Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 09/01/24 in all areas

-

4 points

-

I've got one of these tools, which are great for holding crowns for removing and replacing gaskets, as well as drilling out old stems and closing up watch hands. I'll do a little review on the tool in the next day or so. In fact, I've got half a dozen new toys... I mean, tools, so could do some reviews for them. I even got some boxwood tweezers from AliExpress for about a tenner, which are mind-blowingly good for picking up bridges and the like3 points

-

I always take off the cannon pinion from this plate and grease before reassembling, because if you don't, when you try to set the date in quickset at the same time as the hands being near 12 midnight, this cannon pinion won't slip which is the safety feature of this movement. I came across one the other day that had been spot welded together, which takes away the ability for that safety slip. I don't take any notice of some of the crap they put in service manuals, especially telling you what you should and should and shouldn't replace, clean or disassemble. Saying this part shouldn't be parted and greased is madness, for the reason have stated3 points

-

Here is a small update and a few pictures for those who may be interested. Finally, the cleaning is done! It's been a hard and time-consuming job, but a crucial one, as even the smallest residue of metal particles loosened from the rotor could wreak havoc. The next step will be to inspect all parts under my stereo microscope carefully. I already know that one or two pivots need burnishing. Overall, however, it seems that the damage is limited (knock on wood). I'm guessing this is because the watch probably stopped being used when the oscillating weight stopped working. We should all go back to organic watch oils so that no movement is in danger of being destroyed and users are forced to overhaul their precious timepieces! As far as riveting the rotor axle is concerned, I no longer have any qualms (thanks for all the encouragement!), but I will still wait until it is time to assemble the automatic framework. That is until I actually have to do it. Or, it could be that I'll do it when I feel inclined to.3 points

-

Wearing a new-to-me Longines today. It didn't quite qualify for the 404 club, but I picked it up for only $40 US and some change. It was at a local antique store, with a tag describing it as "Not running no crown". I asked to see it, and I held it and did a few turns-of-the-wrist, and the second hand advanced in different positions, so I took it home. The movement was dirty, but in excellent condition otherwise. And I had the perfect crown for it. Thorough cleaning, fresh oil, a bit of regulating, and it runs beautifully. And the Kreisler band is surprisingly comfortable. The movement is a 23ZS with 17 jewels. Nothing spectacular, but just finding a genuine Longines for that price was a feat in itself. And it's looking fairly accurate so far, so I am a happy camper.3 points

-

3 points

-

Me thinks... there is no cap at all, this is one whole part. Yes Rich, what You did is the only solution. The broken part is loose inside and will turn when trying to drill. It is hipoteticly possible to fix the piece with shellac and then drill it, then dissolve the shellac, but what You did is easier and safer.2 points

-

Could be Tom, i haven't seen it labelled as anything in particular, the biggest holes apparently are for holding crowns while drilling out a broken stem. I think Its just a general vice for holding round parts, wheel arbors , balances etc. But no reason why tubes cant be closed up, i usually use a pin vice. Its out matey, pretty sure the only way to get these out is to pull it out or push it out. The indents hold a broken piece as firm as they click onto a center arbor.2 points

-

2 points

-

2 points

-

I have this same watch,cant remember if it has a date function. it runs quite well for what it is.2 points

-

2 points

-

2 points

-

Whel it is a cylindre. First of all, it is not enough to have it running with no stopping, but amplitude should be at least 90 degr to be sure that it runs confidently. After disassembling, put only the balance with both the cocks on the plate and do the free oscillations test. There should be no difference in both horizontal positions and at least 50 oscillations are expected. If this is not so, then pay attention to the pivots and bearings. As this is cylindre, the axial free play of the balance (if it is big) may cause the teeth of the cylindre wheel to go away from the correct trace on the cylindre mouth, so this is one of the important things to check. Lubrication of cylindre is important here to achieve good amplitude. My experience is tat the best results gives very small amount of moebius 8020 grease only on the trace where teeth make contact with the cylindre. It is a lady's watch and they usually wore them as a pendant on their necks.1 point

