Leaderboard

Popular Content

Showing content with the highest reputation on 08/31/24 in Posts

-

Rich, why have I never heard of Flume ! What am I missing, what have you been hiding from me ? (whilst googling for Flume, I found this great document which is like a Swiss version of Bestfit. Follow the second link on this page https://omegaforums.net/threads/download-official-catalogue-of-swiss-watch-repair-parts-1949-1959.88089/ )3 points

-

It was a cal 2230 from a ladies watch. The rotor pivot had snapped off where it's riveted on, so I had to find a replacement. It was very straightforward to service - with online info when I needed it, e.g. on how to properly lubricate the reverser wheels. The only thing I was worried about was regulating. On a small movement fiddling with the balance weights I could break a pivot. I bought a Microstella tool, but in the end didn't need it. It was (and still is) the only watch I've serviced which didn't need any regulating. The timegrapher was flat in all positions. Amazing. Beautifully made, but I still don't want one3 points

-

The hole jewel in the spiral spring drops in, convex side up. Oil the cap jewel (flat side, it needs cleaning in the pic). Set it in place, getting one of the tabs in the recess, with the other lined up with the opening. Press it down, gently, until you can rotate it 90 degrees. The springiness of the ears holds it in place. The hole jewel is quite small, so don't put too much on the cap jewel, which is quite large in comparison. If the cap jewel setting is loose when installed, you might have to flex the tabs up a little bit. The caps are often different movement side and cock side, the hole jewels should be the same.2 points

-

2 points

-

2 points

-

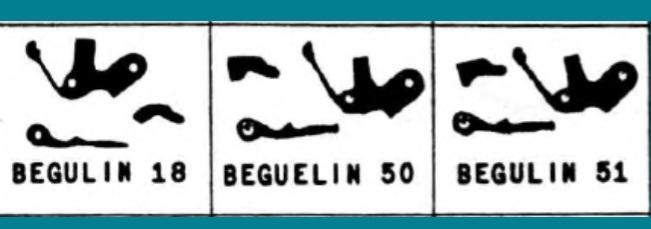

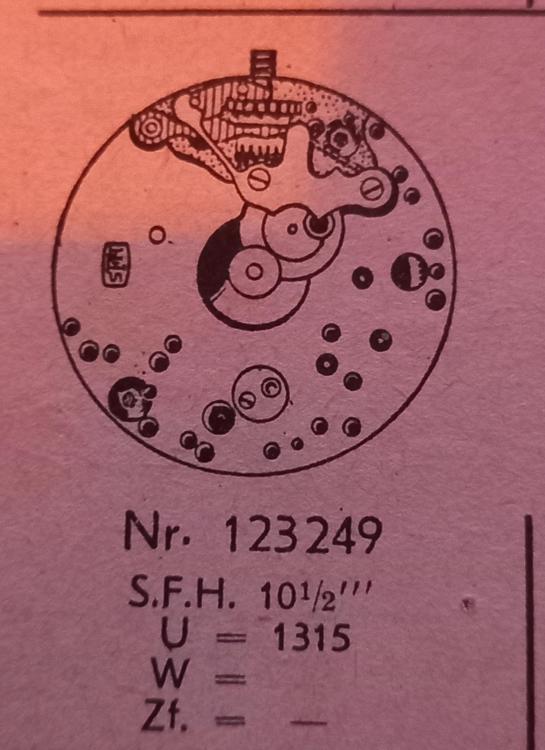

We could have a look at what is suggested so far . Neither are quite there. Looking in the Flume catalog might give more clues Cluedo, who dunnit I like the Flume catalogs, arranged by size and maker but also an added aid of setting levers by hole number. Its also handy to know what the pallet design is if it has one with Flume to narrow the page search down. Cant tell but I will assume stoned, which i may consider to help me focus So 1957 Flume catalog throws a few ideas up, the identification process with Flume is very useful, it cuts down search time, a lot. Clues towards FHF in 3 holes set levers also Cyma and Eberle. Then i see something interesting, the keyless layout is a good match, the set bridge looks the closest so far, the plate size maybe a little bigger than has been given , but that set bridge....... is promising............lets find out who S.F.H is.2 points

