Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/20/24 in all areas

-

Honestly, the best supply of these springs if the Ofrei listing turns out to be wrong - is to buy a boxful of misc Soviet movements from ebay or etsy. Sellers in eastern Europe tend to sell them at rates of like 24 parts movements for $30, providing a long supply of springs and other spares. If you can wait 2 weeks for delivery.2 points

-

It might have a self-adjusting beat feature. It should be around ten degrees side to side. I had to look this one up, so I cheated.2 points

-

I've not seen those soviet ones, but they sound similar to the Seiko type, with three equally spaced arms & one cutout? I start those with one arm in, opposite the cutout. Then set it using my two smallest screwdrivers, one kept inside and holding the spring away from the cutout, the other helping turn it and set the arms as they line up.2 points

-

Forgive for me for saying but i find this doesn't often help, the weight of the collet if heavy can pull the hairspring down a lot,making it difficult to determine if it looks out of flat because of twists. Holding the cock vertical helps but not much. Better way is to fit balance on to a truing tool so the stud can be observed or the collet onto a broach providing the stud is removable for a particular movement. Viewing the hairspring in isolation, it can look just fine, bear in mind that it is not held in any way, both the stud and collet are free. When those are in position twists/bends at either end act on the hairspring's shape. Most commonly is a fault at the stud, as this end is handled more frequently than the collet end, hence disruption and damage happens here more often. Twists and bends at the stud are better handled for me, while the balance is installed. Corrections can be assessed instantly, often a tool needs making to suit the access available around the stud carrier. for the stud height in it's carrier, the pinning points collet to stud need to be in plane with each other . If the hairspring itself is flat the stud height is determined by the collet.2 points

-

They're all like that OH, made that way , i think theys Seiko but thats just a guess. Thousands of setting levers, but many are the same maybe a 20 or so of a couple of hundred different, some i know, a lot i dont. If these are quartz I'll bin em but i was hoping someone might have a handle on this one in particular. Nice one, well spotted, i figured it might be Seiko, i know practically nothing about seiko movements. I bet I binned dozens of these last year when i started sorting through 30 of these trays. Takes me about a week of evenings just to do one tray. I'm about quarter way through the lot. Much appreciated that one rehajm. Could well be Andy, i haven't really looked at them, some look used and some not. If i have it'll be a few years before i find and identify it.1 point

-

1 point

-

If I remember correctly, the most convеnient tool for Slava 24 shock absorber springs is a refill (tube) for regular pen. Use the tube to turn the spring in no mater which direction until one of the arms gets out thru the cutout. Then grasp it with tweezers and just remove the spring. No need to turn it any more, the other arms will get out when they get to diametrically oposite parts of the circle. Putting the spring back is in the reverse way1 point

-

Well, it is weight driven and with Graham escapement. This means no problems with isocronism at all, as the torque is constant and the escapement is isochronous by itself. So adjust the escapement for minimal but reliable drop lock and see what the amplitude will be. Don't forget to lubricate the pallets. PS There is specific behavior of the Graham escapement when changing the depth. If the escapement is shallow (no drop lock), then it behaves as recoil escapement and the amplitude rises and frequency decreases with the depth increasing. When the point is reached when drop lock is present, then amplitude and frequency will not any more depend on the depth increasing. But there will come a point where the depth is so big that the mowement will be not able to work any more.1 point

-

The unfortunate problem of the hairspring is a problem in the watch and typically we get to see the hairspring out of the watch where most of the time it's just fine.1 point

-

It is black paint. Get yourself a small tin of Humbrol black. I used an old watch oiler the thick one for this task worked a treat. Don't forget to remove the old paint first.1 point

-

Thanks all, I appreciate you taking the time to respond to my inquiry1 point

-

This forum post will probably give you a better idea what goes where. Edit This here is a lot clearer. https://watchguy.co.uk/cgi-bin/library?action=show_photos&wat_id=30061 point

