Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 09/08/24 in Posts

-

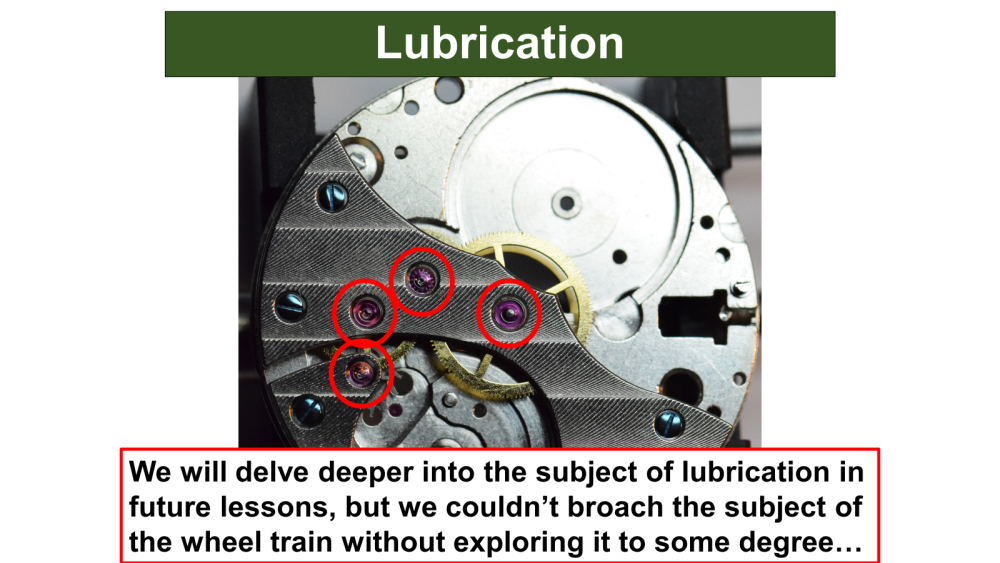

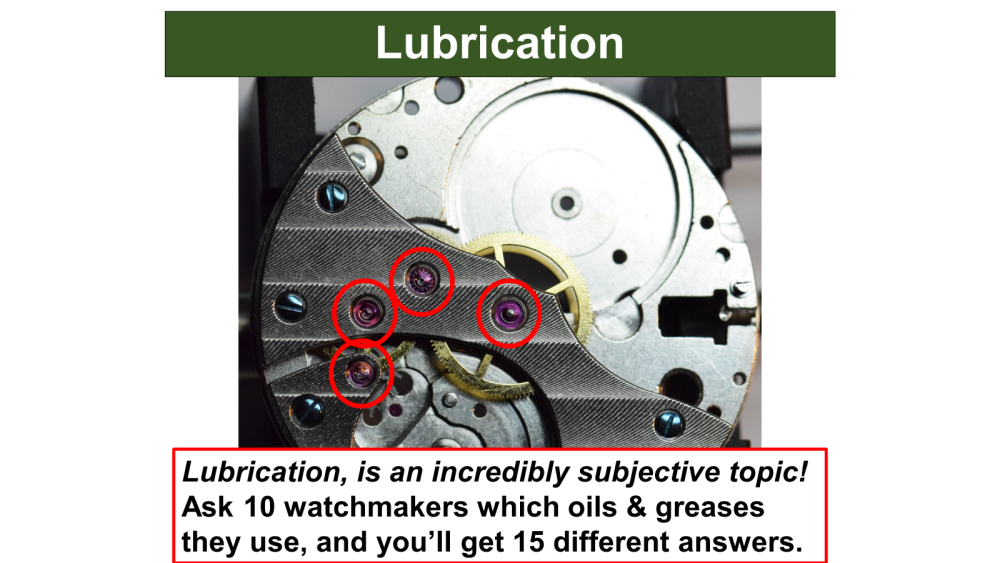

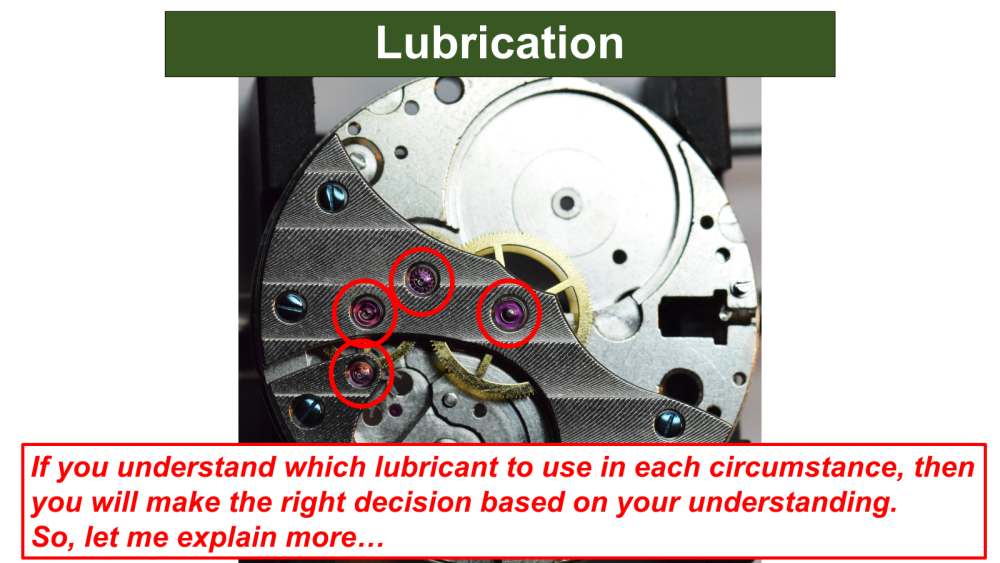

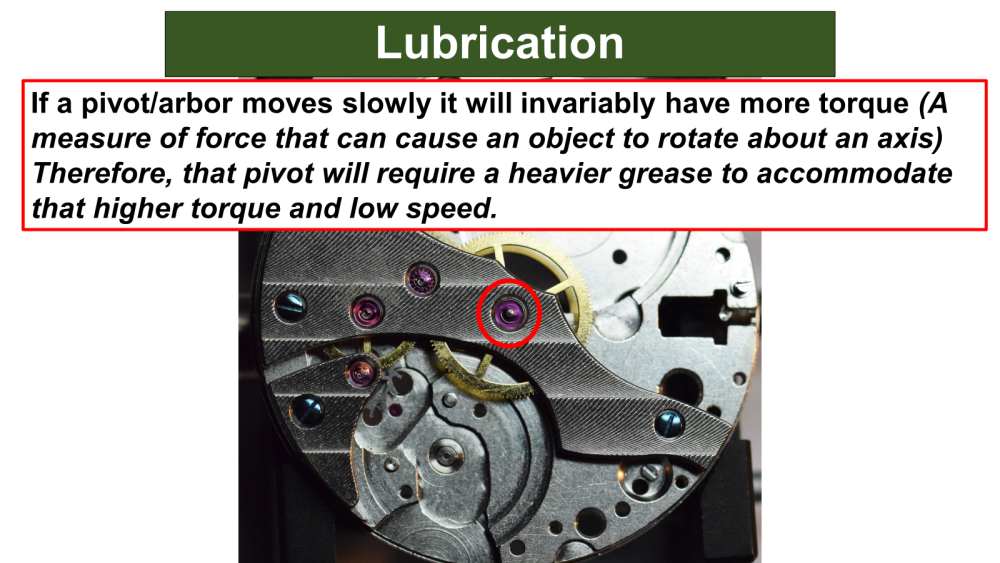

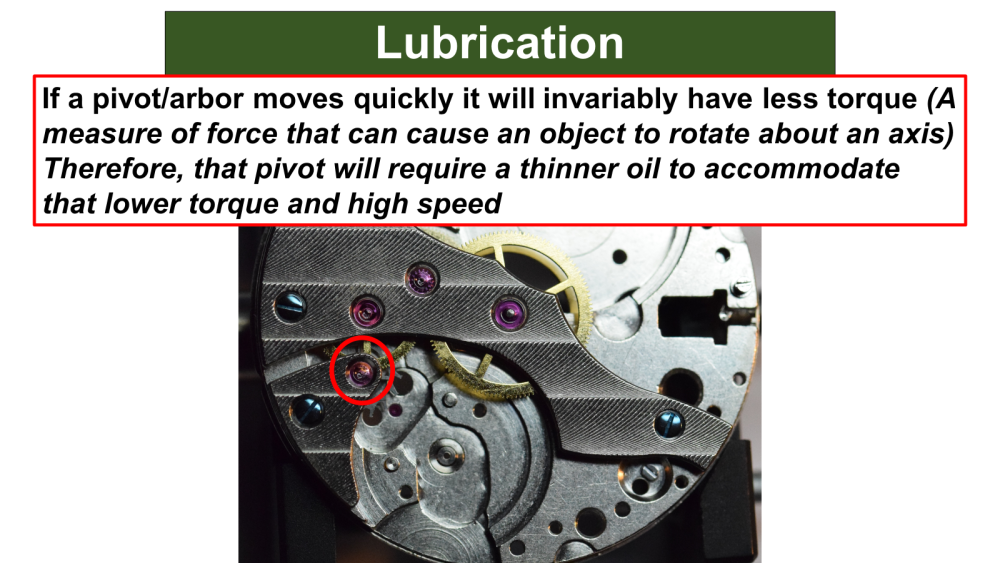

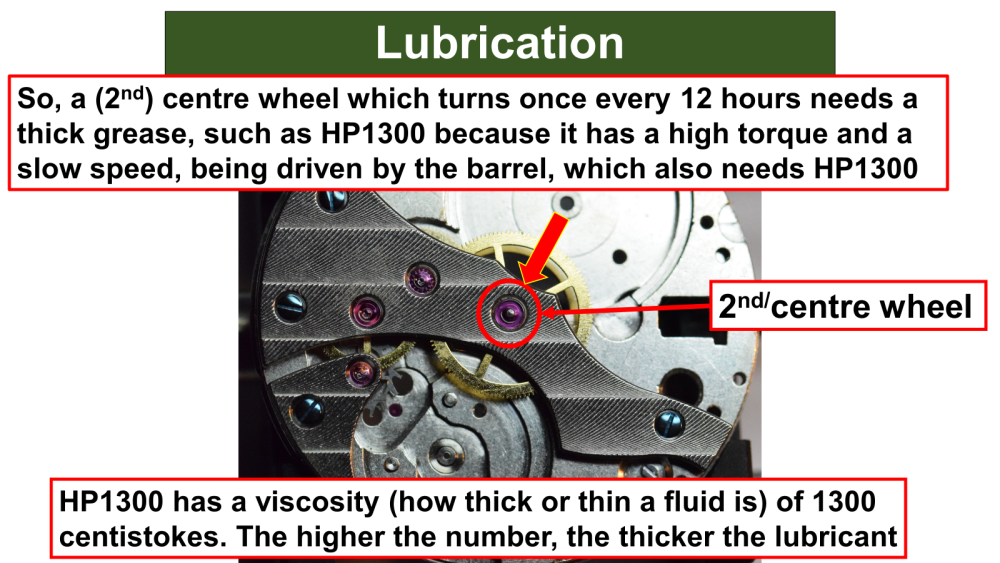

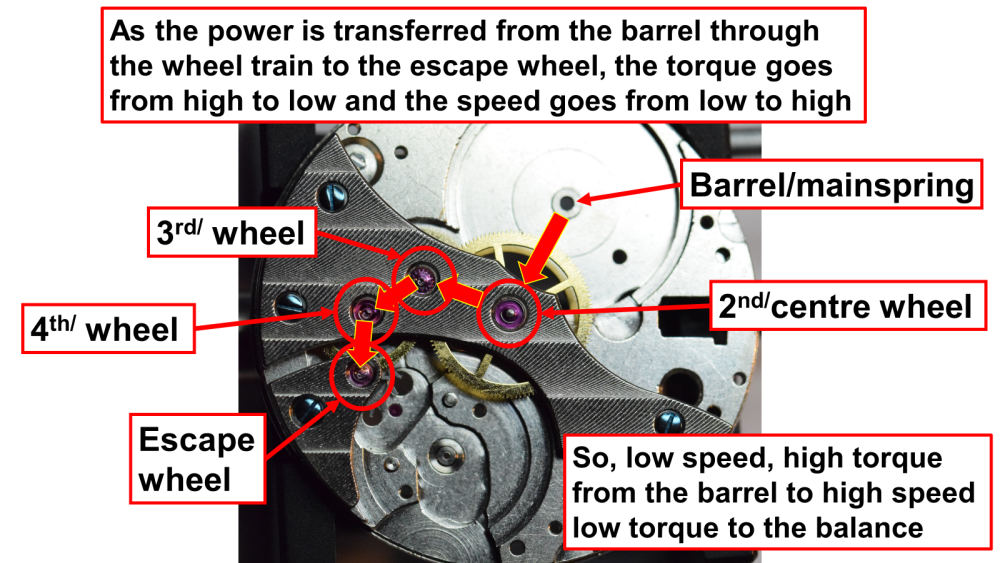

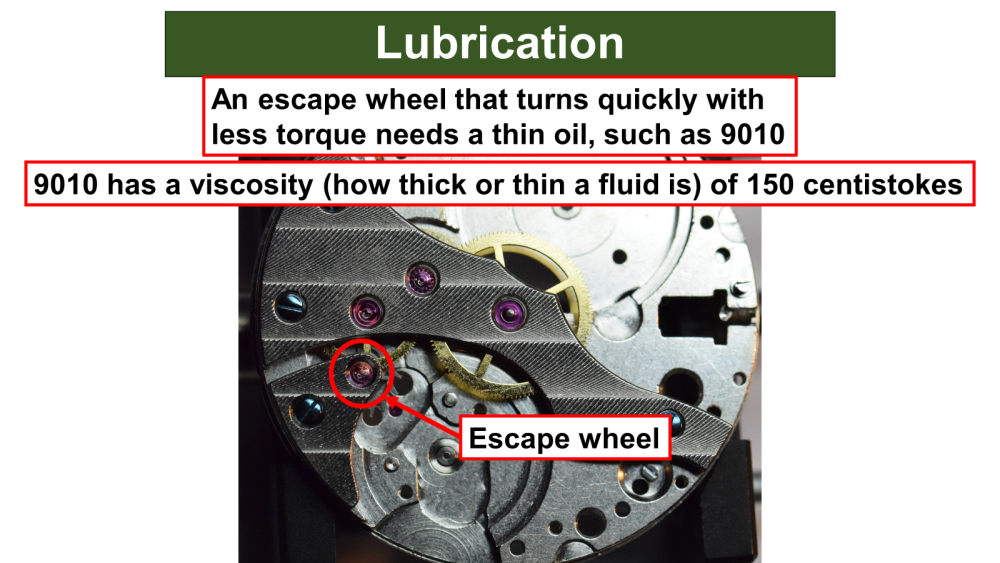

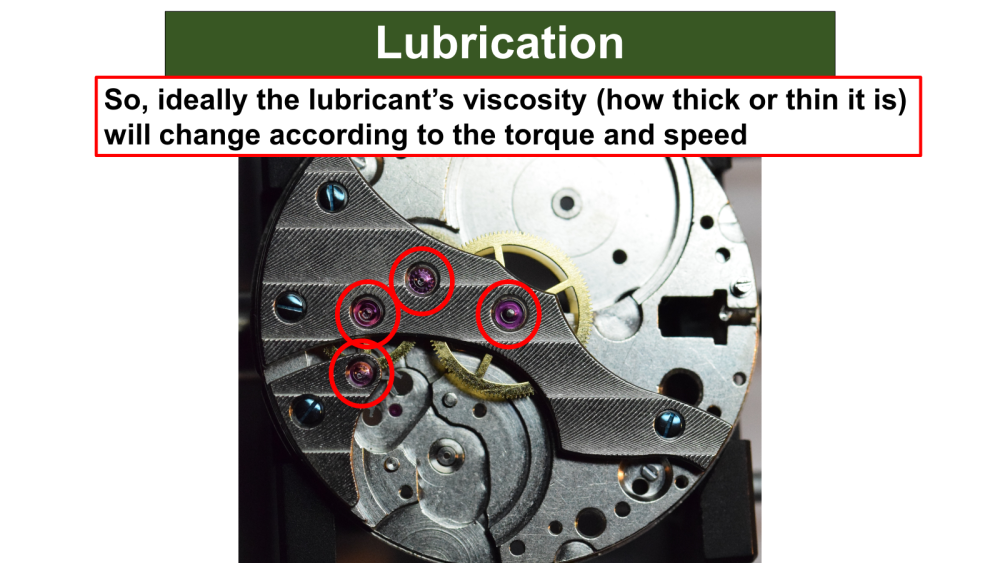

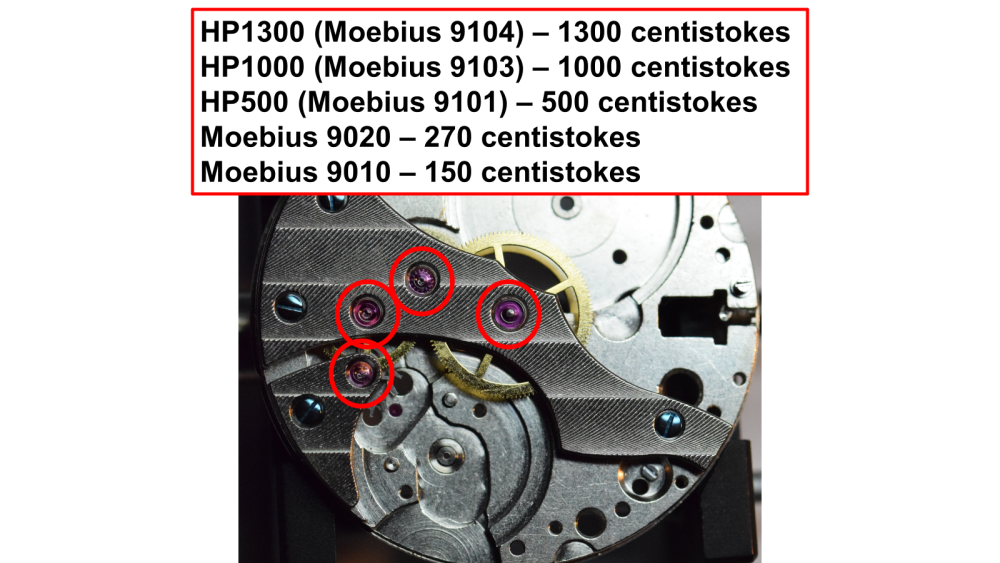

