Leaderboard

Popular Content

Showing content with the highest reputation on 09/03/24 in all areas

-

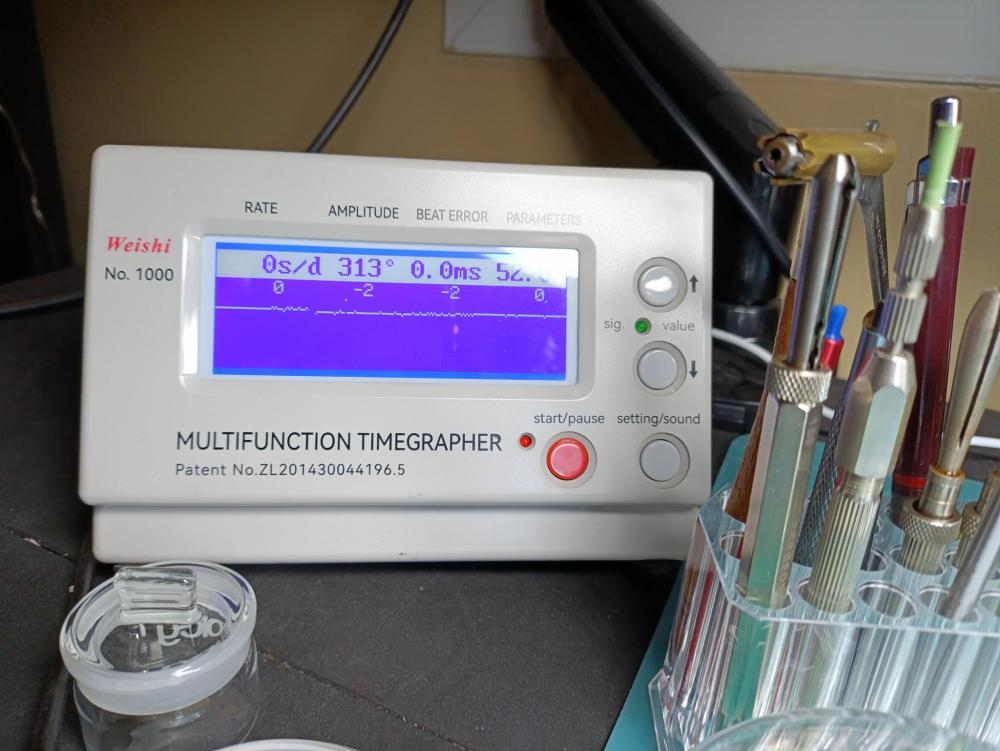

I've had a rough time the past few months, I recently lost my job so lost my mojo in repairing watches for a few weeks, then I had a run of 4 or 5 watches that would just not work, and spare parts lost in the post etc.... anyway long story short, not a great watch repair time. However the watch below has broken my unlucky streak and I'm 'back on the horse' The watch is a Clinton and was won on eBay and was 1 in a lot of 2, so he price is $10.00 US each, so below the £10.10 threshold. It was quite beaten up and non-runner. Here are the before and after pictures: Here is the front of the watch, the crystal was destroyed, and the case dirty and in need of some TLC: Here is the back of the watch, complete with free arm cheese, there were no marks inside the caseback: Here is the movement I needed to replace the stem and crown due to rust, and the crystal (obviously), I also played around with straps, but all the ones I had were either too sporty or too formal, so in the end decided to splash out on a bracelet. I decided not to re-lume the hands as this would have contrasted with the look of the watch and the existing lume was stable (good call? - let me know!): And here is the timegrapher result let me know what you think5 points

-

If there is one tool I love more than any other it is my Jacot tool. We often emphasise the importance of perfect pivot holes, but the truth is we need perfect pivots as well.4 points

-

I am not the one to say if You are crazy, but what You describe is common for the movements with indirect driving of minute hand pinion and 7750 is one of them. The simple explanation is that there is a free play between teeth of wheel that drive the pinion and the pinion leaves (the mesh between wheels) and this free play measured by the hand moving is about 30 sec. This is due to the construction of the movement and is fully normal. To avoid what You describe, set the time finally by moving the hand back, not forward. Wat I mean is if You need to set 12:00, then set to 12:01 and carefully turn back to :00, thus the hand will start moving immediately after pushing the crown in.2 points

-

“Two things are infinite, the universe and human stupidity, and I'm not sure about the universe.” ― Albert Einstein (allegedly). The alarmingly cheap replacement quartz mechanism for the Rotary in this bunch arrived the other day. As I suspected, it is a Chinese clone of the original movement, which meant that not only did I have to replace the movement, but I had to cut and fit the stem that came with the replacement, as it differed markedly from the original. Having said that, it works, came with a free battery, and looks identical once fitted, so all three of this job lot are now working perfectly and looking almost like new.2 points

