Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 09/09/24 in Posts

-

Magnetic rotor starts collecting metal debrie, the moment you take it out of ebauche, I don't see how ultrasonic can remove metals off magnets, use a soft brush to clean the rotor JUST BEFORE it goes back in the movement. Then I am clear on what for did you use a staking set , to do what? And could you have reinstalled it upside down? Rgds3 points

-

How are you spinning the gear train after you put in the in rotor? Are you using a line release tool? Check that the pivots of the rotor are not damaged. Also check that there are no metal filings and magnetic bits in the stator and on the rotor. Remove all the wheels and put in only the rotor and replace the pcb and see if it runs normally. The put in the wheels one at a time and see which wheel stops it.3 points

-

Timex 6517 7266** - a 1966 21 jewel model I got for around $14, hoping the dial was in good condition underneath a crystal too scuffed up to see through. It isn't mint, does have a couple of tiny hairline scratches. But the original crystal polished up so nicely that the whole thing shines now. The Timex M72 was their "Look we have jewels too!" movement. The pin pallets are little upright rubies, most of the train has cap jewels except I think the escape wheel. And the strangest part is the balance, which is a conventional Timex v-conic bearing without ANY jewels. They run maybe a little better than the non-jeweled movements, probably not much. But they do probably last longer. ** (I think... That's what my eyes make out without magnification)3 points

-

This westclox pocket watch is running much better with a dedicated end curve added. I'm now able to regulate it much closer to accurate time without the hs bumping the regulator about that !...... I'm thinking of modifying the fixed hs spacing that can fit a dozen springs. Yet to see what the lift angle should, at default 52° the amp is managing around 150° it also looks visibly low but reserve is very good Friday 14.00 - Sunday 20.00 and it was still ticking. This handy site has helped me date the almost 100 year old " Clunker " new name courtesy of @mbwatch to around 1928 by way of bow, pendant, hand shape and the only paper dial in the " Pocket Ben " series of Westclox. I do enjoy some research, and really enjoying this different side of basic repair on " Clunkers " . https://clockhistory.com/westclox/products/pocketwatch/index.html#:~:text=The History of Westclox Pocket,and first advertised in 1921.3 points

-

3 points

-

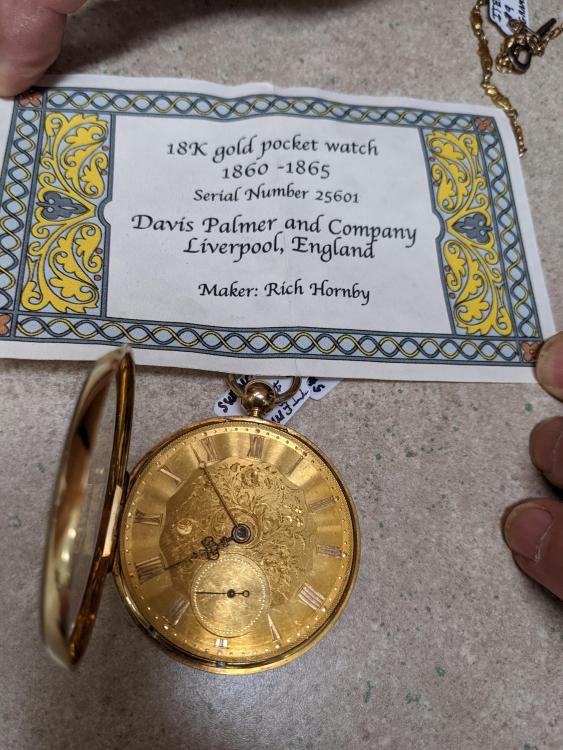

The watch that at the same got me back into watches that i never have worn. Belonged to my late grandfather who was a **BLEEP** so it had no sentimental value to me. When i got it my mom got it "professionally serviced" (Stay tuned for more on that lol.) and gave it to me. It's gold, very grandpa looking and sat in a drawer for 20 years while i bought a bunch of seikos i actually wanted to wear. Then I saw a pic of a similar gold watch on a blue strap and it looked quite attractive. I got one. Yup. I can wear this! Ariston was the department store brand of an old Chicago department store. Was probably a nice watch at the time but not TOO nice. Let's get it serviced! Open it up and it's far prettier than any example of this old movement i can find on the web. Looks to be in great shape too! But is it? (Yes.) Oof. Professionally serviced and there's no crown or caseback gasket in it?! Thank god i didn't wear it. I'd probably have gotten it wet and had no idea it wasn't water resistant anymore like the caseback says. Also bent crown post. Probably have to source a crown but i'm hoping i can take the stem out and just bend/nudge it back straight. Does't look like it would be too hard. Worth a shot if i have to replace it anyways. Turned the thing over to drop it out of the case and a bunch of dark powder and some shards of metal fell out...not good. Took automatic works off...so far so good. 70 years and the balance is utterly perfect best i can tell. Thank god. Zero excessive arbor sideshake. It all looks great, no rust. Why is there a swimming pool of grease under the pallet fork cock all around the keyless works?! SO much grease! The jewel and escapement oiling appears to be impeccable. Did he drop a pizza on this thing halfway through assembly?! Disassembly is done other than the barrel. Real happy to say there's not a speck of rust, not a single slipmark from tweezers or screwdrivers, mine or otherwise. THis movement appears to be in mint condition. I'm not sure what that debris was that fell out of it, all the oil is still wet, there's no rust. I suspect it was gilding or some corrosion from the brass that wears through the thick gold filling of the case. I have no idea what that was. Beautifully taken care of. What a relief. I dont' want to cock this up or have any surprises as i know it was running just fine a couple years ago despite being serviced 18 years prior. So thoughts on swiss vs seiko, seiko being all iv'e worked on. I love the little quality of life stuff with swiss. the tapered or post bottomed screws that sit perfectly upright and wait to be screwed in, zero chance of a screwdriver slip. The little notches for levering up all the bridges and cocks is really convenient. I'm really enjoying working on it. I do like the simplicity of seiko stuff. Way less parts it feels like and things work more intuitively. The sideways sliding crown wheel is a really interesting design. Given that i can't find ANY technical sheet or diagram and only two awful youtube vids of partial disassemblies, hopefully i can get this thing back together and oiled up and running tomorrow.2 points

