Leaderboard

Popular Content

Showing content with the highest reputation on 09/04/24 in all areas

-

My Type B flieger which is an aliexpress case & generic dial over a gorgeous hammered finish Swiss Unitas 6487 rescued from a silly looking 1970s Arnex pocket watch that had a pastoral farming scene on the dial. The 6498 was in basically new condition. I want to upgrade it with nicer crown & ratchet wheels though, and need to find a shorter sub seconds hand. This is at the extreme of what my bony wrist can manage, made worse by phone camera perspective tricks.4 points

-

2 points

-

Whilst searching for replacement oils for Rolex lubricants I stumbled across a post by @JohnR725 where he linked to a copy of the AWCI publication that I had not seen before (the August 2012 issue). An interesting article describes Rolex lubricants by comparing their properties with those of Moebius equivalent lubricants. If you don't want to read the article, here is what I came up with (which I take no responsibility for): Rolex MR4 -> Moebius 9501 or Moebius 9504 Rolex LR2 -> Moebius 9415 Rolex TEPA -> Klüber P125 or Moebius Glissalube A 8213 (Brass barrel) I haven't found an alternative for Moebius 9103 (HP-1000) recommended by Rolex calibre 3135. Perhaps HP-1300 would do, or what do you think? Anyway, the reason I am writing this post is that in the process I found another 37 copies of AWCI's publication from January 2010 to January 2013. I have saved all of these on my OneDrive and you can find the link in the first post in this thread. Have fun!2 points

-

As @nickelsilverhas said, eplilame, which is an oleophobic agent (repels oil), is used on Rolex reversing wheels, but they are a totally different kettle of fish to other reversing wheels that you would find in an ETA movement. With the normal type of reversing wheels, such as ETA ones, you would dip the reversing wheel(s) in a small pot of Lubeta V105 and sit for one minute, then remove and blow off any excess solvent and leave under a cover for 15 to 20 minutes until all the solvent had evaporated leaving a dry coating of lubricant. Don't put the reversing wheels on plastic when drying! So, not in a parts tray. With the Lubeta you removed the wheels from, suck back up with a pipette and back in your jar. You can mix 9010 with a non residue solvent to produce the same thing really, but why go through that ball ache. You can also lubricate the protrusion X2 inside the reversing wheel with 90102 points

-

I also thought it seemed high but yes Andy visually to 180° with marks on the balance wheel and the plate and then adjust the tg LA to meet the same 180° amplitude that i concluded visually. If the balance wheel has 2 spokes this makes marking up easier. This is at rest obviously and check to see that the impulse and fork are lined through so the movement does need to be in beat. I choose one of the spokes as a register then place a dot of ink ( fluorescent would be lovely ) on the rim at spoke center ( i find the bottom edge of the rim works best sometimes depending on where the spokes are positioned in relation to the plate or a bridge. At the opposite spoke ( 180° ) i then mark whatever is next to it , be it a bridge or the plate ( you choose which spoke works best for marking up ). All that remains is to slowly wind up and watch the two mark reach alignment, its kinda fun seeing the approach take place, fluorescent ink and uv light . When the marks get close winding up needs just a click at a time and with time to settle between each click so this part shouldn't be rushed, its easy to overshoot if you lose concentration then you either have ho start over or just guess it. I'm sure you know all this Andy so no offence i just thought anyone else beginner wise reading can pick the bones of the idea and make use of it. Now if someone has an Oris 291 in running order check its lift angle for me2 points

-

There are a few people that have static in there body all the time. I'm not saying this will put it right for all but a small round plaster stuck on the back of the watch, so between you and the watch no direct contact sometimes works. So give it a go and let us know.2 points

-

2 points

-

I doubt that's rust as the main plate is unlikely to be steel or any other ferrous alloy, it's most likely plated brass. Unless something else has been deposited onto the surface it looks to me like the cleaner has started to strip the plating off the brass. How long did you leave it in the cleaner, and at what temperature?2 points

-

Hey Craig, welcome aboard. Our timex Cheif is @JerseyMo , your watch will feel well as soon as Jersey finds you. Glad to have you with us , pal.2 points

-

I am not the one to say if You are crazy, but what You describe is common for the movements with indirect driving of minute hand pinion and 7750 is one of them. The simple explanation is that there is a free play between teeth of wheel that drive the pinion and the pinion leaves (the mesh between wheels) and this free play measured by the hand moving is about 30 sec. This is due to the construction of the movement and is fully normal. To avoid what You describe, set the time finally by moving the hand back, not forward. Wat I mean is if You need to set 12:00, then set to 12:01 and carefully turn back to :00, thus the hand will start moving immediately after pushing the crown in.2 points

