Leaderboard

Popular Content

Showing content with the highest reputation on 09/13/24 in all areas

-

Kalle regularly mentions how he enjoys the interaction with subscribers on the live streams. (Are there any others that regularly live stream?) Personally I wouldn’t want to move through assembly with all the interruptions. Besides that, all the real work has been done before assembly… He does have a library of instructional videos and more planned with his upcoming book (an observation, not a paid endorsement…) Not an opinion I disagree with but I’ll share this amongst y’all- I sent this one into their shop last month… Hear me out- I appreciate heavy patina as much as the next man but this dial has damage…and is visually distracting IMO. I suspect this happened early in it’s life as the rest of the watch is mint- no scratches, tight screw slots, clean and original case. Hat tip to WRT’s Stian who uses the word ‘coherence’- where the parts of the restoration make sense given the wear and age of the piece. Here I don’t think there’s coherence… …This one’s been sitting for nearly two years hoping I’d find an original JLC replacement but no luck. Perrin had an inexpensive leCoultre which the watch has ATM but now the watch is a bit of a franken… If all goes well the watch is going to a known owner who has much interest in vintage but little interest in patina…4 points

-

I have wondered if Kalle prefers not to film service and assembly for liability purposes. After all, they're all client watches and mostly valuable ones. By filming the disassembly, there's video evidence of what was wrong with the watch. But by not showing the assembly, a client can't return with complaints about technique or perceived corner cutting (as we're all doing in this thread!) He's talked before about what a lot of "Rolex people" are like when they come into the shop, with a lot of demands and sometimes fake watches. I can imagine the hassle it would be if they watched a reassembly of their own timepiece and came back to complain that it didn't follow the exact steps they found in a service manual online somewhere. I am satisfied enough when he posts the occasional video from the machine areas or something theory related. I think his shop has better things to do than setup a bunch of cameras when they're trying to get the real work done. The difference between a professional workshop's channel and the hobbyist channels.3 points

-

I watch several channels. These are a few. Weekend Watch Repair Vintage Watch Services My Retro Watches Red Dead Restoration Saving Time - He also makes custom watch bands, which is interesting to watch Wristwatch Revival Nekkid Watchmaker - Love his case rehabs I do like the videos where they keep their mistakes in and discuss them so I can also learn from them. Even then, I do recognize that they are not perfect and some of their technique can be lacking. I do appreciate the comments on here pointing out some of those issues. Someone commented about Marshall laying out the parts on his work mat. I just watched one of his videos where he was unloading the mainspring from the barrel and the end hit the parts, scattering them. He didn't notice at the time that one screw was missing and he never found it. Personally, I'd rather put them straight into a parts tray.3 points

-

3 points

-

I like all those mentioned and pull something different from each. My wife enjoys Kalle and Stian so we watch together and I’m in less trouble when the Esslinger and Cousins deliveries show up3 points

-

Hello everyone! This is my first post here on WatchRepairTalk, and I wanted to share a project I've been working on—a DIY Watch Cleaning Machine that I designed and built myself. Since it's difficult to find a good-quality machine at a reasonable price, I decided to use my engineering skills and create one. Why not, right? Look at a demonstration video on my instagram page. You can follow this page if you are interested in my watchmaking journey! Demonstration video of Akrid the Watch Cleaning Machine I named this machine after my alias from the Dutch watch forum, Akrid (which is also my alias here). It features three stations: one for cleaning and two for rinsing. The final cycle is for drying the watch parts, allowing the movement to be reassembled immediately after the cleaning process. I've been using it for two months now, and it's been working flawlessly! The cleaning results are far superior to what I used to get with my ultrasonic cleaner. See the cleaning results here: Cleaning results of Akrid I'd love to hear your thoughts on the design!2 points

-

I’m trying the best I can. I will show more info and photos when I get back home, and hopefully I can find the issue, with help from the good people here2 points

