Leaderboard

Popular Content

Showing content with the highest reputation on 09/19/24 in all areas

-

3 points

-

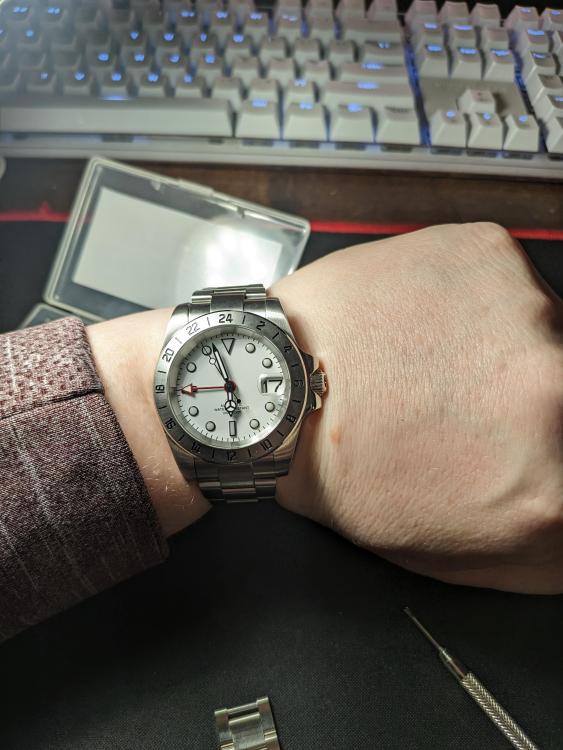

A few of my favorites. Mostly wear the 1016. Still haven't landed on a dive watch. I ended up selling the seamaster as it was too thick. I like my explorer 2 build, but the hands weren't quite right so I have a few sets coming. I might have to pick up an explorer 2 in the future. Secondhand markets are coming down pretty well.3 points

-

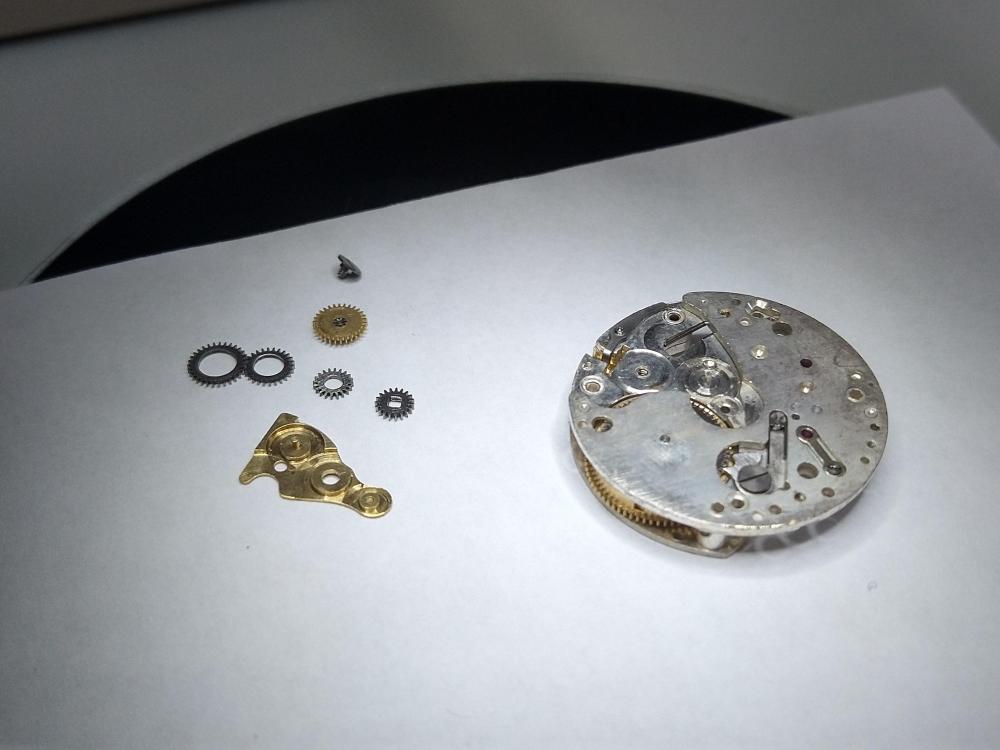

HWGIKE#16 Oris 292 Pin pallet. Snowfall on the time machine but it keeps the time. Case/caseback are a bit battered. Hands were re-lumed before me. My apprentice did most of the work. It was very difficult to push the stem in when the movement was in the case, that was actually the most difficult thing during the service. No major mistakes were made. It should have received a new may main spring, but I have not got one and still runs reasonably well with the old one.3 points