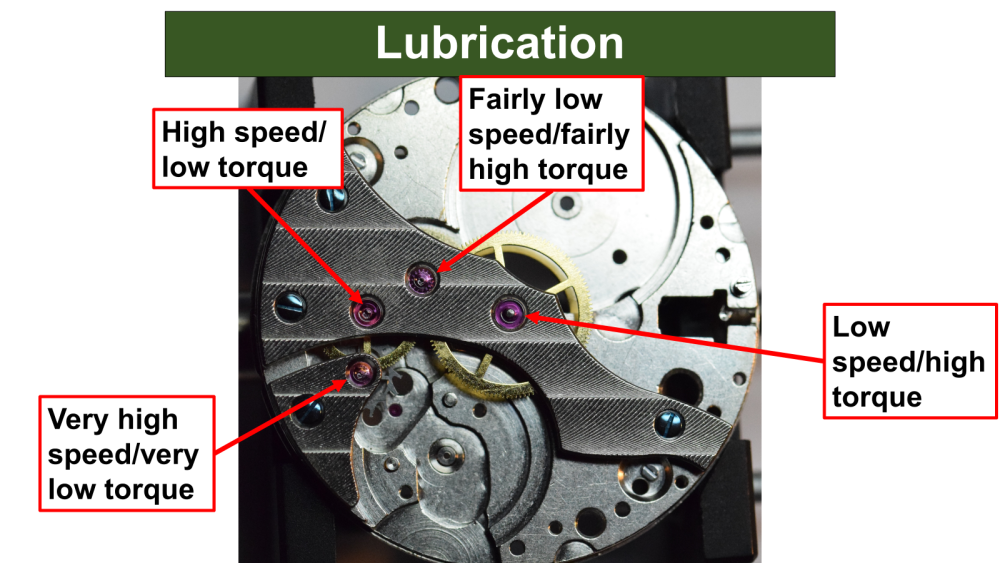

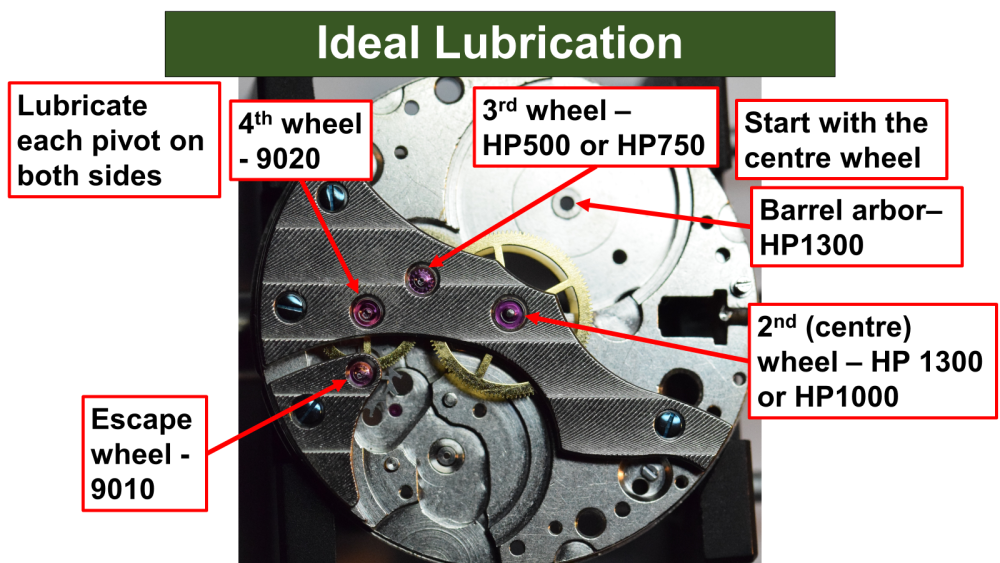

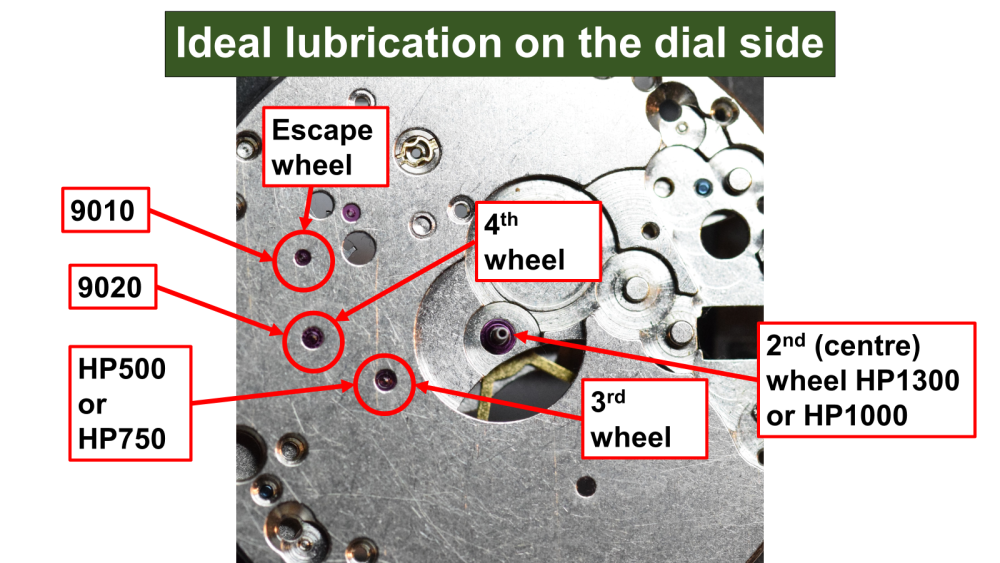

Hi guys, I know this might stir up a hornets nest, especially talking about lubrication, but I really think this is a very subjective matter in watchmaking that needs explaining to anyone who is new to horology, or isn't quite sure to buy yet another lubricant because the service manual says that is what is needed. Higher end isochronistic movements tend to have a bigger variation of lubricants, but they are not always needed and equivalents can be used. I'm not here to tell anyone what to use as a lubricant, I want to explain what I use and most importantly why and it has all to do with torque and speed of the arbor needing to be lubricated. So, the slides will explain more than words, but the important thing to remember is you have high torque/low speed at the barrel and low torque/high speed at the balance cap jewel and staff, there will varying degrees of torque and speed as the force travels from the barrel to the escapement and if you know what that is, you can choose a lubricant to suit that particular torque and speed based on something specific. I once trained a watchmaker of 13 years from a very well known watch company here in England (I won't say which one) and when I asked him what lubricant he used and where, he told me he uses the same as the guy on the next bench. When I asked him why, he told me "Because he uses them." So, he was basing his choices of lubricant based on the guy next to him, with little understanding of the subject. When I started out it was confusing what to use and where and WHY! Also, taking into consideration the size and age of the movement will sometimes change the decision of what to use, where, but most importantly why, because your choice is based on some science and experience, rather than the guy sat next to you. That kind of science you only learn by listening to the guy down the pub tell you what is best!4 points

