Leaderboard

Popular Content

Showing content with the highest reputation on 09/12/24 in all areas

-

4 points

-

Yes, we need each other's support because there are days when you can feel very down and start thinking about giving up. It's easy to feel inadequate when you see the pros on YouTube, but then you have to remember that there is a lot of editing. A step that might take an hour, two, or even three in real life is often done in a few seconds in a video.3 points

-

Hey Joe both of these scenarios are effectively doing something similar, the impulse pin tapping or pushing the outside of the fork horns, pushing the lever moreso against one of the banking pins, without pins or incorrectly set wide pin spacing its easy to imagine that damage could occur at the pallet stones when re- banking happens (excess amplitude causing the balance and impulse pin to swing too far and impact on the outside of the fork horn ) by forcing more total lock at impact not to mention the side impact to the impulse pin itself, i see this scenario as the lever is being constantly RE-BANKED after it has already banked against the banking pins during slide or run to banking. For overbanking this also seems quite easy to remember, the impulse pin has made its way OVER to the wrong side of the fork horn unable to now release the escapement, maybe the fork's gaurd pin clearances were too much allowing the lever to slip back to it's previous banking after a watch impact had unlocked the escapement, now trapping the impulse pin on the wrong side of the fork. OVERBANKED, the impulse pin pushing is now pushing for more banking of the lever. The explanations of scenarios are correct, I may not be right with why those terms are named as such but it does make them easy to remember which is which3 points

-

Knebo realizes the issue he is facing and whats causing it, so will correct it, furthur realizes that the previous watch destroyer ( who obviously had wrongly diag the issue ) had tried to correct " a wrong " by " "a second wrong". Knebo has all ingredients of a watch fixer, DOING REAL GOOD PAL. And here I am hoping my broken English is understandable. Must admit overbanking and rebanking is confusing. Heres a good read on the subject. https://wahawatches.com/what-is-rebanking-or-knocking-of-a-watch-movement/ Rgds3 points

-

Just to close this out - I ended up going with a clasp extension from Cousins. I bought the link extension that is supposed to fit under the clasp as well but that wouldn't work with my bracelet without lots of modification. As it is, the clasp extension needed a bit of fettling to make it work. The holes didn't quite align on one side (it's not that well made) so I aligned it with the existing clasp and drilled out the hole with a 0.8mm drill where they overlapped so that I could install a springbar between them. I also brushed the existing clasp and extension with some small Scotchbrite type buffs on my Dremel to get them both matching a bit better. I think it's turned out OK, considering.3 points

-

"But if I were to say, my fellow citizens, that we shall send to the moon, 240,000 miles away from the control station in Houston, a giant rocket more than 300 feet tall, the length of this football field, made of new metal alloys, some of which have not yet been invented, capable of standing heat and stresses several times more than have ever been experienced, fitted together with a precision better than the finest watch, carrying all the equipment needed for propulsion, guidance, control, communications, food and survival, on an untried mission, to an unknown celestial body, and then return it safely to Earth, re-entering the atmosphere at speeds of over 25,000 miles per hour, causing heat about half that of the temperature of the sun — almost as hot as it is here today — and do all this, and do it right, and do it first before this decade is out — then we must be bold. " ~ JFK2 points

-

2 points

-

How we accomplish something varies greatly. What matters is the outcome. Whether a watch works well or not after a service and for a long time - many years - is not a matter of opinion. It is an objective fact. If the method is right so will be the outcome and vice versa. I never criticise the way someone goes about servicing and repairing as long as the outcome is correct. What I find difficult to cope with is sloppiness, such as dirty and poorly maintained tools, poor oiling techniques, slipping and wrong size screwdrivers, disorder, and so on because it will ultimately affect the watch and its owner and are not the traits of a serious repairer. That is, a serious repairer who cares more about the watch, the customer, and the craftsmanship than he or she cares about the number of likes, the money, and/or the fame. As I said, how we accomplish something varies greatly. This can be seen in any complex discipline from musicians to mathematicians. For example, my number one violin hero is Itzhak Perlman. He is partly paralyzed and his technique is in some ways awkward as a result, but he is in my opinion one of the greatest musicians who ever walked the earth. The most talented people (watch repairers included) are masters of improvisation and thinking out of the box. I wish I were in that category, but I'm not. I don't demand perfection from anyone, myself included, but I expect a reasonable level of knowledge and experience when someone has the intention to teach. Granted, many of the YouTube channels can and should be thought of as entertainment and marketing, but to an unsuspecting beginner, the bad things that sometimes, not always, manifest could be perceived as gospel, and it is already hard to become a decent repairer as it is. Yes, I know, beginners are not my responsibility but I am a teacher (although not in watch repair) and see it as a great responsibility and privilege. This said we can always learn something from just about anyone. I know I do all the time.2 points

