Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/22/24 in all areas

-

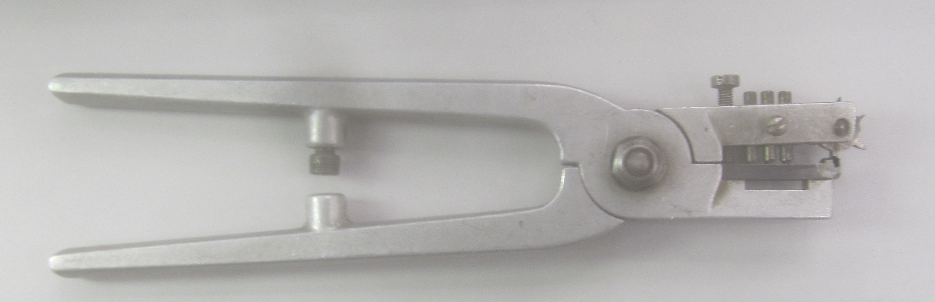

I was lucky enough to get this glass press from ebay a couple of months ago for just £20. It's brilliant. So much easier to use than the Bergeon claw tool, and it leaves no marks. You can hold the press tool in one hand and the case in the other. It takes seconds to fit/remove a glass. I which I'd got one years ago.4 points

-

3 points

-

2 points

-

With a quick dip of your .6mm screw driver about 2mm deep into oil, you get too much oil on the blade, some of which is to be drained down, if you touch any clean surface with it, some oil will drain in a minute, leaving you with little oil on flat surface of your screw driver. As you watch runs on tg , touch the running face of each escape teeth with your oiled screw driver, let escape wheel turn several rounds, then observe the amplitude your getting on tg, you can keep on adding oil as long as the amplitude is on the increase, until amplitude stops gaining. Be careful to oil just the running face of each escape teeth, you wouldn't want oil on non functional sections of escape wheel. Your letting the escape teeth distribute oil on sections it engages. No excess oil which can run/ travel to where not needed. You can add a bit extra oil as reserve. Let the watch run for up to two weeks in all positions or on wrist, then epilame by same approach. Your watch is showing you how much oil should be in its belly, for best amplitude. Rgds Oh please, don't tell de Clark I said this.2 points

-

2 points

-

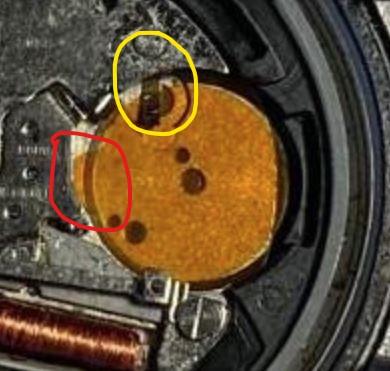

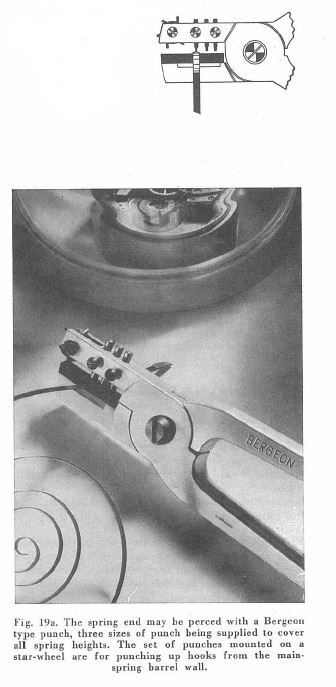

I find sometimes where I work can be really really strange. It was a very strange day with a strange bonus items that showed up? I was asked about the strange pair of pliers? The pliers are now residing in my bench for safekeeping. They looked vaguely familiar wonder where I've seen them before? Yes very strange day. Know the pictures not the best but I can take a different camera and get a better picture if you want to see the star wheel in the front and when I get a chance I think I'll try the thing out and see how it works. Although I'm pretty sure that in order to punish the hole in the mainspring I think the main spring steel has to be softened. For which I used to have a much better way of getting square holes in hardened steel.2 points

-

What decade are you aiming for? Just to remind you I will soon be 70 so don't leave it to long.2 points

