Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/23/24 in all areas

-

3 points

-

3 points

-

C'mon @oldhippy, that's a terrible thing to say! Have some respect for the dead!3 points

-

3 points

-

3 points

-

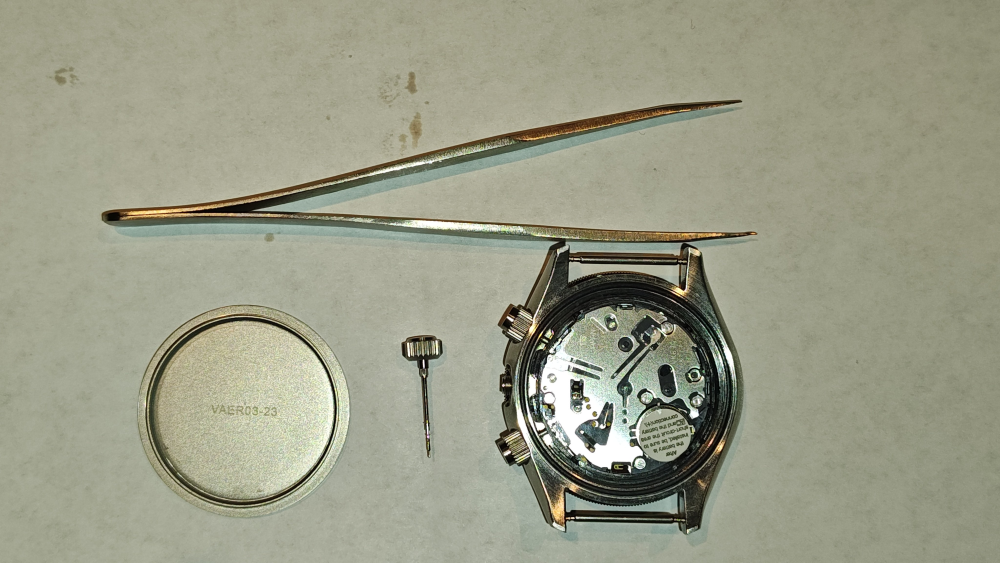

Many people put down a plastic baggie over the dial and hands and then gently pry off the hands. The baggie helps protect the dial. Using plastic or wood tipped tweezers to pick up and place the hands helps as well. This is how it starts. You buy a few rudimentary tools and do a mod. Pretty soon, you will be buying a good set of tweezers, screwdrivers, and much more to start servicing the watch movements, watching lots of YouTube servicing videos, monitoring eBay for other tools, and so on. It gets addicting.3 points

-

Also being 10 minutes late when it’s your shout at the NAAFI bar because you screwed up earlier in the day is a heinous crime with severe punishments dished out Tom2 points

-

It has a 24 hour subdial, obviously only military watches have 24 hours on them’cos them folks who dress funny in crinkly green clothes use the 24 hour clock notation. Tom2 points

-

My guess and I'm not certain in my logic is, that every district caliber will have at least have some distinct parts. Multiply that by the number of calibers and the number is massive.2 points