-

The top section is just the place where the hand goes. No reason to be done separately like a cap. Now I see that the whole axe has been inside. This would make drilling and extracting easier. What I thought was only the upper half is inside...1 point

-

1 point

-

I’m still not sure where the division of the two pieces is but…push: the pinion upside down resting in the hole of a jeweling tool base, pushing on the stuck pivot, or in the staking set hole and a tap with a punch if you can reach the pivot…pull: leaves in a pin vise (don’t crush) plucking the top off the pinion with a removal tool. Those things grip tight!1 point

-

Right you are , on both points you made. About heat, Heat ruins paint, the discolouring might not instantly start , appear, but will in the long run. Dispite being partially color blind, I find the glitter of vintage dials , one of the most attractive of arts mankind has created.1 point

-

A cushion, I don’t know I think I like rubber thing, a better description, maybe a rubber easy button thing I can tell you’re a good bloke1 point

-

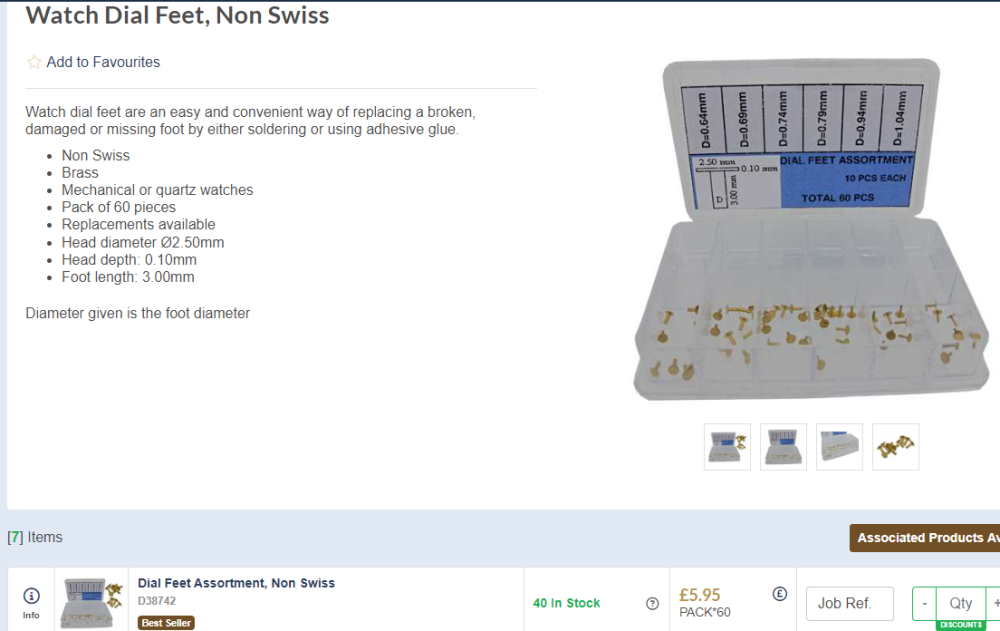

I think leaving the crystal or bezel off will help to line up the dial when the movement is cased, there is a good chance the dial will slip around while casing up is carried out. There is also the thickness of the adhesive to consider, this could easily be thicker than dial feet base depending what is used.1 point

-

1 point

-

Normally the canon pinion cannot rob power or reduce vertical play as it sits on a step of the center staff. Repair: how about drilling a smaller hole into the closed top, push the broken part out, plug and polish the top again? Clamping will be a bit tricky.1 point

-

Alum would attack the whole thing, it is useful in removing steel from nonferrous materials though. The main issue if you try to drill it out is the center post will want to spin with the drill. Though if you hold it rather tightly in the collet it may be ok.1 point

-

It’s hard to tell from the photos where the break is and if there’s a way to get some purchase to split the two pieces. Hairspring cutters? I expect you know but this is an available and relatively inexpensive part… I’ll watch this thread, maybe it will help me with two broken stud screws…1 point

-

Try alum. That is what I used to remove broken screws. Mix it with a little warm water and soak.1 point

-

1 point

-

The length can easily be adjusted. There's always pegwood, if the handles don't work out.1 point