-

I think that hook is for putting the wheels into there pivot holes between the clock plates.2 points

-

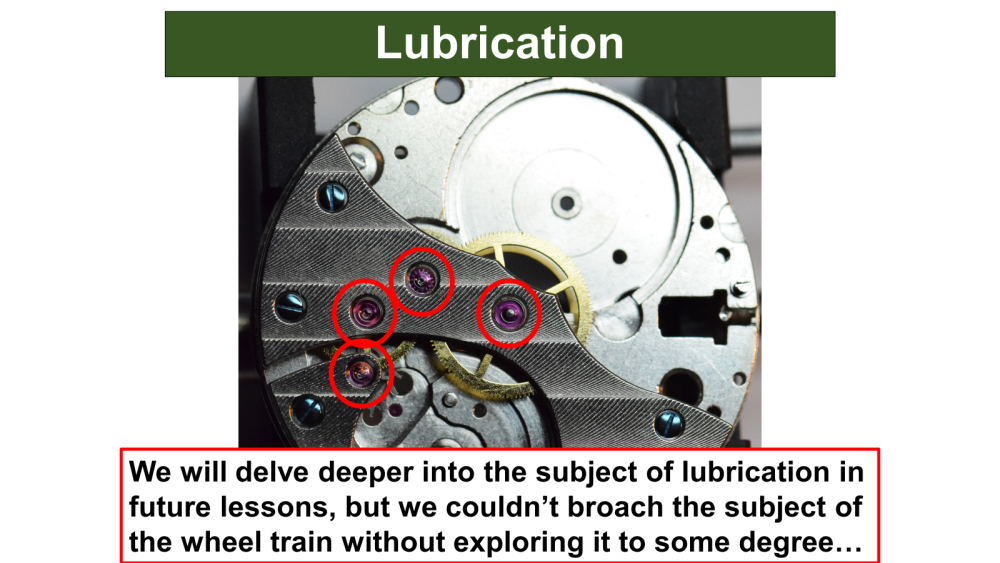

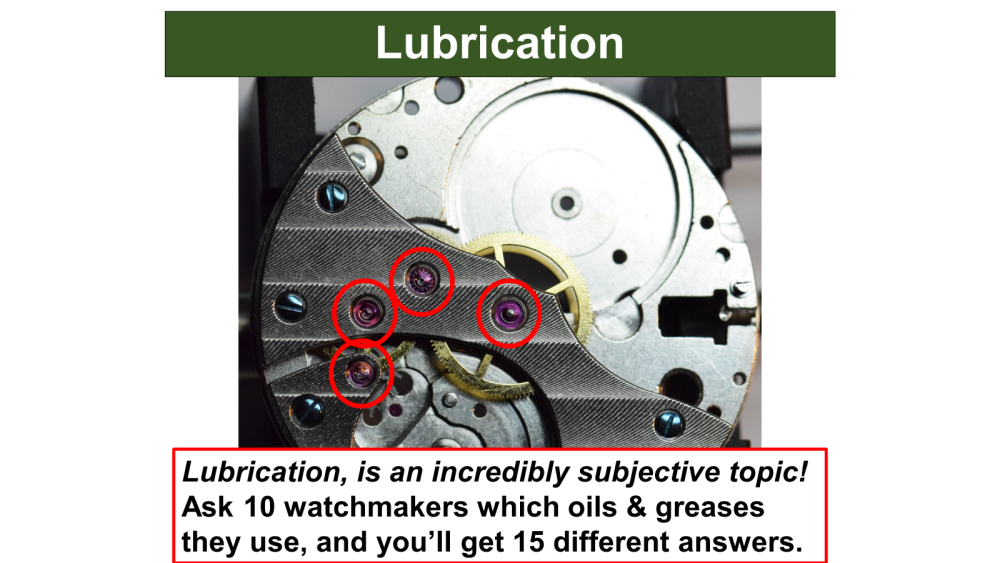

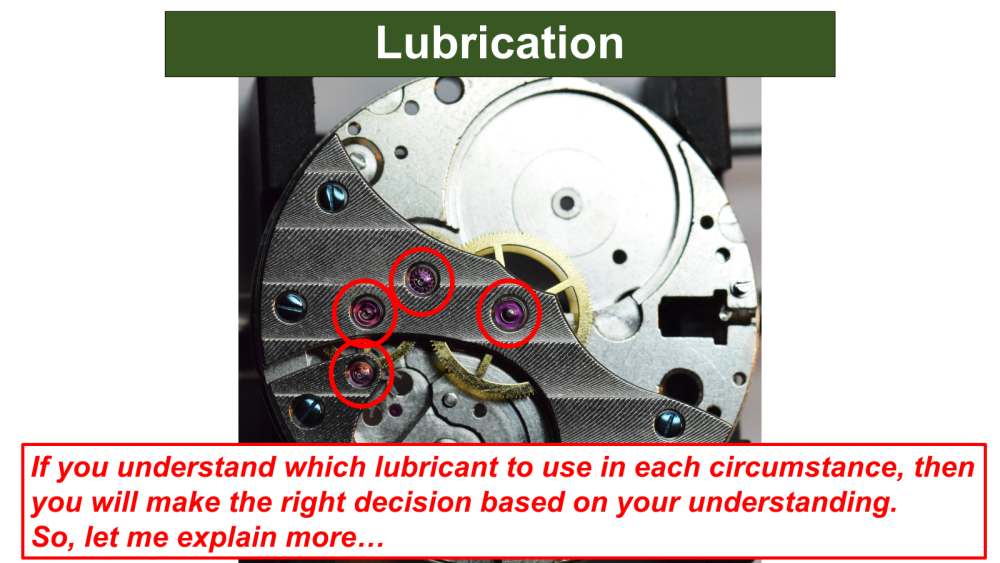

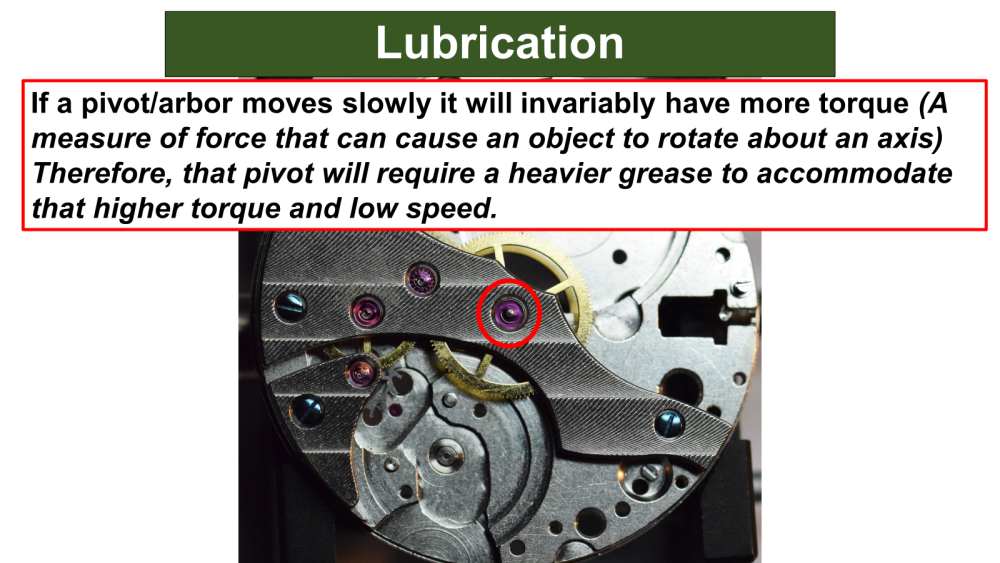

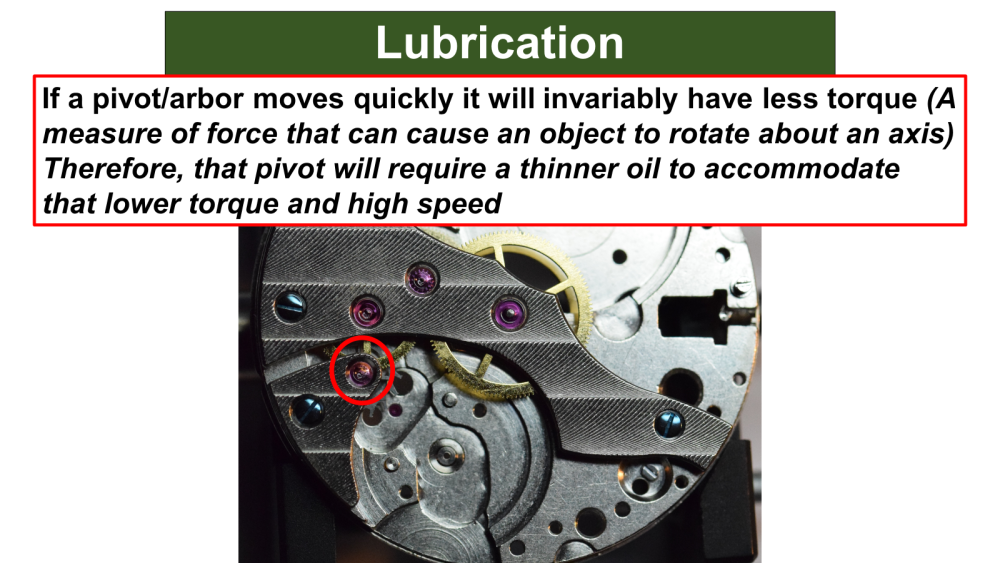

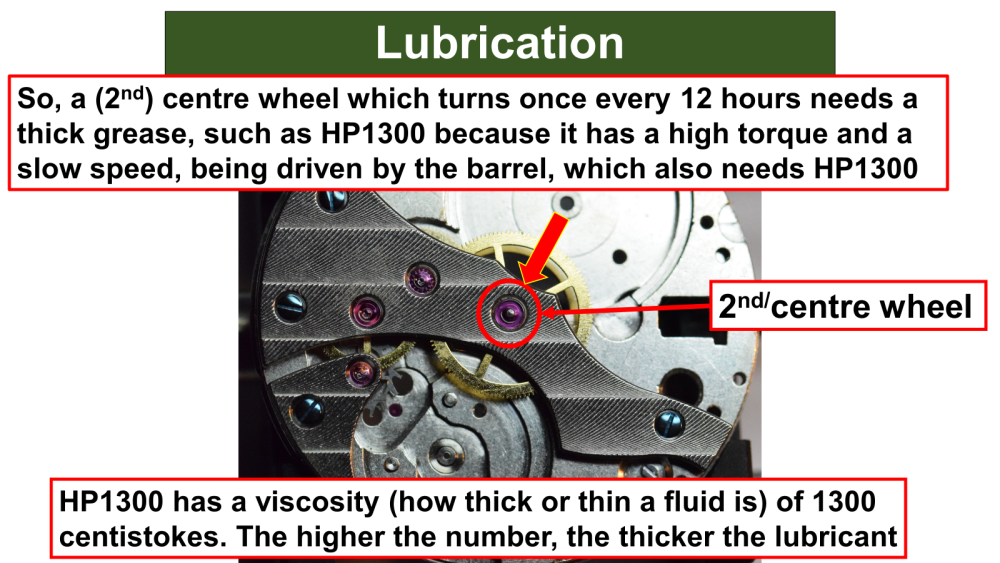

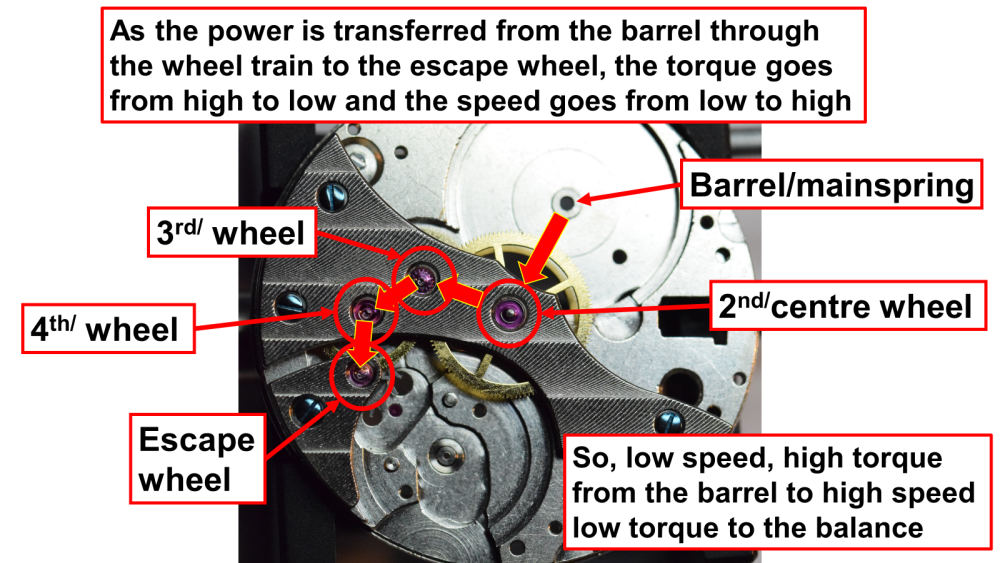

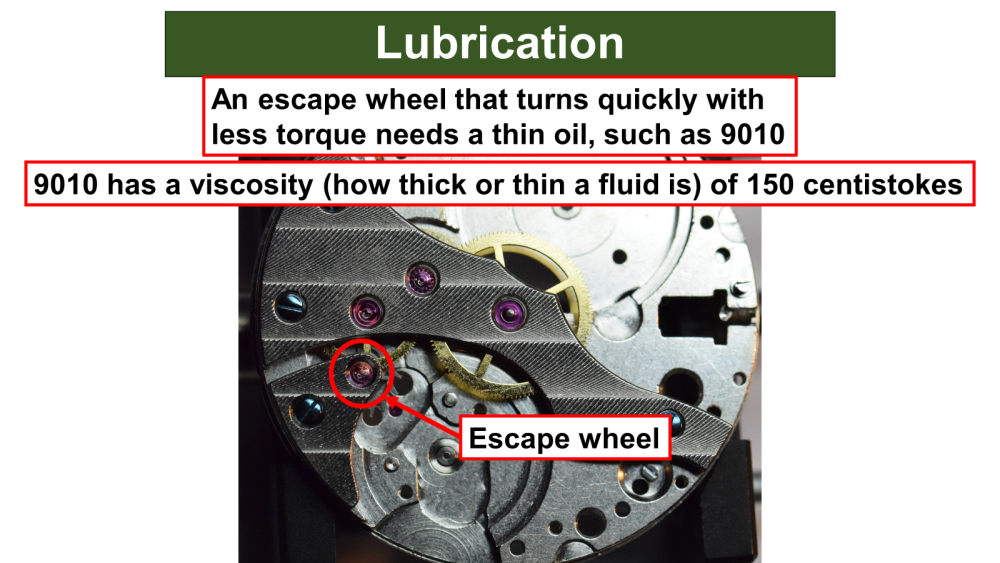

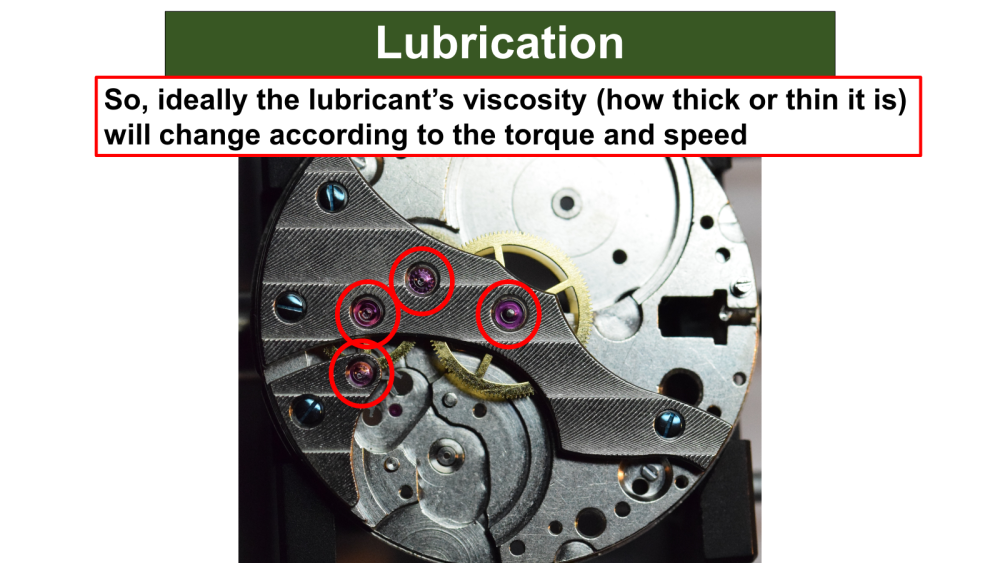

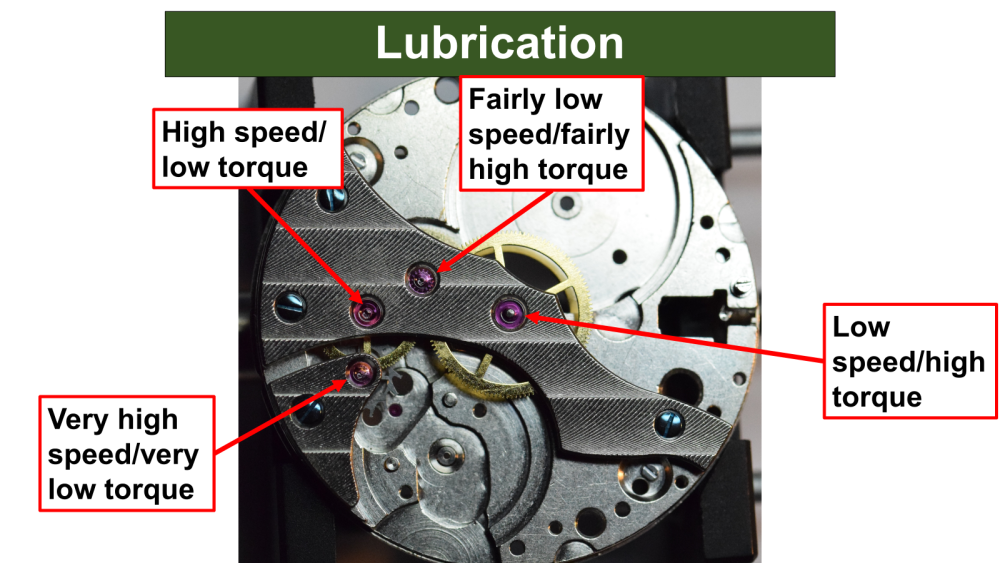

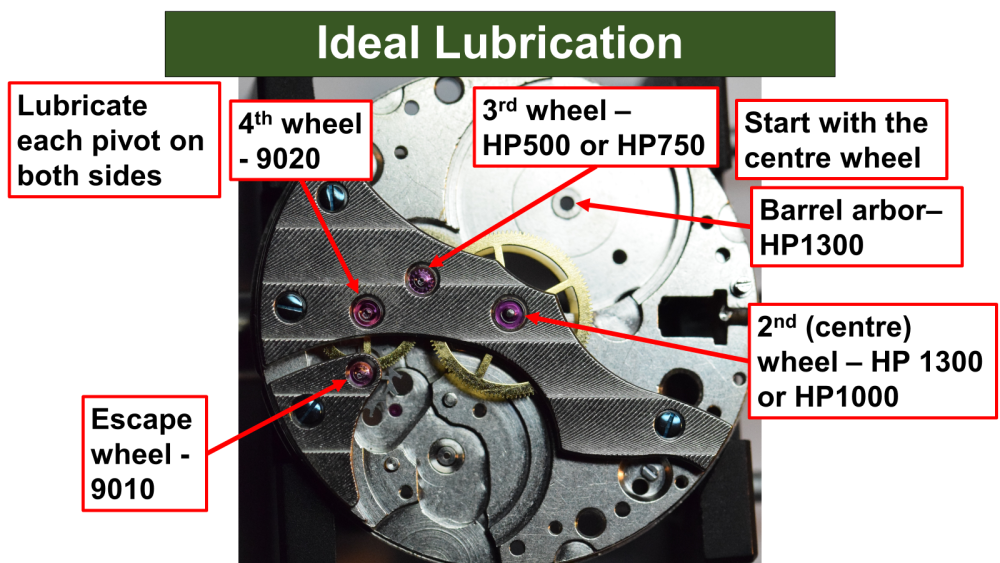

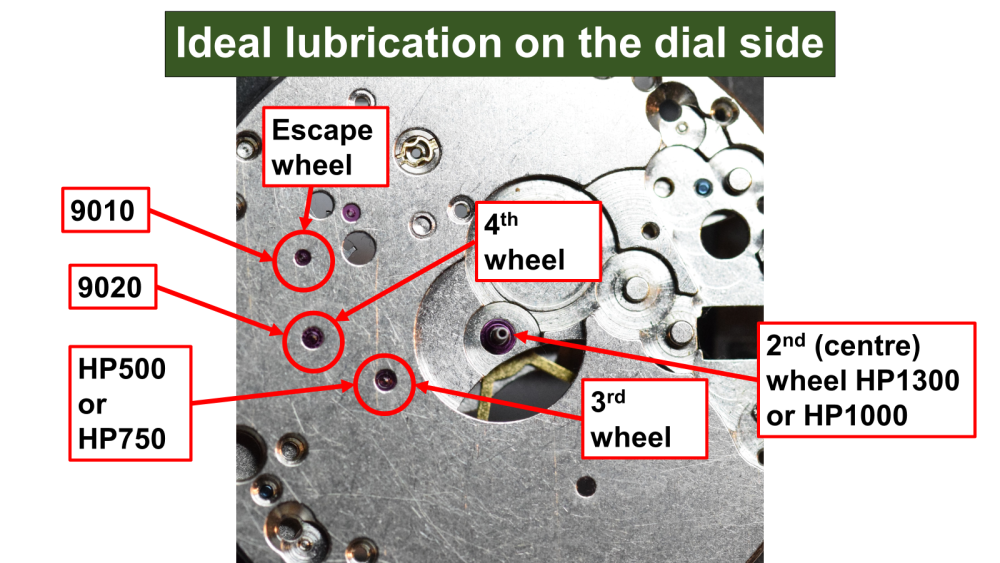

Hi guys, I know this might stir up a hornets nest, especially talking about lubrication, but I really think this is a very subjective matter in watchmaking that needs explaining to anyone who is new to horology, or isn't quite sure to buy yet another lubricant because the service manual says that is what is needed. Higher end isochronistic movements tend to have a bigger variation of lubricants, but they are not always needed and equivalents can be used. I'm not here to tell anyone what to use as a lubricant, I want to explain what I use and most importantly why and it has all to do with torque and speed of the arbor needing to be lubricated. So, the slides will explain more than words, but the important thing to remember is you have high torque/low speed at the barrel and low torque/high speed at the balance cap jewel and staff, there will varying degrees of torque and speed as the force travels from the barrel to the escapement and if you know what that is, you can choose a lubricant to suit that particular torque and speed based on something specific. I once