-

I totally get that. Its me being jealous after all! He is a great content creator, and I need to look at it like that, and not as a watchmaker. And honestly, I like watching his videos. They are very, very well done.2 points

-

You never know. When we are able to visit other planets we might find more elements then we all ready have which is 118. So anything is possible.2 points

-

Wristwatch Revival is very nice as entertainment and he does lots of things very well. But one has to be very careful if you want to learn from it. Sometimes he makes mistakes, realizes it and then talks about the learning from it -that's great! But I also saw him make some big mistakes that he didn't realize -- not so good for learners. ... and I wish he's show some assembly and oiling! Most of the time it's just disassembly. Some theory, which is usually very useful. And fault finding, which is very good and often under-represented in other channels. I agree. He's pretty good. I'm just irritated by the amount of oil he puts on the floor and lid of mainspring barrels. But I don't want to start a lubrication debate here2 points

-

I like Mark's vids, his calm voice is relaxing as you learn so you do learn. Some guys talk as though world war 3 & 4 & 5 have started all at once.2 points

-

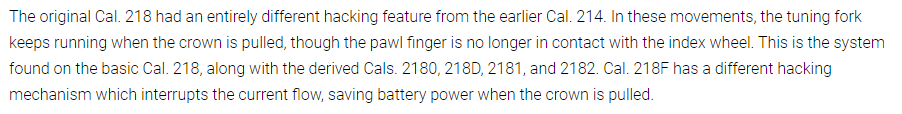

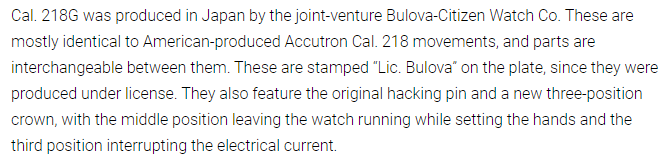

Because the stem is not an electrical switch so hasn't anything to do with the circuit. Therefore the circuit is still powered with the stem pulled it just takes less power as there's no load on the rotor.2 points

-

WRT forum or a library ? So, Found this walkthrough online. Not intended to spoil the fun here, just that it further enriches this already rich walkthrough. https://watchguy.co.uk/service-ebel-triple-date-valjoux-90/ Rgds2 points

-

2 points

-

It is not friction fit, it is riveted. It is still repairable, and relatively easy. Just needs placing the table back on the pnion (not pivot) and gentle riveting with correct punch. Most important is not to try to close the hole, as this will only bring troubles. Alternative ways are possible here like using locktite fixer if the upper portion of the pinion is engaged with the 4th wheel. The table in the end must turn true in flat and radial2 points

-

Seiko 9983-8039 Twin Quartz Finally got it running to spec across all temperatures+-5 Seconds per Year. Treated it to a new dial and crystal that I had been searching for for over 8 months. A single dial finally turned up on Cousins and I pounced on it along with the sapphire crystal. The equivalent JDM 'Superior Quartz' model apparently cost as much as a Toyota Corolla back in 1979. Cost my uncle £500 back then and that was a lot, more than a Rolex back then. Also did a bit of work on the case and bezel to bring it back a bit as it had had a really rough life.2 points