-

Update: got the movement disassembled and sure enough the MS was broken. Ordering a new one took a bit as it calls for a GR4568 which is 420mm long. As Venus is now Valjoux and Valjoux is Eta, which is Swatch, that mainspring is a restricted item. No worries found another one that is similar except the length is 400mm. Had some trouble with the hairspring as the BE was 5.0 and got it down to 0.2. The Amp is not good so and the rate somewhat varies over time and position. Not sure if it is all hairspring, balance jewels or other train pivots etc. But making progress and likely put the chrono works back on and get it going, then do another disassembly to reclean and relubricate the watch works.2 points

-

Ah-ha! Eureka!! I couldn't let it go. I took the balance assembly off and really looked carefully at the hairspring. Lo and behold, there was a very, very, fine thread tangled in the coils. It was buggering up everything. Got it out, cleaned and oiled the upper and lower jewels, got it back together, and just like that, the snow storm on the TG stopped! I had a good trace, albeit a fast one, but it's settling in for a day or two, and then I'll regulate it. Overall, I'm happy.2 points

-

There are texts on overcoil forms. Some come up gradually and gentlty bend in toward the regulator pins, some come up and abruptly streak over. In some cases abrubtness is necessary to avoid hitting the center wheel for example. The curve upwards can be a couple of rather severe bends or a series of gentle bends. End of the day you can make an "overcoil", then check your isochronal error, which is effectively checking the rate at about full wind and about 24h after in one position, imagining that everything is adjusted "nsk nsk" all around. If, at low wind, the rate is gaining, adjust the body of the overcoil away from the balance center. If losing, adjust it toward the balance center. It works and feels like magic when you do it. Of course you throw it out of beat when doing this and you correct that. This is advanced timing stuff but if you're comfy with hairsprings you suddenly become a wizard, and that's motivation to become comfy with hairsprings. A watch with overcoil, while seemingly more daunting than a flat spring watch, offers much more adjustment for fine timing. You can send your 10 dollar flea market find to Besançon haha.2 points