trained a watchmaker of 13 years from a very well known watch company here in England (I won't say which one) and when I asked him what lubricant he used and where, he told me he uses the same as the guy on the next bench. When I asked him why, he told me "Because he uses them." So, he was basing his choices of lubricant based on the guy next to him, with little understanding of the subject. When I started out it was confusing what to use and where and WHY! Also, taking into consideration the size and age of the movement will sometimes change the decision of what to use, where, but most importantly why, because your choice is based on some science and experience, rather than the guy sat next to you. That kind of science you only learn by listening to the guy down the pub tell you what is best!2 points

-

The combined lume from their total 75000 dumped dials must work out to about three shot glasses full of radium paint. I have reached the stage where I do need to get a Geiger counter, while the lume on this particular dial does glow for about 3 seconds after hitting with a powerful UV light. On the other hand, it is only 58 years old as opposed to the spent and blackened radium dials from the 1940's I would never expect to glow at all. It would be nice if ChatGPT supplied a source citation for literally any of its essay on Timex and tritium because it reads a lot like it gave you a description of what tritium is and how watch companies used it, decided Timex is a watch company and thus also used tritium. And the trouble with Google search as of a couple months ago is that you cannot perform one without it spouting the AI nonsense at the top. It's Indiglo blurb was a wrong response to a question I didn't ask, by a party I didn't want to hear from.1 point

