Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/21/24 in all areas

-

Absolutely, this is my National press. I have seen these go for less than £10 on eBay in the past and it is a great piece of kit. I only have plastic and Bakelite dies for the Robur which are fine for standard crystals but the edges are a little too delicate for things like press on bezels and case backs. The National only has aluminium dies (I also have a few brass ones that can be adapted) so this gets used for more demanding tasks, but it would only require minimal modification for your dies to fit and you would then have a very viable alternative to the Robur at a fraction of the price.3 points

-

3 points

-

3 points

-

If I remember correctly, the most convеnient tool for Slava 24 shock absorber springs is a refill (tube) for regular pen. Use the tube to turn the spring in no mater which direction until one of the arms gets out thru the cutout. Then grasp it with tweezers and just remove the spring. No need to turn it any more, the other arms will get out when they get to diametrically oposite parts of the circle. Putting the spring back is in the reverse way3 points

-

From your photo of the sweep second pinion spring, it is on the incorrect side. The sweep second pinion turns in an anti-clockwise direction as we are looking at the movement, therefore the spring needs to be on the underside of the pinion at a six O'clock position and not the 12 O'clock position it is in. I've attached a photo of a similar movement, a 503, where the brake spring is on the correct side2 points

-

2 points

-

That page is for sure gibberish. It does not identify the actual differences between the -1 and -2, which is that -1 is 18000bph while -2 is 21600bph.2 points

-

Well no answers on the old watch but the one i just serviced appears on cursory timing to have a sub 4 second delta in five positions, really good for this movement. It's got about 9 or 10 in crown left, probably a slight heavy spot in the balance wheel. So yeah, running like a champ at around 255 amp dial down and 240 dial up. Hoping that goes up overnight. Not sure why the drop in amp dial up, i re-oiled the balance jewel and added a bit more and that brough tit up to what it is, i might try adding a little more to the arbor pivot there but it's nice to confirm that i haven't lost it.2 points

-

I thinK I would like to do Italy and other Mediterranean countries with Liz (wife) one day. Have fun Richard. Excess baggage for all the watches you'll pick up at flea markets?2 points

-

The spring should sit just below the case and can be cut or filed down till you get the bezel rotating correctly. You're best doing it a little at a time but if you cut too much you can use a spring bar spring but can't remember what size.2 points

-

2 points

-

And it depends on the „reserve“ the manufacturer calculates for increased friction due to lack of service. With half the amount of weight my clock runs still perfectly. The drop takes place at the „I“ index and the swing of the pendulum ends half way between „I“ and „II“. That is in line with the comments of @praezis and @nevenbekriev.1 point

-

Depending on the diameter you could try making one either from a guitar string on getting the correct size stainless wire as example below. https://www.wires.co.uk/acatalog/SS0150-316-050.html?srsltid=AfmBOorigqOKGb1fmAYmh-DR-AHosmVBRoY9GH-IO2KOiDRJh7JU5q1EBhs Edit Just remembered there's also these that could possibly be modified. https://www.cousinsuk.com/product/straight-springs-wristwatch1 point

-

I presume you've got it on Auto as the frequency should be 18,000. Can't see what you had the lift angle set too but it should be 52 Deg.1 point

-

1 point

-

1 point

-

Hard to tell for sure, but the line that goes across the hinge of the spring makes it look like probably a Kif Elastor rather than Inca. This looks like a legit movement for sure.1 point

-

Looks like the crown currently fitted isn't the original. Being a Stainless Case I'd have expected a silver crown 42102ST. https://gleave.london/crown-steel-omega-st42102/ Spring doesn't look that bad and expect it would clean up nicely.1 point

-

I think the website is just blurb. I'd like to see the rest of the movement as something doesn't look quite right to me.1 point

-

I am not sure that page isn’t gibberish, the difference between the movements they cite dials, seeing movements don’t come with dials unless in a watch and can use any dial made for its subdial orientation it just doesn’t make sense to me at all. Tom1 point

-

1 point

-

Coincidentally, £46.75 converts to $60.95 right now, so I'm okay with that price. It's on its way to me right now.1 point