-

Well, there has to be a first time for everything. I've managed to work on watches for three or four years without ever breaking a single screw....until today. Several other screws on this movement were on very (!) tight and had the markings to match, so I used a bit more force than usual. No markings on the head as a warning, so "snap" it went. Furtunately, last year I've bought a shoebox filled with leftovers from a watchmakers estate, and it held a little box marked "AS1012" with 5 new LH threaded arbors and matching screws. Has anyone ever compiled a list of movements with a LH threaded arbor? We could start a thread on the subject?2 points

-

Always willing to put another lubricant on the list... Thank you, I like to go through this with my first years for them to get an idea of what they want a particular lubricant for. I also tell them that technically you can lubricate the entire movement with D5 and 9010. And yes, D5 is never a bad idea to bind when it comes to the end of its life. i suppose that was the great thing about whale oil, is that it congealed and stopped the watch, which was the best thing that could happen. Nowadays, because of synthetic lubricants that doesn't happen. So, progress isn't always the best way. It probably is for the whales though! The thing with common sense is, I've found it's not very common. Maybe it's because I'm a Northerner living in the South I've seen students using files backwards and microscopes with no ring-light turned on (for 2 hours!). Now tell me how common is that kind of sense!...lol. It's all a learning curve. I remember when I became an engineer in my teens and the things I didn't know was frightening, but age, experience, knowledge and a sprinkle of wisdom helps that common sense come to life. Incidentally it's the new day of term on Tuesday for my very enthusiastic first year students. All half dozen of them. One of them already has his own micro-brand watch company and wants to learn more about the mechanics of the movement and the different variations. This is his brand. Check them out. https://www.apiar.co.uk/2 points

-

Good explanation for beginners, i honestly thought this was common sense , common knowledge. Maybe its more overlooked than i thought. I like to have some mineral oil somewhere to bind things over time rather than dry grind them to a halt. I chose D5 microgliss (1200 / 20°C ) as my heavy oil, the rest is hp750 ( figured that was a more mid-way viscosity between the D5 and 9020 ) , 9020 and 9010. Depending where folk live, hotter or colder climates maybe a step up or step down in viscosity will benefit performance. Heres another Castrol GTX , worked wonders for my '69 Cooper S.2 points

-

2 points

-

I hadn't come across a LH threaded ratchet wheel for years, until I worked on an AS 984. I'm always wary when working on AS movements that it may be LH.2 points

-

Brilliant! Which chrono is it? Hopefully a vintage Landeron or Valjoux with loads of eccentric studs. They really sort the wheat from the chaff and you learn loads about how the chronograph mechanism works and the phenomenal amount of adjustments that can be made to the studs to bring it all into concerto. I tell my students when we start working on their first chronograph (Valjoux 7733) "Keep in mind, many things have to be correctly adjusted and set in a movement with complications to allow it to work and to it’s optimum, but only one thing needs to be wrong to make it grind to a halt." It won't be long until your doing walkthroughs of them Haken!2 points

-

2 points

-

Maybe it does Joe, maybe more so on hi-beaters. Correct escape wheel sideshake is most important for more reasons than other wheels this is another one to add to the list. Re-servicing personal collections will probably show due to speed and impacts that this wheel's jewel hole is always dry before others are.1 point

-

Anyway, when the escape tooth unlock and bangs into the pallet jewel, it lands on the locking surface and not on the impulse surface where the grease it. But if too much grease is applied until it spills over to the locking surface, then splashes can occur. Ever wondered why the grease is applied to the exit jewel and not the entry? I think it's to avoid flicking off the grease and onto the hairspring.1 point

-

1 point

-

I'm sure when you came across a sticky hairspring, it wasn't easy to wash off. If it were 9010, that should rinse off easily. But sticky hairsprings can take several rinses to get it clean. What do you guys think?1 point

-

Who says pallet jewel grease doesn't get splashed around? I'm sure you've seen sticky hairsprings. I used to wonder where the oil was coming from. I couldn't believe that oil was dripping out of the capstones and getting onto the hairsprings. When I started oiling pallet jewels with 9415, like any beginner, I put too much and soon I noticed the hairspring gumming up. I'm sure the culprit was the 9415.1 point

-

Yes exactly. Does this actually happen? No matter how small the amount shaken loose by each hit , it can expectedly add up when you consider its does it 28800 times , and over years. Is the amount of oil thats shaken loose too small to be taken into account?1 point