-

I read this as: the chaton is fine, but a groove has been worn into the pivot hole beneath the chaton, in the metal part of the upper block1 point

-

1 point

-

Could you also post photos of the pcb? Was there any signs previous battery leaks?1 point

-

1 point

-

I'm really curious about the procedure for doing this? Then what is the current consumption of this watch with all the wheels in?1 point

-

That is an interesting version of a pin pallet movement. Had to find some photos of that movement. https://17jewels.info/movements/t/timex/timex-m72/1 point

-

On the first tool, I was just chatting with a watchmaker friend of mine about hairspring collet adjusting tools. As @mbwatch indicated, it is to adjust the collet position. You approach the collet slot from the side, slipping it under the hairspring and inserting the straight portion of the hook into the collet slot. He indicates that you can do that operation without removing the balance wheel from the cock, if you are careful enough. He's sending me the hook tool and another type of tool that fits down over the end of the balance staff and has a tooth that fits into the collet slot. The 2nd tool looks to me to be a truing caliper. Maybe it can accommodate different pivot sizes with the different rods. Usually, with truing calipers, there would be an adjustable arm that you would reference as you spin the wheel to determine the high and low spots.1 point

-

1 point

-

Kind of musty and old canvas. Used to Ger some great stuff from the Army, Navy stores.1 point

-