-

2 points

-

This really isn't your best choice they actually make special oils just for allowing screws to be loosened. Conveniently I can never find a picture of the stuff we use at work it comes in a syringe and it's actually for optical use glasses etc. but I find a droplet that on the offending screw and wait a little bit of time and I've never had a problem. So while yes WD-40 is advertised as the universal whatever they do make better penetrating oils specifically for stuck screws.2 points

-

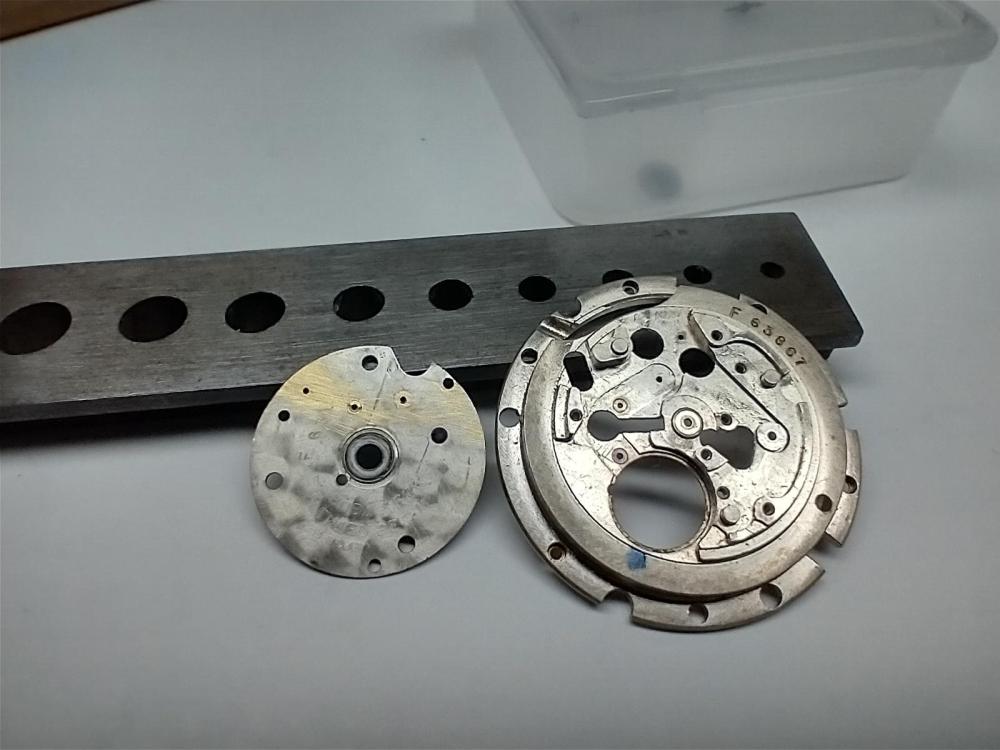

Spot on! The hole in the rotor is stepped and very thin, so the bush would have very little material of the rotor to grip against, add that problem to the extreme force put upon that area and there's a recipe for a disaster right there. It's worth a punt, even if it's just to rule it out in the future. I've fitted two bushes in an upper auto bridge on a Rolex 645 that was not much thicker, but as mentioned, there are difference in forces with a spinning arbor. You can see by the photo someone had previously bodged a couple in and filed not just the bush but a large proportion of the bridge.... Genius!2 points

-

2 points

-

Iv done a 2824.... so I may just Anyone got a nice walkthrough?1 point

-

1 point

-

You can do it! Just get into it! Watch repairing is an amazing hobby!1 point

-

1 point

-

Check the balance tips for wear and balance cups. The tips need to be as sharp as a new pencil.1 point

-

It is funny, but if one works with loupe on one eye, then the other eye is not used. So yes I can, thow i have noticed that I don't close the other eye, just information that comes from it is ignored by the brain.1 point

-

Oops, I wasn't aware of this. I assume it's a solvent? I didn't see this in any small print1 point

-

Why are you losing the stones RIch? I haven't lost one for quite a while (tempting fate). I don't put them in the ultrasonic baskets any more - too hard to find them! I use an old contact lens case, so I can keep the top and bottom jewels separate. A drop of cleaning solution and a minute floating in the ultrasonic, rinse in IPA and done. Yes, they do shine nicely under UV. The last one that pinged off, I found with a UV torch.1 point