-

1 point

-

1 point

-

1 point

-

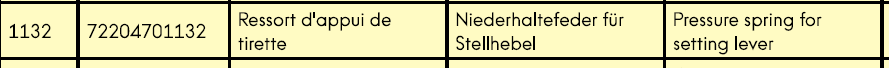

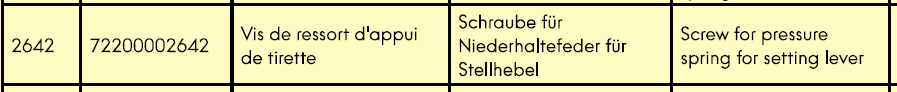

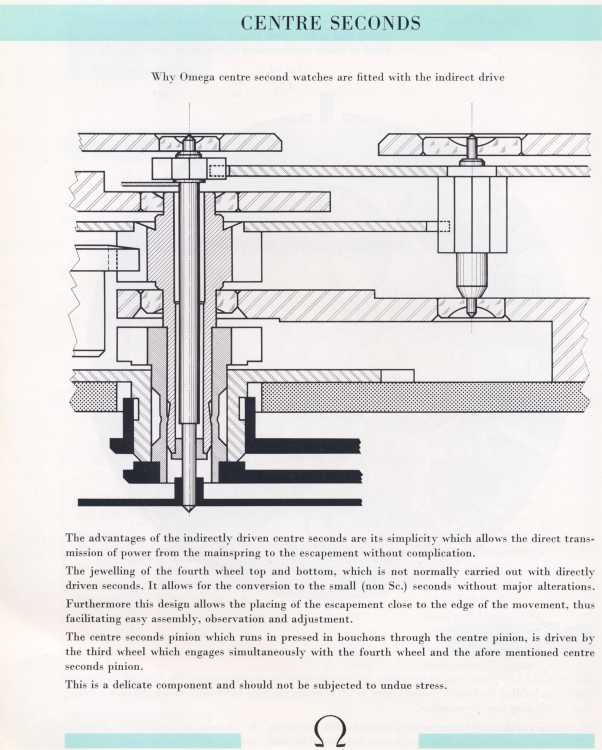

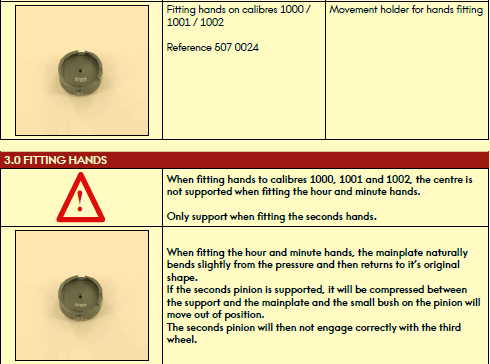

The reason you're not going to find a service manual for this watch is it's a basic watch that doesn't require a service manual. Depending upon the watch sometimes if there was something unique there would be a service sheets for that only but not the basic servicing. For instance technical guide for 610 gives you the technical characteristics on the first page second page the parts unique for 610 third page just talks about the balance and on the last page center seconds. As that appears be very similar to yours I will scan that page for you. But as far as servicing information there is none. Then parts lists the older ones look horrible or in black-and-white and were into parts. Other words 601 unique parts and 600 the base caliber if you're lucky maybe you could find a newer parts list which I did that's attached. Also attached is bonus timing specifications. Then if you look really carefully your spring is underneath. 373_Omega 601 New cousins.pdf1 point

-

I've done quite a few of the Seiko three prong type springs and I just used the same process with the Soviet type and never had an issue. I found the key for me is to use two pairs of open No 5 tweezers, the single 'arm' of set A sits in the center of the spring, and does not do anything, and with set B tweezers, use one 'arm' to rotate the spring. If/when it tries to escape the 'arm' of set A will catch it and prevent it from going anywhere1 point

-

I suppose OH referred to adjusting the self adjusting beat feature? Else 10 deg as amplitude would be much too much here, as I mentioned above. Frank1 point

