Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 09/07/24 in Posts

-

Hey, thanks for your kind words guys! Yes, @Mark's fault-finding course is excellent. It gives you a solid idea about how to go about it and many practical hands-on tips. I've said it before and I'll say it again, watchfix.com is in my opinion the best bang for the buck online course. I'm slowly working myself through the chronograph course now and so far I've only finished the chapter about what parts the chronograph complication consists of and how they work and interact. It's a lot more complex than I had imagined. I'm not the sharpest tool in the shed but Mark makes it crystal clear. It's world-class. No, I'm not in cahoots with Mark in any way! Another tidbit is Kalle Slaap's "Troubleshooting as a Professional Watchmaker" videos.3 points

-

I guess no matter how reasonable ones approach is it will be never enough, neverenough. I am sure OP saves a lot of time and enjoys the knowledge he gains by taking Mark's course. Those who done take the courses, do definitely way better, for instance @VWatchie 's outstanding improvement can clearly be seen in his posts. Rgds3 points

-

2 points

-

Feeling quite pleased with myself - two new things tried today, both of which turned out pretty decent... Thing one was that I had an old dial that had three missing lume markers, presumably after a water ingress (water mark on dial). The remaining markers were nice and aged, so wanted to match that as best I could. Cracked out my daughter's acrylics and set about adding to my usual lume mix (clear acrylic matte and lume powder)... Voila! Bonus points for guessing which are mine! Thing two was that I had a new hand arrive for the W10 - I've never been happy with the match on the hour hand (and still have slight issues with both) but these are the best i can do. One was bright white, the other a very pale green tinge... I wanted to try and get both looking similar to the markers, and rather than reluming went for the coffee method, baking them at 180c for intervals of 5 minutes face down on the granules. The whiter of the two was also soaked in black coffee before baking. Not perfect, but better I think? Toying with the idea of having a crack at those scratches but really I should leave that alone... Might have a play on a test dial just to see... maybe!2 points

-

The strength and the height are the most important parameters. The 9mm refers to the barrel size and should push straight in. The extra 20mm in length won't matter. You could hand wind the original spring. Where are you located, it helps with sourcing materials.2 points

-

2 points

-

Thats the problem, OP keeps swapping parts and call it fault finding, this leaves one with no idea about where the fault is thus its possible causes. Mark offers a course on fault finding, guess he defines fault finding before he start teaching the subject. I think if you take his course you will have a sound understanding as to what fault finding is and how to go about finding faults. No ill intent here, just my thought on whats wasting one's invaluable time. Rgds.2 points

-

2 points

-

Yes, should be fine. Look at the resource section on here, plenty of European suppliers. Typo in my last answer, 10 mm not 20 mm.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

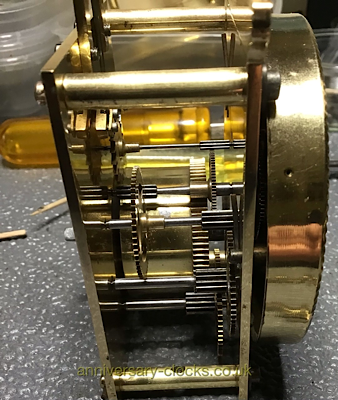

Paint stripper is what I use on the torsion clock bases, then polish , then wash in panel wipe then lacquer but peg holes before lacquering to stop lacquer getting in bushes.1 point