-

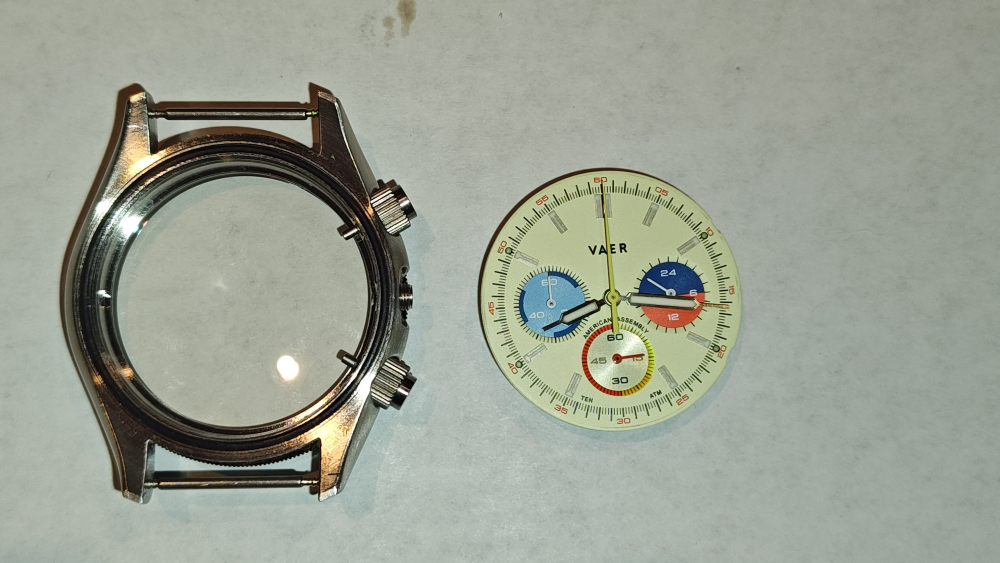

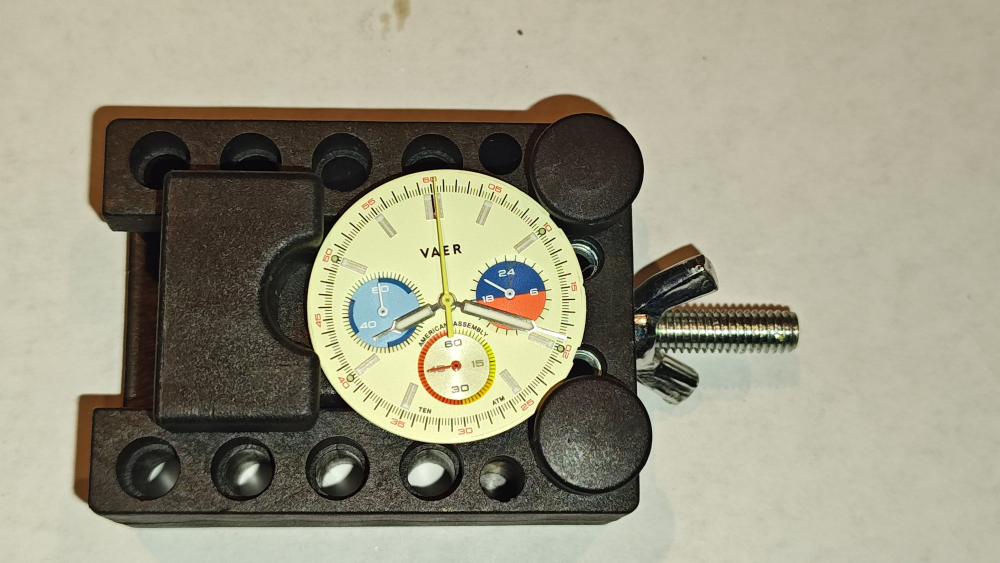

Recently purchased this fun and cool looking watch. Problem, with middle age eyes it was hard to see the hands and the light yellow chrono hand. I contacted Vaer to trade in, and CS gave me a ton of options. Before agreeing, I happened by my watch guy and I mentioned the dilemma to him and he said, just buy new hands and I'll install them. Went to Aliexpress and bought 2 black sets, and orange and blue set. Settled on black hands and replaced the white hand on the blue subdial. I decided to do the switch myself. Went to HF and bought this. Set up on the kitchen counter and went to work. https://www.harborfreight.com/head-lamp-magnifier-58788.html Things learned: 1. The people that put together watches for a living, hats off to you. 2. When removing hands from movements...they like to fly away to never be seen again. 3. Sharp objects next to dials like to leave marks. 4. The tweezers left a slight glaze on the blue subdial, but cant be seen w/o magnifier. 5. Aligning hands must have a secret recipe. 6. If the chrono hand is not installed correctly, when being returned to 12 it will eject. 7. Sasquatch not real, unicorns are, your mom is funny...yes, your mom. Pics from start to finish.2 points

-

2 points

-

They are, i stopped wearing them on my right hand, tweezers nearly slipped through my fingers a few times. I also got the large , too tight. I have stupidly large hands for a bloke of only 5'9" Whatever , but you're wearing pink just the same1 point

-

1 point

-

Cousins' cheapos are very slippery. I like to use a nitrile glove in left hand when I need one. I might order some other brand next time I'll make an order. I just don't understand the sizing. The Cousins large cots (that are a bit too tight at the collar) are marked as 27mm but Bergeon large is 21mm. A*F large is 29mm. My hand size is more like a medium.1 point

-

1 point

-

In the past, priorities were ruggedness, waterproof and accuracy, turning up 10 minutes late for a mission isn't acceptable when the action has already kicked off.1 point

-

I think it would be easier just to find one. https://www.ebay.co.uk/itm/1758509118701 point

-

I've removed one of those with a cheap three jaw caseback tool, using the widest bits & with a bit of clingfilm over the case first to reduce the chance of scratches. I had to hold the case itself in some slipjoint pipe grips to get enough force on it! (Gripping the case in the strap lug slots with a folded microfiber cloth over the grips first).1 point