-

1 point

-

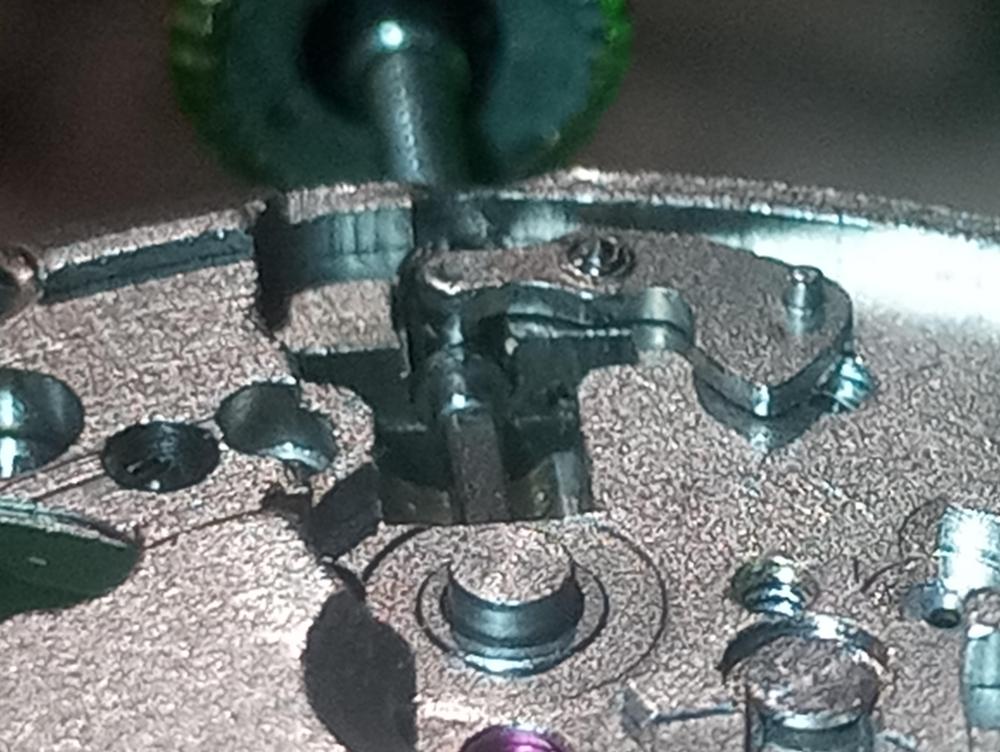

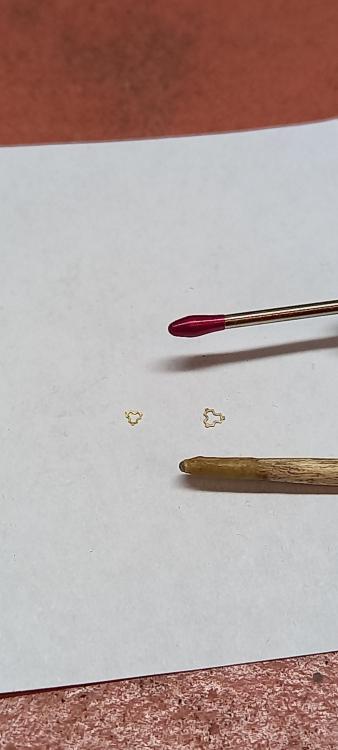

Sorry chaps could only find 2 soviet 2400s in the russian tub and both had the shock springs missing, but heres a picture grab of one and 2 two seiko springs for comparison with 2 moving tools. The jewel picker is great for moving springs, this is the smallest available , shame there isn't a smaller one. But you can make your own wooden jewel picker ( condomed tooth pick ) of any size. Shape a toothpick to what you want and then dip it contact adhesive, set to dry for 2 hours , i like evo-stik.1 point

-

Putting a thin plastic sheet on top has worked wonders for me. It helps a lot keeping everything steady. Work "through" the plastic for the third arm.1 point

