Leaderboard

Popular Content

Showing content with the highest reputation on 09/17/24 in Posts

-

Most of the YT watch channels are irritating to me. But I stumbled on Gentlemen's Watch Services yesterday- just watched one vid and he has the best oiling techinique I've seen. Really good clean work. And he's funny too, "Omega used small screws for this barrel bridge; I'm using a nought-8 screwdriver here- in Imperial that would be- a different number". He has a great trick for pulling the odd cannon pinions on certain Omegas too. This is the vid I watched:5 points

-

@Birbdad, I guess I get what You are asking and will try to answer. First, the results You have shown are not bad, and it is possible that the watch has left the factory like that. But nobody is able to say if it was so or not. The timekeeping standards have not changed last 100 years. There is no matter how old You watch is, it is not old, it is rather modern and contemporary as nothing general has changed in watchmaking last 100 years. The position errors is something that can change easy in the years. It generally changes when the watch is serviced and no mater if it before servicing has been certified chronometer or not, the certificate is not valid any more after service and new certification procedure is needed if it is needed to to prove the quality of service and adjustment. The other way position errors appear is when the watch is dropped or hit strong enough to bend balance pivots. If You are happy with the result You show, then enjoy the watch. If not, then learn how to adjust or give it to somebody who will be able to do it better. Adjustment is possible by balance screws as well as by hairspring alignment.4 points

-

A Russian (USSR era) Poljot 2409 "Field Watch" joins the club today. This is actually smaller than perhaps it looks, with a lug width of only 16mm (although having said that a real "Dirty Dozen" was only 18mm). Ironically it is on a "NATO" strap. It worked just fine when it arrived, so other than a case spruce up, I've not done anything with it yet. It will eventually get serviced when I have a spare moment or two. The lume on it is surprisingly good, considering its age. I presume it is probably from the late 1970s through to perhaps the mid 1980s, but I'm no expert3 points

-

I'm happy with it...for now. Since there's no rotatable stud i'd have to bed the hair spring to center it in the regulator pins to count out that positional error being a poise issue (Everybody else in my other spaces seems to agree it's a poise issue) and this is something i've not done yet. I don't feel comfortable doing either currently on a watch that i can't easily replace that's been in my family for so long. I have no real attachment to my grandfather but my mom really appreciates that i'm keeping his beloved watch going and she'd be pretty upset if i did something to it. I"m fairly certain it's not a chronometer or even super high grade movement. I noticed most 2451's say unadjusted on them. This one does not but it definitely seems like a nicer one compared to most of the ones i see out in the wild and on ebay. I'll probably come back to it soon and at least correct the beat error. I"ll mess with the rest at a later date when i have a bit more experience under my belt.3 points

-

I use copper strand wire from 1mm flex cable finishes at 0.1 mm , bend it to whatever shape you like to fit around components2 points

-

His oilers do look different from what I'm used to. But notice how carefully he picks up oil from the pots- he gets the right amount on the oiler, he knows exactly what he's doing and puts it exactly where it needs to go. On the dial side, right on the side of posts, just enough. On train jewels, just enough, right between the pivot and oil well. He did make one mistake- he had the clutch wheel in backwards at one point (done it a million times myself), but didn't mention it; he just corrected it somewhere and it was right at the end. On the banter- I was bracing myself for having to mute the video, but I ended up laughing out loud several times .2 points

-

Haha- three minutes in and already I have three quotables I am stealing and claiming as my own… …some serious custom shaping on those oilers yes?2 points

-

Welcome to the forum, enjoy. This is new one for me but the the ring surrounding the movement might be a retaining ring. This could be very tight so care is required to avoid damaged to the movement. The other option might be to remove the ring surrounding and crystal, remove the hands and gently push to see if it achieves some movement.2 points