-

My guess is the excessive uneven weight distribution of the rotor is constantly shifting ( unlike a bearing for a pivot or an arbor ) The bush will be under varying side loads when the rotor turns. Can you tell i dont like automatics . Bumpers yes , rotors no. I love the feel of the bump when you hold the watch in your hand and gently rock it back and forth..........haha that sounded really sexual2 points

-

2 points

-

The pallet stones can easily be resized. Of course, You will need bigger (wider) stone and grit 1000 or so flat surface diamond disk or file. You put the stone on the disk and press on it with finger, then move the finger with the stone forvard-reverse on the surface to grind the stone. 4-5 movements and try if it will fit in the slot. May be it is clear without mention, but never grind the rest surface, grind only the opposite one, which is never in contact with the escape wheel teeth PS Chipped stones (if chipping is small) can be repaired too. Rotating brass flat surface is needed and diamond paste about 10 microns particles. You can easy shape and change the impulse surface angle. The stone gets shorter, but usually it is not a problem2 points

-

Well it worked, because I was sitting here trying to figure out how I could see the carpet through the back of the watch.2 points

-

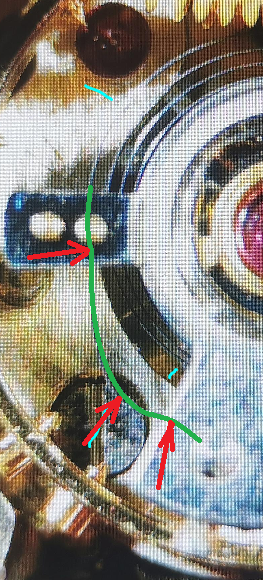

Actually it is only the final curve and it needs attention on 3 places shown with arrows. I would correct all without taking the balance out of the movement, but for newbie it will be easier to remove the balance and to remove the spring from the balance. But my advice is not only to try on practice movements, but start with alarm clock hairsprings. You will need to understand how the hairsprings behaves when manipulated and how to choose the correct place and way of manipulation first and it is easier to start with big springs. Then only move to smaller ones like pocket watches and then wrist.1 point

-

Just for completeness here is the 99p lot ticking away nicely. I could have picked a better time to take the shot as the date is just starting to change on the Rotary. Oddly it takes forever but the number finally clicks into place almost exactly at midnight. I may have a play with this to move it forward a bit, but currently I think it is fine the way it is.1 point

-

This really isn't your best choice they actually make special oils just for allowing screws to be loosened. Conveniently I can never find a picture of the stuff we use at work it comes in a syringe and it's actually for optical use glasses etc. but I find a droplet that on the offending screw and wait a little bit of time and I've never had a problem. So while yes WD-40 is advertised as the universal whatever they do make better penetrating oils specifically for stuck screws.1 point

-

1 point

-

So true. I bought my Bergeon gauges for about £300 to £400 a couple of years back, but I'm glad I did. I've used them a lot. Great to show the taster day students as well.1 point

-

With a very small hammer I have gently hurt the head of the screws, very gently1 point

-

1 point

-

The crown wheel should unscrew opposite to the winding direction. I'd be careful how long you leave it in coke.1 point

-

Remove the balance as is attached to balance cock. Remove the fork, dial and day/date plates. Drop the rest in Coca Cola for a thiry hrs soak. Then all screws including extra small ones, unscrew with incredable ease. Do not wait for the soaked movement to get dry.. Caution: Hold pressure on ratchet wheel with your finger, as ratchet wheel might suddenly get unstuck which can result in breaking ratchet wheels teeth. lol , Let keep it between ourselves if this didn't work. Good luck1 point

-

Hi there. Your 7750 may be experiencing an issue with its friction driving mechanism. Mechanical watches have a connection between the balance and train of wheels on the back of the movement to the motion works on the dial side of the movement, in the form of a pinion or wheel that slips like a clutch when setting the hands, but grabs with friction and should not slip when the watch is running. As that part wears, it may lose sufficient friction and that has the effect of the minute and hour hand losing time even though the watch may be running normally otherwise. Sometimes it is extreme, like losing 15-20 minutes suddenly but it can also be just seconds before the minute hand "catches" and begins to turn. The 7750 has a driving wheel that should supply friction (this part in this disassembly video) and it may need to be replaced or tightened. Do you also notice that it feels easier or a little sloppy to set the time than before, like the hand setting moves too freely? In any case, if you've been using this watch for 10 years it is time to have it serviced by a professional watchmaker. When you take it in, make a note that it seems to lose a little time immediately after setting.1 point