-

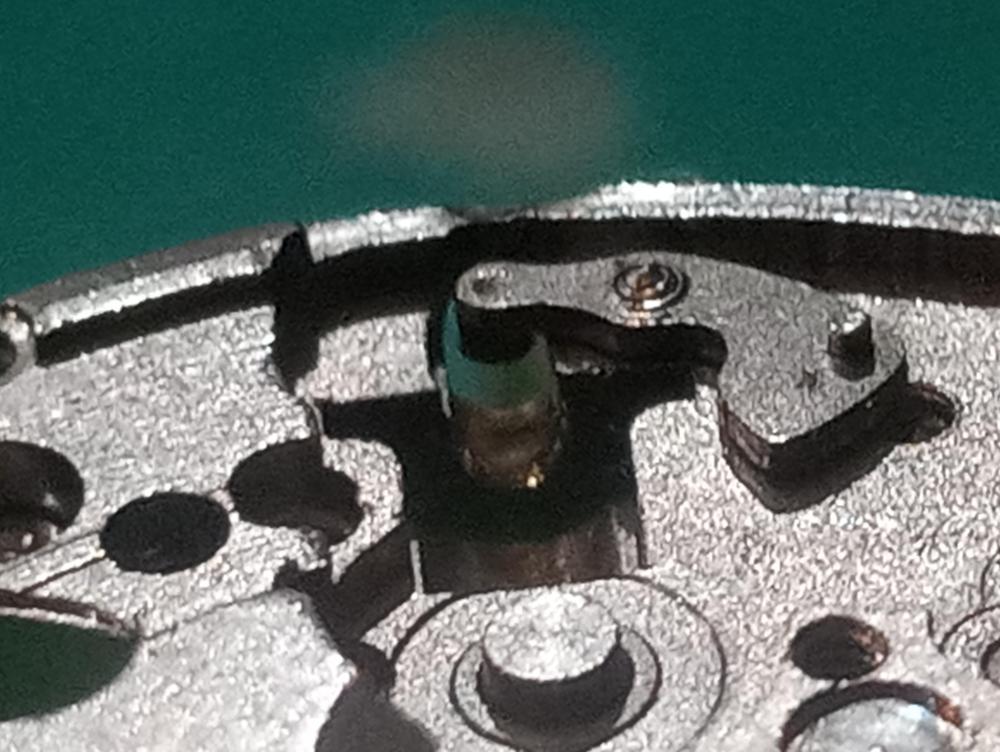

Yes, First the spring. It goes under the seconds pinion. It’s a fiddly one, too - too tight to the pinion can stop the movement and too loose gives you stuttering, but the position of yours looks good. Just pinion on top… …can you de-rust your screws or too far gone?1 point

-

Well, there is not simple answer here. First of all it depends on the escapement type. If it is like Graham or Brocot types with no recoil, then smaller amplitude means better isochronism. Of course, I mean when clock is spring driven and no fusee or other spring torque equilising. If it is Swartzwald type with recoil, then best isochronism is achieved with certain amplitude, which usually is not small. The amplitude mainly depends on the escapement depth and on second place on the torque. If the depth is small, the amplitude is small and the pendulum is forced to oscillate much faster than it's own period. The rate strongly depends on the torque and with the torque decreasing, the rate decreases too and is getting closer to the own oscillation period of the pendulum. Increasing of the depth leads to increasing of amplitude and getting the rate closer to the own pendulum period regardless of the torque, and there is a depth where relatively isochronical work is achieved. But depth can't be increased more than the one where the movement is not able to work any more. And with the wear of the escapement, the possible depth decreases. So it is a problem to adjust the depth in movements with worn escapement (wheel teeth and anchor arms with deep traces of wear) Amplitude is different when measured in angle - the long pendulums have smaller amplitude The scale under the pendulum tip on the picture should actually indicate the reserve - 2 weeks, one week and then wind the clock again. But, it is not so reliable or something obligatory...1 point

-

1 point

-

Make sure when you reinstall the balance on the watch, you loosen the screw that holds the balance stud in place to let it work itself flat. As far as the spring touching the regulator pins, you can slightly open the pins and move the regulator arm through its range of motion, and make sure it doesn't touch the hairspring at all. But I think it may just be the stud is mounted too high in the regulator arm1 point

-

1 point

-

No, you didn‘t. I was surprised about the replies. Long version: You could fill books with the correct answer. Short version: for your pendulum about 1 … 1.5 degrees. After the audible drop of the escape wheel the pendulum shall move another (roughly estimated) 0.5 to 1x the same distance. Frank1 point

-

Some quartz movements have a reset or clear / AC pad, but I cannot find any mention of it for that one. Try taking the battery out again and leave the watch for 15 minutes for any residual charge to dissipate, then re-fit the battery? Also try setting the watch after fitting the battery. (I'm guessing that with the battery in and the coil connected, coil resistance readings could be misleading due to the drive circuitry in the IC?)1 point

