look at the old balance wheel to see where the roller jewel is to get a clue. Then as nice as microscopes are you're looking straight down which would be nice if watches were not three-dimensional. If you look in his they hairspring flap isn't touching any of the balance arms? And yes of its touching anything you'd lose amplitude. Then would it be possible to get a picture of your timing machine in one of the dial positions and then rotating to one of the crown positions?2 points

-

Amen! I say that's not only true in Yorkshire but universally true. Great post! I am not sure what you are referring to but I think most, if not all, of it is freely available on their site. I am extremely happy that we have Sellita selling movements and parts to anyone who wants them without any restrictions. To those who ask, I always recommend watches that use Sellita movements and stay away from any brand from the Swatch group (Tissot, Omega, Longines, etc.) That's a very good, but not so obvious point! People who buy mechanical watches often do so because they care about the technology behind them. Yes, I'd feel duped too unless it had been disclosed.2 points

-

Hairspring smaller than normal, have the coils enough room to breathe? I have something similar going on at the moment. A movement with super high amplitude that was causing the coils to touch in horizontals producing high + rates, vertical positions dropped the amp 50° ish which gave the coils more contraction breathing space but plummeted the rate. Difference was around 300 between the positions. I introduced a better spaced terminal curve that seems to have improved but not quite cured the problem, main issue is the mainspring is too strong. So just wondering if your coils are touching somewhere when contracting, what changes in the vertical positions Rob ? As Joe tells it ,with really low amp, amps that dont register with a tg but are visibly so low the swings get faster, isochronism goes out the window. But at 200° this wont be what you're seeing. Rob was getting 90° with the old original spring Joe after he'd taken an axe to it to straighten it out . Personally I find a a small hatchet less destructive.2 points

-

2 points

-

Yes - that's really helpful. I wonder if all Gruen movements are silent about their origin (the only mark I've found is the number 5 under the balance bridge). I apologise for the typo - it should have been "pivot". I should read my posts more carefully before launching them.1 point

-

In my opinion, this is the best and most bang-for-buck watch repair site. I'm on the chronograph course now and it is brilliant. No, I'm not affiliated with watchfix.com in any way. I took his 101 course. I learned a few things but it's not on par with watchfix.com Yes, that's annoying, especially when he starts explaining something, then makes a minor mistake and starts all over. I'm sure he makes a good living restoring watch cases (genius!), but he doesn't seem equally dedicated to movements and can be super sloppy with his oiling. Correct oiling is critical in servicing a movement and if you don't get it right all sorts of bad things will happen, especially in the long run. It's a topic well worth the time to study and practice. Great! I forgot to mention the Watch Repair Tutorials which is also very good, especially when you're new. I don't agree with everything Alex says, but overall the videos are well-made and very instructive.1 point

-

Good move, Converse is about as designer as i get. Jeans and white t- shirt is my comfy, casual and dress up.1 point

-

1 point

-

No wonder you are having trouble that spring needs to be replaced its a mess.1 point

-

I didn't mean to file the ding. This will be wrong. I mean to fill it with solder, just like with car body filler, but with soldering iron and solder. Then surface of the guard roller must be restored to the correct shape and size. By file, lathe or whatever method You like. Yes, it is small, just like all parts in the watch movement. The main and most important tool in watchmaking is the file.1 point

-

It certainly does work John. I'm happy with my 2 out of 3 and one of those was on an escape wheel.1 point

-

This ding actually may lead to sudden stops with the balance locked by guard pin fallen in the ding. The ding can be filled with led solder and surface smoothed.1 point

-

1 point

-

1 point

-

1 point

-

Over 30 years ago, I got bored of deciding what to wear, so I my life easier. All my clothes are black.1 point

