Leaderboard

The search index is currently processing. Leaderboard results may not be complete.

Popular Content

Showing content with the highest reputation on 09/15/24 in Posts

-

7 points

-

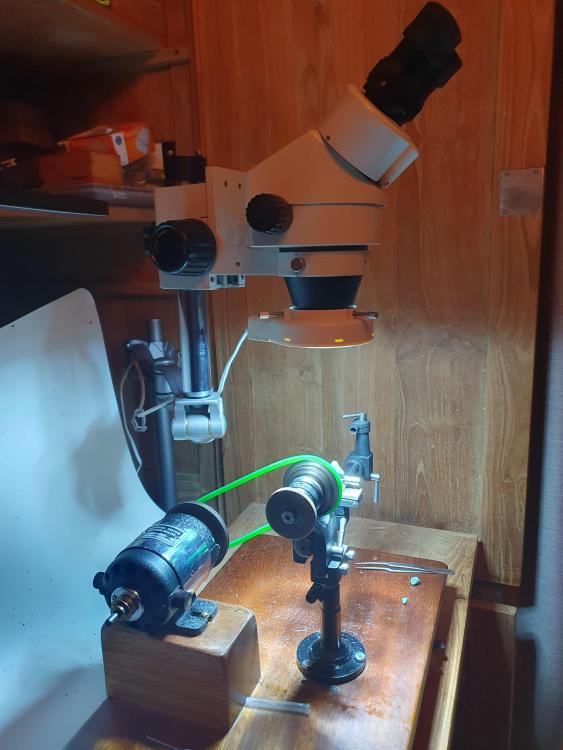

I know it's far from perfect, but nevertheless.. for a first attempt at making something resembling a balance staff..it could have gone worse.. So I'm happy and I wanted to share this and say thanks for everyone on this friendly forum for sharing their knowledge. Much appreciated!! It's small. I used 1.2mm blued steel. The cheap hand gravers @nevenbekriev mentioned (Thnx Nev!) performed like advertised. Having your lathe under a microscope makes it easier as well.3 points

-

Looking good. Stupid question. Is it safe to have it propped up on blocks. Have you got a fridge for the cold beer.3 points

-

Nothing special to do here matey ,done this many times with generic stock hands used on movements that have missing or damaged hands. Reduce the hole with appropriate domed stakes then broach out carefully. If you have a good hand gauge this will help determine the correct size needed and speed up the process. You can do this no problem fella3 points

-

It doesn't look like their pocket watch movements from early 20th century, but it also doesn't look out of place for a 70s watch riding on a high class name. They also used the Felsa 690 auto caliber in watches then, which are some of the most plain looking auto movements ever. (Good movement though) I used to do quite a bit of work for Cartier, and it was shocking to see a piece from the 60s, beautiful JLC , or Zenith caliber, and then one from 10 years later with a stock undecorated ETA 2412 or AS . It was a dark time for Swiss watchmaking.3 points

-

3 points

-

3 points

-

unfortunately in watch repair there is lots and lots and lots of variations of things including casings. for instance if you ever purchase anything from old watchmaker estate stuff for instance it often find handhelds case wrenches for specific case back's. You'll soon accumulate a small collection that you probably never ever use almost popular for some particular case back that probably doesn't exist anymore. All kinds of shapes and sizes. Here for instance is a rather expensive one but you can look at all the examples and get ideas of what exists and there's even a video. https://www.esslinger.com/horotec-maxipress-07-363-deluxe-watch-case-opener-with-dies/ found another informative video notice initially the universal pieces that he says will open almost anything? I would be really careful with Rolex cases of using anything that is generic it's only making contact in a couple of places it works much better if you've something that makes contact all the way around. But little farther in he goes into the different parts that are compatible with this one. then unless we find the catalog page that shows all the die is there currently available I don't think there's any real place where you can find a listing as there would just be too many of them.3 points