-

2 points

-

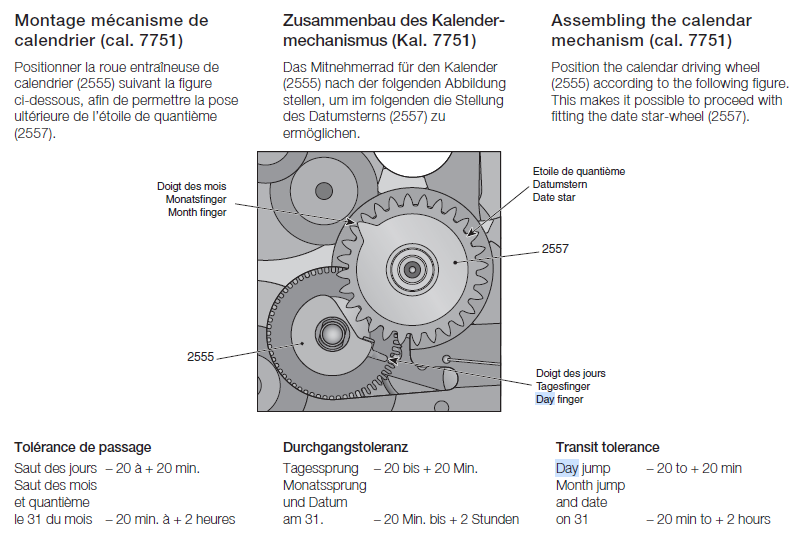

Hello all! This will be a walk-through of my service of my Valjoux 90 triple calendar and moonphase watch by the largely unknown brand "Nivia" (if you happen to know more about then brand than on this website http://www.nivia.com.hk/, please do let me know. I'm curious). I bought it from a private seller who had bought it a year earlier from a professional dealer. It had been serviced by that dealer (so a year ago). I had noticed that it was running with significant differences in amplitude between dial up and dial down positions, so I had previously opened it and discovered some metal shavings, mostly at the pivot of the central seconds pinion. After removing that debris (and re-oiling the escapement)... wait for it... it was overbanking!! Oh boy. Well, spoiler, the mainspring turned out to be too thick (0.15mm instead of 0.14mm; and power reserve was rather low-ish). So now, I'm giving it a full service and a thinner mainspring. As with my service of a Jaeger LeCoultre Memovox cal 916 (see here: https://www.watchrepairtalk.com/topic/29824-jaeger-lecoultre-calibre-916-memovox/), I'll post the walkthrough several stages, as I progress. Today: disassembly. Just a few pictures of the whole thing: I start by taking the bezel and crystal off. And taking some more pictures. hands off Snap-on caseback removed. Some marks of previous watchmakers. very pretty movement, I think. movement holding screws a screw to release the stem, removing the central seconds bridge and pinion Note: the pinion goes on top of the spring. I'll leave the spring in place for cleaning. , I don't have a special tool for this, so I carefully remove the friction-fit seconds driving wheel with my hands levers. Worked fine. I struggled to find the screws to release the dial. After a while I found the eccentric screws that are accessed from the train side of the movement. gorgeous triple date and moonphase mechanism shouldered screws everywhere. the following pictures of disassembling the calendar works is without additional comments. Mostly to record good pictures of the scews and correct positions of levers etc. Some of the pins on the day/month/moonphase driving wheels are a bit bent and one of them even a bit loose. I'll fix that later with the staking set. these shouldered screws are a bit longer than the others. train side (will do the keyless works after) back to dial side and keyless works the lower balance jewels are hidden under this big plate straight foward keyless works Using a rounded stake that just fits around the pins to straighten them and to tighten them in their holes in the wheel. Worked well. the results look fine back to the case. disassembling also the correctors. Lots of very old grease. giving the hands a little buffing with leather. WELL, that's it for today. After cleaning, I'll post pictures of epilame treatments and then assembly.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

I can't remember the size and it's at work but the part that moves is small enough to easily fit inside a 12mm barrel.1 point

-

1 point

-

Mitutoya have a very good reputation but they can be expensive. Machinists sometimes refer to the calliper as the “guessometer” Tom1 point

-

1 point

-

Definately so, Plenty of stars more massive than our sun. Gravitation force is directly proportional to mass, gravitation fields stronger than that of sun fuse more mass into new nuclei ( mass of two or more nucleus) which then decays towards a stable state, simultaneously attractng electrons to fulfill its orbital momentum at all stages, so bigger atoms form and achieve stability. Abundance of life out there, some more intelligent than us is " undebateable ". Not all substances on earth were put together by the sun. Many have come to earth from outside our solar system, but earth is located in a so called life ring in milky way, outside which life as we know it is unlikely to exist. What makes it complicated is that it all is a boiling pot constantly undergoing change. Human knowledge which we call physics is very limited. What I have problem understanding is, why creatures on earth can only live by eating each other.1 point