-

There is no way that skinny spring steel can lift a properly tightened collet. If you don't believe me, try it on a 2836 collet that is unsplit.1 point

-

I know this is an old thread but am just working on one of these for first time. Just thought I would share how I removed the minute dial carrier hub (lacking the special Elgin tool). Used a small pair of angled cutters and a fine-tipped stake. Pushed on the center and squeezed the cutters under the hub while pulling up. Took some doing but got the hub off without taking everything below it off. The minute disk already had a couple cracks in the center but not too bad. I don’t think I caused any more. Also, I can see that the only way you want to set this type of jump hour is turning the crown counter-clockwise (toward you). That becomes obvious when you get this far.1 point

-

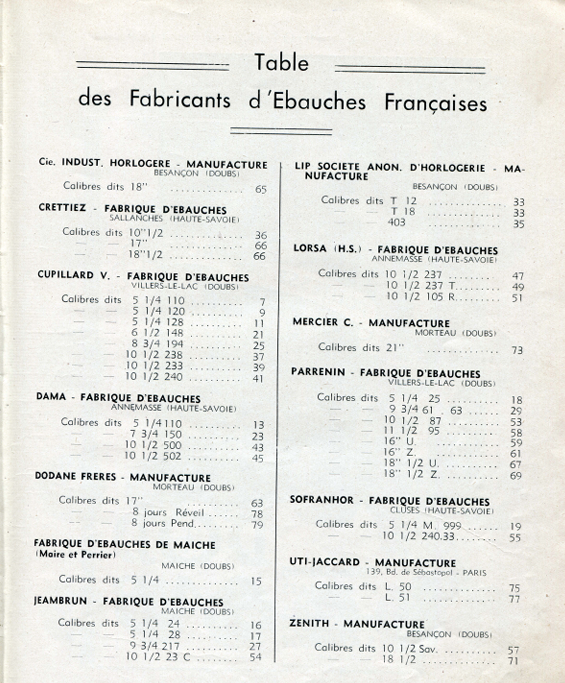

Rich, why have I never heard of Flume ! What am I missing, what have you been hiding from me ? (whilst googling for Flume, I found this great document which is like a Swiss version of Bestfit. Follow the second link on this page https://omegaforums.net/threads/download-official-catalogue-of-swiss-watch-repair-parts-1949-1959.88089/ )1 point

-

1 point

-

It was a cal 2230 from a ladies watch. The rotor pivot had snapped off where it's riveted on, so I had to find a replacement. It was very straightforward to service - with online info when I needed it, e.g. on how to properly lubricate the reverser wheels. The only thing I was worried about was regulating. On a small movement fiddling with the balance weights I could break a pivot. I bought a Microstella tool, but in the end didn't need it. It was (and still is) the only watch I've serviced which didn't need any regulating. The timegrapher was flat in all positions. Amazing. Beautifully made, but I still don't want one1 point