-

I pulled the plug and bought this Elma watch cleaning machine. I payed quite a bit for it, but I reckoned that it was the right thing to do. It works perfectly but was pretty dirty, so after a good clean it looks a lot better. I'm going to replace all the cork gaskets though, so when they arrive I'll probably strip the whole thing down and give it a 'deep clean' and re-wire. I haven't seen many of these for sale, it's normally the off white version, and I'm really looking forward to using it.1 point

-

In the oldest USSR jewels You may see things that look like debris or pitting, but they may be actually in the structure of the stone. What the results from free oscillations test are? Is there noise from the balance pivots rotating in the jewels?1 point

-

See, the cylindre escapement is not free oscillating escapement. The balance is never free and friction in the place where the cylindre wheel teeth touch the cylinder is present all the time. You need to perfectly clean and lubricate at least the escapement parts. The best lubrication I have found for cylinders is Moebius 8200 grease. Just a little quantity on the traces which the teeth have left on the internal and outside surface of cylinder. The down side pivot looks bent. This is no good, but if the free oscillations test is OK, then probably the movement will be able to work.1 point

-

Shouldn't push on the movement, use the case to pry the ring out. Attention, details of advice by clockboy.1 point

-

For a given Inca reference, there are several hole jewel sizes available. So supposing you find in your stock of parts a "bloc" that would be a good fit, but the hole jewel is over/undersize, you can get or find another that would be correct. Inca's website has lots of useful into. "Sus" means upper, "sous" is lower; if you look at the different models on their site the refs end in /0. In practice you add -10 for example for a hole size of 0.10mm. I have some here straight from the factory, "sous", 100.935.20.000/0-10. That's a lower bloc, with 0.10mm hole. The odd thing is on their site, this ref is listed as 935.20/0. My guess is the first 100 is the hole size in microns... the rest? I have some older (like 50 years old) factory packaging where they simply write the hole size before the ref, like 9.104.12.262, where the first number is the hole size. If you know the ref you want, a good supply house will figure it out. All the current models are on the link above.1 point

-

1 point

-

I would suggest that you try to find some donor movements on eBay. Often these Vostok movements can be had for very little money and in the process you get spare parts for future use. Before the war in Ukraine, there were many Russian sellers of these movements, but as of the war, they have disappeared. I guess Russian watch collectors are evil people. Anyway, still a lot of Ukrainians selling these movements, but they are in my experience a lot more deceitful than the Russians used to be so be observant!1 point

-

It looks like a medium or large oiler narrowed into a screwdriver shape and he places like it’s a butter knife, even with the low viscous 9010. No drops for him. The sides of his pots look shallower than mine, too…I’m inspired to up my game a bit…1 point