-

2 points

-

I'm not sure gaskets are supposed to be a tight fit or not. I'd buy 38.5 and 39mm (if available) and try both. I bought a pack of 100 gaskets (Indian) from Cousins. I don't think I've ever used one as the quality is poor. Unless you know they are good quality (Swiss) I would advice against, and just buy the sizes you need. ISO Swiss ones are only about £2 per pack of 2 from Cousins. I usually buy a couple near the size I want, and you soon build up a useful stock.2 points

-

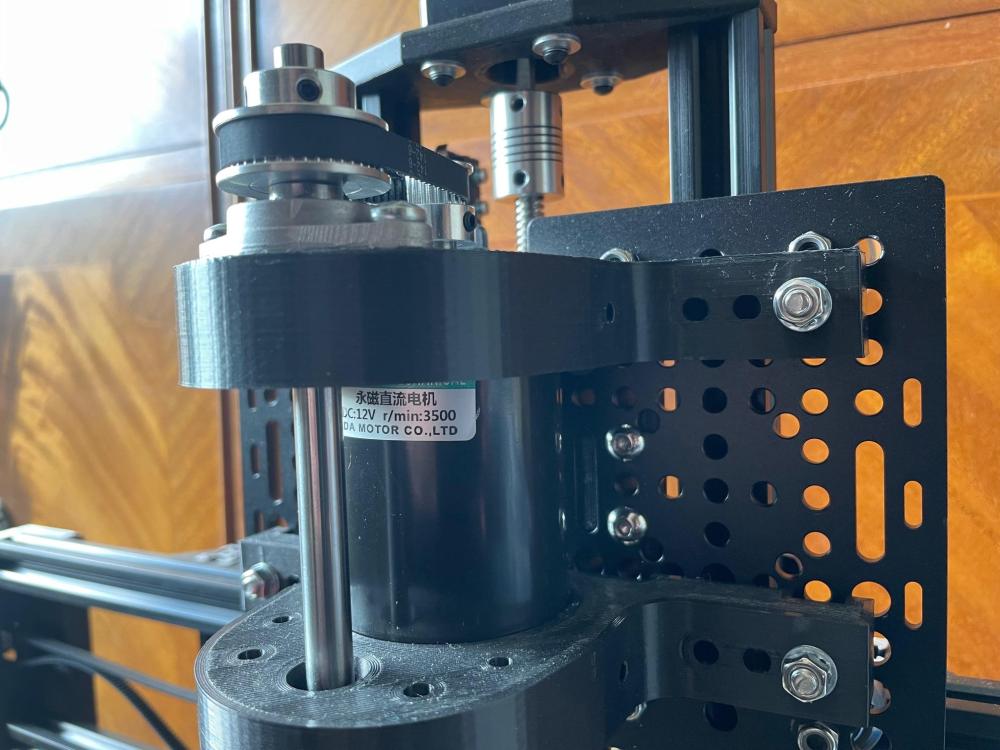

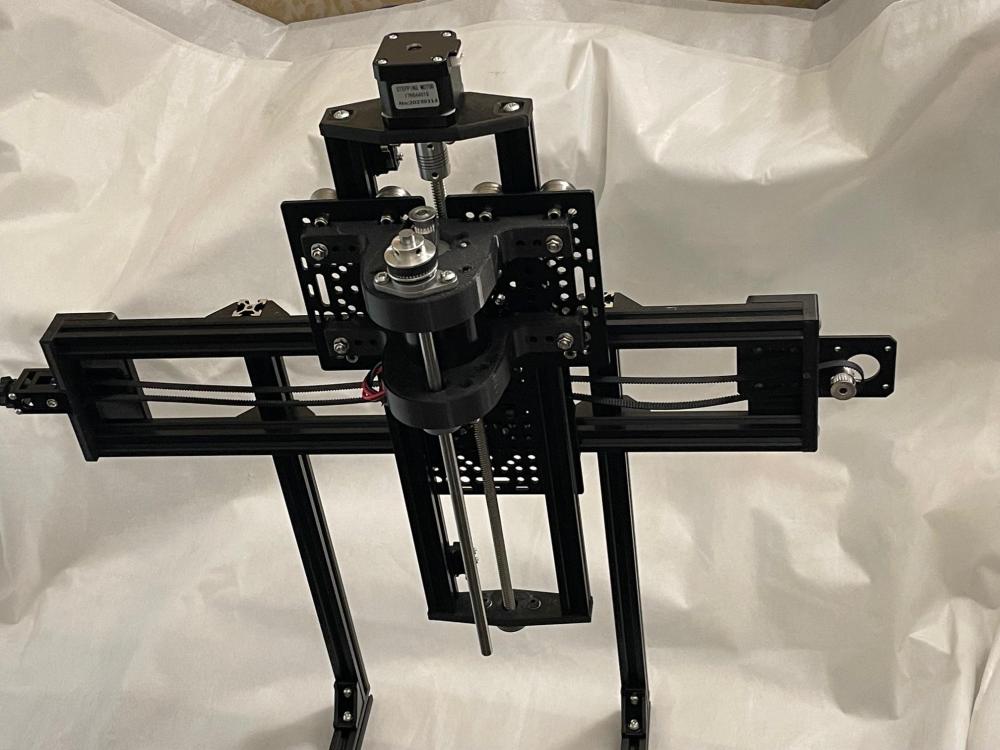

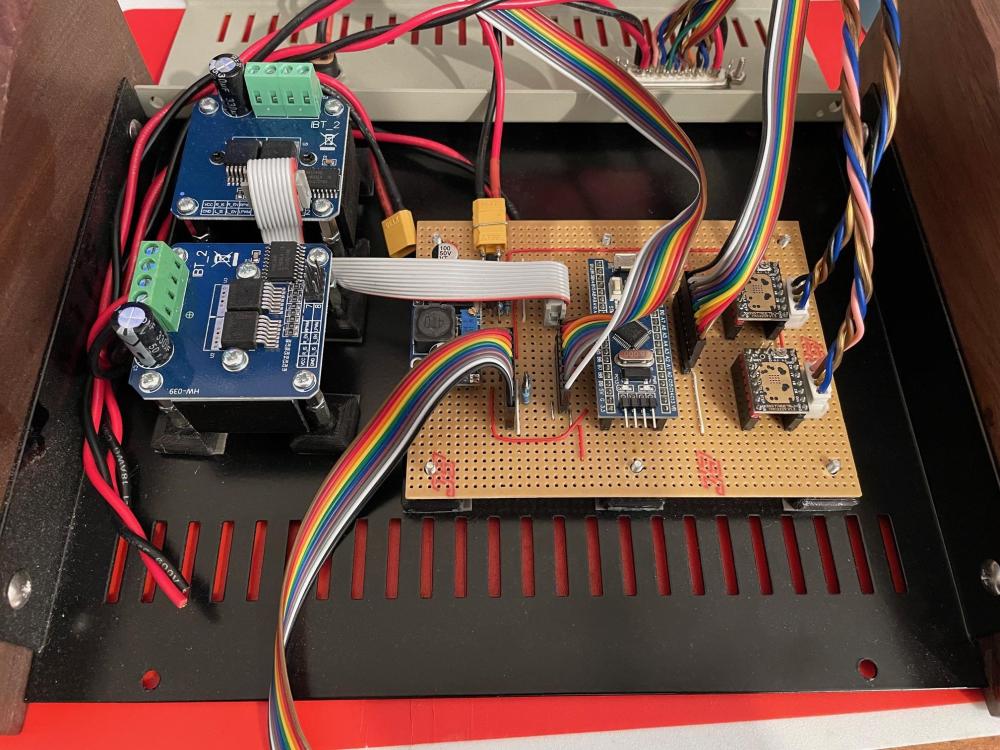

It's a work in progress, I need to finish off the servo control stuff. It uses mostly off-the-shelf aluminium extrusions & common parts for 3D printers, plus some 3D printed items. Functionally, it's the same concept a rotary automatic, except the four in a row linear system is easier to get parts for than a turntable system. It's sized to fit 1L Kilner jars, as a standardised container. The same control system could equally work a rotary turntable. It will be published as an open source design when completed. I have the X motor off it at the moment, to use for testing the servo software. These are the overall frame & control box: The X & Z axis motor drivers are the two small plug-in modules at the right, the one in the middle is an STM32 MCU and the two big lumps at the left are the spindle motor and heater power drivers. [This is all baby size hobby stuff - I program and repair industrial machine tool & control electronics, from CNC mills & borers, to literal car crushers]. Yep, a bit off topic, but video here: https://www.youtube.com/watch?v=1u4WZs5tK0U2 points

-

The problem with these is trying to use the depth gauge when it waggles about on something that's only a few mm.2 points

-

Well... it is dissolved in alcohol, and shellac is used as a food glaze, so ... While we are in the process of confessing to our follies, here is my second attempt at fitting a crystal to this bezel. Apparently I didn't learn from my mistake of tweaking the crystal press "just a quarter turn more to be sure" the first time, so I did it again, just in case this one needed the extra little bit of tweakage that the first one didn't need. Yes it is the correct size crystal, I've just rechecked for the umpteenth time as I still have the chipped original. I can't blame the watch, or the tools, just the tool operator Do I have any more of this size? Of course not, so now I can wait a few weeks for the replacements to arrive on the slow boat, and contemplate my life choices in the meantime. I bought a pack of ten this time. Based on previous performance, that probably only increases my chances of getting it right by a small margin.2 points

-

2 points

-

I updated my cleaner with square jars. I think they really are better than the old round ones. Plus the lid mechanism is very odour proof while in storage. In the video the RPM is a lot higher than necessary just for a test run. If I remember correctly the pro machines do like 200 RPM for a cleaning cycle which is very slow.2 points

