Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 09/10/24 in Posts

-

Hi Guys, Today I have a huge sense of accomplishment and relief after finally finishing restoration of this Ball 999B 16s 21 j railroad grade pocket watch. I started it in April, so it only took me five months to complete; as life got in the way. It also had a lot wrong with it. Broken jewels, broken staff, bent wheel, broken hands, well, you get the picture. It's running great in my estimation. The fact that it's running at all is proof, not of my workmanship because heaven knows it's lacking, but of the high quality of workmanship that went into the watch's manufacture. I feel very lucky to have gotten it back into shape. My only regret is that you can see some of the glue used to adhere the crystal. I thought it was supposed to dry clear. I might retry with some UV glue to see if that's better. Thanks to all the people who gave me input along the way. I couldn't have finished without all their help. Arron.4 points

-

3 points

-

The Chinese are masters at counterfeiting. Stick with someone stateside so if you have any questions, you can call and talk to someone. Esslinger.com is another decent place to buy tools. Pretty good prices and their service is great.2 points

-

2 points

-

Welcome to the forum. First thing is if you're just starting out with watch repairs then I wouldn't start off with expensive tools like Bergeon. Personally I wouldn't trust anything that's branded from AliExpress when there are genuine suppliers where prices don't appear much different. https://www.julesborel.com/products/tools-tweezers-bergeon-tweezers/bergeon-7422-pm-b5-tweezer-brass-non-magnetic-alloy https://www.julesborel.com/products/tools-movement-tools-movement-holders/bergeon-4039-movement-holder-3-3-4-11-ligne https://www.julesborel.com/products/tools-movement-tools-movement-holders?search=2611-tn-2.5 https://www.julesborel.com/products/tools-bench-accessories-bench-mats/BG6808-GREEN2 points

-

2 points

-

2 points

-

Please stop swearing, we don't want any mention of bell bottoms and platforms on here. Hehe.2 points

-

2 points

-

Yes! You would think the reverse given the name. That's what I thought for a long time until I realised that the grease was there to facilitate the slipping of the spring. The spring wouldn't break, but other parts in the movement would be damaged, and it would cause re-banking. Otherwise, I recommend @Kalanag's link and you can also search using this link: https://www.google.com/search?q=site%3Awatchrepairtalk.com+braking+grease2 points

-

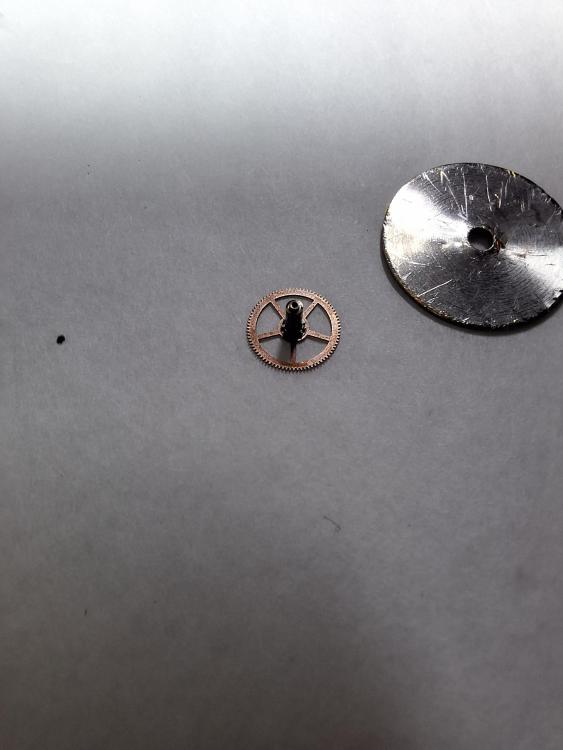

That's the old way the slipping bridle was done, as a separate piece, using a standard spring. If you get a spring with integral bridle you don't use this one.2 points

-

I picked this up at the vintage fair on Sunday for $5. Ineresting little 32mm watch. Seems to be an older size 0 but with production date of.May 1904. With Sir Wm Pitt on the dial and bridge maybe made for British but made to.look like an American pocket watch conversion? The clasp on bracelet say sturdy with a patent date of 1928. Lugs definately a later addition. Was all gunked up so stripped, cleaned oiled and reassembled. Will need to work with the hairspring but everything is there and working. Added new crystal.2 points

-

2 points

-

Following up on how to pull apart thr cannon pinion part # 1020-1219. I have discovered that an old mainspring barrel cover will fit perfectly over the cannon pinion and allow for its easy removal. You'll still need a cannon pinion remover, but theres no risk with bending the center wheel. The pics show a new cannon pinion which I pulled apart to lubricate-- too.much friction.2 points