-

1 point

-

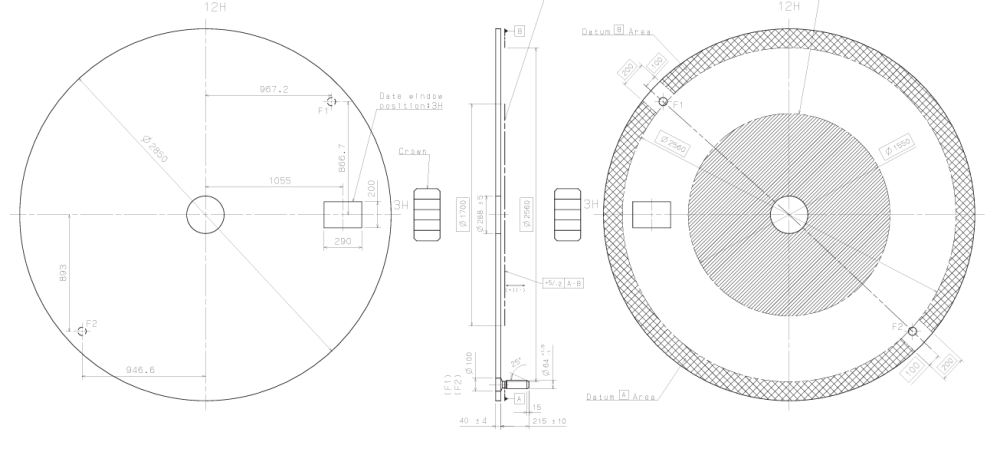

2 reference points on a movement can locate the position of a dial foot hole in the plate if this the fixing method , unfortunately the dial only has one, the hand hole.1 point

-

I agree with @Neverenoughwatches, any other solution I come up with would cost more than a dial or hundred. Tom1 point

-

I dont know how the dial feet are held to a NH34 and without looking but could you temp attach the dial with sticky and mark through the feet mounting holes on the movement ?1 point

-

I tried that, they dont grip the thinness of the spring. Just cut a tight slot in pegwood to set them into or better still the Chinese takeaway skewers are thicker, make better handles. Clear nail varnish holds the springs in place perfectly. Something to note keep the hand lever ones set in close, leaving too much sticking out from the handle gives them excess springy. I left mine a tad too long and one lever acted like a diving board and flicked a practice collet and spring a foot in the air1 point

-

That's interesting use of old mainsprings. I might just make myself a hairspring collet adjusting tool, a couple of hairspring collet removal levers and a regulator pin adjusting tool. Maybe even a pivot locator tool. Just need to make the individual blades and use a couple of old Xacto handles to hold them.1 point

-

This is such a nice model. Timex couldn't make a bad looking watch between 1968 and 1974 if they tried. (they absolutely could in 1975 and beyond though)1 point

-

Found this but still no more details on SFH https://www.ebay.com/itm/2644062642001 point

-

1 point

-

The rivet was broken, I had to replace the completer rotor. Fortunately I found a second hand part.1 point

-

That would be the case with all automatics . Like mentioned earlier because its Rolex folk seem to think the quality is there so it doesn’t need the same amount of maintenance. If you drove a Rolls Royce would you not have it serviced1 point

-

How did you find it to service? What was the movement? They're fine as long as the are lubricated properly and often, but they're not1 point

-

Yes, and it has been described as a design flaw by many including @Jon in my thread about the watch. No problem as long as you service it when needed but if not it can lead to some truly bad things. That's exactly what I'm doing.1 point

-

I agree that on fairly modern stuff that doesn't have decades old dry oil/grease, using a pro machine and pro cleaning solutions, pegging isn't really necessary. Usually. But it really is on old stuff that does have caked up junky oil. I have seen stuff that didn't come off after 2 or even 3 runs through the machine, Greiner ACS 900. Dang thing cost as much (second hand) as a used car. Like mikepilk I preclean with benzine and a brush on stuff that I even suspect a little bit. Peg jewels, push pinions into pithwood soaked in benzine. According to my colleague, who used to work for them, even Rolex prescribes pegging jewels and pithing pinions, preclean, and final cleaning when servicing their stuff. As to the search for an alternative to actual pegwood; regular old pegwood is the choice of pros and manufacturers, and has been for many many years, because it works the best. If you have trouble sharpening it, it could be a poor batch, but more likely not a sharp enough blade. I use the Olfa Black blades in my 9mm cutter knives, they are great.1 point

-

Are you undertaking this task because you don't clean the movements by a watch cleaning machine? If you do have one there is no need to do such a task. If the machine is not performing as it should you need to change the fluid or fluids or there is a problem with the machine. Another thing these cheap ultrasonic baths that you can get from China are crap.1 point