-

Are you asking why shockwaves from pallet stones hitting escape teeth dont shake loose oil from their capillary hold between the pivot and jewel ?1 point

-

As they say size matters ( not relevant to the Mini Cooper ), ladies watches a lighter oil , pocketwatches a bit heavier oils, still boils down to torque, speed and pivot size. Something i also do if something has more sideshake that is liked and its not possible to realistically do anything modification wise about it for whatever reason ( low jewelled movement ?) , that extra space in the bearing hole can be taken up with a thicker oil than would otherwise be used. The normally used oil may leak down the pivot/arbor to the wheel or pinion whereas a thicker oil will hold its capillary action for longer.1 point

-

The trouble with AI is that it is not always very well informed. For what its worth, Indiglo is a non radioactive dial illumination system. Here is ChatGPT's take on Indiglo. .. and with a little prompting, here is what it knows about Radium dials dumped by Timex Dundee. So in other words, Timex dumped a lot of radium dials over an extended period into the Tay Estuary, the North Sea and ultimately into the Irish Sea/Celtic Sea/North Atlantic. As to how much of hazard they actually pose, that is debatable. Not much, unless you happen to be extremely unlucky, and eat a fish that ate a lume flake that Timex made. ... and finally what it knows about Timex Tritium dials. This makes perfect sense. If you really want to know what was on your watch dial however, try measuring the activity with a geiger counter. Rather counter-intuitively if it is still quite "hot" then it is probably Radium, but if it is only sightly "hot", then it may be tritium, and if it doesn't even register, then it is probably one of the many non-radioactive luminous paints. Also if it is still luminous, then it is probably not radium, as the zinc compound in radium dials is almost always spent, so they no longer light up. The radium on the other hand will be just about as radioactive as it ever was, so don't make the mistake of thinking that since it is no longer luminous, it is no longer radioactive, this is not the case.1 point

-

1 point

-

1 point

-

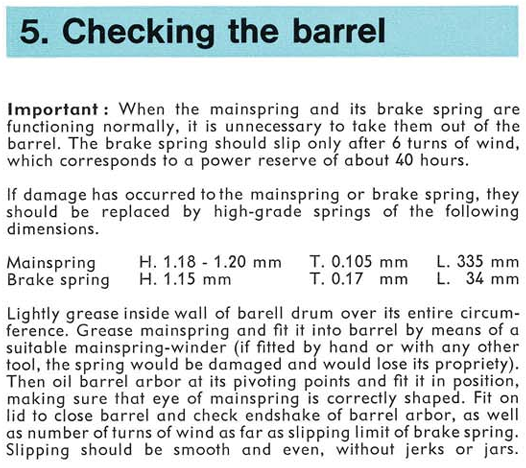

The bridle operates as the brake spring and a shorter one could explain the early slippage.1 point

-

The HMT 0231 have left threaded ratchet wheel screws. I have never seen one marked. And the screws are very soft metal, extremely easy to shear off. I have not worked on its progenitor, the Citizen 0201, to confirm whether it was also left threaded. But I would approach one expecting it to be.1 point

-

1 point

-

Hi Wilson, i looked at your profile hope you dont mind but its good to know who we all are and what we are about. Seems you haven't visited to discuss for a very long time joining 10 years ago, fair to assume you have some experience. Giving us some info about you can help. Guide lines for depth of stone lock suggest less than what is shown the entry stone in particular. There are other things to consider before you think about adjustment of them, to note they should be the same and changing one's depth will alter the other's. Search for Nicklesilver's excellent explanation of the escapement adjustment before proceeding. This may be under the search words of pallet stones depth, escapement adjustment, moving banking pins. These are relevant aspects, also important are the safety clearances of the gaurd pin/safety roller, fork horn/impulse pin of which moving the banking pins and pallet stones can affect. Leaning this becomes invaluable information for escapement adjustment.1 point

-

Not sure if you've got the service manual but I've attached it along with the section regarding the barrel & mainspring. What's the length on the brake spring on the GR2937X in relation to what's shown below? Edit I should have also reiterated the comment from @Kalanag Are you 100% sure that the spring slips? Could it be the arbor not hooked correctly? AS 1700 1701 Service Manual.pdf1 point

-

That all depends on the repairer. If the clock came to me and it needed a complete O/H it would certainly get the full works.1 point