-

1 point

-

Coil resistance should be 1.7k to 2.1k1 point

-

I can't see it being a problem finding an original replacement unless it's a really rare ETA movement. The crown maybe a different thing but I'm sure something could be done to repair the original.1 point

-

Oh wow! I didn't understand the "Time is Money" comment until that last photo. That is interesting... We need a date on that. Reminds me of this 19th century portrait of a guy with Jetsons glasses (actually for protection from the harmful effects of the light from whale oil lamps, whatever those effects were purported to be):1 point

-

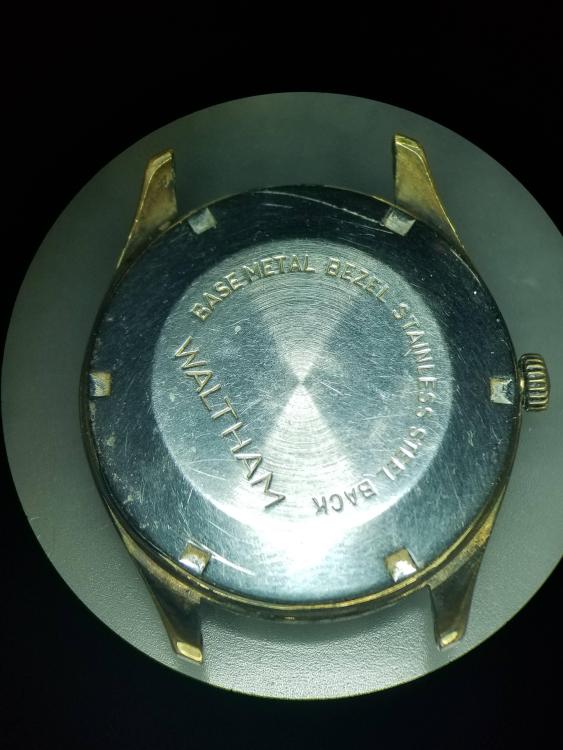

I guess these qualify as 404's. Freebies from a watchmaker friend of mine. I guess he doesn't think that I am busy enough. Waltham automatic with PUW 1463 movement. 17 jewels. It's a runner. I don't know the manufacturer of the "Time is Money" pocket watch. My first experience with a pin set movement. Pallet fork is all metal. A few jewels are evident. Time sets fine. Trying to wind the mainspring has no resistance, so maybe a broken mainspring. Balance seems good. Looks like a mucky mess around the ratchet wheel.1 point

-

When I do vintage work for factories, which is often pieces from mid-20th century but back 100 years as well, they expect to see timing printouts in 6 positions at full wind (minus an hour or so) and at 24 hours. At full wind they really want to see 270+ amplitude, but if that's not possible, similar to John's info above, there are minimums for 24h. They get a bit testy if the amplitude is much below 260 at full wind, that's for sure. When I do work for a local shop, he wants to see 270, but for a mid-range 60 year old piece is happy with 250 as long as it's stable in rate over 24h. The best book I've seen on watch adjusting (precision timing), by Joseph Rugole*, states that if a watch isn't capable of hitting 270 in the horizontals, with not more than a 45 degree drop going to verticals, it's not worth trying to rate it to any high standard. In the Hamilton links from John above they don't state any amplitude requirements, but I'm sure the fellows rating those for railroad use knew the rules and it's easy enough to see the amplitude on two arm balances (especially pocket watches) without a machine that tells you. From the Hamilton stuff I've worked on hitting "ideal" amplitudes is really not an issue at all. So I think the Omega info from John above is probably a good guideline. There's a max amplitude at full wind, and more importantly a minimum at 24h. I've certainly had pieces that sung along at 270+ full wind, and were a disaster at 24h. Then you start getting fancy with balance pivot shape and such, and it becomes rather time consuming. *Watch Adjustments by Joseph Rugole It's a collection of articles he wrote for the Horological Times in the 80s, and it's fantastic. - Also- you don't have to wait 24h to see those rates, most watches have around a 7.5 ratio between barrel and center pinion, so you can let the mainspring down about 3 1/3 turns and that's where you'd be at 24h.1 point