-

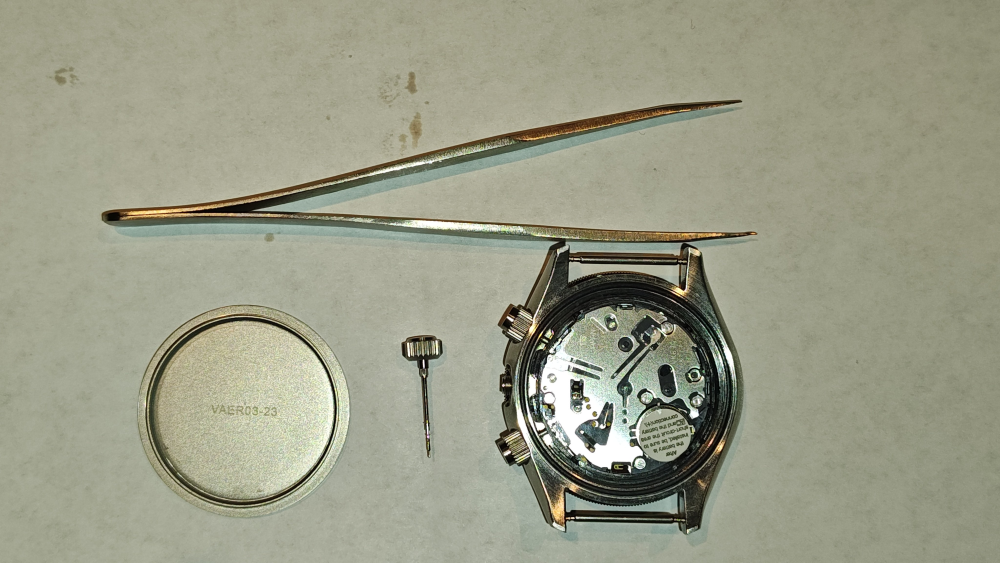

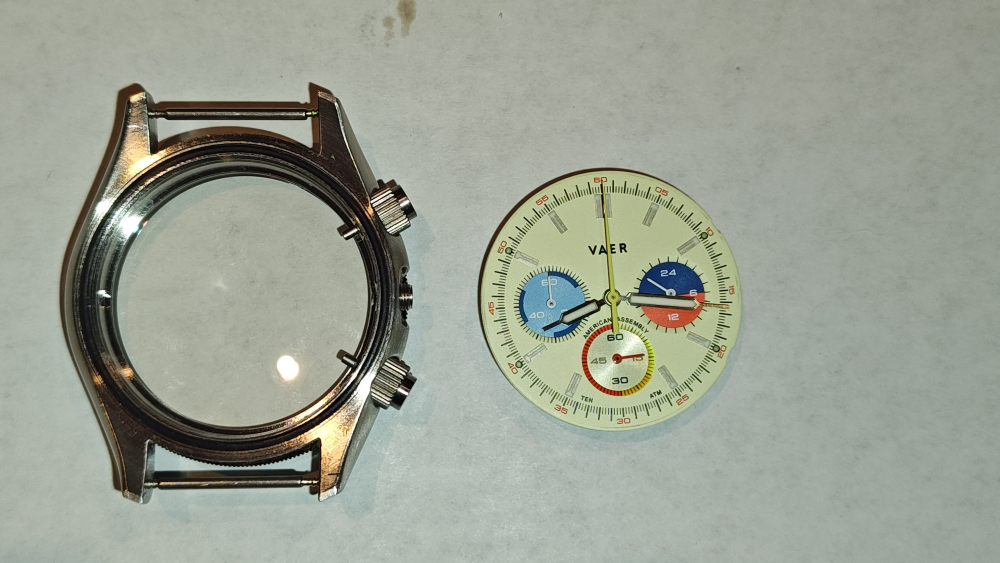

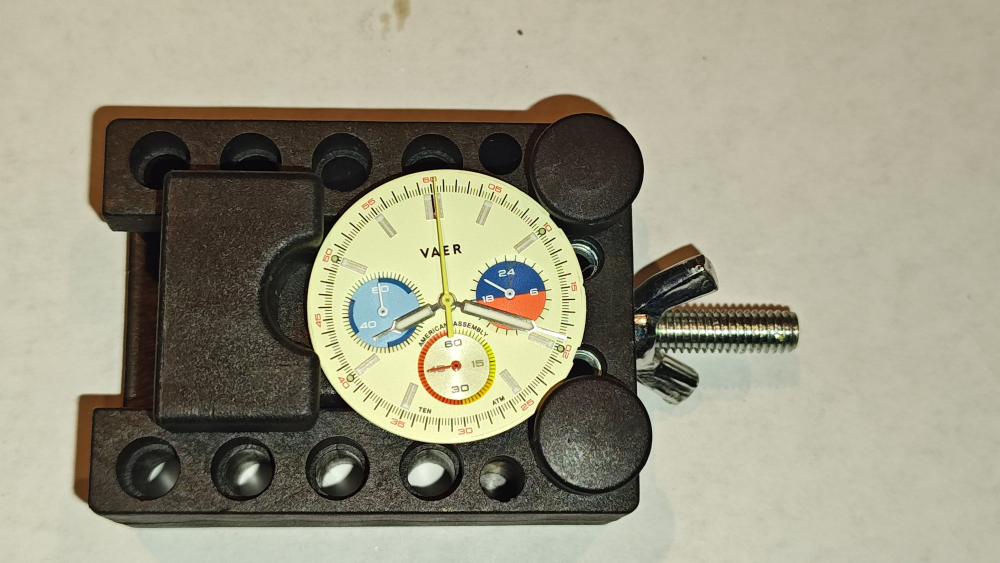

Recently purchased this fun and cool looking watch. Problem, with middle age eyes it was hard to see the hands and the light yellow chrono hand. I contacted Vaer to trade in, and CS gave me a ton of options. Before agreeing, I happened by my watch guy and I mentioned the dilemma to him and he said, just buy new hands and I'll install them. Went to Aliexpress and bought 2 black sets, and orange and blue set. Settled on black hands and replaced the white hand on the blue subdial. I decided to do the switch myself. Went to HF and bought this. Set up on the kitchen counter and went to work. https://www.harborfreight.com/head-lamp-magnifier-58788.html Things learned: 1. The people that put together watches for a living, hats off to you. 2. When removing hands from movements...they like to fly away to never be seen again. 3. Sharp objects next to dials like to leave marks. 4. The tweezers left a slight glaze on the blue subdial, but cant be seen w/o magnifier. 5. Aligning hands must have a secret recipe. 6. If the chrono hand is not installed correctly, when being returned to 12 it will eject. 7. Sasquatch not real, unicorns are, your mom is funny...yes, your mom. Pics from start to finish.1 point