Hi and welcome to the forum Enjoy. Can you post some pictures please, there is a combination of numbers under the six position, they unveil information when decoded.1 point

-

Hi. As Hector has explained the rotor should pulse regardless of the wheels so follow his advice. I do not put rotors in the ultrasonic but clean by hand.1 point

-

The hook tool looks like it is intended to grab the slot in a hairspring collet to adjust it while mounted to the balance cock, but it seems too big unless it is meant for clocks rather than watches. I have seen other tools of the same shape & design, but with the opening closer to 1mm for pocket watches.1 point

-

1 point

-

I use silicone on the pusher where it slides in its tube, and a bit of grease where it contacts the lever on the movement. Same for chronos.1 point

-

In the "run" position, the intermediate minute counter wheel drops down toward the chronograph runner. When down, a tooth should be pointing directly at the center of the chrono runner. When the finger on the chrono runner comes around to advance the minute counter, it should cleanly contact this tooth on its ogive, advance it, the jumper takes over and continues the advance, and the finger should brush by the tooth as it continues. It can touch the tooth, but shouldn't cause the minute counter to advance at all. If the depthing is too deep, the finger can contact a tooth in advance, possibly arc-bout , or tip-to-tip, causing it to block. If it is too light, but the position of the intermediate wheel isn't such that a tooth is pointing at the chrono runner center, the same issue can arise. To center the intermediate wheel, you reposition the minute jumper. If you find you have to change