-

As @RichardHarris123 said there are unique parts across most calibres so if you multiply the calibres by the manufacturers you've got to be looking at 100s of thousands of different parts. I suppose for people that work on the same movements time and time again then the parts would be identifiable but for the average watch repairer I'd think not.1 point

-

1 point

-

One of the minor problems of mechanical watches including quartz watches is they need to be serviced occasionally and squirting it With oil here and there is not servicing. The purpose the tab in that location is to keep the contact from shorting to the main plate when the battery is in. If you would assure that the battery out the watch would not run at all. Then in the midst of all of this if you managed to scratch the quail you're not going to pick up the impulses because typically these machines pick up the magnetic field off of the coil which would not produce a magnetic field if somebody scratches it for instance. Also if your measuring resistance you want to be very very careful to stay away from the wires which are practically invisible because if you just touch them with your probe you will probably break them that's why it's usually best to measure the coil resistance with the circuit removed C could be farther away from the coil wires Then here is an image of where the model number can be found. Notice even in the image it's hard to see C might have to angle the light correctly to get the right reflection.1 point

-

This was the method I was taught in school and I still do. You do have to make sure you do it three times to get the entire escape wheel.1 point

-

I should mention that if you are nickel plating, I highly recommend copper plating first. It's easier to do than nickel (can be done at room temperature, whereas nickel is best at about 60°C) and most importantly, can create a thick layer to fill defects. This is easily sanded/polished to a good finish. Nickel adheres well to copper. I've just copper plated a case I'm working on which was badly pitted. 20 mins plating and all pitting filled.1 point

-

Enso not all casebacks have an openning notch. The usual method for removing stubborn screwdown casebacks is cyanoacrylate glue, just regular superglue. Thin set fast , thick is slower to cure but has a stronger bond. Glue a 16mm nut onto the back, i clamp it up so it gets a tight hold, it hasn't failed me yet. A word of warning from experience, one of my first attempts removing a back like you are showing ended jn disaster, it was a false screwdown on a lucerne watch, i completely trashed it trying to twist it off lol. Just make sure there is definitely a join between the case and back.1 point

-

Hadn't heard of epoxy, but I've used super glue to open a caseback like that. Superglue a nut to it. Wrench it to loosen. Use acetone to remove the super glue.1 point

-

They do come it handy for a good many things. I've made up quite a few things for watchmaking.1 point

-

I must get a 3d printer and learn how to use one lol. Next big purchase1 point

-

Not tweezers for removing hands unless you have the specific pair, even then........what you need is some good quality hand levers and a piece of shaped paper to slip under the hands to protect the dial.1 point

-

1 point

-

This is a handpiece that attaches to an 'E' type micromotor. It has a 1:5 gear ratio that multiplies the speed of the motor by five times. That is to say that if the micromotor runs at 20 000 rpm, the diamond bur will be spinning at 100 000 rpm. Most newer dental clinics use this type of handpiece instead of the air powered handpiece with that familiar whine.1 point

-

The dies seem nice, but many of the vintage ones I've seen are chipped on the edge. A new set is well beyond my budget.1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

Welcome to this great forum! Based on my own experience, I recommend buying a 3135 clone from AliExpress and practicing with that before working on an original Rolex. The approximately 80 bucks are well-invested. Apart from the free-sprung balance wheel, the construction of the clones is identical.1 point

-

Hi and welcome! Definitely do not open up your Yacht Master until you have worked on many other low value movements. You will probably break a few at least, and lose a lot of parts before you get your legs under you, but it is very fun and rewarding.1 point

