Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/25/24 in all areas

-

4 points

-

Originally bought as a parts movement, this Vostok 2214 arrived with a chunk missing from its crystal and the dial covered in sand. As I cleared the debris off the dial, I was smitten with its blue-purple sunburst. And since I am all about bringing back the most hopeless basket cases (and since I found the lost part I needed it to donate right under my nose) I went ahead and serviced it. I love how it came out and it runs great. I even took my first stab at re-brushing the caseback with a result no worse than the rusty and pitted dial.3 points

-

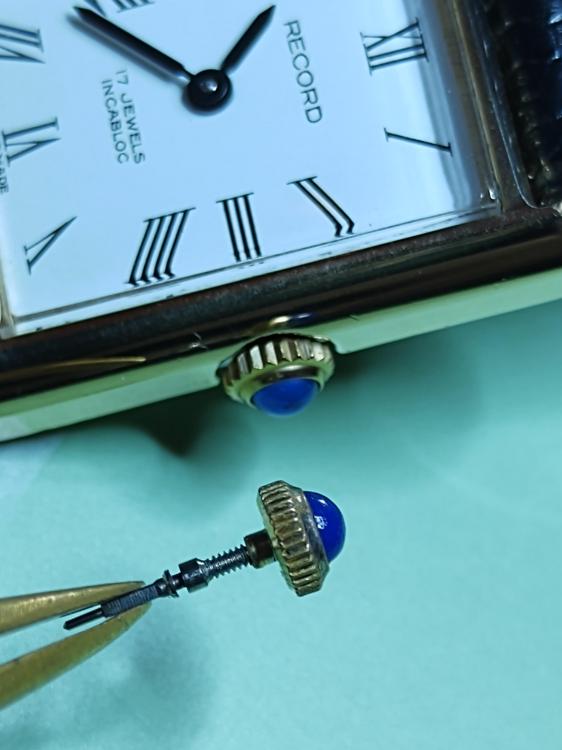

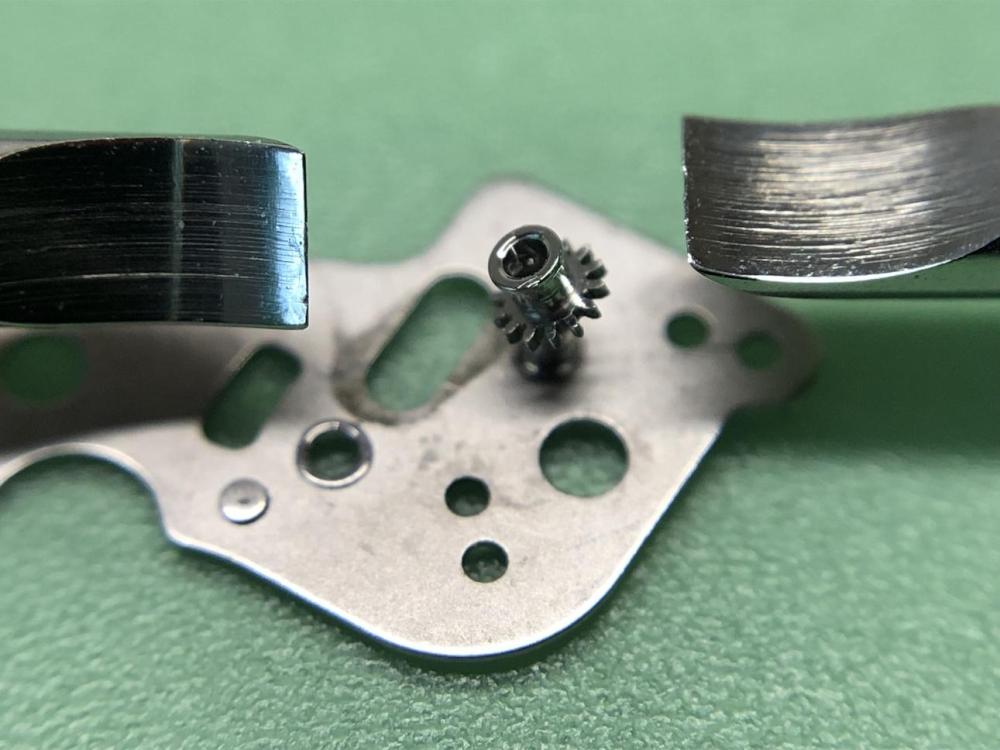

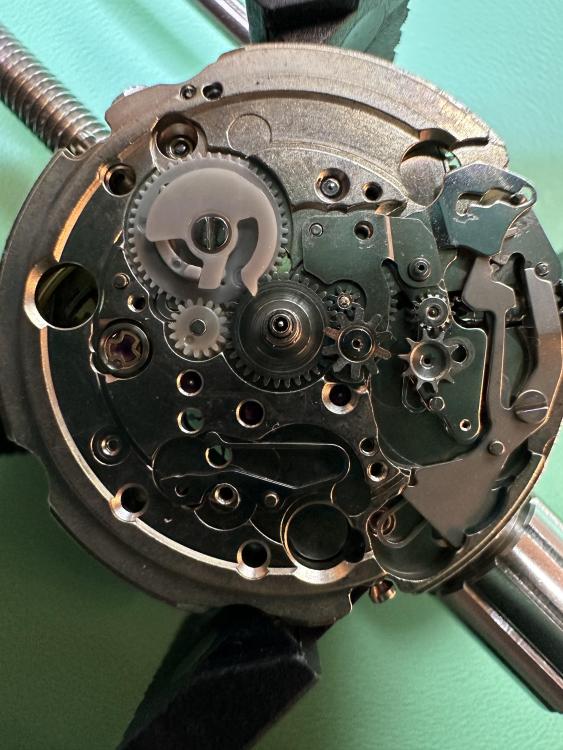

A small update for those who are interested. Last Friday I finished the disassembly and for those of you who are interested, I have added new pictures to the link I published in a previous post (please sort by name in ascending order). It was over 300 pictures. In the long run, I plan to create a service walkthrough and then I will have plenty of pictures to choose from. I was a bit unsure whether I should dismantle this cannon pinion-like part on the "Cover mechanism" because Rolex explicitly writes "Do not dismantle". But, since the whole movement is covered with metal debris, I chose to do it anyway. However, I had some headaches because it did not work with my trusted cannon pinion remover nor with some of my presto tools which were all too big. I tried to pull the tube off by clamping it in my staking set and pushing the tube up with brass tweezers, but that only resulted in the tip of the brass tweezers breaking off (easily dressed) but better than damaging the tube. After looking through a bunch of videos I finally found a video where @Markshows how to do it. Many thanks! The parts are now soaking in a degreaser (Horsolov) and I will brush them all off before it is time for the cleaning machine. Getting everything perfectly clean will be a challenge considering the service neglect and damage made by the loose rotor.2 points

-

The curved washer you refer to is definitely designed to go directly onto the hour wheel - i have it here and it fits nicely under the dial face - which isn't there... However, your idea with a thin washer under the minute hand is great. Only, I have no such washers available. Oh well - 3D-print, an assortment of tiny drills and a bit of patience had me making my own. And it worked. The watch now keeps time as intended and has approximately the look I was aiming for. 3D-printed washers & fitting drills: Washer fitted under minute hand, holding hour wheel down: Result: @mbwatch Thank you for pushing me in the right direction2 points

-

As a newbie myself I understood that doing anything to a dial is a terrible idea (unless it doesn’t really matter if it ends up in the bin and you’re just trying something to learn)2 points