-

I did some additional cleaning and discovered that the bars actually run the full width of the watch case in the slot cut in the gold part of the case. See red lines on pic. It seems that maybe I should push on one end and push it entirely out the other side. I placed a small screwdriver on the end closest to the crown side and tapped on it and it did move a bit out towards the other side. It doesn’t seem as if that could do any damage if I continue to push it through until I can grip it with pliers and pull it out the other side. Am I missing anything? Nucejoe, I just reread your comments and I think this is exactly what you are suggesting, correct? Ok, got it! Once again thank you to everyone for your help!3 points

-

That is very good for a first time. I can tell you my first go never looked like a balance staff.2 points

-

hopefully those are solid blocks of concrete? Yes it seems like it would've been better to have a foundation of some sort into the ground. but maybe this is considered a temporary structure or non-permanence. Somewhere you can build things like storage sheds as long as it's not on a permanent foundation of any kind. A clever way to get around some building codes.2 points

-

before the sleeve was invented typically found on 18 size lever set American pocket watches and others you will have a screw on the side like in the image below let's see what universal looks like? so if universal you mean it depends upon the particular case and who manufactured it at a time where there were not exactly any standards then yes there universal. Kinda like a wheel for a car round they attached to the car there universal same thing. oh here's a link that has a few of them maybe they're not really universal? https://www.ofrei.com/page441.html2 points

-

2 points

-

2 points

-

that's an interesting comment? For those that don't grasp what this watch is which was me up until a few seconds ago I have a link. this is a watch repair discussion group I don't suppose you have pictures? We love pictures of watches that people are going to or are thinking of servicing. https://watchbase.com/panerai/caliber/p-3000 they have a interesting website and the cost of this watch is interesting? I assume because you're inquiring you must have one then yes we really love pictures the movement and will love pictures as you disassemble. Pictures are also handy when it comes time to reassemble. Then looking at the website looks like they make most of their own parts and they do offer servicing which means they probably do not sell spare parts. Then typically with in-house movements nobody has spare parts at all. Which means servicing becomes extremely problematic if you cannot replace any of the components at all including more than likely the mainspring. https://www.panerai.com/en/movements/hand-wound/pnmx00879w.html then typically service manuals only exist if the manufacturer wants people to service their watch. Which typically only be in the old days because currently I don't think anyone wants us servicing their watch. which brings up the challenge today of purchasing spare parts if the watch companies don't want to sell us their spare parts.2 points

-

A cheap cable tie tensioning gun? If you cut the end of the plastic gripper out and added a split plate - or ground out the metal end plate slightly and cut that down? that could probably work? https://www.ebay.co.uk/itm/1460038850002 points

-

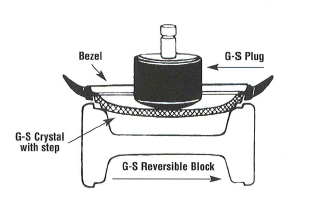

probably one of the most popular ways to insert round crystals is with a press. In the early days of GS crystal Cabinets usually one of them would have a crystal press foot operated. otherwise you can use one of the hand operated case presses and here's an image of what you're trying to do. You support the crystal on the outer edge and you push in the center preferably with something that's not going to scratch the crystal. Then the entire crystal will shrink with the pressure and of course you want to be careful not to have too much pressure otherwise it shatters and I will skip over how I know that. That's way more common with the foot operated press by the way is you can put a lot of pressure. They case the crystal will shrink and your movement will drop in place and the crystal is held really really nice and tight. Then I'm also attaching a PDF that explains about this shows how to put some other crystals in and gives some nice crystal information. G-S+Hand+Press+Instructions.pdf2 points

-

2 points

-

Hi. What you are attempting has already been done by may from the plans put forward by Joe Collins. If you look up mainspring winder by Joe Collins you may still be able to get hold of the plans and other information;. Initiall builds for 400 day clocks they have bee adapted for all types of clocks except fusee clocks which have a very powerful spring. i have built two of these and another in metal under construction as time permits. Regarding the spring retainers , I tried several DIY versions but in the end bough5 ready made ones as they are quite strong.2 points