the depthing, this will affect the centering as well- perhaps not enough to matter, but it may be. This is because as the intermediate wheel comes toward the chrono runner, it rotates around the minute counter wheel. So it can be a bit of a back and forth. The eccentric for the depthing of the sliding gear (the part on which the intermediate minute counter wheel is fixed) is at the red arrow in the pic. Something to check as well, is the freedom of the sliding gear. It is acted on by a wire spring, and it should be very free. It's held in place by a shoulder screw (or two, can't remember), if it isn't free, and everything is clean, it might need to have the underside of one/both of these screw heads retouched. You can test by simply loosening the screw a fraction of a turn. If you reposition the minute counter wheel to correct the intermediate wheel's position, you may have to adjust the hammer. When in zero position, the hammer for the chrono runner should be in full contact with its heart cam, and the hammer for the minute counter should allow a slight freedom of the cam. You should be able to push the minute counter wheel in both directions, with the cam coming into contact with the hammer before the jumper tip goes over a tooth. The big screw on the hammer alters the spacing; but you may find that with everything positioned well, and good contact with the chrono runner, you have too much freedom in one direction and none in the other. In this case you must file the face of the hammer slightly to favor freedom in the correct sense. The face must be repolished too. I have done this many times, but don't recall having to do it on a Landeron x48 family.1 point

