Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 08/30/24 in all areas

-

This is true, but the danger in using a sharpened oiler or a broach to peg jewels is not scratching but chipping. A softer, tougher material can easily cause cracks or chips in a harder, more brittle one. I have learned the hard way and only use an oiler or similar to clear a jewel if nothing else works.3 points

-

I always peg before cleaning. If the jewels are dirty, I do a pre-clean with some naphtha and a paint brush working the bristles in to the jewel hole. I then peg and use the sharpened oiler. Between the Elma cleaner and rinse, and rinse and IPA, I blow the fluid out of the jewel holes. If not, you can get a visible residue left on the jewels. The IPA just evaporates, no need to blow the holes.3 points

-

Right, I have of course seen all the elaborate Breitling aviation watches for example. Nothing like that one though. And I had found and gotten started on that slide rule bezel article yesterday before work interrupted. And since I don't usually post here, today is an instance of an heirloom passing the wrong way up the chain. This Casio was my kid's first watch at age 9, but the strap broke after a few years and he got another one new (cheaper than replacing the strap). I kept it around and eventually did buy a genuine replacement strap & buff out all the deep gouges a child puts into the crystal on one of these. Today I will use it to time his 5k cross-country race.3 points

-

I have very little experience of Rolex - I just serviced one for a friend. It had the same problem as yours - the rotor pivot was broken and the rotor had been dragging across the movement. From what I have read, this seems to be a weakness in some Rolex - weak rotor pivots.2 points

-

2 points

-

@oldhippy You seem to be critical of all things from China My 60W ultrasonic is made in China and does a good job. But there are baked on bits of crud that cleaning machines and ultrasonics do not dislodge. Hence pegging, just to be sure. There's a report somewhere of a test which shows amplitude improvement on movements (cleaned in 'professional' cleaning machines) from pegging various holes. You would be surprised how many things are made in China, but not labelled as such. I just had a look on the back of my new Philips monitor - made in China. As is the Amscope microscope on my desk. Your phone, TV, computer, vacuum, car etc are possibly made in China. If you have any Apple product (not me ) iPhone, iPod, Mac book, it is made in China. I wonder if any Bergeon/Horotec tools are actually made in China?2 points

-

Are you undertaking this task because you don't clean the movements by a watch cleaning machine? If you do have one there is no need to do such a task. If the machine is not performing as it should you need to change the fluid or fluids or there is a problem with the machine. Another thing these cheap ultrasonic baths that you can get from China are crap.2 points

-

The reason the brake spring should be in the 6 O'clock position is because when the pinion turns in an anti-clockwise direction the pinion leaves should be dragging away from the end of the spring. In this orientation there is no chance the spring will catch on the pinion leaves as they turn, especially if the end of the spring is damaged in any way. If the spring was in a 12 O'clock position, which is incorrect, as the pinion leaves turn they are turning into the spring and as I've said if the end of the brake spring is damaged it may catch the pinion leaves and bring the watch to a stop as the spring lodges itself into a pinion leaf. In the 6 O'clock position this could not happen. This type of centre seconds hand, which is known as an 'indirectly driven' sweep second movement, as opposed to a directly driven sweep seconds movement, which has a fourth wheel passing through a hollow centre wheel or like ETA do it, the fourth wheel (which they call the 'seconds wheel'- not confusing at all!... lol) passing through a fixed centre pipe and cannon pinion and driving wheel which is synonymous with ETA design. Anyway, I got away from the point I was trying to make, that most modern watch designs don't tend to use a brake springs, sweep second pinions, or an 'indirect drive' sweep second design. These are old types of movement layouts. The spring that goes underneath the sweep second pinion obviously has a cock that goes over it, as the spring pushes the pinion upwards towards the jewel. The other sort is what you would find on vintage Rolex's and the like, with a brake spring on top of the sweep second pinion, as in the photo of this Rolex 1570 The problem is that because many fettlers have been at these types of watch movements and have fitted the second hand without properly supporting the pinion and brake spring by putting a small slither of mainspring between the the top of the pinion and the underside of the brake spring and then support the lot on a block as you fit the second hand, otherwise the spring will get a nice dent in it where it makes contact with the pinion and that will drastically decrease the amplitude. I would say about half of all brake springs of this type are dented. Always best to try and flatten it back out. The good thing about brake springs are if the amplitude is too high and causing knocking, you can increase the tension of the spring against the pinion to reduce it. In the ideal world, there should be just enough tension to stop 'flutter' or what is known as 'backlash' where the second hand stutters instead of sweeps. There should be no more than about a 10 to 20 degree drop in amplitude when the spring is fitted; the less the better without creating flutter2 points