-

Fantastic. Every second of this is interesting and informative. It's neat to see how an independent watchmaker adapts an existing movement layout (probably Unitas 6498) and then manufactures the plates and bridges in house. I've been interested in RGM for a long time and that's probably the only luxury watch I would be keen to own - something with strong ties to the original pre-WW2 American watch industry.2 points

-

A recently cleaned up Swatch Irony "Big Feature" Steel YGS737 gets a fresh cell and an airing today. This was one of several in a job lot of spares or repair Swatches I picked up ages ago. The case still needs a little work, and it is on a band borrowed from a different Irony, but I have a replacement band on order and I hope to get a chance to polish the case this evening.2 points

-

The one with the extra overlap holes is so that threads can be cut, there needs to be an edge to create the chips and somewhere for them to go. The one with single threaded holes is probably a screw guage so you can size a screw then you would use a matching threading plate to make a required screw. Tom2 points

-

The „secret“ ingredient of Evapo Rust See important comment of freds4703!2 points

-

Hello everyone! This is my first post here on WatchRepairTalk, and I wanted to share a project I've been working on—a DIY Watch Cleaning Machine that I designed and built myself. Since it's difficult to find a good-quality machine at a reasonable price, I decided to use my engineering skills and create one. Why not, right? Look at a demonstration video on my instagram page. You can follow this page if you are interested in my watchmaking journey! Demonstration video of Akrid the Watch Cleaning Machine I named this machine after my alias from the Dutch watch forum, Akrid (which is also my alias here). It features three stations: one for cleaning and two for rinsing. The final cycle is for drying the watch parts, allowing the movement to be reassembled immediately after the cleaning process. I've been using it for two months now, and it's been working flawlessly! The cleaning results are far superior to what I used to get with my ultrasonic cleaner. See the cleaning results here: Cleaning results of Akrid I'd love to hear your thoughts on the design!1 point

-

Hello watchfriends, I have serviced (new mainspring) a Rolex 3035. But it won't start. If I give the balancewheel a little puf of air, it runs very nice (yesterday for 14 hours), but then it stops. this morning I gave it bit of air again, and it starts running again. When it's running the performance looks reasonable on the timegrapher (beat error 0.2 and amplitude 245, not adjusted). On the timegrapher the amplitude goes to 245, then dops to 200 en again goes to 245. What could cause this problem? The escapement? Thank you all in advance for suggestions. Gr. Hans1 point

-

You could get a whole movement for less than that and cheaper. Balance and roller seem ok, wheel hole taken a bit of a battering, hairspring looks dirty or worse could be rusty. Also thought it looked a little small for the wheel. Seven months on and the thread watch is running well, the missus said she can hear it when I'm sat at the far end of the sofa reading. It's still within a minute or two per week. England on the dial Cheltenham, Great Britain on the dial Wales. Towards the end of business Switzerland were making their watches.1 point

-

1 point

-

1 point

-

See, cylinders are actually less complicated. They just have pecularities. Modern watchmakers are frightened by them and claim that they are hard to work on, but it is because they are not prepared and familiar with cylinders1 point

-

I have a 17J (!!!) Cal 627 from Ystragynlais, and that doesn't have any stripes . I feel cheated.1 point

-

The crucial thing is that you have a smaller cylinder inside the inner coil before pressing it smaller. Or it will kink and break. Hands up all who have done that - yep, everyone.1 point

-

I love that they bothered to put stripes on the bridges. Maybe you can polish a turd ? And I still love the click spring. The balance looks like a steering wheels from the 70s1 point

-

Difficult to tell with the angle of @djd photos but the eBay spring does look a little smaller. Did a quick measure on the screen of the eBay one and it's about 45% of the balance size.1 point

-

It seems to me that the hairspring is not from this balance. At least the stud is different, and the spring looks smaller compared to the ones shown above.1 point

-

1 point

-

1 point

-

Wind every 12 hrs and up to 90% of full wind each time. That helps keeping power supply a bit more steady, compared to winding every 24 hrs. To improve on steadiness of power supply, one can wind three times a day, thats winding every 8 hrs. Where in Sam's hill ,did a single wind per 24hrs come from. It rather has to do with our mindset, habbit, but has no technical significance. You seek steady rate, keeping power supply steady helps. Makes sense but us humans are not sensible, just think we are.1 point