-

Got a text from a friend letting me know the local Habitat for Humanity Re-Store just got a bunch of watches in, so I ran over for a drive and found a few really neat thing! First off is this Cimer ladies' watch for $1. I had a hunch it had radium lume, so I had a rock-collecting friend test it with his scintillator, and sure enough it looks like it. Here it is with and without UV light. Then there was this miniscule Westclox ladies' watch for $1. Vintage Timex, $1. The rest don't technically qualify for the 404 club, but since I got them at the same time: a Biltmore pocket watch for $8, these two Timexes for $6 and $10, and a Galco stopwatch for $20. Inside the back it says "Jules Racine & Co."2 points

-

2 points

-

Hi, I have recently purchased a 1918 Waltham, size 16, grade 645, 21 jewel. It hasn't arrived yet, but I also ordered a size 16 salesman display case. It has Waltham Watch Co. stamped on the front and back bezel. What I didn't notice is that it is missing the crown. The watch I ordered comes in a 10k rolled gold plated case, but the crown looks smaller and like the stem will be much shorter. Does anyone know the measurements of the crown and stem that I will need for this setup and if there are any bits inside the crown housing bit on the case. The seller is unresponsive, and this is my first pocket watch, so I am absolutely unsure. Maybe someone has a similar setup that could enlighten me. I have supplied the eBay watch and salesman case pics (you can see the crown is missing). I have seen other salesman cases and know what the crown looks like, but after looking them up, I have noticed that they can have different stems. I'm very excited to get this beautiful watch. Many thanks in advance for your help.1 point

-

I wonder if it is some custom variation of the K&D Midget staking tool, less the base it would have fitted on to? There is a thread on those here:1 point

-

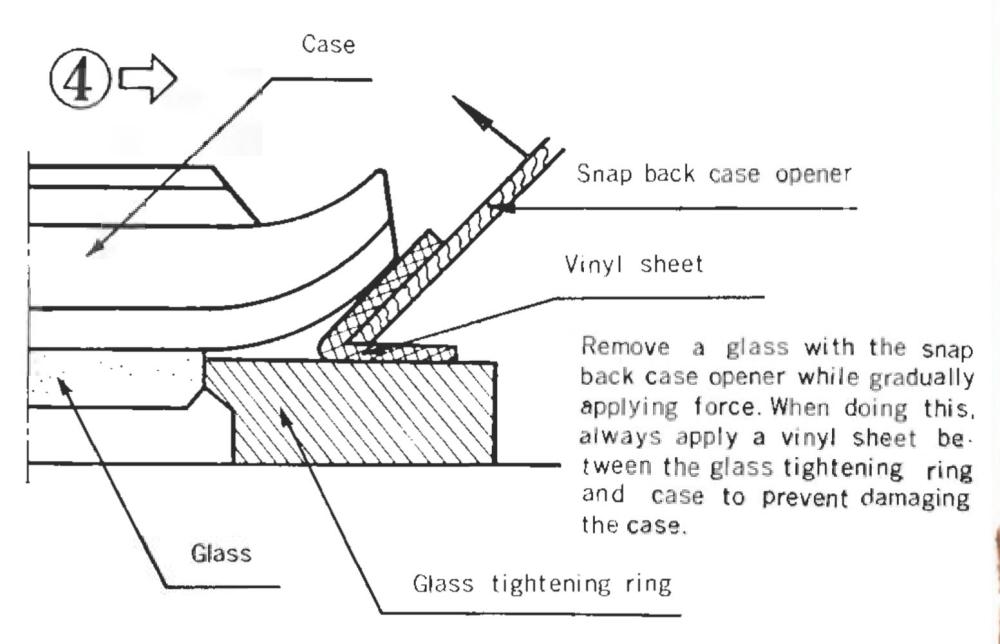

Pulling the stem from out of weak brass threads of a crown tube sounds very possible if the crown doesn't have a steel inner with a plated or solid material wrap. This is where the Robur comes in with its curvy male and female dies, no grabbing going on and usable on any height of acrylic crystal. Seems like a good idea when the crystal wont quite release, i wouldn't use a case knife though, too risky for case damage even with protection. Just something to lever between the case and lifter, a simple chisel shaped delrin probe would suffice or two as opposite levers.1 point