-

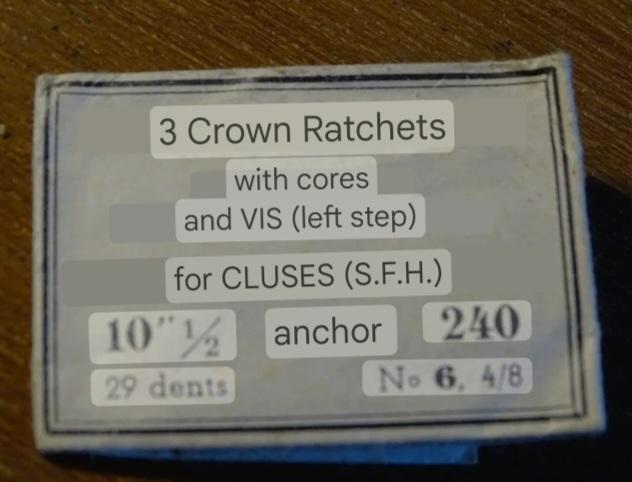

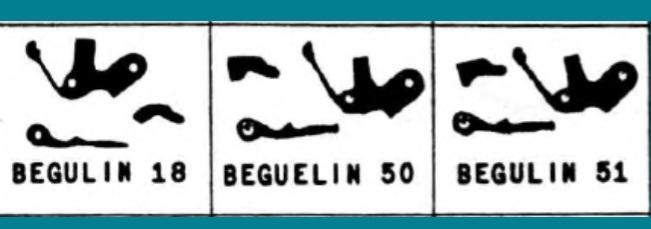

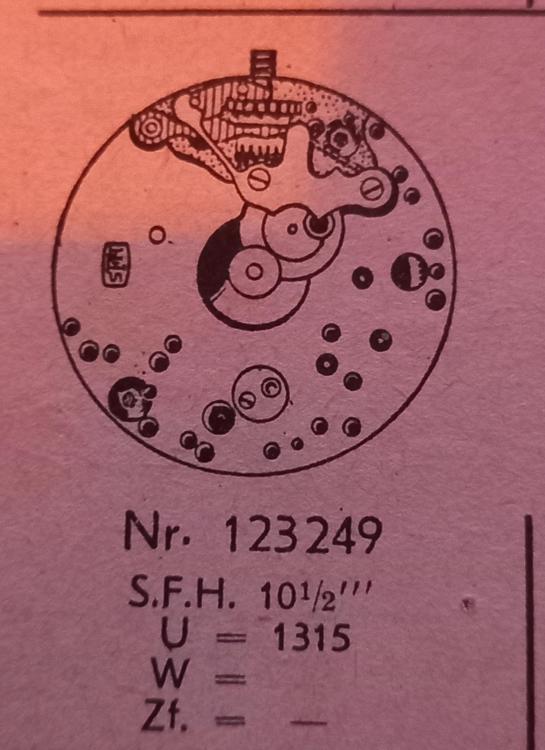

We could have a look at what is suggested so far . Neither are quite there. Looking in the Flume catalog might give more clues Cluedo, who dunnit I like the Flume catalogs, arranged by size and maker but also an added aid of setting levers by hole number. Its also handy to know what the pallet design is if it has one with Flume to narrow the page search down. Cant tell but I will assume stoned, which i may consider to help me focus So 1957 Flume catalog throws a few ideas up, the identification process with Flume is very useful, it cuts down search time, a lot. Clues towards FHF in 3 holes set levers also Cyma and Eberle. Then i see something interesting, the keyless layout is a good match, the set bridge looks the closest so far, the plate size maybe a little bigger than has been given , but that set bridge....... is promising............lets find out who S.F.H is.1 point

-

The main thing is to get the watch in good running order with good amplitude, then the tg reading will be more reliable. If you've already found an obvious fault in the movement then fix that and re-test rather than determine if that fault is causing your tg to play up. Ask for help if you need it when resetting the impulse stone murks.1 point

-

That would be the case with all automatics . Like mentioned earlier because its Rolex folk seem to think the quality is there so it doesn’t need the same amount of maintenance. If you drove a Rolls Royce would you not have it serviced1 point

-

it would suggest more troubleshooting on your part. In other words why is it not running dial-up? That means you get stuck checking the pivot on that end and/or the jewels. usually because the age of these watches and not necessarily known as a stellar quality watch the jewels may be a poor condition. Plus of course classically anything that's vented somebody may have worked on it before you. So I can a watch you have to look at the pivot and everything related to it1 point

-

1 point

-

I understand your hesitation in this process, but you are building it up in your head, I believe. I've done the same with new methods that could prove disastrous, but always find the fear is something my head wants to cling to first and tell me it's all going to go wrong, but the foundation of my experience will be the judge of that. Anyway, failure is usually your best teacher, so if you break the top because you hit the rivet too hard, then that will be invaluable lesson that cost £25 or so. From that you will be able to quantify how hard not to hit the next one. I'm sure you will ace it. What you believe, you become!1 point

-

Could you perhaps tap it and insert a screw to get some grip? The risk in that, is that you could be expanding the broken off piece, wedging it tighter in the cannon pinion. Have you considered closing the open ended cannon pinion with a bit of solder, or is that cheating1 point

-

1 point