-

Greetings from Western Australia. I first took apart a timepiece, a simple alarm clock, some time in the 1970s. I was fascinated as a child with how things worked. Unfortunately, I was better at taking things apart than at putting them back together. A few years ago, inspired by watching YouTube videos of amateur watch repair, I was bold enough to replace a broken rotor pivot on a 1968 Bulova watch I'd bought on eBay. I was successful, although it was a difficult challenge as neither the screwdrivers I had nor my tweezers were antimagnetic and just removing and replacing the case clamps was a substantial challenge. I started being a bit more serious about it as a hobby this year, acquiring some proper tools, lubricants, etc. and I have restored a number of watches of different types: automatic, manual wind, and quartz. I've revived a pin pallet pendant watch, and I've been impressed by the build quality of some of the early Seiko quartz watches from when I restored a non-running V400A movement. I've lost parts and broken parts -- that almost goes without saying. I'm not planning on adding to the YouTube community, but if I did I think my channel would have to be named, "Mistakes were made," as I have had "learning opportunities" from almost every watch I've worked on. My latest project, one I'm very pleased with, has been a Seiko Rainbow ladies watch with a 1104A movement that had suffered some water damage. It wasn't running, but all the rust was superficial, although the dial is sadly marred. I lost the seconds pivot friction spring when I was trying to just give it a final clean-up and it jumped and vanished. I lost a dial screw when I failed to tighten them before putting the parts into the ultrasonic ... somehow one ended up out of the jar with my cleaning solvents and in the water and when I found it days later it wasn't much more than a brown smudge in the ultrasonic. I broke the tail hook off the mainspring trying to wind it into its tiny 6mm barrel ... I have some Chinese winders but nothing that small, so I made one out of a piece of 5.5mm brass tubing with a 3D printed pusher and using one of the arbors of the bought winders, but when I was trying to get the tail to go into the barrel of the winder it caught on the tubing and came off. Fortunately, it's not a rare movement and a donor was purchased from eBay which filled all the gaps created by my inexpert efforts (and successfully using a different mainspring winder 3D printed using designs found in this forum). (I have a resin printer initially bought to print miniatures for DnD.) Professionally, I am a secondary school mathematics teacher and I also have a background in electronics. I've made a budget timegrapher using tg-timer from https://github.com/vacaboja/tg and a microphone made from a piezo transducer and simple TL071 op-amp preamplifier. I can't currently justify the cost of the microscope I'd like but have found my cheap Chinese digital microscope to be empowering. In short, I'm having fun! Now, if only I can work out what to do with the watches once I've finished with them. I want them all to be worn, not just the few I keep for myself! In the short time I've been here I have been impressed by the support and encouragement of the members, and I hope to be able to contribute positively, and more so as my experience increases. Glen1 point

-

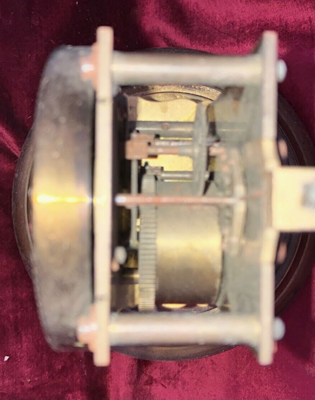

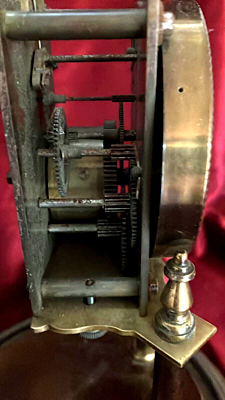

Dell is right it would be lacquered brass. I have repaired many with the 8 day wind up movements, never seen a battery one before. Looks in a hell of a mess.1 point