-

Somewhere recently on the group someone was pointing out the obsolescence of mechanical watches because of course smart phones. I was going to ask a question the salespeople at work but since I found the whole subject in the waiting I didn'tsort of. I work in a mall store that sells watches and of course services them and say goes for instance are literally flying off the shelf and they're not necessarily known a super good timekeepers. It would be interesting to see if any of the watch companies do offer stock and whether you'd actually make any money at all? I have Seiko has stock probably not. On the other hand Seiko is so diverse in the so many other fields. Oh dear I will get in trouble again. The last time I commented on microscope I got annoyed with the discussion and did not participate anymore on the other hand this discussion just end it all by itself? So yes having a microscope is nice. We have one at work not in the best location for me but we do have one. People look at it all the time. I have mixed feelings about people who work under microscopes often times in that other discussion the microscopist set up the looked straight that we as opposed to watchmakers are typically look into their work. But I got chastised by somebody that microscopes are the way to go today and that I'm an old senile goat although the word old senile goat wasn't actually implied but it was definitely there. Then the pivot polishing tool had one sold it. I'm not authorized to discuss my experience somebody will swoop down and burn me at the stake like last time. There are other ways to polish pivots though although it would be nice if you to watchmakers lathe. Then if you really want to get obsessed about your pivots for better everything and if it's practical which it isn't always especially on vintage replacing the balance staff. I know somebody who worked in a Rolex shop authorized Rolex and he said they changed more staffs for timekeeping issues and anything else. Just the slightest bit of anything in other words not perfect they just change the staff. Vintage becomes a problem of getting the right staff and introducing issues because of prior work. Like often times on the pocket watches I do the jewels are slightly different size's of I change the staff I'd have to change the pivots size or and change the jewels and we don't taken enough money to cover restoration of watches back to the original factory condition. So I usually just leave things as they are but I will polish the pivots if I don't like the amplitude and or I can see a difference between dial up and Dial down. Oh and just to nail my coffin shut microscopes do not necessarily allow you to see better if you don't grasp what it is you're looking in the first place. Oftentimes seeing something really big and not grasping what it is isn't going to help Or if somebody I know who makes YouTube video is who I help with will send me a video and the pivot looks like it's flopping around in the whole because you're looking at it at such a microscopic level were the pivot is just fine so sometimes things can Actually look worse because of the magnification you're looking at them. Will be really nice to find is original watch company timing specifications of what they expected?So for instance the Elgin watch company in 1955 had the specifications of -10 to +50 seconds a day. It unfortunately what I'm looking at doesn't specify how many positions and it definitely doesn't specify amplitude although some or else the document there is a reference to amplitude. Rather than amplitudes by degrees it refers to a number of turns the balance wheel has and if it's too little it goes back to the escapement adjusting department and If it's too much it sent to the mainspring department where the swap with the weaker mainspring. If you look in the vintage Elgin parts book They did have weaker mainsprings that of course no longer exist. Than not just Elgin even Rolex has weaker mainsprings which seems weird it seems like we show stronger mainspring skip that amplitude up. Yes I have an obsession with poking fun at amplitude. then railroad grade timekeeping and look at the year because were dealing with a very very nice watch. Cheers example of railroad timekeeping which might actually beat out on Rolex over time. In the last thing when you're dealing with watch running issues watches can just wear out. Especially when you seven jewel watches the bearings will get worn or people of played with your watch before you. Typically on American pocket watches the banking pins always have been played with. Things done to the balance wheel lots of creative and interesting things have been done to the watch before you got it which makes things interesting if you're trying to restore it to something that's got keep time trying to figure out what somebody is done to this watch before you and try not to think about why they did it because it makes no sense at all. One of the last watches is working on had the balance wheel out of round they bent the bimetallic arms in by several millimeters so it's grossly out of round it looks horrible when it's spinning. Then they get text 16 timing washers off I'm guessing they were put on to make up for the watch running too fast because somebody bent the balance arms? Yes the joys of vintage both wristwatch and pocket watches Hamilton 992b 950 timing.PDF1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)