-

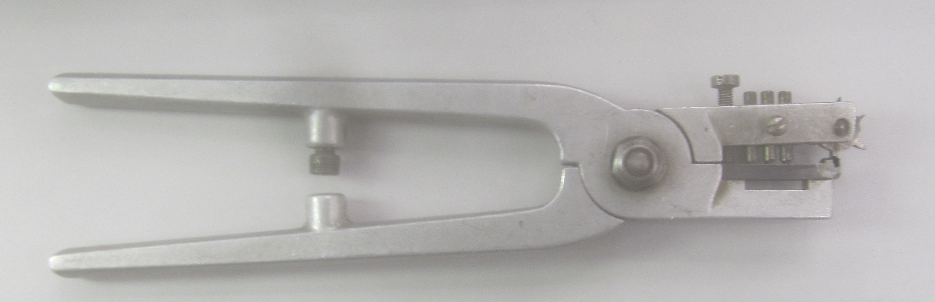

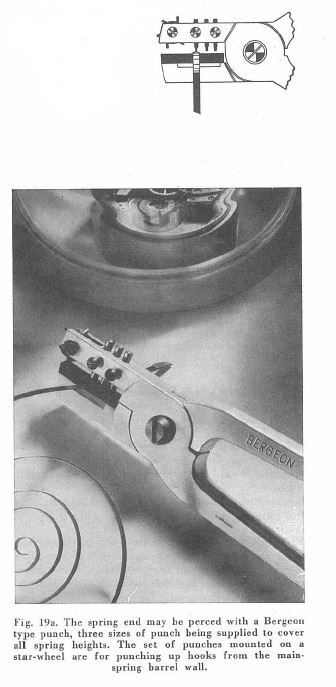

I find sometimes where I work can be really really strange. It was a very strange day with a strange bonus items that showed up? I was asked about the strange pair of pliers? The pliers are now residing in my bench for safekeeping. They looked vaguely familiar wonder where I've seen them before? Yes very strange day. Know the pictures not the best but I can take a different camera and get a better picture if you want to see the star wheel in the front and when I get a chance I think I'll try the thing out and see how it works. Although I'm pretty sure that in order to punish the hole in the mainspring I think the main spring steel has to be softened. For which I used to have a much better way of getting square holes in hardened steel.1 point

-

1 point

-

I think a knife would be a lot harder and a lot more brittle. Have you not got any old generic rotors you could try on?1 point

-

Looking at the case, the crown, the dial and the movement the watch is original for me!1 point

-

Difficult to tell from a few photos but nothing jumps out to me as being a fake. I think between the dial, hands and crown it would be an expensive repair and probably not cost effective. Edit Just though I better point out that the watch is actually a 7069. The 4810/502 is just the movement.1 point

-

https://archive.org/details/20thcenturycatal00purd/page/n5/mode/2up It's an interesting link you can download the book of radio formats. If you figure out the proper search terminology there are other horological books here catalogs and repair books just not a huge quantity of them Then here's a picture of an interesting tool which I'm sure does not exist anymore. It looks like at the end there is the part for putting the hooks in the barrels and then the other part is for punching the mainspring. You will note the word annealed as punching hard Springs well basically hard Springs Cannot be punched and have to be cut.1 point

-

It is black paint. Get yourself a small tin of Humbrol black. I used an old watch oiler the thick one for this task worked a treat. Don't forget to remove the old paint first.1 point

-

I use reverse plating, with stripping solution from http://www.youplate.co.uk/stripping.html It works well, and quite quickly, but you have to keep checking and stop as soon as the plating is removed, to avoid too much pitting. There is then plenty of work to get it prepared for plating. Plating hides nothing - the finish you see on the brass is what you will get when plated.1 point

-

Sounds as if you are doing very well, we all those times of being on our hands and knees looking for a needle in a haystack. You will find a way using your tweezers and screwdrivers which suits you best. It's fine reading books but there is nothing better then getting your hands dirty. What clocks have you worked on?1 point

-

I check alignment of hands at 12, 3, 6 and 9 o’clock just because it seems to make sense to me, ymmv. Tom1 point

-

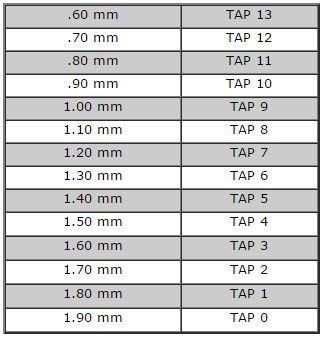

That screwplate appears to be metric. So the sizes listed are the thread size, 20 is 2mm, 13 would be 1.3mm. So you would want to start with 1.3mm as your diameter. But- it might (probably) not cut the thread so much as cut and form the thread by displacing metal. I say that because it looks a little dubious in quality. So try a little smaller and see if you get a good thread form. You can turn a taper from say 1.15 to 1.3, and then thread that, and see where along the taper you get a full thread. Make a note of it for the next time you need to thread that size. The old Martin screwplates had a screwy (haha) numbering system. There were two main designations from Martin, L and B; both seem to have the same thread diameters regarding their numbering, the difference is the pitch of the thread. Martin G plates were for left hand threads. Funnily enough, the "backward" numbering system for watch stems and crowns corresponds to the Martin sizing, I guess it was taken up at a time when Martin screwplates were the primary threading tool for watchmakers. 99% of the time I use industrially made metric taps and dies for threading, but sometimes for an old piece I will use a Martin plate. The threads are a little more rounded on their crests. I find that for a given size I need to turn a little undersize, as mentioned above. With new "real" metric stuff I turn to the nominal diameter.1 point

-

0 points

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)