-

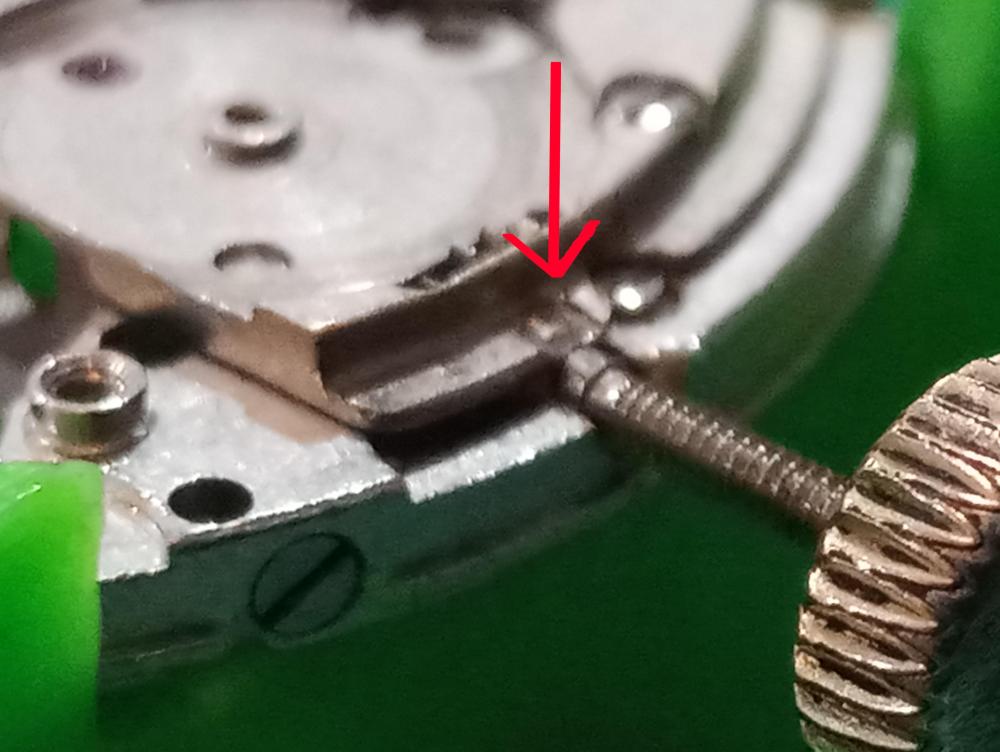

@Neverenoughwatches Yes, I am concerned a bit that this area might be or eventually become fatigued which would lead to a more drastic repair approach. No, no improvement or difference with the new stem.1 point

-

I got tired of waiting. I drilled out the centre of the pivot with a 0.2mm carbide drill and reamed out the hole with a dental root canal file.1 point

-

Hello and welcome from Leeds, England. This is indeed a great site. I believe that the top rank you can gain by taking part is 'distinguished member' with advanced member being at Mark's discretion.1 point

-

Personally i didn't like those terms, in fact i think i asked mark if i could change mine at the time, maybe thats the reason ?1 point

-

Hi GPrideaux. You will soon be a addict here. lol Did you know member's standing used to be; new member, addict and superaddict before, then Mark changed it, superaddict is now referred to as advanced member, but practically an addict. Rgds1 point

-

Gaday Glen welcome , 5am UK time ( heaven knows why i dont sleep ) you look exactly like my junior school maths teacher, white hair white beard. He was great,Mr............. cant remember his name but it will come to me. Thats how it started for most of us, as a kid i was always taking things apart to see how they worked. We're a great forum of good lads with plenty of knowledge and lots of banter, enjoy you time here. Rich.1 point

-

I am inclined to agree Joe, no offence to Colin and we all have our different ways of doing things and that mostly boils down to our time availability, experience.and skill set. How i go about it and I'm sure you do too Joe, if i discover a fault lays within a component I want to know exactly what that fault is, how it affecting the function group and what I'm going to do about fixing it. I must admit i have lost track of whats happened here1 point

-

1 point

-

Water purification is a subject that even some manufacturers don't understand. About 20 years ago, I was called in to investigate why instruments coming out of a top-of-the-line Swiss vacuum autoclave were coming out with rust. I discovered that the autoclave was supplied with a "deionization unit" that uses ion exchange resin technology. This is an antiquated technology that uses a resin that binds ions like calcium and magnesium and REPLACES it with sodium ions. It is basically a water softener and not a deionizer. I had a heated argument with the manufacturer as they had absolutely no idea of what they were doing. I pulled out a TDS meter and showed them that the water coming out of their deionuzer was not free of ions. And still they could not understand. Their conclusion was that the water in Singapore is of such low quality that it is unsuitable for use with their autoclave. They claim they have no such problem with Swiss Alpine water. I advised my client to tell them to go home and sell only in Switzerland.1 point