-

Just my thoughts, but what is best in my head is a pre soak and pegging to save cleaning jar contamination , a plate and a few bridges take a few minutes to peg, if pinion leaves are caked up i may chuck those in as well or they sit in a tin floating in the ultrasonic. Bergeon come thinner than this.2 points

-

The pegwood is slightly absorbent, and deforms to the shape of the hole, wiping away any deposits in, and around the holes. I use pegwood then a sharpened oiler. I imagine the oiler would remove any really crusty bits in the hole, and it's useful for pushing out the bits of pegwood when they break off.2 points

-

Yes, and it has been described as a design flaw by many including @Jon in my thread about the watch. No problem as long as you service it when needed but if not it can lead to some truly bad things. That's exactly what I'm doing.1 point

-

Amazing as usual Jon- thank you for the expanded explanation! I see so many indirectly driven seconds movements and thus this type of spring, though they are usually of the yoke style, like Longines 10L. Most of the springs are bent a bit as you describe- what a great suggestion to avoid it….ty again…1 point

-

we end up with way too many problems even discuss this. For instance the Chinese love the clone stuff and they like the clone their own stuff. So often times a product that will look identical from a variety of sources will be actually different products of all different quality levels. one of the YouTube channels I subscribed to for 3-D printers basically was giving up even reviewing Chinese products. The frustration was at the productivity typically be asked to review may not actually match the final product. Even if it did match the final product of the company tried to have good quality control the products they purchase to go in the printers may or may not have good quality control. but there are some good Chinese products out there at a good price and they do have good quality control. But is also just the opposite out there if you're not careful and really can't tell by visually looking sometimes. another problem of anything hard in they jewel is the possibility of shipping if you do not go straight in. You could conceivably chipped the edge. Or if you're dealing with anything of vintage which has natural stones that tend to be flawed anyway it's not going to take very much to chip or break those. I'm rather curious about this one because the final rinse in our Elma very exotic expensive cleaning machine is isopropyl alcohol specifically recommended by them to rinse off the rinse that wasn't drying. I don't recall seeing anywhere that said we have to? I'm attaching an interesting Omega document from the 50s on cleaning and oiling watches. On PDF page 6 you can find the following image on pegging out. Oiling Omega watches 1957.PDF1 point

-

Peeps, stop giving Chinese design ideas. Sure hate to wear a rechargable ultrasonic underwear?1 point

-

I have seen so many comments not just on this site but on the net that chinese tools are a mindfield, you might get a good one then the next is crap, they don't seem to have inspectors for quality control, if they do they must all be poor sighted or like Stevie Wonder.1 point

-

I agree that on fairly modern stuff that doesn't have decades old dry oil/grease, using a pro machine and pro cleaning solutions, pegging isn't really necessary. Usually. But it really is on old stuff that does have caked up junky oil. I have seen stuff that didn't come off after 2 or even 3 runs through the machine, Greiner ACS 900. Dang thing cost as much (second hand) as a used car. Like mikepilk I preclean with benzine and a brush on stuff that I even suspect a little bit. Peg jewels, push pinions into pithwood soaked in benzine. According to my colleague, who used to work for them, even Rolex prescribes pegging jewels and pithing pinions, preclean, and final cleaning when servicing their stuff. As to the search for an alternative to actual pegwood; regular old pegwood is the choice of pros and manufacturers, and has been for many many years, because it works the best. If you have trouble sharpening it, it could be a poor batch, but more likely not a sharp enough blade. I use the Olfa Black blades in my 9mm cutter knives, they are great.1 point

-

1 point

-

That's exactly how I use it. The syringe tip doesn't give you the control and will end up a mess. I always find that the Sternkreuz sets really hard.1 point

-

With the use of a modern, 40KHz ultrasound cleaner, I don't think jewel holes need to be pegged anymore. I usually only peg brass bushings with a round smooth reamer, with very light pressure and more of a rotating action. My objective is to burnish the brass.1 point