-

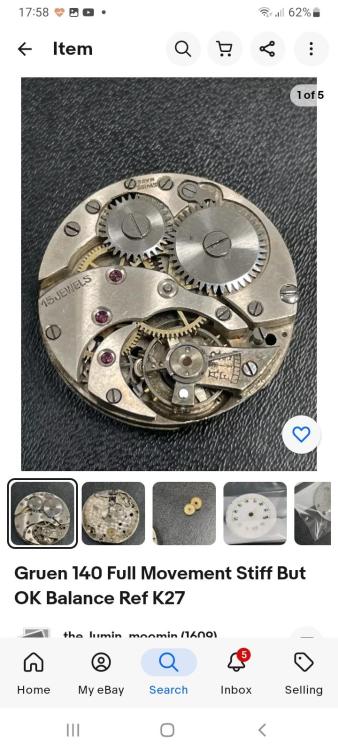

Found it ww , 10mins with the old bestfit and a strong cuppa. Its a Gruen 140 page 140 of part 1 , give me your thoughts. Just verifying it with a full picture before i fully commit Was pretty easy, no setting bridge just the 2 pieces and a yoke spring that isn't shown in Bestfit, the setting lever looks like moby dick without a tail Method in my madness yep a Gruen 140 is pretty damn close shame, we dont have the watchmaker's side Be interesting to know if Aegler made this.1 point

-

Holy crap all in black in sweltering heat, one cool dude for sure, Lee van cleef wore all black in his movies he was one helluva cool dude1 point

-

1 point

-

At the end of the day anyone can start a business and register it, watch repair or otherwise, that business doesnt have to make a profit or a loss, I'm fairly sure it doesn't even have to be operating year on year but its probably a good idea to put something through even just a repair for a friend once a year. Tax return forms with something like this with little expenditure ( haha yes i know good joke, who's want to let Bergeon in on that one ) take minutes to complete. But nevertheless a legally minimal operating business can open doors to other companies. Haha all fired up and ready to enter your watchcave .1 point

-

Yep thats what i read H , you're on fire today matey Only sticking point i can see is completing the form for non vat registered there doesn't look to be an option for it. We can all make up a watch company name, i did this for my cousins account, this cant be checked with UK's HMRC but anyone if vat registered this can be viewed with companies house. I assume other countries will have similar registrations.1 point

-

1 point

-

$450 down to $400, I'm sure he can do better than that, like Tom said he can only say no to a cheek offer. Me old mum used to say " if you dont ask son, you wont get "1 point

-

Hi. You can get a silver oxide conductive paint (not cheap) for re drawing Brocken and cracked tracks. I have used it ti repair coils works ok. You can get the paint off eBay ( conductive Paint).1 point

-

Sadly that's not how my brain works haha. If i put my mind to do something i will go nuts till i do it. It's even worse when it's something i know i can do that just isn't working That said I have an update below but not getting my hopes super high up. I can show one of them. I'll try to remember to take a photo tomorrow. These were new springs that were taken in and out of barrels at least a few times. I've been wondering if that can actually damage or weaken a modern spring. I also may or may not have had a mishap with the mainspring winder on both of them but they still looked about the same as when they were brand new so i just made em flat again and reused them. They're SO tight on the arbor getting the arbor of the winder out without pulling the spring out is incredibly difficult. I've tried two fourth wheels, one being literally unused so I think it's safe to assume that area is fine. And interesting on the magic leaver. Unsure how that would affect amplitude but if my latest go fails i'll give it a shot. As for the "Don't worry about amplitude thing." I'm REALLY trying to improve my service quality. I just feel like i wont' ever learn if i can't get the same amplitude from a watch that it had when i took it apart and usually this is not a struggle at all! With this one though i'm thinking 260 at full wind will probably be my cutoff. I won't be happy about that but if i can get that i'm gonna just get this damn thing back on my wrist. Endshake is tough cuz i never really have a frame of reference. They SEEM normal for the movement. That is something i can definitely check which i shall do tomorrow if this doesn't work. LATEST UPDATE: I put a not very old stock seiko mainspring in scavenged from another watch and my amplitude got as high as 250 at one point but mostly hovers around hte high 230's. Keep in mind this is on a watch that i've taken apart a dozen times, did a slapdash escapement lube, basically it's lubed just for trouble shooting. I"m hoping this will solve it once it's cleaned and freshly oiled. I'll keep you guys posted. If this DOES solve it i'll recap all the weird random stuff that went wrong here for future reference to the rest of the forum.1 point

-

No need to apologies, this is what the forum is for.1 point

-

Attempted 3 success rate 2 , another 30 or so saved and its paid for , 20 years maybe .1 point