-

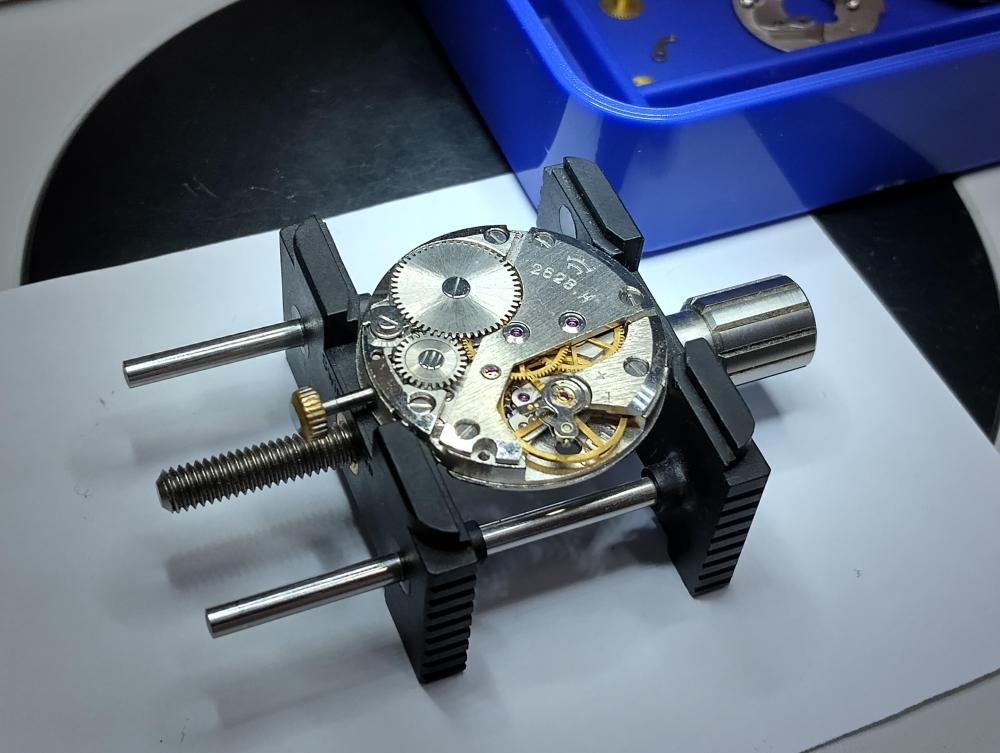

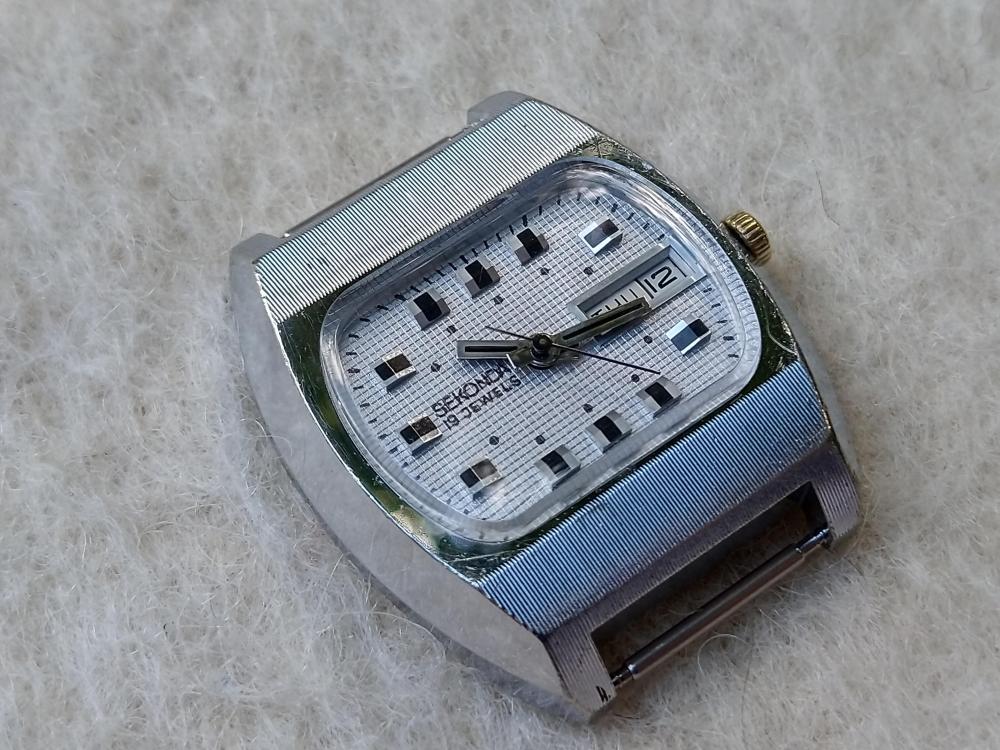

HWGIKE#12 Raketa 2628H 61009 Full service. Major mistake(s?) were made. What does the one do who does not release the power before taking off the pallet bridge? Well that's a good opportunity to practice how to glue the pallet stone back with shellac. I am actually happy about it because now I have a shellac syrup I can apply at any time anywhere where it is needed. I still need a pallet warmer though because I don't want to wait a week or so for the shellac to dry. I also managed to break the balance stuff? I had 6 weeks off when I could not touch my lovely watchmaker tools at all, but before I went the balance stuff was ok.. so do I think and when I returned one of the pivot was broken.... well we had visitors meanwhile, but it is highly unlikely that they played with it... anyway I bought a balance complete, but the new staff was too long so i had to borrow some Russian spacers from a poljot movement for the balance cock to adjust the end shake. Its performance is surprisingly good, almost a straight line on the time machine and the amplitude is great too. My Jaquemart automation pocket watch now converted to wrist watch. Original case was lost some while ago, but I managed to buy the movement which is cased now.2 points