-

That simple circular slide rule bezel is such a neat idea I'm surprised I haven't seen many others. There are aviator style chronographs with bezels for time of flight, and speed/heartrate versions but that simple logarithmic scale slide rule is neat. I feel myself slipping into the rabbit hole of slide rule bezel watches. I wonder if pcbway could fabricate them with sufficient precision, or perhaps I could try printing some decals and .... Your starter down the rabbit hole is here -> https://www.ablogtowatch.com/how-to-use-a-watch-bezel-slide-rule/ ... or here -> "JUVENIA "Arithmo" w/Slide Rule Bezel" - > https://duckduckgo.com/?q=JUVENIA+"Arithmo"+w%2FSlide+Rule+Bezel+&t=newext&atb=v124-1&ia=web1 point

-

Eyup H like most ideas i have tried this, i know Bergeon do broaches small enough to fit inside escapement and balance jewel holes. I wasn't over keen on the idea, pivots can crack jewels we know this, an accident while pegging with a broach might have the same effect. If theres something really hard stuck in a hole i would poke it out with something sharp like this but to regularly peg with steel doesn't sound like a traditional method. Broaches have a cutting edge, smoothing broaches i assume Mark is using , I didn't watch more than a few seconds of the video so depends why exactly he did that. Smoothing broaches have cutting edges, polished pivots riding in jewel holes, though steel on jewel its not the same to me, would it potentially scratch the hole . My cleaning style is eclectic and can be different from day to day, i get bored easily and hate monotonous tasks. I like modern technology cleaning, whizzy , spinney, shakey devices but i also like the personal approach to traditional all manual hand cleaning of a movement, getting in touch with it, I may see something not seen before and learn ffom it. Most cleaning days is a combination of the two, pick from the bones of this anything that gives you . I have a couple of little basic items i like to use and by chance @oldhippy used one of them in his day, i think old tradesmen think alike regardless of the trade ( like old allotment boys come up with simple ingenious ideas and make use of anything and everything ). A small screw top lid ( brilliant ingenuity eh ) in this i put a little paraffin, this stuff shifts dried on oil unlike anything I've used to date, it doesn’t evaporate and wets metal surfaces as quick as Usain Bolt on a track day . The plate and bridges receive generally a 15 minute soak in this after scraping heavy dirt off with a chisel edged pegwood. Then i peg the jewels using pegwood or toothpick soaked again in paraffin, after a quick dry in tissue paper i then rinse off in brake cleaner and blow dry. Really stubborn dirt and its usually unnecessary or if i just feel like it i float the tin or a deeper wider tin in a mini ultrasonic cleaner. The other basic item i like to use is the soaking pegwood holder, it just looks right traditional on my bench, thats just a little glass candlestick holder. I just love tradition and a traditional looking workshop ( note the paraffin and API jugs, this is a cruet set i picked up for a quid at a boot sale, again just an example of how i like an environment to look and feel ) mine does have modern stuff mixed in as well, just not a lot but....just because some equipment makes life that bit easier and quicker. Just finish my special first morning coffee and I'll chuck a couple of pictures up to explain what I'm talking about. Have a great day H and everyone X The floaty tin is more specifically for cleaning balance and hairsprings.1 point

-

Ahhh yes dz, the rubber thing, this is one of the important tools most needed by all watch repair guys, i would get two of these, you never know which watch may require more than one rubber thing ................You'll get used to me...........eventually . Typical dry sarcastic Yorkshire sense of humor1 point

-

As the jewels are harder than the broach, I don't see any problem. I hadn't thought of using broaches, I might start using them on crusty jewels.1 point

-

Soooo many tools to choose from dz, soooo many, did i say that twice ? thats because there's soooo many. Most of mine are old vintage tools, some over 100 years. I like the old stuff, better quality i think than modern gear unless you're paying big money. Take it one step at a time as you progress, buy bit by bit as you need the tools this way if you decide its not for you then you've already cut your losses. I knew from the start i wanted to stay with it so financially I went a bit crazy, then a bit more crazy then just full on crazy , if there's a random obscure tool then i probably have it . Always keep an eye on the bay for old gear bargains. Tom has linked you to the basics, start here, always ask us before any big buys you decide to invest in. There can be a lot you need to know to prevent you from wasting money.1 point