-

1 point

-

Evaporust is pH neutral. Evapo-Rust is a water-based rust remover that works through selective chelation to remove iron from rust: Chelation: A synthetic molecule in Evapo-Rust bonds with iron in the rust, holding it in solution. Sulfur-bearing organic molecule: A sulfur-bearing organic molecule pulls the iron away from the chelating agent, forming a ferric sulfate complex. Free chelating agent: The chelating agent is then free to remove more iron from the rust1 point

-

this would actually be the best plan for both you and the customer. Attempting to fix a watch that was never designed to be repaired leads to lots of problems for you. Then if you can't quite get it right the customers going to be unhappy with you not the people who made the watch. It's best to explain to the customer that it's not a real watch it only looks like a real watch and it's really cheap is is not meant to be repaired. the problem with watches are people only see the outside they somehow think it's real and the just don't grasp what they have at all. so education of the customer explaining the outside looks real but the inside is not and it can't be repaired ever is the best option.1 point

-

I have to say the westclox is starting to get on my t..s now. The hairspring just did not have enough room to breath so i introduced a terminal curve which it didn't have or rather not good enough to allow rate adjustment without the coils touching. The regulator was then in the way of the hairspring but was easily fixed by reducing the fixed pins. I couldn't understand why the watch did not have an external time setting function. It does but poorly designed, pulling the pendant activates a bar with a sliding pin inside it, a sloped slot on the bar draws the pin to one side that brings the timesetting wheels into engagement. The pin also has the help a plain flat spring set into the top plate to help draw the pin into position. Problem is looks like the time set has never worked, i couldn't pull the pendant at the start of disassembly and even after adding more slope, more polishing and grease to encourage the pin to slide its still very stiff to pull the pendant . More work needed to this 100 year movement, again i think it was overpriced at a dollar. I think the actual figure was $1.59 in 1929.1 point

-

1 point

-

Small but (I think) very good looking watches. I have a couple of them although mine have the Wostok 2209 movements inside. https://watchmender.wordpress.com/2023/01/28/sekonda-field-watch-wostok-2209/#more-4841 point

-

the problem with a fake watch is it specifically designed for one purpose only and repair is not one of those purposes. Its sole purpose of existence is to extract money out of people who fail to grasp what exactly their purchasing. So it looks like a Seiko but of course it's not going to be a Seiko because that would be too expensive it's a Chinese clone of a Seiko whatever was cheap at the time this thing was made. this means no replacement parts at all and basically working on one is a waste of your time if you value your time.1 point

-

you're doing exactly what I was taught in both schools grease. Then my favorite current grease is 9504. I really do not understand why some of the watch companies not all of them but some of them insist on using oil which with time is been getting heavier but still oil and epilam makes no sense to me.1 point

-

1 point

-

I suggest you let the kid in you who have been curious about watches, get one or better yet two cheap Seiko, ETA or AS watch/movement in need of repair, he( the kid will fix the watch for sure), he then happily thank you. Show us the watch you think you want to work on and ask for our thoughts. No shortage of members here who would share their knowledge. Good luck and welcome to this forum.1 point

-

1 point

-

1 point

-

My Type B flieger which is an aliexpress case & generic dial over a gorgeous hammered finish Swiss Unitas 6487 rescued from a silly looking 1970s Arnex pocket watch that had a pastoral farming scene on the dial. The 6498 was in basically new condition. I want to upgrade it with nicer crown & ratchet wheels though, and need to find a shorter sub seconds hand. This is at the extreme of what my bony wrist can manage, made worse by phone camera perspective tricks.1 point

-

1 point

-

I've been using a rust removing formula posted by one of the science channels (Elementalmaker) on youtube. That consists of 5g tetrasodium EDTA per 100ml deionised water, plus a small amount of citric acid to bring it back to around 6.5ph, using ph test paper. It works in a similar way to evaporust, but using a different chelating agent and seems rather milder. I have only used it on tools and non-critical parts so far, but the results have been excellent. These are some parts I've done today; the spring winding arbours were probably in for around 4 - 5 hours as they had heavy rust, and the taper pins & screws for a couple of hours is it was fairly light surface rust. You can see darker grey mottling on the arbours from where rust had stated to eat in to the surface.1 point