Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/18/24 in all areas

-

I think somewhere on the other page was hinted that may be perhaps there were more pictures in a discussion somewhere else on the message board that I couldn't actually find. I think oftentimes people fail to grasp how big the message board is and if they left other discussion somewhere in the universe they should give us a link. There is always the other method it's a bit problematic though. If we had the proper measurements of the stem we can see what matches that.3 points

-

2 points

-

Many old clock springs don't have holes in them. There is a tool for clock mainsprings. Any good clock material suppliers will stock them. I always made my own, heat the spring end after shaping it then use a punch to make holes and file them to the required size. You can use the tool if a spring breaks at the end, but don't remove to much length because the clock will not run its full time.2 points

-

There is no such tool as all springs come with a hole. It surely was inserted before coiling. If your spring is broken, buy a new one2 points

-

I've literally measured a few hundered of them using a feintaster. Using a fine touch, you should be ok2 points

-

Hi By pushing the spring you are completing the cycle started by the day/ date wheel . You will probably find the nib that carries the wheel round is worn and unable to complete the cycle. You will have to remove the day/date complication and replace the wheel so it carries the ring further allowing the spring/detent lock in2 points

-

1 point

-

1 point

-

So this is a mainspring punch, of course i have one , not what you think it is for regarding watches. As franks says,and as far as i know there is no tool for punching out the eye of a mainspring for an arbor hook to latch on watches ( maybe clocks ? OH will know that ) barring drilling the eye out and filing to shape, something i did recently and is tricky, this tool does not do that. What it does do or did do is create an eye at the barrel wall end of the spring in conjunction with a compatible pair of pliers that cut a hook into the barrel wall itself. Fairly sure, but kind of guessing that this appertains to old pocket watches only and not wrist watches.1 point

-

Unfortunately this too many variables to give you an answer to the question. Probably depends upon who manufactured the watch. Plus of course the quality of the steel and back to manufacturing again. Then usually balance staffs break. Sometimes when they break they break the jewels also. But for some bizarre reason sometimes they bend and if you're lucky you can bend them. So sometimes you're lucky and you can bend them back and other times you're not lucky.1 point

-

That's normally the case with a good watch repairer. I can't see any harm in letting him have a look to give you a price and timescale.1 point

-

For $400 you could get a shed full of torsion springs sent from Horolovar to Australia including a book I would have thought, worth sending them an email http://www.thehorolovarcompany.com/1 point

-

Interesting video, I've been told not to measure a staff's length for fear of damaging the pivots yet here we have a guy tapping a pivot straight with a punch and hammer...............1 point

-

Bending a pivot it causes it to be "work hardened", so the heat is meant to counter that. Work hardening, also known as strain hardening or cold working, is a phenomenon that occurs during the plastic deformation of metallic materials. As a material undergoes plastic deformation, its strength and hardness increase due to the accumulation of dislocations and the increased interaction between them. The process of work hardening can be understood at the microstructural level through the interactions of dislocations. When a material is subjected to plastic deformation, the number and density of dislocations within the material increase, leading to the entanglement and interaction of dislocations. These interactions impede the motion of other dislocations, increasing the stress required to overcome further plastic deformation. Consequently, the strength and hardness increase. Work hardening can be countered by thermal recovery and recrystallization processes that can restore the ductility of a hardened material by rearranging and/or replacing the dislocation structure. Recovery involves the rearrangement of dislocations into low-energy configurations, while recrystallization involves the formation of new, strain-free grains in the microstructure.1 point

-

This initially sounded unusually exciting because I had never seen or heard of bent pinions. I don't mean to be snotty, but terminology is important, especially when we do not have any pictures.1 point