-

Thanks to all for your reply's I have found the way to let down the mainspring , at the bottom right you will see a lever with a vertical pin that needs to be pushed in at the same tme apply pressure to the key thus taking power out of the spring. Thanks to all1 point

-

Heres how a flat coil should look, IN or OUT of the watch, it must be CENTERED,FLAT & LEVEL parralel to the balance rim. https://www.zeitwinkel.ch/detail/the-importance-of-the-hairspring.html Most coils must be studded and often a bend near the stud is necessary to get the end curve in regulator arm's boot-pin . In the picture, John has shown where a fault is in your coil, which must be sorted out ,in addition all above mentioned criteria be met. Good luck.1 point

-

1 point

-

The way we are carrying on at the moment, its more likely that the highly evolved cockroaches will be having this conversation after we have nuked ourselves into the history books.1 point

-

What makes you think I know how to type? True I took touch typing a very long time ago but I don't type at all the most part I use dictation software otherwise well it be very unreadable if I typed it by hand and I just wouldn't do it. But dictation software gets unhappy with me and whale that can be an issue so let me pop up and see what the heck it did okay it's quite simple it just says your practice movements and skip over the garbage in the beginning. In other words take your practice watch and gently pull the hairspring how it's the same place as the real watch and see what happens then see if he can put it back where you found it.1 point

-

1 point

-

Good if you can get a well made one in good condition with all the extras. When they go for cheap they tend to have parts missing or broken, abused beds out of alignment runners. You'll use it one day, i guarantee1 point

-

1 point

-

That is a fantastic deal. They rarely sell under $400 US now1 point

-

Hi! If you plan to work on more old pocket watches, you will end up using it on every project for a variety of tasks. Lots of things need pushing, driving, staff replacing, closing.1 point

-

@Eliminator you will need a decent staking set, most of the Chinese ones are soft and not worth the postage or the pixels on the website. Safe way it too look out for a decent vintage set, plenty of information in the tools section here with lots of good advice. You will also need smoothing broaches. A ball bearing and reamer is most definitely not the way to go. Tom1 point

-

1 point

-

My first foray into the 404 club is an accidental one. My girlfriend's 13 year old daughter picked up this cute little Timex at a thrift store for $1. She'd been wearing it semi-ironically as a fashion statement and I asked if she'd like it to work. "Sure." So I took it home, tried a battery, and it lit right up! So of course I had to clean it up, polish the crystal, and lubricate the stem. Not bad for $1! I made a little video of it functioning: Then while searching for an instruction manual for her, I found this: And this was her response via text:1 point

-

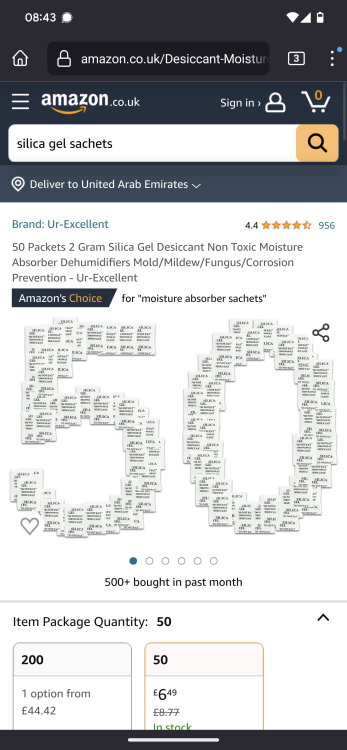

Sometimes it's good to challenge yourself just to see how far you have come. Looks like you will have a high percentage of useable parts that will come in handy some day for sure. When I store parts like this I usually put them in a small sealable bag with a silica gel pad inside. You can get these on Amazon for a matter of pennies each and it's cheap insurance that the parts will be in good condition when you need them, see below. For removing rust (iron oxides) I have found commercial rust remover works well eg evaporust or similar. And for verdigris (copper/brass corrosion product) I have good success with white vinegar from the food isle in the supermarket, you can also use any spare on your chips, but don't get them mixed up I did a study at university on using coke to remove rust and used an electron microscope to see the after effects. The problem is that the acid in the coke attacks the steel indiscrimenently unlike the commercial rust products which are pH neutral and only react with the iron oxide. But I know some people have good success with coke or tea or...? So I don't mean to come off as saying they are wrong, I would just advise that anyone should just try the commercial stuff out and then compare to the coke etc and see what works best for you.1 point