-

Just wish certain youtubers with enormous audiences would stop telling that audience to go and buy pocket watches to get started, when really meaning a modern, working ST36. And every week several more people show up on reddit subs asking what to do with a trashed cylinder escapement or American Waltham or Elgin they don't have the tools to work with, or worse - their family's heirloom railroad watch. I did watch many of his early videos but stopped because they lacked variety. It was mainly just straightforward service of high end brands and rarely any challenging repairs or tooling explanations of more interest to me. More interesting than seeing a clean Daytona go from +8s / 260° to cleaner and +1s / 295° after service.1 point

-

Hard to find data on these movements. No reference to mainspring in the GR database, Cousins or Jules Borel. Must be a reference somewhere1 point

-

Thing about Marshall is he is not just about watches, he has been a successful content creator around a d&d type card desktop game. A lot of his followers come from there. He is a member here BTW though doesn’t interact much these days. So he is a successful entertainer/commentator who now also dabbles in watches with mainly high end tools and selling tools and lubricants. Also mentioned was Stian from Vintage Watch Services, also a member here. I believe he has completed courses with the BHI which is more than most of us here have done. glass houses and stones and all that. what I have learned about watchmaking is there are a myriad of ways to accomplish an outcome, mostly what is right or wrong is a matter of opinion. Tom1 point

-

What I see is that the donor spring width is almost 1.9. The original will be the same. This only means that the measurements are nod that correct. And yes, the lid thickness is the smallest thickness, not with the lip. If the amplitude varies, then check what I have written about the 3rd wheel in previous message.1 point

-

I think someone with the following and income of Wristwatch Revival should be at least 99% accurate in things they do. He makes a lot of mistakes, he does correct a lot of them, some of them are just missed. Its stated on his Patreon page, he makes $6,700 per video, just from patreon. At that rate, I think it should be more accurate work, nicer movements, and more in depth. He does a lot of junk no name things, and I cant help but think "wow, he spent $15 on ebay, cleaned and lubricated it, and made $6,700". I guess that's just life. He is more entertainment value than instructional. And yes, I am jealous he makes that money, doing the same thing I do, but at a lower level. To add to this topic, I really enjoy watching Kirk Rich Dial Co restorations. A lot goes into dial restoration, and there aren't many channels showing it. I wanted to get into dial restoration as well, but after watching them, I don't think its financially feasibly.1 point

-

Hey @Nucejoe Thanks! Yes, I saw that one. Hardly any information on how to service it, but still nice as a reference.1 point

-

Oh I see. What happened to energy conservation idea ? lol I know it ain't your fault, Andy. Thanks.1 point

-

So I ended up refinishing the case myself. I am pleased with the results although it would have been cheaper to send it to rePlateit. And they probably would have done an even better job than I can do. I relumed the dial myself also as it was radium but I didn't do the best job. As I am just using this watch myself it is good enough. I may try the relume again at some point. As a side note because I replated the case myself I was able to take the hardware from the old strap that was on it, replate them and make a new strap with some scraps of leather I had laying around.1 point

-

Late to this discussion but here’s my two cents… Wristwatch Revival is good. First one I stumbled across. He may not be a pro, but that’s his whole thing. He gives the impression that anyone can do it, and is clearly learning as he goes. His later videos show far more competence. French Watch Collector similar, but probably more competent. Does a lot of chronographs. I like Kalle at chronoglide, but I really wish he’d get to the point sometimes. Nekkid Watchmaker is my favourite. From my part of the world so there’s a connection there, seems highly skilled especially with cases, but always humble. I take the points about his oiling - I’ll take more notice.1 point

-

1 point

-

Ahh love your sense of humor H its probably not so far away from mine Hmm.....started to laugh.....maybe not quite so funny for the owner of the back door1 point