-

1 point

-

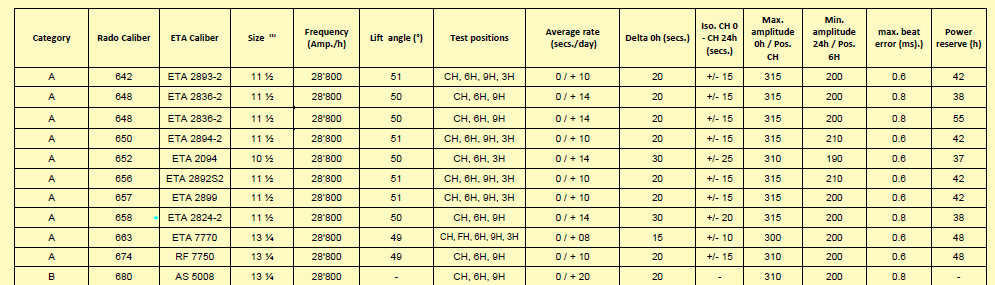

the reason for the unadjusted is officially on paper it's unadjusted. In real life it is adjusted to certain specifications. The reason for this is watches imported into the US were at one time subject to a tariff tax based on a variety of parameters like how expensive the watch is, number of jewels things like timing specifications. So to get around this it says unadjusted. but of course it was adjusted. the problem with timing specifications is typically there were never scanned. Technical documentation appears to have only been scanned typically for parts. Which is why we typically do not see the servicing information. Then even harder to find is all the bonus documentation the various interesting stuff the various watch companies had. Specifications of things upgrades new tools whatever. Which also means timing specifications for the most part do not exist sort of. At one time when ETA which share the documentation you would typically have a technical communication for servicing and the manufacturing information with all the nifty movement specifications including timing. Another way you might find timing would be as if you had access to Swatch group perhaps the various watch companies would list the various watches they had that they were using and they might list their timing specifications all in one place which would be really useful for us right now. Except I'm going to have to make a minor modification through a number as 2824 is too old we need to add a number to make it a 2824 – two. So basically were comparing to a modern watch with screwless balance. Or basically less things for watchmakers to screw up as soon as you add things like movable screws or timing they can play with their going to play with the watch. But still we get modern timing specifications so I like that Delta five seconds I assume and six positions and your watch totally sucks with the Delta in four positions I can see why you're very concerned. Now that my amusement is out of the way let's look at timing specifications. two separate companies conveniently I did not copy who they are. The first one only has one 2824 and the second image has more of them in the various grades. Plus minor technical amusements of how average rating is expressed. I've actually seen it expressed one other way not listed below. So in the first one it's given as zero seconds with a plus number. The second snippets is a plus and minus number. Then the third method I saw of was basically the same as the second except it wasn't zero that you're aiming for you had a target rate with a plus and minus error basically. then testing of watches always good the test and six positions avoid surprises. But official timing specifications as you can see from the two snippets below three is the most common and I do see on the second image a couple of just two positions. Then obviously the more positions you add the harder it is to get within the specifications. Rolex typically times in five positions although that six position isn't going to change very much. Omega does do their master chronometer in six positions. But even Omega other typical wristwatches are three positions.1 point