-

@Simeon there’s this video as well to make a regulator pin adjustment tool Tom1 point

-

1 point

-

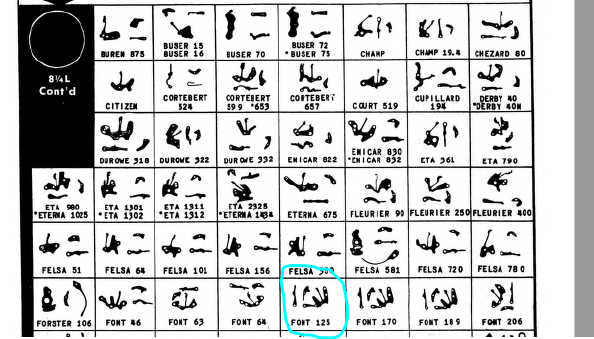

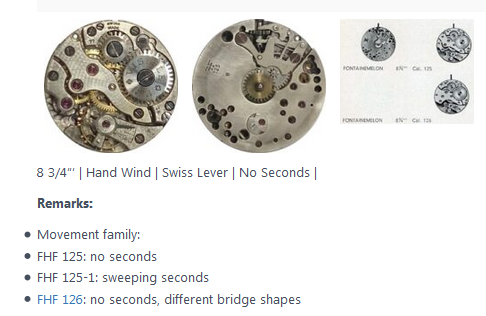

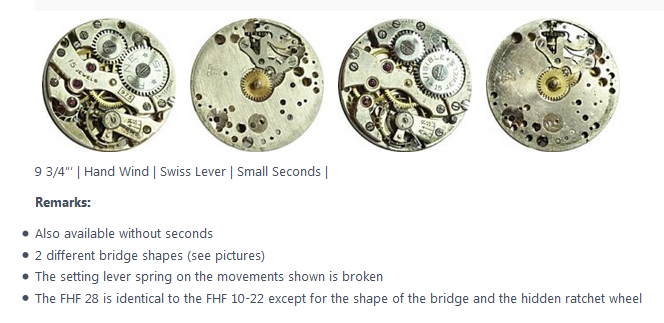

when asking for help for dedication of a movement it's helpful to give us a size that is measured on the dial side and not in millimeters. I'm attaching a chart you need to be in lignes as that's what all the watch references use. so looking at the chart we find that is an odd size which is a problem. but I guess that makes it close to 9 3/4 a starting point. Less things for me to look at. as you're discovering finding a mystery watch can be a bit of a challenge. The Swiss and I don't know if others countries or watch companies did this but the Swiss came up with a interesting system of fingerprinting a watch basically. As the plates can change typically the setting components do not. So have what they basically call a fingerprint system which is why we need a clear picture of setting components. But your one component is unique enough I can work with that. The size is needed because they're listed by size and if we don't have a size it increases how many somebody has to look at or perhaps not look out at all because there's too many to look at or we might miss one because were trying to go through too many then in order for the fingerprint system to work watch has to exist. What I mean by that is whoever made the movement had to make sufficient quantity that parts were available. The somebody took the time to record the setting components for identification for finding parts. The problem with watches there a lot of watches that there is no identification at all and there's no fingerprint system that works because nobody cared about the spare parts at all. then if you have the physical bestfit book the fingerprint system works a lot easier because the setting components will actually fit on top of the pictures. Then a course in the absence of having the physical watch we need a good picture so I've rotated it so it matches what I'm looking at the bestfit book it makes it a lot easier when I'm trying to find something. How and I didn't just look at the bestfit book I looked at several other books and no I can't find it at all. On the other hand I might've been tired and missed it as I was suspicious of the size measurement and had to expand my search considerably. fortunately the one visible setting component is very visually unique which does make looking to the books easy except as I said it doesn't seem to exist? I always find the initials confusing because I'm never sure what maker that is especially when the letter H isn't found in the name of the company at all. Even more confusing when you look at the online listings they use the letters FF. so for instance snipped out the website below you do have FHF except it goes to the same place as fpnt so obviously are not the only person confused. http://cgi.julesborel.com/ now in the absence of me finding really fingerprint parts let's look at the other confusions of this discussion like it was a promising link except? You notice in some of the descriptions they even reference that the plates can be different and that comes about because? Companies they get a custom-made movement for instance can have different plate designs the setting components will be the same but the plates will not this is why comes back to the setting components have to match and that definitely does not. so on the website link we get this image there was your other choice once again setting components wrong and I really wish this website instead of showing just the plates when you go down the list they should show the front and the back as that would make it so much faster. so basically a watch has to have come into existence at a time when people were making up the fingerprint system sometime in the 40s up until perhaps the 70s that this watch is not from the 70s. A lot of newer watches we use the same setting components of the fingerprint system is in a broken and modern watches more useful in vintage but only if it was ever documented now just a reminder sometimes the crown will screw is left-handed and typically is not marked and occasionally the ratchet wheel all the oh I have no idea why so just remember they could be left-handed and you're actually making them tighter rather than looser. Then here's an example out of the bestfit book so you can see what it looks like then struggled something and no that's not what it is setting parts are wrong in one of the vintage books I did find some that were not exactly the same and also unhelpful because it's a brand that doesn't seem to exist at all.1 point