-

Seiko S-14 is a more gentle alternative to the claw type. You're not supposed to tighten it to the point that the crystal releases (cracks). You first apply enough pressure for the ring to hold the crystal. Then you tighten it a bit more and wedge the crystal off with a case knife as pictured in the manual. These are affordable and abundant in Japanese auction sites.1 point

-

Design of the tool waggy showed is wrong , as it puts stress on the crown's female threads which might strip it. The stem itself if accessible ! best be carefully grabbed , as oppose to any method or tool that exerts force on female thread of the crown . We see lots crown & stem broken by the owner.1 point

-

1 point

-

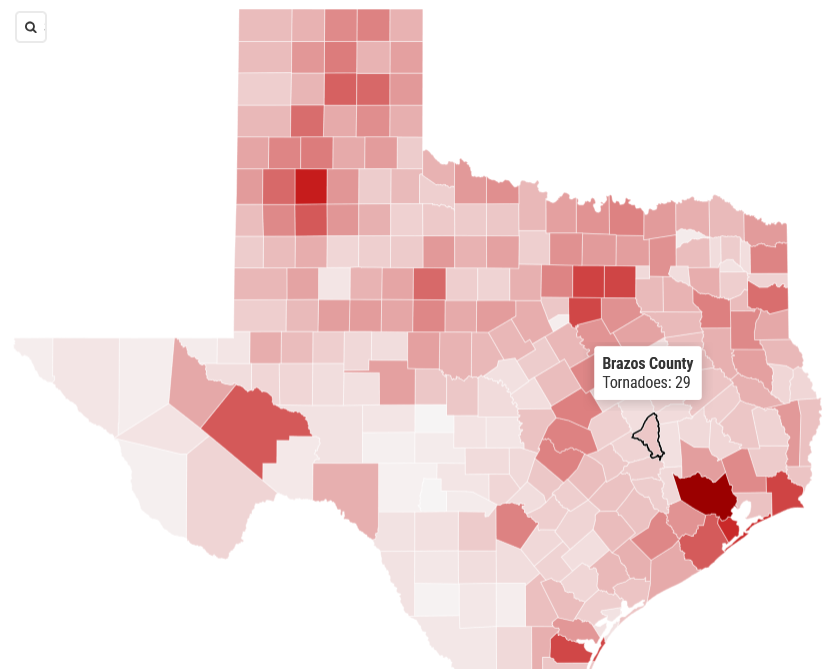

It is very common to install these sheds as shown here in Texas. If you DON'T live in tornado prone area, it is generally not an issue. As you can see in this map, where I am there were only 29 tornadoes since 1950. You can buy strapping systems that provide 30" screws into the ground and a strap to anchor it at each side. I have thought about doing this. Pretty cool video. Here in my 'other' domain (where I am typing today), the power cool does not offer net zero billing. People **BLEEP** about it, but they ignore fact that they are using the power company as a sort of 'battery' like the guy says. The solar ideas are interesting and I have the skill to implement them. However, I must remain focused. For many months as I have split my time between two domains, I have been able to do very little watch/clock work. So, I am working like hell to get this shop up and running. While messing with solar might be fun, I will remain focused on horology! I may install a fridge for the beer...definitely a good idea!!1 point

-

I am going to dig a post hole about 2 feet deep. Then I will put the ground rod in and drive it the rest of the way with a small sledge hammer. Then I am going to back fill the hole with rock salt and soak it with water.1 point