-

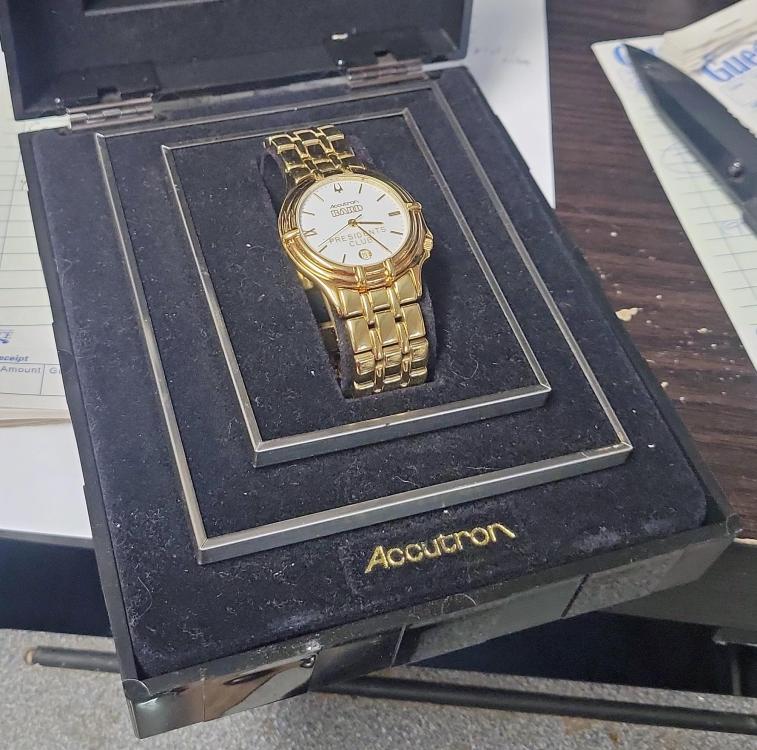

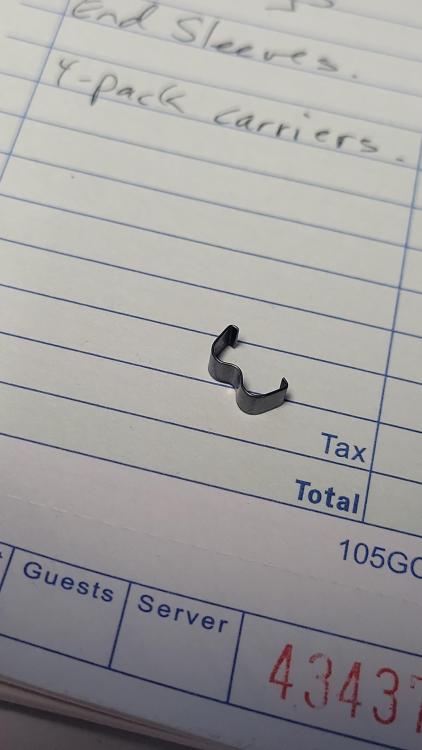

I gotta say, this looks like an unworn watch. T3, so 1993 (the year I graduated high school!). Box is in very decent shape, and came with the original instructions and warranty cards. Neat! There is just this one extra piece that I assume came from the box somewhere. Maybe it's a spring to hold the lid in place or something.1 point

-

1 point

-

OP, are You sure this hairspring is original to the balance? I have some doubts. Have You tested the free oscillations frequency? We need photos of the balance/hairspring in place. Only then really helpful advice on how to manipulate the spring will be possible. The pivot is bent so slightly that it surely can be straightened. In such case I only use thick brass tweezers. Just like the ones on the pictures above, but made of brass. I don't heat them when pivot bent so slightly.1 point

-

1 point

-

Hi and welcome! I went to school in Dayton, Ohio & much of my wife's family lives by the shores of Lake Erie.1 point

-

Yah that’s a good way to think about it. Since I have the pivot tool from my Seitz set I give it a go with the expectation I may be replacing the staff. I’ve had great success with the tool though, a great time and hassle saver when it works. I’ve only had couple two or three snaps out of six or seven, one while learning how to do it and one where I miscalculated the pivot width and went too small in the jewel hole… …I don’t understand the heat/cool idea- ‘twas bent at room temperature and it didn’t snap so just bend it back. I’ve done the following for wheel pivots, too…1 point

-

$450 down to $400, I'm sure he can do better than that, like Tom said he can only say no to a cheek offer. Me old mum used to say " if you dont ask son, you wont get "1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