-

1 point

-

It's specifically used on certain Rolex reversers, where they need lubrication in certain areas, but if it makes it to other areas, they don't work correctly. For everything else, you wouldn't use epilame, but you would want to use Lubetta V105.1 point

-

I'm one of those. I have an extremely low skin resistance and at those funfair strength testers where you grip two metal rods to test your "strength", all I have to do is lay one finger on each rod and the meter goes off the scale, the lights and alarms all go off. I recently changed a new pair of sneakers and the insulation must be really good because I store up a charge very quickly and touching anything that is grounded will give me a slight tingle. And this is in Singapore, where it's so humid that static electricity hardly ever builds up. But coming back to the watch, I don't think static electricity can affect the electronics as the metal watch case acts as a shield. The possible explanations I can think of for the puzzling problem is 1) Temperature - it could be your body heat is causing a bad solder joint or contact point open the circuit. You test this by heating up your watch in an oven or with a hairdryer. 2) Movement - it could be a loose contact that opens when jarred around. 3) Gravity - it could be a loose contact that comes open when the watch is no flat on its back.1 point

-

I've heard about this before, I dont think it was static related though, something else going on in the body. I was permanently static charged as a kid, my dad constantly getting me in a headlock and rubbing his knuckles on my head .1 point

-

Hi and welcome to the WRT forum. We all are Mr STATIC, Oops I sure hope your students don't read this . lol As we walk specially if one drags his foot on the ground/ carpet..... etc . We collect static electricity in the capacitor our body is, as our body contains many elements which charge no $ fee to host charged electrons. Rgds1 point

-

Some old movement parts started out with thin plating, and may have been through a number of servicings, potentially losing a bit each time. I've seen many that have lost part or close to all of the plating.1 point

-

1 point

-

@mbwatch Excellent job, and also a very nice case. I have a couple of pocket watch mechanisms that might fit in a similar exhibition case, I'll need to take a trawl round AliExpress and see if I can find something suitable.1 point

-

Something that i started doing some time ago was preempting a loss and measuring the capstone before working on it. The diameter you can grab from the chaton but get the thickness wrote down just in case.1 point

-

That patch up looks as though it would have more stability than a bush , its frictioned to a lot more material . Its the uneven weight that gives them the ability to turn with movement ofvtge watch. That's why i like the bumper automatics. I dont know enough to know of there cons yet but the Nivada one i picked up the other day is 80 years old and has no wear in the auto works,1 point

-

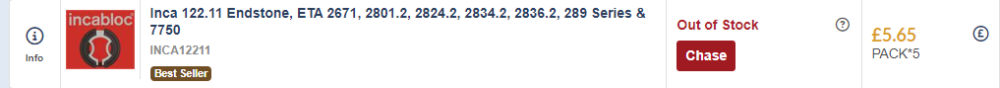

From Cousins site you can download Pdf's for Incabloc. Looking in the ETA document The cap jewels (Pierre de c. pivot) are the same upper (dessus) and lower (desous) 122.11 https://www.cousinsuk.com/product/inca-end-stones Unfortunately out of stock, but they usually restock pretty quickly. These are common parts, so worth having a few in stock.1 point

-

1 point

-

Hey, Jens Don't listen to these guys Jens, they even break watches they haven't attacked. lol Welcome to the WRT forum pal.1 point

-

50w should be good for watch work Andy. It will cut a lot of the thin sheet material we would want to do for watchmaking, you do have to think about though the farther away from the centre of the galvo head the more of an angle the cut will be also a sheet material vice is required to minimise warping of the material from heat. Lots of folk in the modding community use 50w to make and engrave dials. These often come with a 110 and 220 mm lenses, I would look at a 70mm too for the small scales you would want to work to and would give finer detail. One thought I have had is it would be an interesting experiment to try rust removal using a fibre laser at low power and high frequency. Have a look at the YouTube channel laser everything and their website, it’s not watch related but loads of laser resources and information. Tom1 point

-

Nev, I can sort it out with one eye shut . Can you ? lol1 point

-

1 point

-

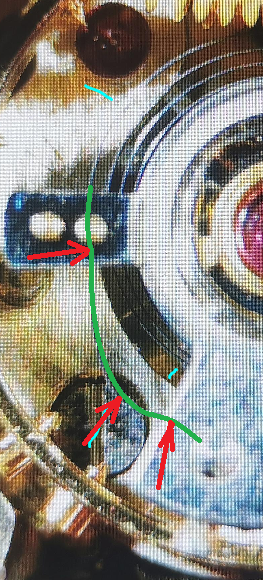

Actually it is only the final curve and it needs attention on 3 places shown with arrows. I would correct all without taking the balance out of the movement, but for newbie it will be easier to remove the balance and to remove the spring from the balance. But my advice is not only to try on practice movements, but start with alarm clock hairsprings. You will need to understand how the hairsprings behaves when manipulated and how to choose the correct place and way of manipulation first and it is easier to start with big springs. Then only move to smaller ones like pocket watches and then wrist.1 point