-

Finally completed what's been a bit of a long term aim for me - a 1:1 homage of the 6105-8009... I say 1:1, there are a couple of very small differences along with the different crystal type - bonus points if you can spot them. A slim case from Ali also arrived - bought to see how I like it, and have dropped in the movement and dial from a previous build. I may go a bit further down that rabbit hole eventually, depending on how I like it... so far it feels like there's something missing, having become used to the later version. I'm not altogether pleased with the black/grey bezel insert - my black didn't fit quite right - though may stick it on a grey NATO which could look nicer... Pics alongside the real thing:1 point

-

1 point

-

Sorting out hairspring in place is not a good idea if your a beginner. Removing the balance complete ( if you feel confident) gives you a chance to see the coil, check pivots and make sure all is OK. Provide a side and top view of the hairspring coil, we might see faults that you now miss, and show you how to correct it. Felsa made good movements, this is the first stupid design of theirs I ever saw. Had it been a standard ratchet wheel, your watch would be ticking now. No worry, take your time , ask questions and let us work with you to fix your watch. Best wishes.1 point

-

1 point

-

Check if ratchet wheel rubs on barrel bridge. Possible cause, Ratchet wheel's centre square hole ,dislodged from barrel arbour square shoulder.1 point

-

I agree with you, they are not restorations, but reproductions. I don't have the eye for the kerning or any of that, so I'm clad you pointed out the inconsistencies! Another channel that the average viewer doesn't understand that its not well done? The square Bulova dial that they did that had 2 different finishes in an X pattern I thought was really cool.1 point

-

Interesting idea - I'll try and do some tests with a contact mic over the weekend. I'd not seen this thread before; the mic connections in that video are a bit messed up! While it would work, it's likely to pick up noise an hum, as shown. The battery and signal at the three pin plug are correct as shown - but the signal ground to the phone or PC should be directly from pin 3; that's the metalwork ground connection. The video also has signal and ground swapped at the TRRS plug; on any modern modern mobile phone, the top sleeve is the mic input and the second ring (TRRS) is ground. The tip and first ring are headphone or aux stereo out. For a normal PC that uses stereo plugs, the mic input would be tip and the ground on the sleeve. (Or use both tip & ring for mic, for a stereo input).1 point

-

1 point

-

Sorry I didn't realise you were trying to measure the depth of the barrel. You could measure the total depth of the barrel, then subtract the depth of the base by measuring where the teeth are.1 point

-

Marshall is still my favourite, for the simple reason he shows the full re-assembly sequence of whatever watch he's working on, which many others skip parts of. He also admits it when he realises he's made a mistake. I don't agree with everything he does by any means, but it's entertaining and has some useful information. Some of the others are good technically, but often spend too much time on things other than the movement itself for me to stay interested, or just skip too much of the re-assembly.1 point

-

It's a lab stirrer with an Elma basket. The round lid was part of the old round jars but I decided to recycle it since the diameter was a good match with the new square jars. It is just loosely sitting on top of the glass jar and I also upgraded the old design by gluing a ball bearing on top of the lid. When I do the dry spinning cycle with higher RPM I have to hold the lid and jar down with my hand but that's not a big deal, I don't clean movements that often. Some day I might build a programmable system with a more rigid frame. Now I'm using a flexible shaft coupler like this between the motor and the shaft so it doesn't matter if the motor axis is not perfectly upright1 point

-

1 point

-

1 point

-

1 point

-

That crown vise is nice! Heavy block, really useful when removing an old gasket from a diver type crown. Also inserting a gasket on the stem is easier vs holding the crown and stem with tweezers.1 point

-

I have been cleaning and polishing the brass plates the last two days. The battery juice has caused dezincfication of the brass leaving patches of porous copper. I might have to dig my polishing lathe out of storage to buff out the damage. I have a question about the prep work prior to to applying lacquer. What material would be suitable to plug the pivot holes to prevent lacquer from getting into holes?1 point