-

2 points

-

1 point

-

1 point

-

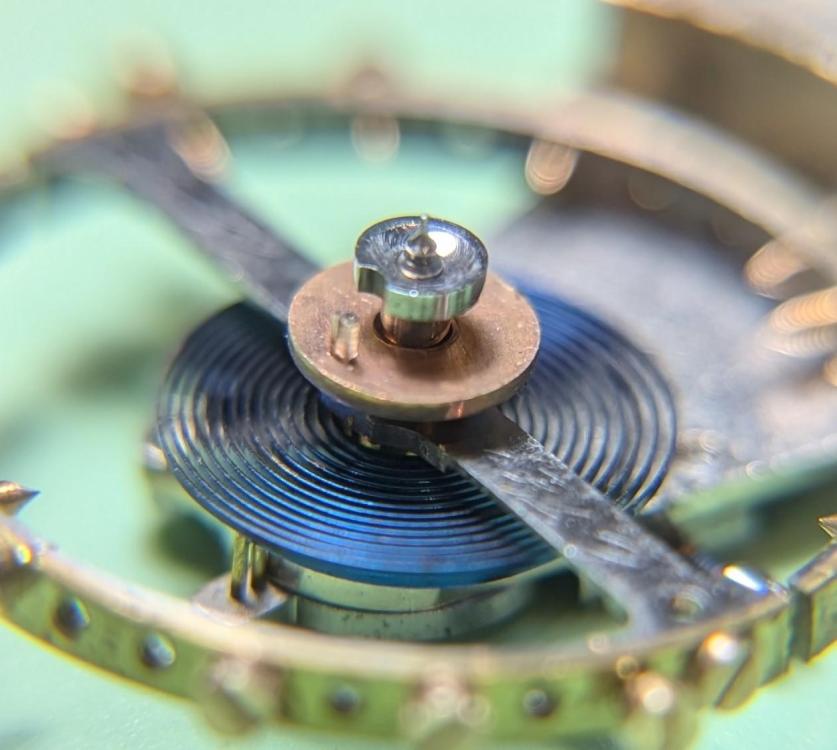

I think it only tells me that I am unable to move the pallet stones by grasping them with tweezers and gently wiggling. On my other old watches where they were not secure, they moved readily out of flat with the fork but I hesitate to push harder. Same for the roller jewel, not movable by wiggle or push. The roller table is copper in color and has the look of a complete part manufactured and meant to be replaced as one. I have also looked over the sale listings and noticed the same, a couple have obvious shellac blobs but most do not. I am leaning toward this being their correct manufactured state, but will still hold out for a yes/no from someone who has worked on a lots of American watches.1 point

-

I was very exited when i saw they do not use plastic movement spacer anymore.1 point

-

You could try supergluing a small torx or pentalobe bit into the screw head, letting it cure fully, then trying to unscrew it? If the screw comes out you can break the bit free and try the same with the others. The last resort is very carefully drill through the head using eg. a 1.2mm or 1.0mm bit in a pin vice. Once the head starts to move, twisting it out. You should be able to remove the rest of the screw after removing the back.1 point

-

1 point

-

I presume you mean stripped the head and not the thread? Have you tried with either a flat blade or a torx bit? Edit You may also have success with the smallest DR from a set like this. https://www.amazon.co.uk/Mesee-Extractor-Damaged-Stripped-Extension/dp/B0D7MHH5KH/ref=sr_1_15?crid=13R0BWWI19IZG&dib=eyJ2IjoiMSJ9.DvAKsAL-pid5egNQxHpMSDme3IPVmI5x8Wf19RtREscDFxRMZSeQ-NkNhXgTnryIUVD4PxgJbe6BWSXSB8BMb42rixEADGRxpl_P52pCaobvyb4CeytnpdtkalxmUe0as5h86TznmCHRvCepxVoERViDJdciYG4ECxAn8ooYVvewg9IxftunMVnO-VTMch3-WdIf7eS0hS6Igtl0Sch4Iw.L095Ig0bZXz7rNMdVagbcvp8kl7m4X21D3CDWmA2GWk&dib_tag=se&keywords=1mm+screw+removed&qid=1724589768&sprefix=1mm+screw+removed%2Caps%2C131&sr=8-151 point

-

In the few ads out there with a pic of the underside of the fork most look like yours but one shows shellac. Other Hamilton models like 912, 956 show stones without it. What does your check of the firmness of your settings tell you?1 point

-

A lot can go wrong with a dial, a lot can go wrong with anything in watch repair, but dial finishes dont like heat or solvents or tool slips and they can be expensive mistakes. Scuse the pun but your technique needs to be dialled in before you start so it would be good to practice on something similar and not important to you beforehand. The times we think to ourselves "why did i start this,why didn't i just leave it alone"1 point

-

Fear interferes with the job in hand. I used to be like this sometimes at work years ago if it looked like i was in for a heavy lift, that fear weakens you. Nowadays i dont even think about it, just roll up my sleeves and power up. My point being and reinforcing what Jon has said, dont let the job get into your head too much, think it through and be confident in the knowing of what you are doing. When you're confident , fear has no place to roam in your head. You'll do it H, you're a skilled watch guy dont let anxiety tell you any different mate.1 point