-

One really wonderful use of a fiber laser is putting holes in mainsprings. Like if you need a square hole of fiber laser has no problem. Or one time I needed a round washer with a square hole and I asked nicely at work and one was made for me. Out of curiosity which fiber lasers are you looking at?1 point

-

What's the thickness of the rotor material? The reason I ask is that I've been looking at Fibre Lasers and just trying to decide what other applications it could be used for as to what power to get.1 point

-

So true. I bought my Bergeon gauges for about £300 to £400 a couple of years back, but I'm glad I did. I've used them a lot. Great to show the taster day students as well.1 point

-

I don't know, guess its in one those holes , usually near the stem . If OP blindly pushes a tool in THE RIGHT HOLE , he might push on the WRONG PART INSIDE RIGHT HOLE and ruin his watch, he needs to see what he is to push on. A must, is; High magnification and good lighting.1 point

-

I have discovered , that with good lighting and high magnification, one can actually spot where the stem release button is hidden.1 point

-

Good if you can get a well made one in good condition with all the extras. When they go for cheap they tend to have parts missing or broken, abused beds out of alignment runners. You'll use it one day, i guarantee1 point

-

You'll need to insert a thin lever to release the clips as shown in the video around 5 minutes.1 point

-

Ah…now it makes sense. Thank you all…I’m grateful two piece cannon pinions just became more rare …1 point

-

Wearing a new-to-me Longines today. It didn't quite qualify for the 404 club, but I picked it up for only $40 US and some change. It was at a local antique store, with a tag describing it as "Not running no crown". I asked to see it, and I held it and did a few turns-of-the-wrist, and the second hand advanced in different positions, so I took it home. The movement was dirty, but in excellent condition otherwise. And I had the perfect crown for it. Thorough cleaning, fresh oil, a bit of regulating, and it runs beautifully. And the Kreisler band is surprisingly comfortable. The movement is a 23ZS with 17 jewels. Nothing spectacular, but just finding a genuine Longines for that price was a feat in itself. And it's looking fairly accurate so far, so I am a happy camper.1 point

-

if you look carefully at the eta 2804 document one of the reasons they may not surface treat the Canon pinion assembly is that they're basically lubricating everything with HP oil. The center wheel jewel is lubricated the friction points of their center wheel and the shaft itself it goes on. we also get problems of how occurred is the tech sheet and seeing as how Swatch group typically doesn't like us do not going to update the tech sheets on the eta website you'll have to have access the newer documentation. what you might be seeing on the escapement lubrication is originally if you have an old enough document I believe it's 9010 for the pallet stones. Later on it was 941 then they came out with the 9415 supposedly for higher frequency watches only. Then Debbie documentation that was either or and now it's just the grease. But maybe it's because all the watches are higher frequency now or they know watchmakers are cheap and are only going to use one lubricant anyway. I snipped out to images from two separate Omega documents which shows you that they're not entirely truthful? The old one in black and white although thanks to Acrobat screwing up its black and yellow light yellow notice what they surface treated in the 50s? Then the other image is from 2019 notice the before and after so before and unfortunately this is a coaxial escapement example that's why there is that weird escape wheel slid treating the pallet fork and escape wheel in the early example. Then currently they treating just about everything except the balance wheel and the bridge and some other mystery components. Yes the Omega or Swatch group service center the final rinse of I think it's a separate machine is filled with this stuff and they go through it by the gallons huge quantities they use. It's because they feel that with the newer cleaning methods though remove the surface treatment that the factory put on so there replacing it. But you do get a discrepancy from the 50s look at all the stuff they're treating then later on they say all look we just treating a few things and now they're back to treating everything again. But in real life the factory service treats way more things than your aware of. Notice the reference to surface treating the balance pivots that's to keep the oil from running down the pivots. If you look carefully at the eta manufacturing guide for watch it will tell you that the balance staff the entire thing was surface treated just because it's easier to treat the entire staff than just the pivots. But notice in the technical sheets there is no mention at all of surface treating those pivots? Minor discrepancies in technical documentation.1 point