-

Hahaha, I've wondered the same thing! And he's not the only one doing that. If they keep all the parts, I'm just impressed. Yes, dirty benches are a big no-go. Funnily, I just stumbled upon their channel just this week. To be honest, I found it horrible. It's not a restoration, but basically making a new dial. Hardly anything of the original dial is left at the end. And if you look closely, they are not great reproductions. The printing is consistently too thick. I saw a video of a Omega Constellation pie pan dial (which, in my opinion, was still quite nice as it was) and the "restoration" visibly softened the edges of the "pie pan" from sharp to rounded. It didn't look original at all at the end. Well, that's my rant for today. Indeed, for the unsuspecting beginner it is very hard to distinguish channels with a "teaching" function from those that are just "entertainment". But we also can't expect those Youtubers in the entertainment category to permanently tell everyone not to take them seriously. I'm sure if you were to watch every video chronologically, it would be clear that they're also just learning and are not pretending to teach. At least for Wristwatch Revival / Marshall. Hahaha, that's definitely true!! I did watch many of his early videos but stopped because they lacked variety. It was mainly just straightforward service of high end brands and rarely any challenging repairs or tooling explanations of more interest to me. More interesting than seeing a clean Daytona go from +8s / 260° to cleaner and +1s / 295° after service. Yes, absolutely, that's also my observation and disappointment for that channel.1 point

-

Rockets and watches have one thing in common, the science behind them is easy, the engineering difficult.1 point

-

I think some of the smaller ones could quite easily end up in half anyway so maybe not a bad idea to at least cut them in half to start with. Maybe put a piece of electrical tape in the middle first then you've got something to hold.1 point

-

Great! Happy to see that you're back at it. Keep us posted! Ohhhhhh!!!! I'm so glad that you are writing this! Not glad that you went through it, but that I share the experience with someone. Please have a look at my post and drawing here (and ignore the ones that followed):1 point

-

1 point

-

1 point

-

1 point

-

I can't remember the size and it's at work but the part that moves is small enough to easily fit inside a 12mm barrel.1 point

-

I agree but he is one of those people who never takes a break from talking which in the end becomes almost unbearable and I can't stand him putting all the parts on the work mat. How the hell does he manage to avoid the parts disappearing? If you then look at his (and Nekkid Watchmaker's) lubrication technique, I for one will not be happy and probably neither will the owner of the watch a week or a few months later. When he then cleans the oiler in the Rodico which is so dirty that it is more black than green, I'm out. Need I point out that Moebius 9415 needs to be stirred before use? I'm afraid I can't agree. Perhaps I should have named this thread "What's your-favourite love to hate YouTube watch repair channel"1 point

-

Late to this discussion but here’s my two cents… Wristwatch Revival is good. First one I stumbled across. He may not be a pro, but that’s his whole thing. He gives the impression that anyone can do it, and is clearly learning as he goes. His later videos show far more competence. French Watch Collector similar, but probably more competent. Does a lot of chronographs. I like Kalle at chronoglide, but I really wish he’d get to the point sometimes. Nekkid Watchmaker is my favourite. From my part of the world so there’s a connection there, seems highly skilled especially with cases, but always humble. I take the points about his oiling - I’ll take more notice.1 point

-

1 point

-

Thank you @Nucejoe That means a lot to me from a true watch repairer! The article is good. Nothing new to me, though (except the clarification on terminology ). I especially agree that modern oils and mainspring alloys can quickly lead to re-banking on old watches (1950s and before) and that it's often a wise choice to opt for a weaker mainspring from the outset. In my case, the one I found in the movement was 0.15mm, whereas the original mainspring should be 0.14mm. I actually ordered a 0.13mm mainspring... I think (hope) that I'll still get sufficient amplitude (we'll see!) and a small boost in power reserve (because the spring will be a bit longer).1 point

-

Seiko 9983-8039 Twin Quartz Finally got it running to spec across all temperatures+-5 Seconds per Year. Treated it to a new dial and crystal that I had been searching for for over 8 months. A single dial finally turned up on Cousins and I pounced on it along with the sapphire crystal. The equivalent JDM 'Superior Quartz' model apparently cost as much as a Toyota Corolla back in 1979. Cost my uncle £500 back then and that was a lot, more than a Rolex back then. Also did a bit of work on the case and bezel to bring it back a bit as it had had a really rough life.1 point