-

Try these, https://www.emmywatch.com/db/movement/eta--2451/ Downloadable. https://watchguy.co.uk/cgi-bin/files?subdir=ETA&dir=Technical Manuals&action=documents Rgds1 point

-

There's an issue with the minute counter. Could be the jumper spring is adjusted too strong, or the depthing with the chrono runner finger not correct, could even be the minute counter hand touching the dial.1 point

-

Just so others can imagine what all they are missing which can be learnd from Mark's fault finding course, which I haven't taken ( wish I could ) but have seen a few free lessons by him on youtube. What you done and say above, is not troubleshooting. its eliminating , a tool to resort to for when you can't spot on the fault but have found its whereabouts, such as , when damage to a escape teeth is only visible under microscope and you don't have a microscope, if you gained good amplitude and nice steady lines on tg, by replacing the escape wheel ! you conclude the fault was there , without actually seeing the damage.1 point

-

Hi Wilson, Actually, the most important thing when adjusting the pallets position is the drop lock. Yes, the entrance pallet looks to deep, but it is possible that the banking pin is to open and thus artificially enlarging the total lock. So the first thing to do is to check the banking pins position. When the pallets position is correct, the exit pallet mus be slightly 'deeper' at banking position than the entrance pallet1 point

-

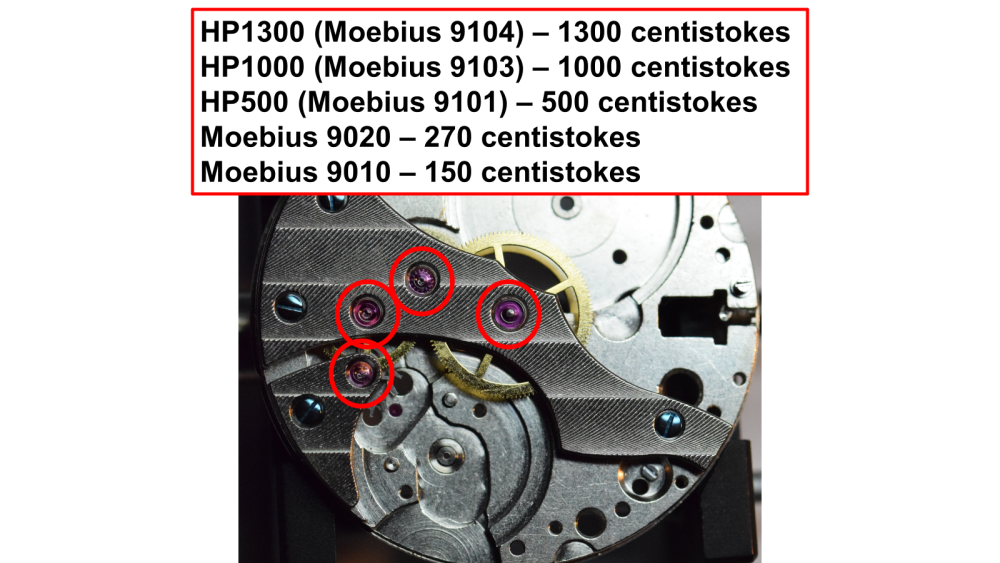

you mean more like a few dozen hornets nests I do find horological lubrication quite amusing. For instance do the watch companies study the effect of their lubrication choices for the running of their watches long term? So in other words when you look at the tech sheet and they give a recommendation is it really the right recommendation at all? For instance people work in the service center's for various companies that replace a heck of a lot of components which makes you wonder if maybe the lubrication choices are not correct because they don't care they will just replace stuff. I like that potential for a drop in amplitude. We would need to have more than one watch to do a test because just doing a one-off watch doesn't really show too much? For instance I have a basically a brand-new 6497 Swiss watch. Gear train the entire thing HP 1300 balance pivots 9020 and escapement 9415. After servicing of anything it showed too much amplitude and even 24 hours later the aptitudes looks spectacular at almost 300° dial up and down on the other hand the watches sits around here and occasionally I wind it up to see how it still is not entirely a fair test. But it does make me wonder if the Swiss are going with too low of viscosities on their lubrication or oil where Greece should be used for instance.1 point

-

Anyway, when the escape tooth unlock and bangs into the pallet jewel, it lands on the locking surface and not on the impulse surface where the grease it. But if too much grease is applied until it spills over to the locking surface, then splashes can occur. Ever wondered why the grease is applied to the exit jewel and not the entry? I think it's to avoid flicking off the grease and onto the hairspring.1 point

-

Always willing to put another lubricant on the list... Thank you, I like to go through this with my first years for them to get an idea of what they want a particular lubricant for. I also tell them that technically you can lubricate the entire movement with D5 and 9010. And yes, D5 is never a bad idea to bind when it comes to the end of its life. i suppose that was the great thing about whale oil, is that it congealed and stopped the watch, which was the best thing that could happen. Nowadays, because of synthetic lubricants that doesn't happen. So, progress isn't always the best way. It probably is for the whales though! The thing with common sense is, I've found it's not very common. Maybe it's because I'm a Northerner living in the South I've seen students using files backwards and microscopes with no ring-light turned on (for 2 hours!). Now tell me how common is that kind of sense!...lol. It's all a learning curve. I remember when I became an engineer in my teens and the things I didn't know was frightening, but age, experience, knowledge and a sprinkle of wisdom helps that common sense come to life. Incidentally it's the new day of term on Tuesday for my very enthusiastic first year students. All half dozen of them. One of them already has his own micro-brand watch company and wants to learn more about the mechanics of the movement and the different variations. This is his brand. Check them out. https://www.apiar.co.uk/1 point