-

1 point

-

I finally got back around to an ETA 1093 that I had started servicing and then gave up in frustration a few weeks back (See this thread for self-pity and complaining, or don't bother). Basically, the train was running perfectly free until I installed the barrel bridge, at which point it seemed to bind up. Anyway, moving on I lubricated the escapement and installed the balance. As expected, the movement started running but with really low amplitude (around 150 degrees) - not surprising considering how tight it became with the addition of the barrel bridge - I had also over oiled the train with the removable end stones so I intended to strip and clean the movement again anyway. I slowly started stripping the watch again, checking each wheel for end shake and giving it a general look over to try and find what was binding. Once I removed the barrel bridge, the train freed up again and turned over well with just a few puffs on the escape wheel. I now had a donor movement in hand, so I pulled the barrel bridge from this one and tried that in place of the original. The train bound up again. Looking at the two barrel bridges side by side, I couldn't see any differences - they both looked flat and there wasn't any signs of rubbing (I suspect that this 'fault' was present when- I got the watch and it was running with low amplitude because of this - rather than specifically needing a service). The centre seconds wheel, also has a slight wave to it and is not running entirely true - this probably wouldn't effect running too much but I at least get the chance to try and true the wheel up again or replace from the donor before installing. I then turned to the barrel and swapped in the barrel complete from the donor, reinstalling the original barrel bridge it was like night and day - so much better. I then pulled the barrel arbor from both the serviced original barrel and the donor barrel and compared them with my 15X loupe. I couldn't see any difference - if anything the serviced orignal looked better because the square ratchet drive on the donor was a little chewed up and it was yet to be cleaned. I installed the donor arbor into the serviced original barrel (it had a new mainspring so I wasn't ready to give up on that yet), installed it back into the movement with the original barrel bridge and again it seemed so much smoother and free. Now I have the correct combination of parts, I am going to reclean everything and reassemble tonight and see what I get. There was no appreciable endshake or play with either barrel arbor and it seemed the same with both barrel bridges so I am going to rule out the barrel bridge becoming oval and binding but I can't for the life of me determine what was the problem with that barrel arbor unless it had always been slightly too big for the barrel bridge bearing from the factory or misshapen in some other way. I can't see the barrel arbor wearing and not the brass barrel bridge. Perhaps if I had a microscope (hoping Santa Claus brings me one this year) I could see a microscopic difference between the two. It's also a lesson to check each component for free running as well as endshake when inspecting it. Barrel arbor to barrel, barrel complete to barrel bridge and the rest of the train when installed. If you install each wheel individually and inspect in isolation of the rest of the train, you can determine easily which wheel is dragging. It takes a bit longer but it avoids having to fault find on an assembled movement.1 point

-

Thank you @Nucejoe That means a lot to me from a true watch repairer! The article is good. Nothing new to me, though (except the clarification on terminology ). I especially agree that modern oils and mainspring alloys can quickly lead to re-banking on old watches (1950s and before) and that it's often a wise choice to opt for a weaker mainspring from the outset. In my case, the one I found in the movement was 0.15mm, whereas the original mainspring should be 0.14mm. I actually ordered a 0.13mm mainspring... I think (hope) that I'll still get sufficient amplitude (we'll see!) and a small boost in power reserve (because the spring will be a bit longer).1 point

-

I would limit any approach to a YouTube repairman to professionals running a proper company. Two that spring to mind are Chronoglide and gentleman’s watch service. https://www.chronoglide.nl https://gentlemenswatches.co.uk whilst there are many talented amateur watch repair folk on YouTube making money at this work, some of them are members here, you don’t have the security as a consumer of a fully insured business in most cases. Tom1 point

-

Welcome to the forum. Repairing the old movement would be an option but you'd need a lot more experience to try, Now you've got the GM10 the easiest option is to remove the old dial feet and fix new ones. https://www.cousinsuk.com/product/watch-dial-feet-non-swiss1 point

-

Reverse osmosis was a game changer in water purification. Before RO filters, I had water distillers in my clinic, which were like running all day, just to produce enough water for the clinic. It used to heat up the whole sterilization room and the electrical bills were phenomenal. I helped 3M trial the use of direct water mains to RO water supply to dental chair units. RO filters provide bacteria free and almost distilled quality water at a fraction of the cost and at an incredible flow rate. The RO water actually dissolved the mineral buildup in the plumbing of my dental chair until the brass fittings looked brand new internally.1 point

-

1 point

-

1 point

-

1 point

-

Hello and welcome from Leeds, England. Definitely not a watch to start on. Omega might fix it or say it's too old, a decent watch repairer could do it but getting parts may be difficult.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)