-

The reason the brake spring should be in the 6 O'clock position is because when the pinion turns in an anti-clockwise direction the pinion leaves should be dragging away from the end of the spring. In this orientation there is no chance the spring will catch on the pinion leaves as they turn, especially if the end of the spring is damaged in any way. If the spring was in a 12 O'clock position, which is incorrect, as the pinion leaves turn they are turning into the spring and as I've said if the end of the brake spring is damaged it may catch the pinion leaves and bring the watch to a stop as the spring lodges itself into a pinion leaf. In the 6 O'clock position this could not happen. This type of centre seconds hand, which is known as an 'indirectly driven' sweep second movement, as opposed to a directly driven sweep seconds movement, which has a fourth wheel passing through a hollow centre wheel or like ETA do it, the fourth wheel (which they call the 'seconds wheel'- not confusing at all!... lol) passing through a fixed centre pipe and cannon pinion and driving wheel which is synonymous with ETA design. Anyway, I got away from the point I was trying to make, that most modern watch designs don't tend to use a brake springs, sweep second pinions, or an 'indirect drive' sweep second design. These are old types of movement layouts. The spring that goes underneath the sweep second pinion obviously has a cock that goes over it, as the spring pushes the pinion upwards towards the jewel. The other sort is what you would find on vintage Rolex's and the like, with a brake spring on top of the sweep second pinion, as in the photo of this Rolex 1570 The problem is that because many fettlers have been at these types of watch movements and have fitted the second hand without properly supporting the pinion and brake spring by putting a small slither of mainspring between the the top of the pinion and the underside of the brake spring and then support the lot on a block as you fit the second hand, otherwise the spring will get a nice dent in it where it makes contact with the pinion and that will drastically decrease the amplitude. I would say about half of all brake springs of this type are dented. Always best to try and flatten it back out. The good thing about brake springs are if the amplitude is too high and causing knocking, you can increase the tension of the spring against the pinion to reduce it. In the ideal world, there should be just enough tension to stop 'flutter' or what is known as 'backlash' where the second hand stutters instead of sweeps. There should be no more than about a 10 to 20 degree drop in amplitude when the spring is fitted; the less the better without creating flutter1 point

-

Right, I have of course seen all the elaborate Breitling aviation watches for example. Nothing like that one though. And I had found and gotten started on that slide rule bezel article yesterday before work interrupted. And since I don't usually post here, today is an instance of an heirloom passing the wrong way up the chain. This Casio was my kid's first watch at age 9, but the strap broke after a few years and he got another one new (cheaper than replacing the strap). I kept it around and eventually did buy a genuine replacement strap & buff out all the deep gouges a child puts into the crystal on one of these. Today I will use it to time his 5k cross-country race.1 point

-

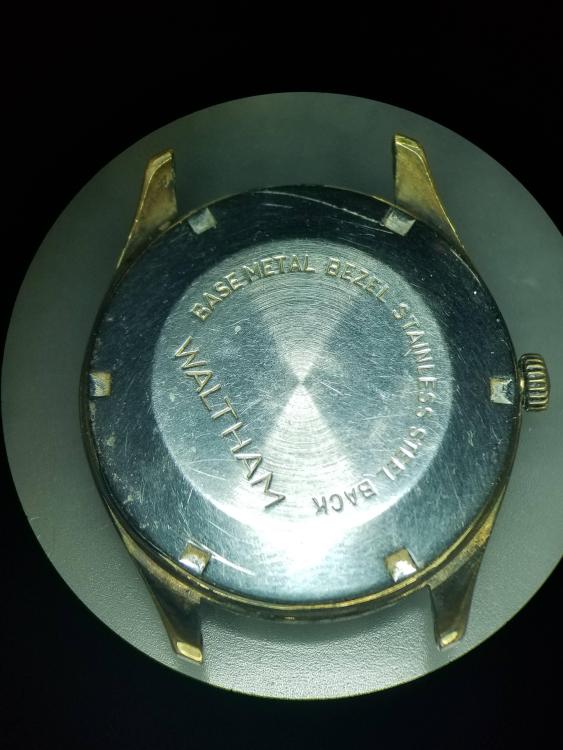

I guess these qualify as 404's. Freebies from a watchmaker friend of mine. I guess he doesn't think that I am busy enough. Waltham automatic with PUW 1463 movement. 17 jewels. It's a runner. I don't know the manufacturer of the "Time is Money" pocket watch. My first experience with a pin set movement. Pallet fork is all metal. A few jewels are evident. Time sets fine. Trying to wind the mainspring has no resistance, so maybe a broken mainspring. Balance seems good. Looks like a mucky mess around the ratchet wheel.1 point

-

I just purchased the 1998 printing of the two book set for $90 from https://www.jewelerssupplies.com/ I prefer to be able to look and browse paper and don't like searching using (usually poor) search functions. Having once upon a time been paid to produce written material I was concerned about violating copyrights by sharing scanned copies but the printed catalogue has no copyright notice anywhere.1 point

-

If you enjoy and find useful the downloadable Bestfits, please consider buying at least the proper download at some point for 10 bucks (reprints are around 90 and honestly worth every penny). If we don't support the supply houses finding parts will only get harder. Same goes for going through the Jules Borel or Cousins databases to get part numbers; I understand as a hobbiest the temptation to find the parts cheaper on Ebay and why not, sometimes, but try to give business to the supply houses when you can.1 point