-

Good explanation for beginners, i honestly thought this was common sense , common knowledge. Maybe its more overlooked than i thought. I like to have some mineral oil somewhere to bind things over time rather than dry grind them to a halt. I chose D5 microgliss (1200 / 20°C ) as my heavy oil, the rest is hp750 ( figured that was a more mid-way viscosity between the D5 and 9020 ) , 9020 and 9010. Depending where folk live, hotter or colder climates maybe a step up or step down in viscosity will benefit performance. Heres another Castrol GTX , worked wonders for my '69 Cooper S.1 point

-

The trouble with AI is that it is not always very well informed. For what its worth, Indiglo is a non radioactive dial illumination system. Here is ChatGPT's take on Indiglo. .. and with a little prompting, here is what it knows about Radium dials dumped by Timex Dundee. So in other words, Timex dumped a lot of radium dials over an extended period into the Tay Estuary, the North Sea and ultimately into the Irish Sea/Celtic Sea/North Atlantic. As to how much of hazard they actually pose, that is debatable. Not much, unless you happen to be extremely unlucky, and eat a fish that ate a lume flake that Timex made. ... and finally what it knows about Timex Tritium dials. This makes perfect sense. If you really want to know what was on your watch dial however, try measuring the activity with a geiger counter. Rather counter-intuitively if it is still quite "hot" then it is probably Radium, but if it is only sightly "hot", then it may be tritium, and if it doesn't even register, then it is probably one of the many non-radioactive luminous paints. Also if it is still luminous, then it is probably not radium, as the zinc compound in radium dials is almost always spent, so they no longer light up. The radium on the other hand will be just about as radioactive as it ever was, so don't make the mistake of thinking that since it is no longer luminous, it is no longer radioactive, this is not the case.1 point

-

1 point

-

0.3 mm Mix Moebius HP1300 with HP750 and you've got yourself HP1000! Unless you don't have HP750, but you can mix the different HP greases to a degree. I agree, the application for both is for low speed/high torque arbors, so because the torque is fairly high you aren't going to see much if any difference, which will show itself as an amplitude drop (more in vertical positions). I'm going to put up a post about lubrication, torque and speed, which hopefully makes sense and will obviously stir up a hornets nest! You are not going to see any real difference between the two greases when used on a high torque arbor; if you started playing about with the viscosity of high speed/low torque arbors such as the 4th, escape and caps then you will see a loss in amplitude, or at least the potential for a drop in amplitude.1 point

-

Brilliant! Which chrono is it? Hopefully a vintage Landeron or Valjoux with loads of eccentric studs. They really sort the wheat from the chaff and you learn loads about how the chronograph mechanism works and the phenomenal amount of adjustments that can be made to the studs to bring it all into concerto. I tell my students when we start working on their first chronograph (Valjoux 7733) "Keep in mind, many things have to be correctly adjusted and set in a movement with complications to allow it to work and to it’s optimum, but only one thing needs to be wrong to make it grind to a halt." It won't be long until your doing walkthroughs of them Haken!1 point

-

1 point

-

You have to be careful with this one. The jewel slots look a bit larger than the jewels. After you remove the shellac, the jewels might be too loose to trial fit it for testing.1 point

-

From what I've read, the figure I've seen most is that the lock is 1/3 of the jewel width (Fried suggests this). But, I have also seen suggestion that it should be 1/4 or 1/5 jewel width. The entry jewel does look a bit deep - it may be the camera angle. See how it performs on the timegrapher after a service. Is the amplitude is too low, try pushing the entry jewel in a touch1 point

-

1 point

-

Looking for advice. As mentioned in the video (forgive me for my poor English) there are 3 cycles/programs. Now the thing which I'm struggling with, is the time each program should run. How long should the wash, rinse programs be? P.S.: For anyone who is interested. The "Wash" cycle runs 200rpm forward and backwards, then the speed goes up to 500prm for a short period of time, aka different agitation levels. The "Rinse" is 800prm, to directions, w/o any agitation levels (configurable). Would be nice to add a "Spin" cycle at the end of every program, to get rid of the liquids in the basket. But this probably for the times if or when the motor could be raised up from the water. Dry is still work in progress. I would imagine, the amount or rotations doesn't matter much? Maybe keep them low and just blow dry warm air? Let me know what you think. Thank you1 point

-

Hi here’s few pics, I know that the wire on the fusee barrel should be straight and aligned -it’s almost impossible to keep it on the barrel-I was hoping it would sit better when it ran when I got the clock the wire was loose and all over the barrels -not wrapped. When I wind the mainspring barrel the wire is tight between the two ready for the spring to slowly pull the wire over-but it doesn’t move. The fusee barrel appears to be stuck-it will wind the wire up but won’t rotate the other direction to allow the main spring barrel to pull it. Apologies for the poor description A little bit about the clock for those that haven’t seen one before.. The pic is of the clock without its glass hood-it looks nicer than that . It’s a Congreve rolling ball clock. The ball rolls from one side of the platform to the other every 15seconds instead of a pendulum. It hits a lever which then tips the platform to allow the ball to roll in the opposite direction. They are notoriously difficult to set up and don’t keep good time it has lots of little weights and rods to adjust the levers and platform, and a little spirit level at the front as it has to be completely flat to work. It’s a lovely item-I just wish I could get it to work!! Sorry-there’s more.. The clock doesn’t have a click spring to keep it in place and the main spring is about 2”” wide-the ratchet whelk also doesn’t have anything to keep it in place. I’ma little nervous about completely winding it as all of that power will be on the-not great click and it’s screw1 point

-

1 point