-

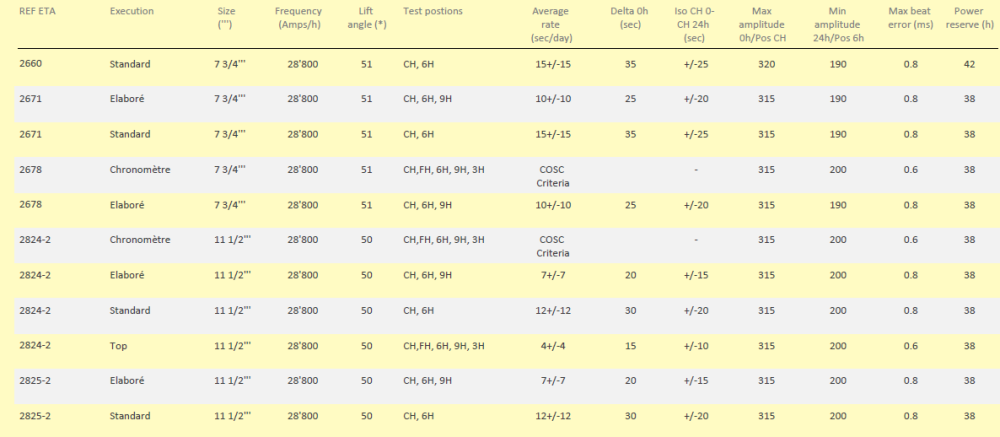

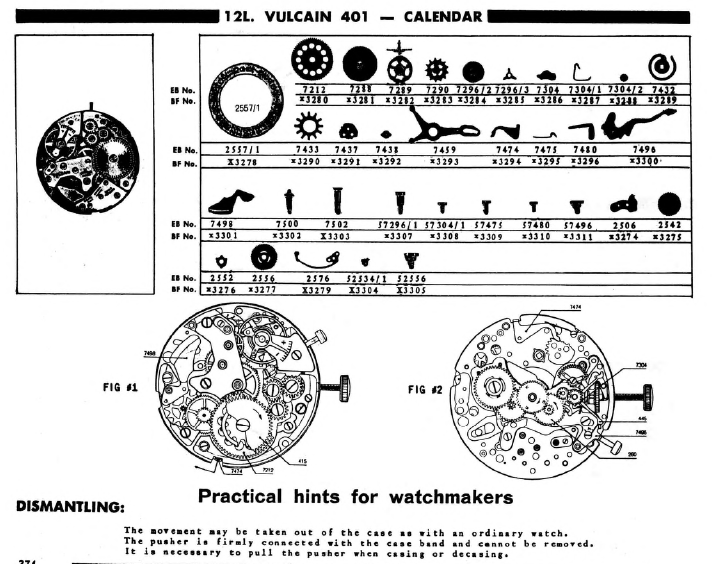

for a diagram if it exists we need to identify who made the movement and it's not made by Waltham. this is word be helpful to have the diameter of the watch measured on the dial side a better picture of the movement helpful for trying to identify out and any numbers or symbols found on the plates. In the absence of that the best guess currently is that it is a Vulcain Calibre 402 or possibly a 401. Depends on whether it had a calendar or not. from the bestfit book see if this batches what you have as I'm not finding a tech sheet conveniently anywhere. just in case I guessed correctly here's the rest of what they had not a lot but better than nothing1 point

-

I'm attaching a whole bunch images and information on what you have. Yes it's a common problem that comes up of how do I remove it? then yes there are variety of types yours is more noticeable because the square on the backside other times you don't see the pin itself as it looks like the normal center wheel unless you look really really carefully. then I enhanced and snipped out your image which looks interesting? If you look at all the images attached there should be a center pin that just needs to be pushed out. then pushing out is not quite the correct term needs to be pushed out usually with the hit of a hammer as they can be an quite tight. the reason why there so tight and if you look at the literature below the friction is not here it's in the pin going through the tube. So the cannon pinion this supposed to be quite tight on the pin itself. Then attaching your image slightly enhanced it looks slightly different than I'm used to seeing almost like a center circle?1 point

-

1 point

-

1 point

-

Thanks for the comments. When I said 'rewire', that sounded a bit grand as I only intend to replace the main cable in, as it doesn't look great. I'll leave the rest well alone! Indeed Richard...living in Devon, I can testify to that!1 point

-

Hi John, I believe that @watchweasol knows how to put the clock in beat. Usually, when not in beat, the sound is described as tik..tok...........tik..tok............tik..tok................ and one way this is rectified is by moving the down side of the clock case left or right, no mater if it will stay tilted. By 'tik..Tok' I understand that tik is silent, and Tok is much louder, and what I have written concerns this case.1 point

-

I considered getting one of these jump hour watches. Most all seem to be zero or one jewel pin pallet movements. Trying to get all of those pivots to line up into the one bridge just seems like quite a hassle. But it would be a good conversation piece. I think I like the red band for that watch. Makes it stand out more.1 point

-

I have absolutely no idea about clocks but thought i would have a quick look to see what you were up to WW .Looks interesting but I'm not ready for them just yet. I couldn't help but notice your shaving/dusting off brush, i litterally brought mine up to my watchroom a month ago for that exact same reason . It makes a nice change to see such a long standing well respected member working on something, it doesn't happen too often, love it.1 point