-

Trust you to have the right tool . Next time I need a pivot straightening, I'll send it over. You must have straightened hundreds without a single failure? Those tools are as rare on ebay as rocking horse poo, and as new ones cost £642 and balance staffs are about £10, I'll stick with changing the staffs.1 point

-

It is showing 21600. I checked that against the audible frequency of the movement by counting it for ten seconds, just in case the auto speed was wrong. I'm going to verify the end float etc. later today, though the amplitude was around 200 & seems unlikely it is something sticky & still get that? The beat error is not good, ~5.2, but that's surely not going to throw the rate off so much? I'll have a go at that at well. Examining the photos I took while dismantling the watch, I cannot see any obvious misalignment in the original hairspring? It was cleaned with the balance fitted to the main plate as usual. The hairspring is rather smaller than usual in this & I wonder if it was affected by the ultrasonic cleaner? My old one died a few months ago (the transducer separated from the tank) and I got a much bigger and more powerful one. I've not had any problems with any other movements, but this does have an oddball spring?1 point

-

Funny how one can make it sound like a simple affair and then someone else can.............kind of not. Lol After reading joe's and geotex's comments, it makes more financial and reputable sense to just save those for date watches and buy the appropriate non-date version movements required. Makes no sense to cause yourself a headache now and a potentially bigger one further in the future. It may actually be a recognised and acceptable modification but why take chances. My trade is different but the same principles apply, make it right first time and you only make it once. Happy customer means happy business I'm not a watchmaker and never will be in the true sense of the word. I think I'd make a good apprentice and with luck one day be a good amateur maybe even part-time professional with the odd qualification. At 57 i am a pro in my trade with 40 years of experience of it and a businessman with 37 years experience with past success but winding down now, trademen with physical jobs can only last so long. To build a reputable business you need principles and methodology that you stand by while working. It takes time and a lot of effort to build a reputation, stick to good principles that you set for yourself af the start and your reputation will grow. There's a saying here in Yorkshire " you're only as good as your last job " and its absolutely true. People risk their own character when recommending , for some it can be like recommending themselves. I rarely do it for others. So that follows that good reputations take time to grow. Those same people that are slow to recommend only need to blink to generate critism, that follows that criticism can dent and destroy a reputation. Get it right , get it right and keep getting it right. Rich.1 point

-

In case you didn't check all shakes in gear train , balance and fork, try loosening screws to all cock and bridges, to create some end shake. A CAP STONE MIGHT BE PRESSING ON PIVOT. Reclean balance setting , peg jewel holes. Check for bent fork, misaligned pallets. Rgds1 point

-

SW200-1b has no date complication, perhaps best would be to buy one, it will answer all your question. Rgds1 point

-

1 point

-

1 point

-

If you don’t know your options…present it back? Seriously, the top of the list is replace the balance or staff and there’s the low probability of success bending with a seitz pivot tool but with that amount of bend would it even fit in a jewel? …and just because the watch is no name doesn’t mean the movement is anonymous. Maybe there’s a replacement out there?1 point

-

Hi also try welwynwatchparts .co.uk Usefull site fir pars etc.1 point

-

Part No's given by @thor447 are correct but think you'll be lucky to find a replacement genuine bezel.1 point

-

Try this site: https://speedtimerkollektion.com/collections/categories/bezels__inserts1 point

-

1 point

-

I have a new rule when working on Accutrons: no turning screws without a pair of tweezers guiding the blade of the screwdriver. Because I also have a bad habit of bending pawl fingers... But that said, this could not be a more beautiful sight: I followed Rob Berkavicius's procedures here and it runs smoothly from 1.05 to 1.90v, which is more than enough range for a silver oxide cell. Now to clean up the case and assemble the calendar works!1 point

-

personally I find when you're dealing with American pocket watches that of 100 years of interesting things have occurred to them. I find that static poising I can easily get a Delta within 15 seconds and that's good enough. I often find if I try a dynamic poise I end up chasing my tail and things don't usually get better. In other words when you're grossly out of poise static it to really close and then if you want to be a perfectionist you can dynamic poise.1 point