-

you can buy a bezel removal tool but, these are easy to remove. Use a thin blade such as a pen knife to slowly pry up the bezel. know that you will however need a crystal press to push it back into place.1 point

-

Been a few weeks since anyone posted. Heres 25 candidates for the 10:10 club. 25 watches £203.00. I have a few favourites. The Nivada on my wrist, bit small at 30mm but its a lovely little bumper automatic. The Doxa, cant wait to get to this, the Cyma is a nice size, Citizen Eagle 7, Leonidas GSTP. Mickey Mouse Timex.1 point

-

I've removed one of those with a cheap three jaw caseback tool, using the widest bits & with a bit of clingfilm over the case first to reduce the chance of scratches. I had to hold the case itself in some slipjoint pipe grips to get enough force on it! (Gripping the case in the strap lug slots with a folded microfiber cloth over the grips first).1 point

-

1 point

-

I'm a little confused here as the last number does look like 8? Versus 6? https://ranfft.org/caliber/10349-Unitas-6498 Then usually those other numbers are references to changes in manufacturing. Conceivably in this case it refers to a Caravelle watch that somehow was changed. Or the most common reason the numbers there is for height on the dial side. For instance I have an image showing that there were three sizes but this is from the ETA information and this watch has been around for a long time so there'll always be all sorts of interesting variations. It appears to be the same as what you find on the Bulova watch it's a date code which I believe is 1972 http://cgi.julesborel.com/cgi-bin/matcgi2?ref=CAR_16OA1 point

-

1 point

-

It is black paint. Get yourself a small tin of Humbrol black. I used an old watch oiler the thick one for this task worked a treat. Don't forget to remove the old paint first.1 point

-

The problem with modern springs are there really hard to bend and you have to be extremely careful not to break them. They're basically hardened to the shape they are and they are very resilient to being bent into something else. I'm glad you recognize that is the unfortunate problem of vintage watches where you never quite know what you're going to get. Then even if everything looks perfect well tomorrow might bring another day where you find a problem The good and the bad of your purchase is it's basically a Hamilton a very nice Hamilton. The bad is it's a ball Hamilton and we don't know what they changed if anything? I'm rather surprised the pocketwatch database actually has something? https://pocketwatchdatabase.com/search/result/ball/1B7401 Then the problem with a watch like this would be somebody servicing the watch wouldn't actually understand what they have and they probably shoved in a mainspring that they thought would work and you probably have the wrong mainspring. Which brings up the problem of what exactly is the right mainspring?1 point

-

The case clamps suggest the movement comes out of the front.1 point

-

1 point

-

Did you try remove the casing screw and clamp? Many watches unfortunately design that way,if you remove the screw and clamp,the movement will drop down a little then you can tilt out the casing ring. Also,check the oscillating weight position,not to stuck on the casing ring when you tilt and take it off. And make sure the stem is out too before you try to remove the casing ring. Some casing ring of just have a hole instead the cut out for the stem.1 point

-

1 point

-

Looks fake to me. Also looks like the complete pendant tube has been pulled out with the crown instead of unscrewing it.1 point

-

1 point

-

If I'm understanding you, you said how to fit a new lyre spring. To fit a new incabloc lyre spring, it is in slide 16 of the presentation. press out the Inca setting enough so the 'T' part of the spring can fit in the slot of the Incabloc setting, then press it back into place with a jewelling tool. If you mean how to attach the lyre spring arms over the cap jewel, let me know and I'll post something Many thanks! I use the term 'Goldilocks' a lot in my lessons. And yes, there are always three bears. I call them Peter, Paul and Jill. In watchmaking, especially stuff involving the escapement I tell my students, "If you're going to rob Peter, then Paul is somewhere in the shadows with a baseball bat wanting paying and just when you think you've paid him off, Jill comes out from behind Paul with a flick knife because you fell into the trap of making an assumption. If you're gonna rob Peter, you have to pay Paul, so if you adjust the endshake of the pallet jewel , you have to take into account the height of the guard pin with the safety roller and Jill is the escape wheel hitting the top half to three quarters of the impulse face of the pallet jewel. Peter, Paul and Jill, I love those three!1 point

-

1 point

.thumb.jpg.855ec4d2c6a843b0981b824425517bf8.jpg)