-

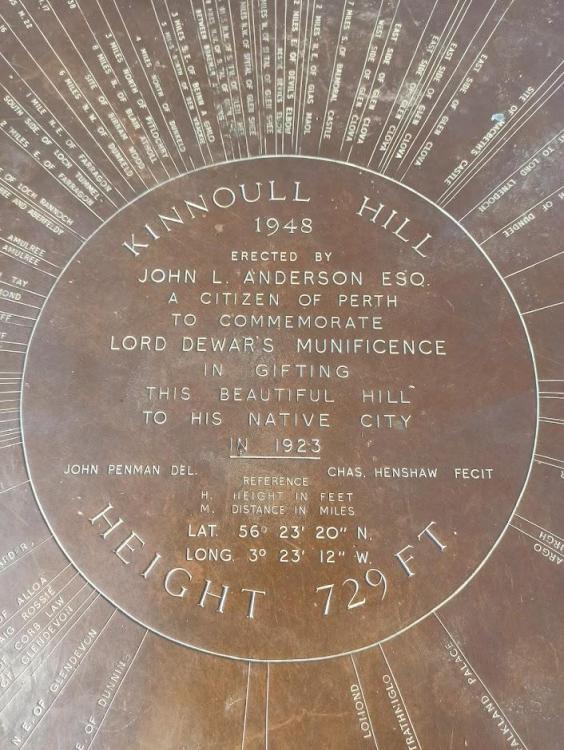

The as new Casio MQ-24 went for a wee trip up Kinnoull Hill this afternoon. Don't ask me where Kinnoull Hill is, there are enough clues is in the pictures. If you are ever in Perth, and fancy a walk, Kinnoull Hill is well worth the effort. Admittedly the view to the north was misted up, but the view to the south and east, past the tower made up for that. The plaque by the trig point tells you what you can't see when the mist is in, and we mustn't forget to thank our feudal overlords for their "munificence" ( I think it means bear faced cheek, but I haven't googled it yet ), in "gifting" this piece of Scotland to the Scots.1 point

-

1 point

-

Feeling quite pleased with myself - two new things tried today, both of which turned out pretty decent... Thing one was that I had an old dial that had three missing lume markers, presumably after a water ingress (water mark on dial). The remaining markers were nice and aged, so wanted to match that as best I could. Cracked out my daughter's acrylics and set about adding to my usual lume mix (clear acrylic matte and lume powder)... Voila! Bonus points for guessing which are mine! Thing two was that I had a new hand arrive for the W10 - I've never been happy with the match on the hour hand (and still have slight issues with both) but these are the best i can do. One was bright white, the other a very pale green tinge... I wanted to try and get both looking similar to the markers, and rather than reluming went for the coffee method, baking them at 180c for intervals of 5 minutes face down on the granules. The whiter of the two was also soaked in black coffee before baking. Not perfect, but better I think? Toying with the idea of having a crack at those scratches but really I should leave that alone... Might have a play on a test dial just to see... maybe!1 point

-

Thats the problem, OP keeps swapping parts and call it fault finding, this leaves one with no idea about where the fault is thus its possible causes. Mark offers a course on fault finding, guess he defines fault finding before he start teaching the subject. I think if you take his course you will have a sound understanding as to what fault finding is and how to go about finding faults. No ill intent here, just my thought on whats wasting one's invaluable time. Rgds.1 point

-

1 point

-

Oops, I wasn't aware of this. I assume it's a solvent? I didn't see this in any small print1 point

-

A friend has the 20W version of this but I'm thinking about the 50W as being easier to cut with. https://monportlaser.com/collections/fiber-laser-engraver?srsltid=AfmBOorc2FoLjLS8_rAXsoEk3I-ZWNdSviIICuN39w8zGj1Su2r4Rfve1 point

-

One really wonderful use of a fiber laser is putting holes in mainsprings. Like if you need a square hole of fiber laser has no problem. Or one time I needed a round washer with a square hole and I asked nicely at work and one was made for me. Out of curiosity which fiber lasers are you looking at?1 point

-

Well I now own an Anniversary clock. <insert happy bunny icon here> I will have to get hold of the Horolovar book now and the tool for adjusting the beat. Another thing that I cannot find in Australia. There are times I wonder how our country ever moved forward. Picking it up tomorrow. 5 hour round trip, which with stopping to collect and then dropping into my son's in Heidelberg, that will probably be all I will do tomorrow.1 point

-

I am an Australian American living in the beautiful Gold Coast, Queensland Australia. I love Grand Seiko and Seiko watches, and recently came back from the Grand Seiko Shizukuishi Studio in northern Japan where I was blown away by the design artistry and technical excellence. More later on that (including photos, if interested!)1 point

-

Two ways, I found (and often, both of these ways combined): 1- Address the cover's lip, where the latch engages, which can be stretched outward again. Carefully, and not too far. Smooth-jaw pliers with a mirror-polish on the jaw surface can do some of that. I made a special brass jig which has a sort of "tongue" which reaches below the case lip inside the case cover, and allows me to lightly peen the lip with my hammer (using a hard plastic head screwed onto it). That way is very time consuming. 2- Address the spring's latch slot in the case . The slot in the case, in which the latch-part of the spring rests, only allows the latch to spring-outward so far, then stops it. As you may notice, in the case of a worn lip, if the latch could only come outward just a little bit more (sometimes only .2 mm) it could once again grip the cover's lip. So by filing the trough of the slot a little deeper, you allow that latch to project a little further, in order to catch the lip that has been worn down. But beware: however much you file that slot - is also how much you must file the shoulder of the stem that pushes the latch spring from within, so that the crown is still at the correct height and the stem itself can still wind and set properly at the correct depth. It is best if you do a bit of both methods. And very gradually. Test the working now and then. Don't do too much at once.1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)