-

Hello, I have been a precision watch enthusiast for many years. I acquired an Omega Seamaster ‘Peter Blake’ 20 years ago and a Rolex Yacht-Master 10 years ago (caliber 3135). As I’m approaching retirement, I want to learn watchmaking. I searched for information on Rolex 31X5 calibers on your forum. I found the information I needed. Thank you all! However, I want to practice on a less expensive movement (and not on my personal watch...). So, I’ve decided to go with a Seiko NH34 GMT. Why GMT? Because I often travel across multiple time zones, and I’ve always dreamed of owning a Rolex Explorer II, but the price is prohibitive. I’ll start the journey as soon as I receive the movement and a few tools...1 point

-

So people, im trying to figure out what i have here. I bought this stuff about 18 months ago. Story is i had an ebay search on watch parts, and one day it threw up a seller wanted rid of excess bits that she'd bought from cousins. They sell plastic cases of random parts originating from who knows where, possibly India. The seller was into some sort of craft stuff, picked through what she wanted and banged the rest on ebay for about a fiver per case. Turned out she had 30 or so of these casee, so me being me i offered her 80 quid for the lot which she accepted. 4 days later a delivery lady struggled to hand me a parcel weighing 10kg lol. I've been through about 7 or 8 and threw away a lot of parts i thought were unidentifiable quartz bits. Looks like i was wrong and have one shed load of seiko parts, up to now discoverable as 6309 bits. Now i also throught these had being pulled out of watches for repair, some were rusty and some damage but seems like only 10 % is trash, mixed in with hair and rubble, but most of it is new. All different parts of a movement, lots of keyless parts. Pallet forks escape wheels , bridges ,plates,barrel completes, pin pallets, small bags of cap jewels , collets, hands, springs. Trying to understand where this stuff has come from, factory floor sweepings ? factory seconds ? Mumbai side street ?. Anyone know ?1 point

-

If they were the brown sometimes mottled, they were probably bakelite. It was used for all kinds of stuff, even jewelery, antiques. Brittle but quite resilient in other ways, molded resin i think it had asbestos in it. Ive been after those for ages expensive, rarely seen as a full set now, occasionally sold in singles.1 point

-

Well, it is all on it's way. Now I need to build a bookcase for the workshop. I'll fix a clock one day and post pictures on here. I will. Really.1 point

-

The Vigor Bergeon won't even grab low dome. That old black tool was quite handy the assorted fitting were good not sure what they were mad of but they never broke or chipped.1 point

-

Certainly an ambitious price This is a sold price https://www.ebay.co.uk/itm/226263423357?_nkw=crystal+press&itmmeta=01J5WBCFZCF0A8RF9ARCXMC717&itmprp=enc%3AAQAJAAAA8HoV3kP08IDx%2BKZ9MfhVJKn8D%2BW%2FVEkRZYdjKvUPOfskDP2NOyMu5imRSKeKmO2W854raCd4nNt6iiSOyFtfMAOATIl8Sv6j5H7ecDGaJIqyTFFuUruRd9md%2FBBPstzuxtlax4lEHtAnT%2BSCARLedCupDIE9J2xCMMmLS7RavqykEFjWbrQ9TF2P0Lm%2F5Kg6qDqp5VKt0AGvzmm25nI%2BDQokmWlwKeJYdHdjvYcdVEZBI6LSXF3MiqPW2O%2B0ih%2FqI2LjBMrzY9nc9G%2BcgM2ZeVXRRIeS8Gx64wl%2BITTUyuAUoW0oK0JgHq0F394D2h8vmw%3D%3D|tkp%3ABk9SR-r_sYuvZA&LH_ItemCondition=41 point