-

1 point

-

That's the 'foil for coupling pinion' associated with the 'coupling wheel'. I've done my best Picasso on your pic to try and indicate where it goes. Place the foil first as the wheel should go on top. Movements from the same family in general have the same base parts ... just additional parts to deal with additional, or different, capabilities. You might find this document useful too: Pforzheimer Uhren-Rohwerke.pdf1 point

-

What better friday night can you have than picking a totaly unfamiliar movement apart while sipping at a nice glas of Barollo wine. Today a new shipment of watches arrived and I got a "Nilax Digital Automatic" among the other treassures. Usually I just throw them into a concrete wall just to see what kind of the effect it does on a seventies watch, maybe a black hole will appear who knows, but tonigt my curiousity took over. Dark thoughts turned up in my mind like, what better combination can one find a Swedish watch with a German movement and probably assembled in Taiwan. So here comes some PDF:s as usuall from me describing my adventure. The first one shows the disassembly and can be found in the link below. PUW1560D Disassembly.pdf Just so you will be prepared, this is how it looked like at arrival... Enjoy and maybe I will post the Part II in anear feature..1 point

-

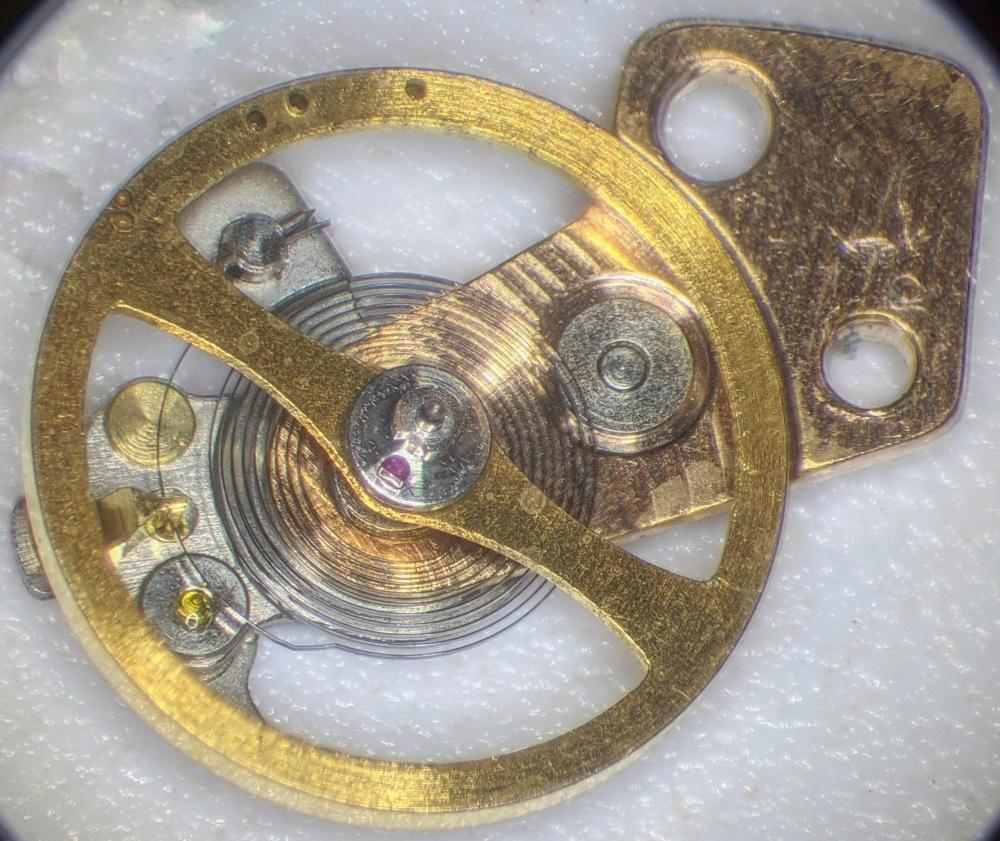

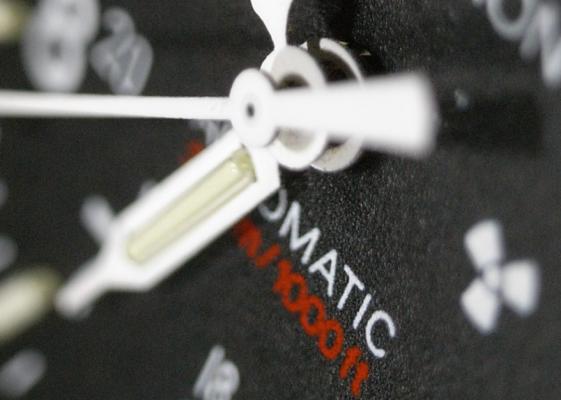

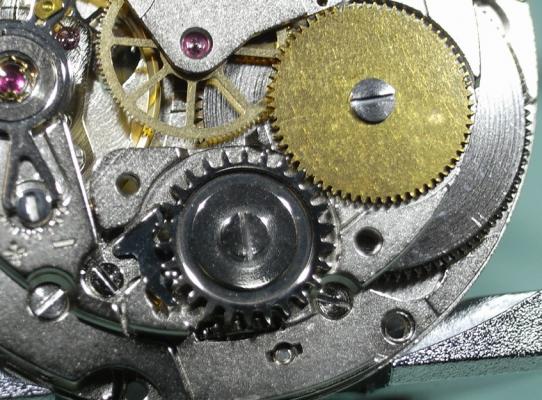

ETA2824 Service - The Radioactive Watch! Yes this watch is Radioactive ... so to speak :P It contains H3 Tritium Tubes to illuminate the dial at night. This watch belongs to my brother, and he has owned it for many years. I have to say that Marathon Watches are great "bang for buck", as this watch has served him well over those years, and he rarely takes it off his wrist. Unfortunately, on one of the rare occasions that he did (to wash his hands after work) he dropped it on the ground, and it stopped dead ... right at his quitting time 3:30pm. He was very angry with himself, and asked if I could found out what damage had been done by the drop, and repair it ... of course I was happy to help my bro :) While he was with me, I pulled the Caseback off and could instantly see the problem. The Hairspring was jammed up and the Balance was seized. I told him there also could be broken pivots, and I'd have to dig further to assess the total damage; but not to panic, as all parts for this movement are readily available (at the moment) ... so he left the watch with me. So I removed the movement from the case, pulled the Hands, and the Dial off to inspect the Calendar Works ... everything looked good. Next I removed the Oscillating Weight, and checked that the bearing hadn't been damaged by the impact ... it was fine too. Next I pulled the Automatic Work off the movement, so I could gain access to the main body of the watch. Here's a reference photo of the Automatic Work