-

1 point

-

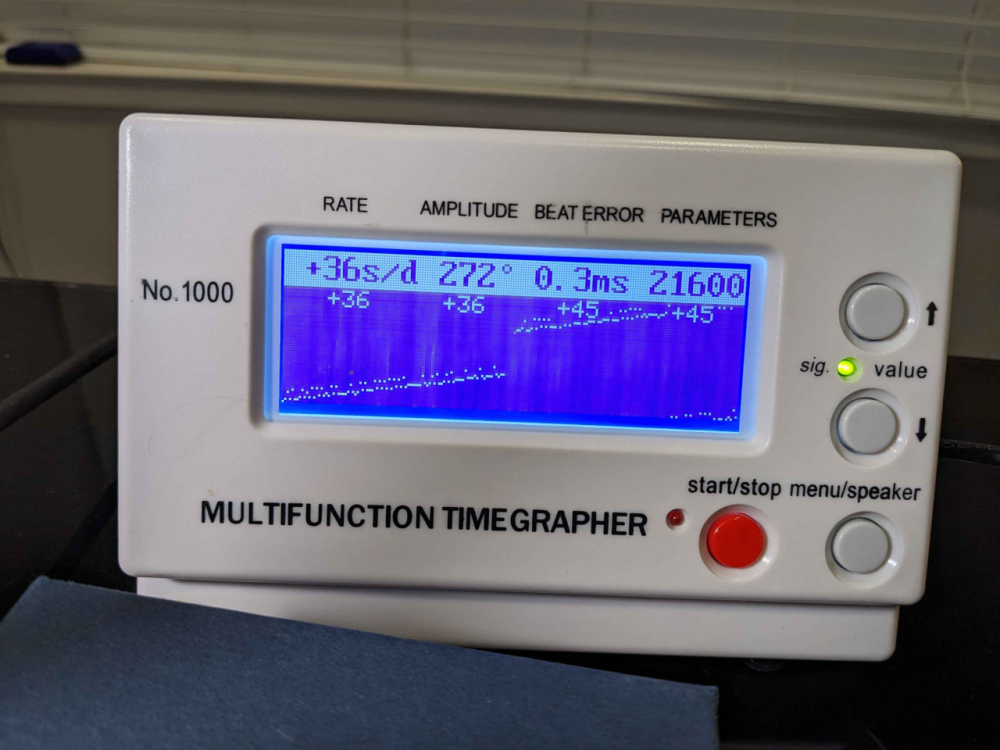

Yup, all the good standards. 9010 for fast wheels and balance jewels, hp1300 for slow high torque wheels, 9415 for escapement, grease for rubbing parts and keyless works, 8213 for the barrel walls and 8020 for the mainspring itself, just a little film of it rubbed on from some watch paper. Yeah i'm going to replace them after this and i do use synthetic good standard oils but see below for update. FINALLY SOME ANSWERS. See above. Nothing unusual, hp1300 for low speed high torque wheels aka barrel, 3rd wheel and center wheel. Okay big update. Look at this. This is the second watch using the generic mainspring i thought might be underpowered and responsible for half my troubles. The amplitude climbed 60 degrees as it settled into the service. This confirms a number of things! FINALLY some answers. 1. The gr2377x mainspring that @mikepilk recommended IS indeed powerful enough for the 7s26 movement. Something is wrong with the escapement which i'm going to investigate now, or maybe there's an eyelash or something in the movement, i don't know but look at that amp. I did notice that when i was lubing the pallet stones it would skip a tooth periodically for some reason, i figured i was just short stroking my manual advancement of the escapement but it appears something weird is going on there. I have many pallet forks and escape wheels and i'm going to reinspect. 2. This is the same mainspring that couldn't get barely 210 out of the other watch. This seems to confirm that indeed SOMETHING is wrong with the other watch. what? I don't know. But it's not my ability to service i don't think now which makes me feel good. This has been in the back of my mind during all this.1 point