-

Honestly, you're well on your way to being a great watchmaker if you undertook this type of repair. This is something I see even seasoned watchmakers don't want to mess with. If you' re interested more in escapement theory, which I think everyone should be, have a look at this book. Anyone can clean and lube a watch. It takes real skill to start messing with the geometry of the escapement. escapement book.pdf1 point

-

1 point

-

Aside from AS, I only really recall seeing left hand threads on ratchet wheels on 8 day movements. The reason being the ratchet winds in reverse. There is a rather special form to ratchet wheel screws aside from the thread; they (the good ones) are reinforced where the thread meets the head with a fillet.1 point

-

The chaton is replaceable and this one MUST BE REPLACED with a new one, cuz the groove in which shock spring locks is ruined, therefor might lets capstone sit unlevel in the setting thus pushes balance pivot to rub on Chaton's hole. Check balance pivot under high magnification for wear, where it rubbed on chaton hole, as well as the pivot's cone . Good luck.1 point

-

I don't see this video in the topic's past history to my surprise. Watching George Daniels work and listening to him philosophize is completely fascinating. Watching Daniels handle a fine handmade tourbillon and silver engine-turned dial without any finger coverings and quickly mash the minute hand onto his masterpiece with the back of his tweezers makes me dizzy. (Hoping to prove the timekeeping superiority of a mechanical watch over an electronic one was a lofty goal)1 point

-

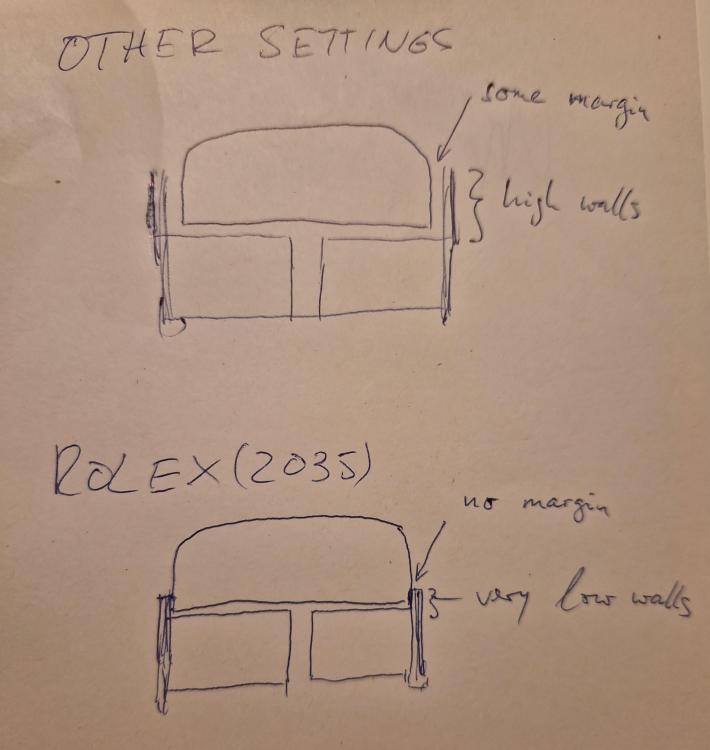

Well, some good news. I found the intermediate crown wheel. It was somehow stuck within another similar wheel. But this project remains challenging: I wanted to "quickly" oil and insert the balance jewels. Normally, this takes me about 15min. This time, I was on it for 60min. I had to do and redo it many many times because the fit between hole jewels and cap jewels is so tight. It really felt as if the cap jewel was too big for the setting (I also tried all combinations of hole jewels and cap jewels; but all jewels are supposed to be the same and have the same part number). See the drawing below. Normally, I can easily "drop" the hole jewel onto the oiled cap jewel. Here, it just wouldn't fall into its place. When pushing it on, it often moved around and messed up the oil dot (moving it away from the center). To be honest, I'm still not a 100% sure if my oil drops have now remained in the middle. Has anyone else made this sort of experience with Rolex (or other brands)??1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)