-

2 points

-

Try these, https://www.emmywatch.com/db/movement/eta--2451/ Downloadable. https://watchguy.co.uk/cgi-bin/files?subdir=ETA&dir=Technical Manuals&action=documents Rgds2 points

-

1 point

-

1 point

-

1 point

-

1 point

-

Hi Axel, Something makes me thing it has nothing to do with the calendar. To be sure, remove one of the calendar wheels and try without it1 point

-

1 point

-

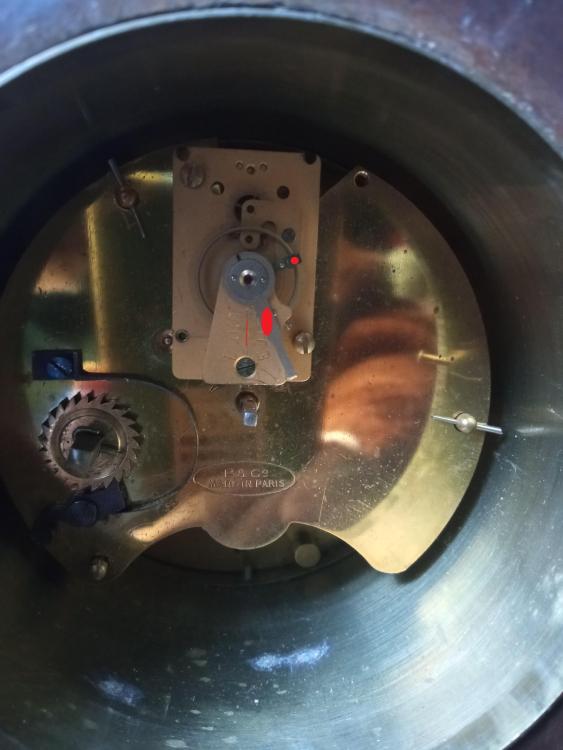

Line up the regulator by following the red line and spots then adjust accordingly. The movement has had a replacement platform which is the wrong size and is from another movement as it has had holes drilled in it that do not match your movement. It also has the wrong screws put in. It has been re-bushed and not finished properly. To me it is a bloody mess.1 point

-

Yes, it operates on single 1,5V battery, but the base is not driven by the battery, it is driven by the base coil, which generates voltage from the passing magnets through it. So, it is possible to use silicium transistor, but slight modification of the cirquit is needed as to add some bias to the base of transistor. My first question will be if the coils are intact, as this is the main problem in such watches. You don't need more powerful transistor and there is no reason AC122 to last for only 5 mins. The resistance of the coils there should be several kiloohms and no big current can pass thru the transistor.1 point

-

I never put the rotor into the ultrasonic. I just use rodico to dab off any dirt or bits stuck to it. But before you throw away the old movement, get a spare pcb and do a swap. Sometimes a defective circuit can produce an electrical pulse but it's period is too short the drive the rotor. The pulse tester is sensitive enough to pick up the pulse but it does not test the length of the pulse.1 point

-

For the price of a rotor here in the UK it's often a lot easier just to replace it than trying to clean all the filings off them.1 point

-

From what you've said I'd suspect the rotor and the first thing I'd be swapping out.1 point

-

Silicon transistors require a higher base bias; I found the original patents for the clock circuits, and those do not have any real bias to bring the base in to operating range, relying on the very low base voltage threshold and possibly even the leakage of the germanium devices. It would not do any harm to try a PNP silicon device, though it looks unlikely that it would work if the circuits I found were accurate. Those are actually gain-graded devices - the higher gain ones they have should be perfect for the clock!1 point

-

Aside from AS, I only really recall seeing left hand threads on ratchet wheels on 8 day movements. The reason being the ratchet winds in reverse. There is a rather special form to ratchet wheel screws aside from the thread; they (the good ones) are reinforced where the thread meets the head with a fillet.1 point

-

I just recorded this video which demonstrates exactly what I meant. The balance comes to a stop completely seamlessly.1 point

-

If you buy from a reputable supplier and not eBay then they'll have already done this. Edit Unless it's a reputable supplier that also has an eBay listing. https://www.ebay.co.uk/itm/2542020982831 point

-

You might read the discussion in this interesting thread: https://www.watchrepairtalk.com/topic/30176-braking-grease-a-myth1 point