for ya Next I undid the screw of the Balance Cock and began to gently lift it ... and hey presto, and Hairspring dropped back into place, and the movement started tickin away ... these are a solid movement indeed! I carefully watched the movement ticking away, noting to see that the Pallet was working properly, and that the Train Gears ran smoothly ... all seemed fine, and the problem with this movement was resolved. I could have just stopped there, but this movement hadn't seen a service in over 8 years, and was already out of the case and 1/4 stripped, so I deiced to burn the midnight oil and do a complete service on the watch. And yes, that is a real radiation dosimeter, as I wanted to be sure nothing from those glass vials had leaked into the movement I was handling ... I'm glad to say it was clean B) Continuing with the strip down. All mainspring tension was removed from the unit. Notice with this movement too, that the click is on the Crown Wheel; instead of the Ratchet Wheel. Balance and Pallet was removed Crown Wheel, Ratchet Wheel and Barrel Bridge was removed. This is a reference photo of the Click Spring sitting on the Barrel Bridge. Under the Barrel Bridge there is a small Balance Hack to be removed as well. Next I flipped the movement and removed the Calendar Work. Then the Keyless Work Back the to other side and Train Gear was removed. Here is a reference of the Gear Train. Lastly the Automatic Work was stripped. Back from a bath, and all parts clean and ready for inspection and assembly. All pivots where intact and unburred, no damaged teeth or pallet stones, and no wrapped gears ... GOOD NEWS!! Ready to be put back together! :woohoo-jumping-smiley-emoticon: Nice clean and shiny Gear Train, Train Bridge and Barrel back in place and oiled Back on with the Barrel Bridge, Ratchet Wheel, Crown Wheel and Click Keyless Work clean, oiled and working smooooooth Automatic Work back together as well The rest of the re-assembly wasn't photographed ... sorry guys, it was VERY late, or should I say EARLY, in the wee hours of the morning, and I just got carried away with the build :huh: But it all went smoothly and as per the reference photos early. After the Dial was attached, the hands where next. Let me tell ya, these are NOT easy to fit correctly! With those glass tubes of H3, there is NO room for error fitting them. You literally have a couple of thousands of an inch to play with ... here's the photos to scare ya :o. This type of watch will really test your hand setting abilities. Here's she is all back in the case with the Automatic Work and Oscillating Weight fitted, purring like a kitten! Job Complete!! And as you can see, it now is showing my quittin time of 4:11am OUCH!! :hot: Hope you enjoyed this post as much as I enjoyed working on this movement. It was really nice to finally work on a watch that hasn't been molested, with nice clean screwheads, and no rust to deal with.1 point