-

I would have loved to have such a tool when I recently popped off the stem from my grandfather's Elgin with monocoque case, but the tool is way too expensive. I tried my cheapo Presto tool and it didn't work. Resorted to using end cutter pliers, carefully getting the jaws under the crown. A bit of pressure and the stem popped off. The other challenge was getting the crystal off. I used one of those claw crystal lifts (cheap version of a Bergeon 4266). The crystal stubbornly didn't want to come off. So, I had to tension it a bit more. Got it off, but the crystal cracked. The alternative for the claw type crystal lift for me is a Mido Ocean Star tool. Got one from a watchmaker friend of mine. Practiced with the old crystal and that looks to be a much better solution. The Seiko S-14 tool set looks to be another option. Not sure if you can find the Mido or Seiko tool new. I do see them on eBay, but probably not too frequently.1 point

-

Ah, good idea. I have ruined a couple of pocket watch subseconds hands by using a punch on long tubes. A pin vise didn't occur to me.1 point

-

1 point

-

Yes, domed punch. I’ve successfully used a pin vise but only when there’s a long tube. Not sure you’ll get a purchase on that small bit…a bit of kapton tape on the stump might help save the finish1 point

-

It’s more like a locating pin for instance of something was inserted than twisted to lock it in no screws. Nothing on the backside. Plus, there doesn’t seem to be any way to lock the spring portion that holds a pivot. It’s a bit strange. It’s almost like it’s used to set a pivot into a balance by pushing with your finger. I had a thought while typing this I grabbed this part from my staking set, which is also K&D and it fits perfectly. The mystery continues.1 point

-

Can you make anything out from what appears to have been ground off the case back?1 point

-

I have a set of unused ones that I would sell they owe me £40 so that plus postage if interested I will post pictures. Dell1 point

-

I thought we used presto tools for this ? Lol i was in the middle of suggesting the same thing 3 hours ago but then suddenly realised i was on a promise just came back to my reply and see you thought the same tool.1 point