-

So, I said when i used one of these balances I would provide an update. Do they work? Are they legit? I'm still almost 100% confident they are real just based on clearly being from the same tooling but possibly factory seconds likely with minor cosmetic defects. The one in the photo here which has a little hair trapped under the hairspring is the one i used. Did it work? Boy did it... So the 7s26 is not exactly famous for being a high accuracy movement. From the factory a delta of 10 to 20 is not exactly uncommon. I put the balance in and the bone headed design of how seikos stud is made it's almost a guarantee you'll put a slight twist in it when you install it that you have to correct and that's what happened. I corrected the twist and like with all seiko balances had to do a tiny bit of correction on the terminal curve to make sure it perfectly tracked the open regulator pins and stayed centered. I then closed them up and did my final timing and adjustment. On a 7s26C with the balance from sofly i got a six position delta of ONLY FIVE SECONDS. Which is a tie for the smallest delta i've gotten on one of these movements. It's been in a 7s26 on my wrist now for 8 days and has lost three seconds. Not PER day, 3 seconds in 8 days total. Based on my experience now i'm confident enough to buy these and I will likely order some more very soon.1 point

-

1 point

-

I guess this qualifies, as I paid $80 for a lot of 8 watches. While some will make good projects, the one that really caught my eye is the one with the scalloped case. It's an Elgin with a Grade 524 movement from 1937. I got the lot many months back and finally got around to working on it. It turned out quite nice, I think. Though, the balance gave me fits with several issues. I got a donor movement and swapping out the balance didn't help much. The donor itself ran better, so I did a movement swap until I can work through the issues with the original movement.1 point

-

I think that hook is for putting the wheels into there pivot holes between the clock plates.1 point

-

I can't wait for it! This is a very interesting, and I believe an underestimated question. It makes me think of the many YouTube channels where they often are very careless with the oiling. Everything looks fine on the timing machine (when they occasionally show it), but what about a week or a month later? Probably a disaster when the oil has spread leaving jewel holes dry and other parts contaminated. Here is an update for those of you who are interested. Yesterday I tried to oil the anti-shock system but failed miserably. I tried between five and ten times. It was not a pleasant experience. I got it somewhat right but far from acceptable so I gave up. I took a long walk to relieve the pressure and felt defeated, not to say failed After a good night's sleep, I looked through my stereomicroscope (40X) in the morning (having a day off) and realised that it was even worse than I had allowed myself to accept yesterday. However, filled with new energy, I removed the cap jewels and chatons, cleaned them in Horosolv and rinsed them in IPA. What I had failed to do over and over again was to place the chaton perfectly on the cap jewel, causing the oil to end up sticking on the chaton and spread out. The margin between the cap jewel and the chaton is almost non-existent, so if you fail to lower the chaton perfectly, you're screwed. This is in line with the precise fit between the parts of a Rolex watch but in this case, it was no help. It probably works if you have an extremely steady hand and practice long enough but you shouldn't wobble more than a few hundredth of a millimetre. I then remembered that I had an automatic oiler (Bergeon Automatic Oiler 1A) that I had not used for several years because I learned to oil cap jewels manually with good precision. When you lower the chaton towards a cap jewel on the IncaBloc, the margin between the cap jewel and the chaton is wider so you do not need to be as precise. By lubricating using the automatic oiler I got a satisfactory result. Maybe it was a tad too much oil but I still feel very satisfied. I don't think there is much risk of the oil spreading if the movement is subjected to severe trauma, which is why you want to avoid too much oil. Too little oil would shorten the service interval. Now that I look at the pictures again I think the amount of oil looks more or less perfect! When everything was done, I tested the free oscillation of the balance in all positions (apologies for the background music that I did not think of) and if I may say it myself, it looks wonderful1 point

-

you mean more like a few dozen hornets nests I do find horological lubrication quite amusing. For instance do the watch companies study the effect of their lubrication choices for the running of their watches long term? So in other words when you look at the tech sheet and they give a recommendation is it really the right recommendation at all? For instance people work in the service center's for various companies that replace a heck of a lot of components which makes you wonder if maybe the lubrication choices are not correct because they don't care they will just replace stuff. I like that potential for a drop in amplitude. We would need to have more than one watch to do a test because just doing a one-off watch doesn't really show too much? For instance I have a basically a brand-new 6497 Swiss watch. Gear train the entire thing HP 1300 balance pivots 9020 and escapement 9415. After servicing of anything it showed too much amplitude and even 24 hours later the aptitudes looks spectacular at almost 300° dial up and down on the other hand the watches sits around here and occasionally I wind it up to see how it still is not entirely a fair test. But it does make me wonder if the Swiss are going with too low of viscosities on their lubrication or oil where Greece should be used for instance.1 point

-

1 point

-

I should mention that if you are nickel plating, I highly recommend copper plating first. It's easier to do than nickel (can be done at room temperature, whereas nickel is best at about 60°C) and most importantly, can create a thick layer to fill defects. This is easily sanded/polished to a good finish. Nickel adheres well to copper. I've just copper plated a case I'm working on which was badly pitted. 20 mins plating and all pitting filled.1 point