-

1 point

-

OK, not OH but still can give some thoughts. I don't understand the meaning of Sorry, I am not English, know all the words, but still can't get the meaning. But what I see on the photo is that the exit pallet is not correctly sharpened. It needs good sharpening or shaping, then burnishing/polishing. The tick....Tock sound as described and the uneven advancing of the second hand just point incorrect setting of the depth and (coverage?) of the escapement. Sorry, I here use 'coverage' as direct translation of Russian term 'охват', which is the needed Russian term for the case. But I am not sure if coverage is the correct word here... The pallets must 'cover' whole number and a half teeth of the escape wheel. For example 7.5 or 9.5 or 12.5... I don't know the number, it is not important, but .5 after the whole part is. The 'coverage' is regulated by changing the distance between the escape wheel and the anchor (by moving the anchor bridge). Changing the distance affects the depth too. In anchors that 'cover' small amount of teeth, like 3.5, the distance almost doesn't affect the coverage, but strongly affects the depth. In reverse, in the anchors with big coverage, the distance almost doesn't affect the depth, but strongly affects coverage. In anchors where the pallets are on diameter sides of the wheel, the distance doesn't affect the depth at all, but only affects the coverage, and extremely strong. To have regular movement of the seconds hand, You need correct coverage. What it means? Well, when a tooth leaves one pallet, the another tooth tip will fall on the rest surface of the other pallet. It's tip will make small flight until it happens, the wheel will turn suddenly a little ahead and will stop. The same thing will happen again when this tooth leaves the impulse surface of the pallet and another tooth will meet the first pallet... The free flights of the teeth before hitting the both pallets must be equal. If they are not, then the sound of the hitting on the one pallet (for ehamle the exit) will be louder than the other (entrance), this means the coverage is not correctly set. The coverage is correct when the free flights (and advancing of the wheel) to both pallets are equal. So, regulate the anchor bridge (the distance between the wheel and the anchor) until the correct coverage is reached. The depth of the escapment is regulated by moving the pallets in the slots here, not by moving the anchor bridge. The depth is correct when the tip of the tooth folls on the rest surface, just a little below the edge of the impulse surface (there must be drop lock on both pallets ) in this escapement.1 point

-

That's nearly as bad . Surely it's more logical to have earth as green (i.e. green grass) and live as red (red = danger). I'm surprised there's any of us still alive.1 point

-

WTF. What is the logic with that ? I bet that has caused some appliances to go bang.1 point

-

If it has original German wiring, be wary that the red wire is earth. Great machines. I've got a few1 point

-

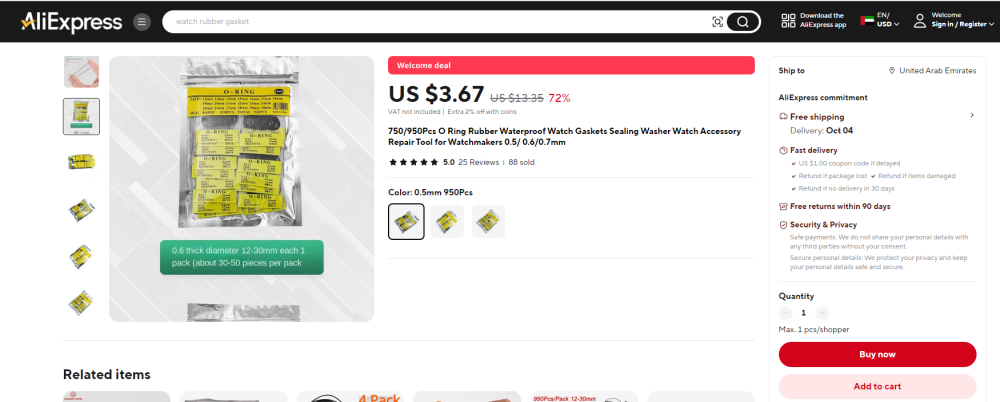

Measure the old one and purchase a new one.. Cousins UK would be a good site visit. I recommend you use silicone grease to lubricate the new gasket.1 point

-

1 point

-

There's the 10:10 club for most of the rest of your haul. Sounds like a ritzy ReStore! I don't think I've ever seen watches or anything even watch adjacent at the one near me!1 point

-

Got a text from a friend letting me know the local Habitat for Humanity Re-Store just got a bunch of watches in, so I ran over for a drive and found a few really neat thing! First off is this Cimer ladies' watch for $1. I had a hunch it had radium lume, so I had a rock-collecting friend test it with his scintillator, and sure enough it looks like it. Here it is with and without UV light. Then there was this miniscule Westclox ladies' watch for $1. Vintage Timex, $1. The rest don't technically qualify for the 404 club, but since I got them at the same time: a Biltmore pocket watch for $8, these two Timexes for $6 and $10, and a Galco stopwatch for $20. Inside the back it says "Jules Racine & Co."1 point