-

1 point

-

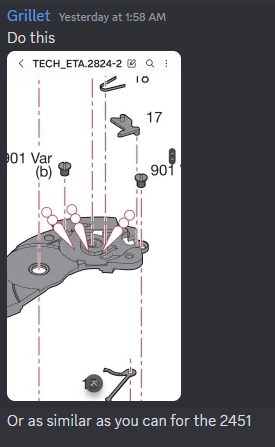

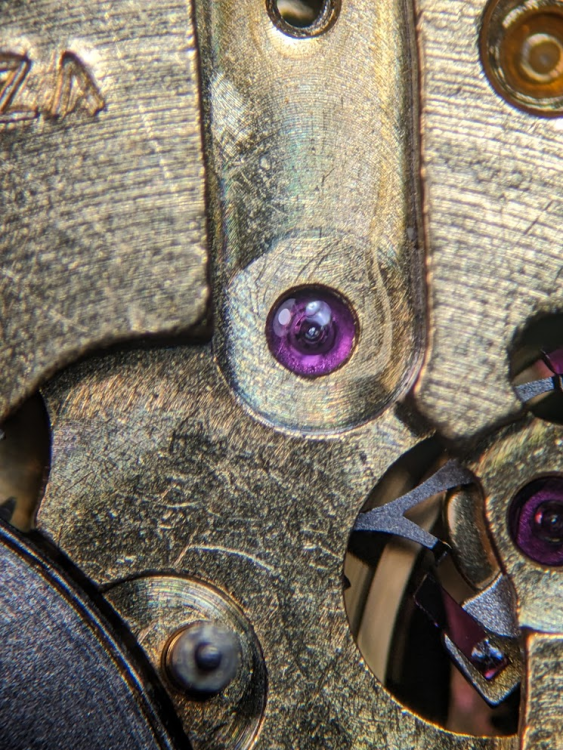

Went and put a tiny sheen of grease under that spring slide area and got the assembly put together how i assumed it should go and it works. I used a dab of molykote where the spring end slides across the mainplate and a dab of 1300 on the post for the click spring. Still a little weirded out by The wheel sliding over the bridge like that, where to oil it. I was told to use hp1300 and basically follow the oiling recommendation of the 2824 and use hp1300 on the edges and the rim of the raised portion of the barrel bridge above that the crown wheel slides across and the flat portion. Just cuz it made sense i also used a little molykote on the inside of the rim of the crown wheel which will slide across that flat cutout where it interfaces with the crown wheel cam. So i got the crown wheel on which was very finnicky. Apparently you have to have the stem in and the stem components at least of the keyless works in otherwise the crown wheel cam will not stay engaged with the post on the underside of the barrel bridge it swivels in. Then the ratchet wheel goes on but not before oiling the arbor pivots from the edge with some hp1300. Interesting little system here for the hand winding! I let the escape wheel scratch a little groove in my epilam and then oiled the escapement with 9415. At first i had to do a double take because the pallet fork engages with the escape wheel at the bottom of the pallet jewel, it's very odd and makes it very hard to oil the escapement directly on the jewel as it barely catches any of the oil so I ended up oiling the teeth themselves and just distributing it around. I did notice this earlier but forgot to ask about it. I love how the train jewels are designed to be oiled from the outside unlike the seikos i'm used to working on, so fast and easy! All of them are those indented reservoir jewels but the dial side escape wheel jewel. I oiled it just like the others but i'm wondering if that's not the correct method, it almost looks like you're supposed to oil the pivot itself instead of the jewel but it did suck the oil down without making a mess. Getting the balance in these is SO fiddly due to the post on the balance cock and the raised rim around the hole for the lower pivot. Very annoying! But i got it in and it started right up. I'm a bit concerned just HOW tight the winding tension is. REAL tight but i eventually felt the bridle slip so I think it's fine. Even at no wind it's about as tight as the seikos i work on at full wind. Odd. Other than having to figure out how to get the crown wheel cam in correctly and the fiddlyness of the balance and train wheels this was a joy to work on so far. Now the best part of working on a watch, letting it run all night while i have a beer and play Elden Ring. I'll put it on the timegrapher when i get up and if it's running healthy do the motion and keyless works and get it on my wrist.1 point

-

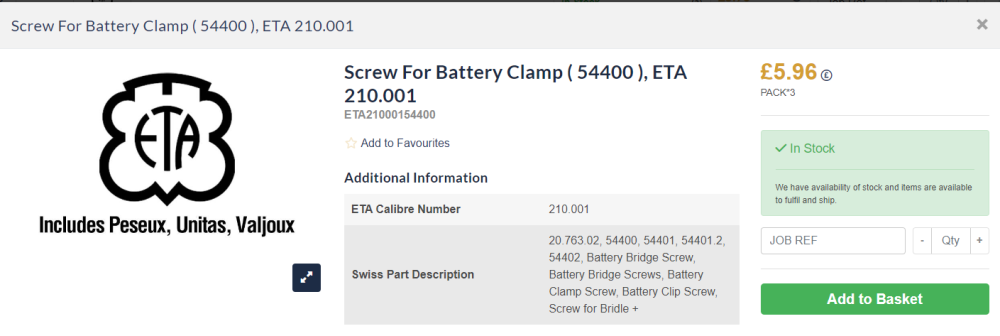

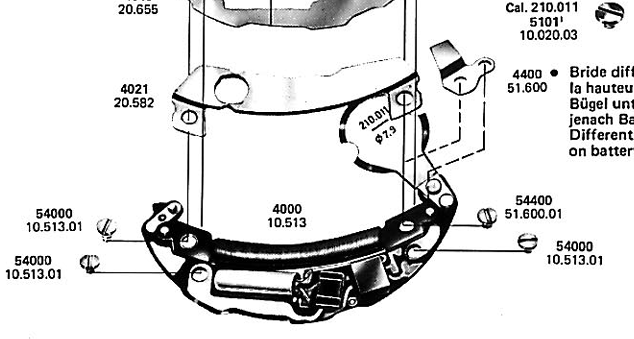

I would get a couple of these selections first, good chance of finding something to fit https://www.cousinsuk.com/product/battery-clamp-screws-wristwatch Tom1 point