-

1 point

-

I think that your issue is your magnification and practice, you can get better with practice and/or you could switch to a visor which would give you stereo vision and help in your depth perception and field of vision, or better still a stereo microscope if you budget and accountant will allow. I use an Optivisor when I use a visor as I have tried other cheaper versions with poor results. Also if you go down the road of a stereo microscope (which I recommend) you can pick them up fairly inexpensively on Ali Express, some will scream at me for saying this, but you get 90% of the quality(which is enough) for 10% of the price of brand name ones. PS I have been informed from a source I trust that AMScope do not make their own scopes, they simply buy them in and re-brand/box them1 point

-

Thanks, Jon That's a good point When I come to reassembling the movement I most probably would have just put it back under the pinion without any thought to what side of the pinion it should go. Thanks again!1 point

-

Mine was originally black but it was in a bit of a state so I cleaned it up and gave it a fresh coat of paint. Green was all I had but I rather like it. I have also seen these branded as BMC.1 point

-

From your photo of the sweep second pinion spring, it is on the incorrect side. The sweep second pinion turns in an anti-clockwise direction as we are looking at the movement, therefore the spring needs to be on the underside of the pinion at a six O'clock position and not the 12 O'clock position it is in. I've attached a photo of a similar movement, a 503, where the brake spring is on the correct side1 point

-

https://archive.org/details/20thcenturycatal00purd/page/n5/mode/2up It's an interesting link you can download the book of radio formats. If you figure out the proper search terminology there are other horological books here catalogs and repair books just not a huge quantity of them Then here's a picture of an interesting tool which I'm sure does not exist anymore. It looks like at the end there is the part for putting the hooks in the barrels and then the other part is for punching the mainspring. You will note the word annealed as punching hard Springs well basically hard Springs Cannot be punched and have to be cut.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

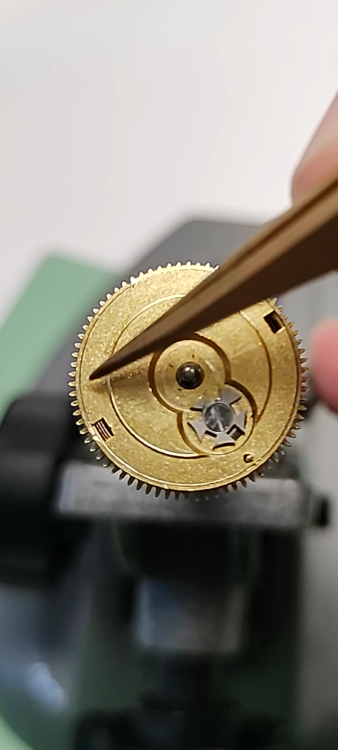

Well, I took the plunge. Following advice, I held the barrel arbor in a pin vice and then held that pin vice in my bench vice. Holding the barrel so it didn't unwind I carefully levered off the finger. That part appeared to be a wedge fit onto the arbor. Once that was off I allowed the barrel to turn slowly anti- clockwise, holding the barrel between finger and thumb. It came to a stop after turning 315 degrees. Putting it back I will need to turn 315 degrees clockwise before fitting the Maltese cross. Thanks everyone who helped. Steve.1 point

-

1 point

-

this answer is incorrect for variety of reasons? Early American watches typically used flat hairsprings because are easy to make. But they went to over coil hairsprings for timekeeping reasons. But there's a problem with them to get the over coil in exacting location it's easier to pre-make them. This means if you're missing one it's easy to replace it. I'm attaching notes from the 1915 parts catalog that explains how you would do that in other words you have the timing screws. But as watchmaking got better we don't need over coils typically. So the modern flat hairspring each one is vibrated to the balance wheel. So if you have a modern flat hairspring and detritus swap you'll have timing issues unless you have a way of changing the timing screws. Now I would've agreed with you that this is probably an over coil and I couldn't tell from the picture but I did look up the hairspring and as you already discovered its flat. A lot of times with the early flat hairspring is because they didn't have modern timing machines yet they weren't invented they left the hairspring a little longer so it's not pin exactly where it's supposed to be. So initially pen it at the very end and see if you're running slow. In which case you can move a little more in and speed the watch up until you get close to where you're supposed to be. This is where if you have access to modern timing machine that can measure beats per hour doing this is really quite simple.1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)