-

Are the pallets upright jewel pins as on a 21j Timex, or still metal while they packed more jewels into the train? I have never seen a bezel like this and now I really want one.1 point

-

@Simeon - I took an 8 cm section of a broken wristwatch mainspring, filed a V-shaped notch in one end, and another slightly-hook-shaped notch in an edge just a bit down from the V. I chuck it in a pin vise and use it to help align pivots on full-plate movements. It's so thin that I can reach around and over obstacles easily with it. Makes setting all the pivots much easier.1 point

-

1 point

-

1 point

-

1 point

-

the image is from a PDF off of their website. conveniently as way saw items were circled because we've had this discussion before. Usually people are looking for the mainspring which is really hard to get because it is a different size and because everyone keeps lumping all the watches under a general category of the original watch when they've been changed to run at the higher frequency plus of course the Chinese have made unknown modifications. On the other hand there still an outstanding watch to start with.1 point

-

1 point

-

Beautiful little river, walked a fair length of it during our stays at thr CClub site, so is the Bradford.1 point

-

Hey guys, My wife and I started our little company in Borneo back in 03. When covid hit and things got crazy, I stumbled down the horological rabbit hole. I fell HARD. Next thing I know, I'm on this forum, modding, assembling, and restoring old watches. The wife, bless her heart, she put her foot down and said I cannot buy or make any more watches for myself. Well, a horological addict is still a addict and I am no quitter. So I figured, why not make some watches for my employees who have been with us for over a decade, they deserve something special. It sure is not for me. So the planning started early this year, scouring the interwebs for parts that will scratch this itch and make my watchmaking dreams come true. It was a tough slog, looking at all those tempting parts, dials, hands, cases and movements. I think I managed to gather all the parts that I needed and with some waiting, elbow grease and much choice swearing, I think I put together what I want to gift my guys and gals. So here's what is wild. I got about 40 of these things to make by the middle of the year. FORTY. Its like I got a whole watch making factory in my actual factory. Wish me luck folks, I am on a watchmaking mission, and nothing is going to stop me. Except maybe the wife, if she finds out how many watches I'm really making. Stephen1 point

-

So the next thing on the list to have the case back engraved. My hand writing sucks, and the wife is definitely not going to allow me to get a fibre laser. So Youtube and this forum to the rescue. Seems like nothing a little vinegar, salt, a trip to the hard ware store and a 9 volt battery cannot fix. Still working on how to get everything coming pretty, but its on its way. The plan is have each employee's name "engraved" on the caseback.1 point

-

It's good practice to peg the hole jewels. As I suggested, most don't bother with the balance hole jewels, unless there looks to be hardened crud on them, or there's a problem with amplitude. The smaller holes are a real hassle to peg. It's hard to get the pegwood sharp enough, then it breaks off in the hole. I use an old sharpened oiler to push the bits out. The holes that are really essential to peg (thanks to info from nickelsilver) are the pallet arbor jewels. As they aren't lubricated, and tiny bits of dirt can kill the amplitude. Even if I don't peg any other jewels, I always try and do these. Happy pegging1 point