-

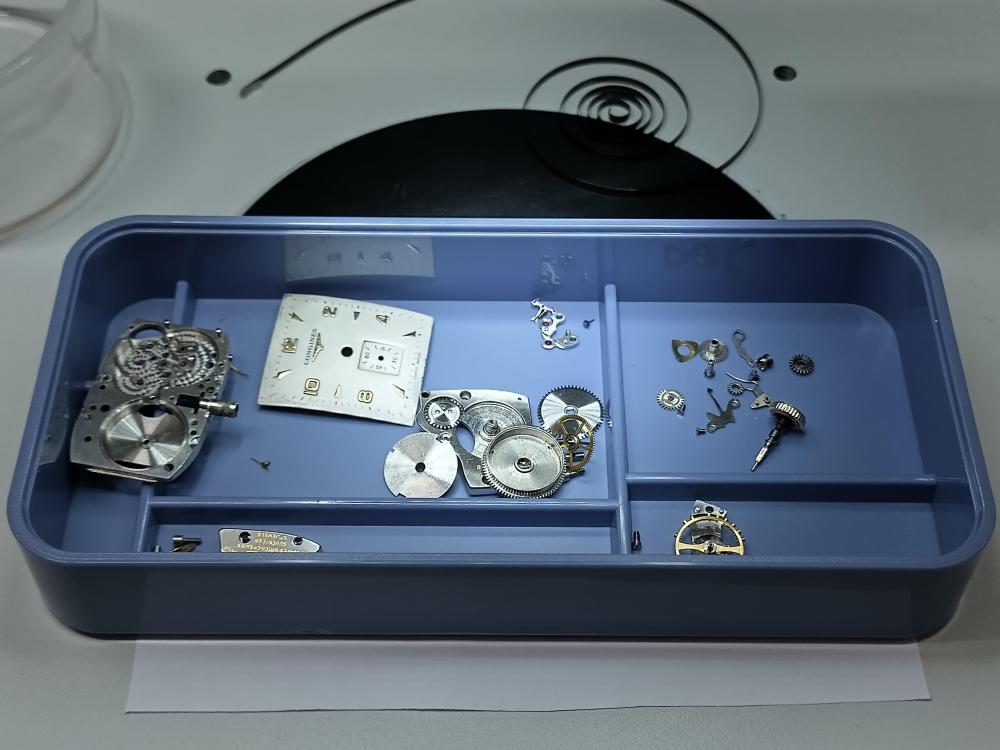

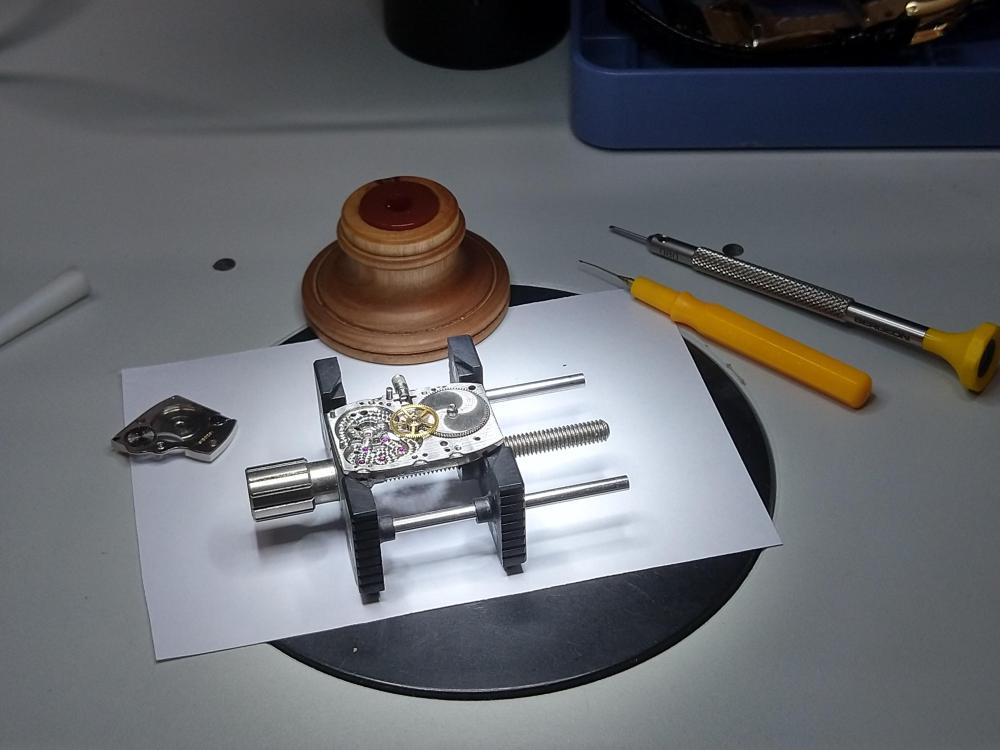

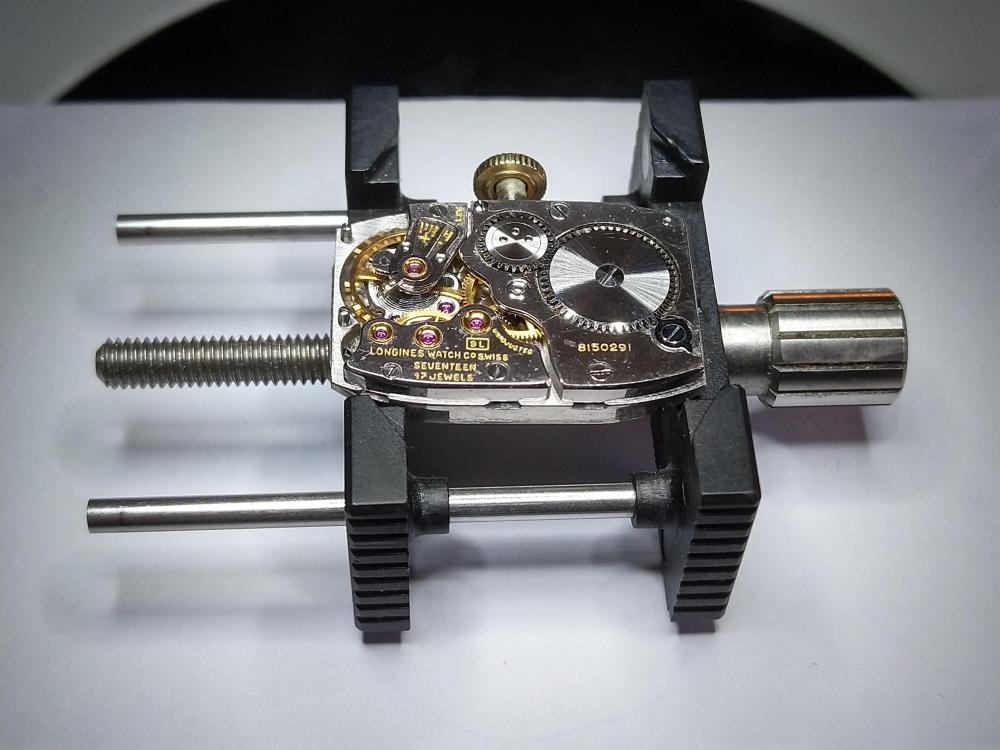

HWGIKE#13 Longines 25.17 Full service. I have a new number one enemy. Hairspring was replaced with hairspring with Breguet overcoil. Spent about 8 hours with just that. Nice performance at the end. A little bit awkward shape, my movement holders did not like it, otherwise a nice movement and was good to work on it. This is a watch I sold earlier, but came back as it was not a reliable runner. Had to work on the case too, it came apart easily now its a tight fit.1 point