-

If it's labelled as Deionised, it should have been produced in a reverse osmosis system. https://en.wikipedia.org/wiki/Reverse_osmosis If you used more than small quantities of deionised water & don't have a free source, it's worth setting one up. You can get the parts from various suppliers on ebay. It's basically some cartridge filters to keep particulates and chlorine out of the RO element, the RO unit itself & some tubing. A basic system with sealed, disposable filters is around £40 or one with replaceable cartridges (so cheaper in the long term) around £80. All the filter housings etc. are cheap enough separately, so you can build one from scratch or add better pre-filtering if you live in a hard water area, so the RO membrane lasts longer. I built one some years ago when I was using quite a lot & the stuff was £4 per gallon to buy. (Some kits also have a mineralisation adding stage after the RO unit, to give purified drinking water some flavour.. Not needed for cleaning or chemistry uses!) Examples:1 point

-

Hi @VWatchie, I did buy HP1000 for the purpose of following the Rolex oiling chat to the T. But frankly, if I were going to make the decision again today, I'd save the money and just use 1300 instead.. and have not worries about it.1 point

-

1 point

-

It's the dissolved oxygen (O2) in the water that corrodes the iron/steel, the minerals in tap water act to increase the conductive properties of the water (ie making the water into a better electrolyte) allowing the galvanic cell to exist. This is the reason that salt water is far more corrosive than fresh water, the salt turbo charges the corrosion cell. The battery water is deionised to remove minerals (mainly calcium) that would be formed as part of the electrolysis reaction and reduce the performance of the battery. Instead many car batteries have sulphuric acid as the electrolyte, which does not form deposits, but is an excellent electrolyte in solution, and adding deionised water just re-dilutes the solution back to what it was when it came out of the factory. I was once on a tour of a fresh water lake in Canada where whey tried to use the standard method of measuring the purity of the water by reading the electrical conductivity. They were puzzled by the fact that both their devices were defective, then (after scratching their head) realised that their instruments were fine, it was the fact that the lake water had no minerals in it, and the water could not conduct electricity. I would be interested to know how they are treating the battery water, are they removing the minerals, or simply replacing them like they do with water softeners, ie replacing the calcium ion with sodium. If it is the former then all good, as you are making the water a poorer electrolyte, but if it is the latter than you still have minerals in the water and your water is still acting as a good, possibly even better (??) electrolyte, as you would be replacing 1 calcium ion with 2 sodium ions. This is the limit of my chemistry knowledge, so if there are any chemists out there please feel free to add to this or correct my mistakes.1 point

-

Just a minor update. I'm gonna dust off this watch again this weekend hopefully and try replacing the mainplate or train bridge with a spare to get to the bottom of this mystery. But I serviced and repaired the hairspring on a 7s26c i'd had around i mentioned, put in that generic mainspring. Got the amplitude up into the 255 to 265 range on it and really focused on correcting the hairspring from a pretty bad state and trying to adjust it as perfectly as possible and get the everything as fine tuned as possible. I managed to tie my record and get a six position delta on a 7s26c of only five seconds and in four days it's gained one second of time! I definitely haven't lost it. Something is wrong with the watch i started this thread on. The 2377x generic spring for this works and can keep great time but I'd definitely get the next stronger one to get that amplitude up a bit. I'll test that out at a later time. Either way it feels great to have my fav watch back on my wrist and running phenomenal, and I treated her to a double dome sapphire.1 point

-

Several months back, I was perusing eBay looking for a cheap watch to work on. Saw this lot of 8 watches and got them all for pretty cheap. What attracted me to the lot was the scalloped case of the Elgin. The movement turned out to be an Elgin Grade 524, manufactured in 1937. I finally got around to servicing it. The balance wheel had lots of issues (bent hairspring, wheel out of true, roller table not fully set on balance staff, and a loose roller jewel). I ended up finding a 1936 donor movement to steal the balance out of. Well, that doesn't seem to work well with these older timepieces. So, I serviced the donor and got it to run pretty decent. I ended up doing a movement swap with the watch. Now I have a movement that I can use as my guinea pig for a variety of balance work. The watch turned out quite nice i think. Case just needed a clean and light polish. Crystal was in good shape. Added a leather strap to finish it off. Love the look of that case and dial.1 point

-

1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)