-

This vid should be helpful.. From 48 mins of the vid.1 point

-

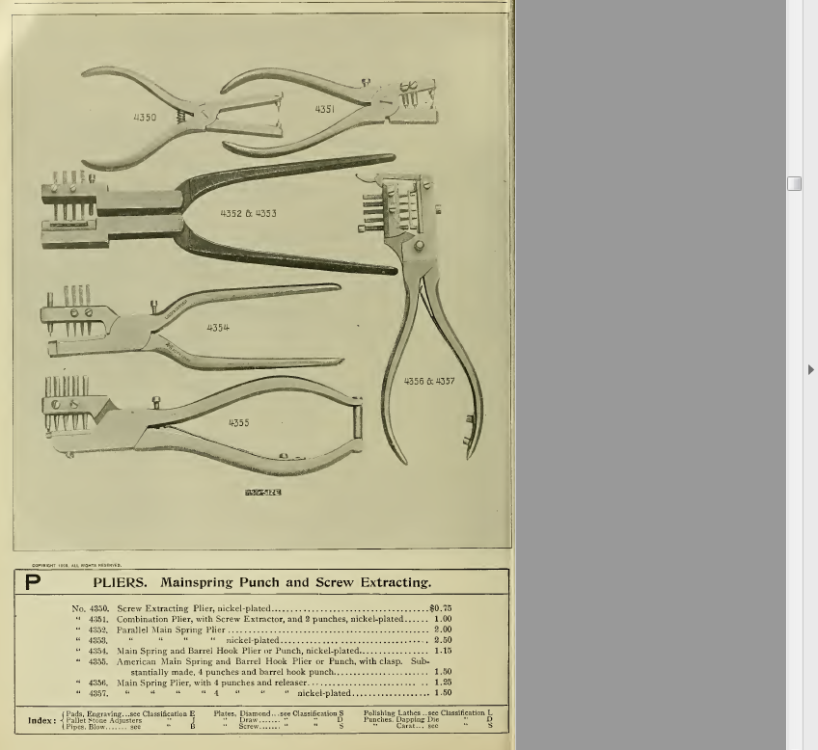

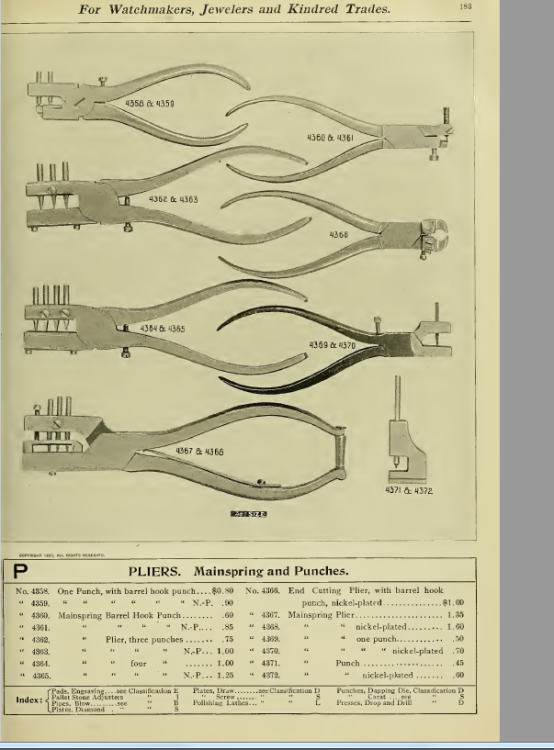

It was just a guess on my part OH, i figured start with the thinnest punch which is missing here and work up to the size you need. Has to be for pocket watches for these size of punches. I tried it a couple of months ago when i hatched up the inner coil of timex spring. A complete no go with this tool, i ended up drilling out a new arbor slot with a carbide drill and then sized it like you said with an escapement file. I may never use them but i just love old tools, i used to be the same with my joinery gear in my workshop, old and quality was the only way for me.1 point

-

I have some vintage catalog pages. I do believe most of them are for the barrel but it's possible especially the ones that only have one punch like at the very end and the one that looks like a tiny staking set it might actually punch a hole in the mainspring. Typically the preferred would be to buy the right spring in the first place. Although if you are really obsessed with the end of the spring there are a variety of ways of doing it's just that their very very expensive.1 point

-

This forum post will probably give you a better idea what goes where. Edit This here is a lot clearer. https://watchguy.co.uk/cgi-bin/library?action=show_photos&wat_id=30061 point

-

Another option you could try Col, though a bit laborious, is to try installing one train wheel at a time, checking the end and sideshake as you go. Lack of endshake is an obvious amplitude killer and can be seen on each wheel ,sideshake can be less obvious if only looking at one wheel at at a time, cumulative excess sideshake over the complete train can foul up the wheel and pinion meshing, can be difficult to pin point with it all in place , but introducing one wheel at a time makes it easier. Not just dial position checks so include crown positions.1 point

-

1 point

-

So this is a mainspring punch, of course i have one , not what you think it is for regarding watches. As franks says,and as far as i know there is no tool for punching out the eye of a mainspring for an arbor hook to latch on watches ( maybe clocks ? OH will know that ) barring drilling the eye out and filing to shape, something i did recently and is tricky, this tool does not do that. What it does do or did do is create an eye at the barrel wall end of the spring in conjunction with a compatible pair of pliers that cut a hook into the barrel wall itself. Fairly sure, but kind of guessing that this appertains to old pocket watches only and not wrist watches.1 point

-

Many old clock springs don't have holes in them. There is a tool for clock mainsprings. Any good clock material suppliers will stock them. I always made my own, heat the spring end after shaping it then use a punch to make holes and file them to the required size. You can use the tool if a spring breaks at the end, but don't remove to much length because the clock will not run its full time.1 point

-

Problem with polishing is that often these hardlex crystals get chipped on the edges so it might be impossible to get satisfying results. I don't mind an aftermarket crystal but I don't mind a few scratches either. I just bought the same replacement crystal for a different Seiko model. I haven't installed it yet but it seems ok quality. Spencer Klein claims to sell very exact copies of the original, mine was some random from ebay.1 point

-

0 points

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)