Thank you so much for the warm welcome! And even a fellow Norwegian I already love this forum! My first and only little project so far was a Seiko KZ211K1 / Landshark / Atlas 7s36 movement. I have a friend who is a real watchmaker and he told me this was a pretty bad decision for a starter movement, but now I have already dissembled it so its no way back Im afraid. One of the first screws I ran into was so small you have to use a custom screwdriver from Seiko or make one yourself of your smallest one. That felt like to big of a challenge on my first hour... but I somehow managed to get it done, and It felt so good! Next step now is cleaning. I have tried to learn what chemicals to use, but I understand this is a somewhat complicated subject. And we seem to have pretty strict rules in Norway so a lot of the brands and chemicals I see online are impossible to find. I think I will start with IPA which I already bought, and maybe buy Zippo Lighter Fluid? Honestly, this movement looks so clean, which was somewhat of a disappointment. The movement would probably be a lot better off If I had just let it be. But at least now I can learn some stuff. A few things i learned: -I loved working on these small things. -The parts were a lot smaller than they looked on youtube -I need to focus on taking my time. I was rushing and making mistakes because of it. Cant wait to find another evening to work and learn!1 point

-

I would do this. a bit of sandpaper on a rat tail would clear it right up. Its just a dial spacer so not a terribly precise part.1 point

-

watch repair is all about practice. Like for instance take your practice movement apart put it back together don't worry about cleaning or lubricating not yet. Just for the fun of it put it back on the timing machine is it still running out as a luck? Taken apart put it back together you'd need lots and lots and lots of practice it's good to practice on something that's disposable. It's also good the practice on something that is running because of give you timing machine experience. Then you can get experience when mysteriously it quits running because sometimes practice timepieces do that. This is where if you wife kids.cats you could blame them. Or maybe are timing machines defective somehow just in case it doesn't run ever again not saying that's what happened but just in case the problem isn't necessarily with the apps themselves a lot of the problem is the pickup. We hear the watch ticking as an audio sound a lot of the apps pick up the audio and that's not the best way to do it. Traditional watch timing machines have a sensor that picks up the vibration. for instance the pickup image above does work with some of the phone apps. Although you typically have to get the adapter so you can plug it in. you need to develop a timing procedure/ In other words you wind the watch up and wait at least 15 minutes up to one hour is considered fully wound up. then in watch repair think of it as diagnostics not regulation at least initially. In other words you put the watch on the timing machine look at it dial down, dial up and a crown down at the minimum. Dial up and down should be basically identical in one of the crown positions you typically lose amplitude but it's a good diagnostics because a lot of times people only look at their watch in one position and then they wonder why it has problems when it doesn't run on the wrist. Oh and then typically the only regulate or check the regulation one position then they ponder why they're having timing issues. Then ideally you want to wait 24 hours and reevaluate your watch to see how it's doing. Then your timing machine results are really interesting? are the images the two extremes that you see or what has the second screen looks better but the amplitude is too low especially if it's wound up. Typically at the end of 24 hours in one of the crown positions you should have at least 200°. then serviced in 2010 and now it's 2024 which is 14 years ago. Just as reminder if this is your daily watch at some point in time the gaskets will disintegrate water will slowly seep in and the cost of the repair will become very expensive. Then timing Rolex as a procedure? So in other words they do not put her on timing machine like you just did in time it in one position they follow a procedure. The procedure is the time the watch in five positions fully wound up and as I said they wait a little bit for the settled down then they time and again 24 hours later and they look for the maximum difference between those had that number can be up to 25 for your watch. Then the second procedure is to time the watch and all five positions fully wound up and average those together in other words all those numbers divided by five as they typically don't check and six positions because they don't have to and that number is supposed to be between -1 all the way up to +6 seconds. So yes conceivably you can check the watch in one position and it will exceed that because you're supposed to be doing an average. Then a big disappointment for this group would be the maximum amplitude that your watch is supposed to have either dial up or dial down is 280° which is sad because for this group the minimum amplitude any watch should be should be at least 300° on the other hand those people don't care if the watch keeps time they are only concerned about the amplitude. then at 24 hours the minimum amplitude is 200° in any of the crown positions. This is a real good way to tell how your watches doing is to lead wind down for 24 hours and see what it's doing because initially watches wound up tight can look pretty good at the very beginning but 24 hours later that may be another issue1 point