-

I have wondered if Kalle prefers not to film service and assembly for liability purposes. After all, they're all client watches and mostly valuable ones. By filming the disassembly, there's video evidence of what was wrong with the watch. But by not showing the assembly, a client can't return with complaints about technique or perceived corner cutting (as we're all doing in this thread!) He's talked before about what a lot of "Rolex people" are like when they come into the shop, with a lot of demands and sometimes fake watches. I can imagine the hassle it would be if they watched a reassembly of their own timepiece and came back to complain that it didn't follow the exact steps they found in a service manual online somewhere. I am satisfied enough when he posts the occasional video from the machine areas or something theory related. I think his shop has better things to do than setup a bunch of cameras when they're trying to get the real work done. The difference between a professional workshop's channel and the hobbyist channels.1 point

-

1 point

-

.......my dream is phone turned off, isolation in my watchroom, shut the door heating on , coffee perculator brewing in the corner, big tv on the wall in front of my bench, surrounded by books, tools and watches ........heaven in a nutshell ❤1 point

-

Kalle provides a lot of information, not a lot of practical. He shows us taking a watch apart we rarely see anything put back together. I would like to see a lot more theory put into practice. Joe i really like, very entertaining. My favourite at the moment is saving time, thoroughly enjoy watching this guy. He takes apart and puts back together, plenty of history among his info and he involves other folk to help in his restorations. The Bond Gruen video i particularly liked. You can post question on their videos Joe, some will answer. Mike - Retro watches has his own facebook group also is one of Mark's admin staff for his watch repair group. Thoroughly nice bloke , spoke with him a few times. Completely agree , i stopped watching marshall shortly after i started. I think he edits a lot to make his content look more professional, i figure all about the money. His work is sloppy, lots of throwing parts around, tbh quite poor technique, i felt i had to unsubscribe from his channel Jealousy is a negative emotion matey and isn't worth the mindspace, its about reviewing something honestly and expecting to watch honest content.1 point

-

I like all those mentioned and pull something different from each. My wife enjoys Kalle and Stian so we watch together and I’m in less trouble when the Esslinger and Cousins deliveries show up1 point

-

I picked this up at the vintage fair on Sunday for $5. Ineresting little 32mm watch. Seems to be an older size 0 but with production date of.May 1904. With Sir Wm Pitt on the dial and bridge maybe made for British but made to.look like an American pocket watch conversion? The clasp on bracelet say sturdy with a patent date of 1928. Lugs definately a later addition. Was all gunked up so stripped, cleaned oiled and reassembled. Will need to work with the hairspring but everything is there and working. Added new crystal.1 point

-

1 point

-

1 point

-

No. Was set at £175. I got it for 64%. I'm happy with that. I know it's early, but It was (is) my Christmas and New year present. Can't buy anything now until February 2024. But think of the fun I can have till then. Oh gosh, I'm a tool Saddo.1 point

-

1 point

-

I’m working myself through Mark Lovic’s “Watch Repair Lessons & Courses”. Before enrolling I wasn’t sure the courses would be worthwhile to me, as I had spent a huge amount of time researching the Internet on how to service watches, and had serviced several Vostok 24XX movements (very affordable movements, BTW). Now, in hindsight, the courses have proved to be extremely valuable to me. I’ve learned things that I just haven’t been able to find elsewhere, like how to easily transfer watch oil from the bottles to the oil pots, how the get the right amount of oil onto the escape wheel teeth, how to remove rust from pinion leaves, that I shouldn’t oil the pallet fork jewel bearings (and why!). The list could be made very long. Anyway, yesterday I finished the level 2 section of the course, named “Lubrication and Re-Assembly”, and as I beheld the magic of seeing the movement come to life again I shoot a slow-motion video of its beating heart, i.e. the balance wheel. For anyone interested you can see the video here. Thanks for reading!1 point