-

I've been doing this for several years now but never heard of various names for case backs, except for "screw on" and "snap off". That type of case back is called - and you probably guessed it - Rolex case back!1 point

-

Yep, now don't I feel like a silly boy. I did try to do that earlier, but clearly not sufficiently. Thanks for the help1 point

-

Another $5US pick up. Interesting jump hour or "digital" watch. Not sure why the long tub on the stem. Too bad on the cracked acrylic as probably won't find a replacement. Has a BF 866 that had a tweaked hairspring, broken pivot on the escape wheel, and missing pin pallet and cock and screw. Luckily I had a donor movement that had a completely toasted hairspring that I was able to scrounge from. Also got the hairspring sorted out enough to run (still needs work). Found a new use for a jewel picker that Alex Hamilton recommended for use on the balance jewels shock spring; that brass pin that holds the hairspring in the stud, use the jewel picker to hold the pin straight out to reinsert in the stud hole!1 point

-

A PRE-CLEAN is always helpful, I dispower the movement through the click , remove the balance complete, cock and fork, wind the gear train and immediately drop it in cleaning solution, gears would turn slow in fluids, if you enjoyed watching this, repeat. Check how free the train turns, gives you an idea of the health of movement's gear train. Fork pallets and impulse jewel are shellaced in place, shellac can be lost in ultrasonic bath, especially in cleaning solutions that contain petrolium product or even hot water, as you already have given all parts a bath in ultrasonic, first thing I do is to check if enough shellac is left to keep the said jewels in place, both best not be put in ultrasonic but cleaned by hand. Check pallets face under high magnification, anything less than shining face is unacceptable, jewel holes must be visually checked to make sure they r not chipped , cracked, ,,,, etc. I peg pallets with tooth picks. Peg jewel holes with food pegwood. I think one can't over clean hairspring, usually let the whole balance complete with cock attached in bottle partially filled with lighter fluid, for hours, cock down , balance up and impulse jewel above the fluid level so to avoid losing shellac thats on impulse jewel , swirl the bottle every ten minutes or so, be careful to keep impulse jewel higher than the fluid level, so to avoid exposing the shellac to the fluid too long. On the other hand one can't rely on ultrasonic to clean and peg jewels in balance setting, cap stones must come out ,checked and pegged,, drop the cap stone on a flat thick hard cardboard, flat side facing the cardboard, put your finger on cap stone, pour some lighter fluid on the card board, rub the stone on cardboard, you can push down on capstone as hard as you like, this pegs the cap stone , then drop it in lighter fluid , shake a little and fish it out with your finger or a clean tea spoon, this washes away any paper debrie aggregated around the cap stone. Unless balance complete is seperated from the cock, you wont have a good view of pivot on cock side, which might be bent , worn , short,,,, etc. Clean the fork horns and guard pin and in between spic span with a soft brush and lighter fluid. Check all gears, ,pivots and pinion leaves, jewels on main plate and bridges and their shakes. Put the cock and balance complete back on mainplate and observe how freely it turns, with a puff of air balance should keep oscillating for 30 seconds, twenty would do, check balance pivots end and side shakes. Impulse jewel is easy to peg . Check each escape teeth , pivot cone with microscope. You can then claim you have done some cleaning, pegging and checking. This beats having to go back , another year down, and wonder why your tg signals something is wrong. Keep us posted with progress on your project. Good luck.1 point

-

1 point

-

Your instincts are spot-on ! What added to the initial confusion in my mind was that somehow I'd managed to turn the caseback a little anti-clockwise with my 3-proged opener but couldn't achieve the necessary alignment again to turn it further. If I had though, I would still be turning it now as it was indeed a press fit - and I actually managed to secure it again after replacing the battery ! What a great forum people like you are maintaining. Many thanks !1 point

-

1 point

-

Further to the above. You can remove both pieces of the old broken pin and replace it with a new one. I didn't know soldering requires skill. Rgds1 point

-

1 point