Leaderboard

Popular Content

Showing content with the highest reputation on 09/21/24 in Posts

-

4 points

-

Pleased with how this has turned out, the quality is poor , a few modifications needed , mostly around the hairspring and getting it to breathe unobstructed. I thought i could install the balance with the top plate on by unscrewing the bottom bearing for the balance. Very awkward indeed, i even filed a lip off the bottom plate where it penatrated but that still didn't give enough room to install it safely. In the end i unscrewed three plate screws and wedged paper between the top plate and bottom pillars to enable me to just sneak the balance between the plates. On top of that some adjustment to the time setting lever parts that wouldn't allow the pendant to pull out easily. Only getting around 18 hours of run time , but in that the movement had gained just one minute. The time set is stiff as is the winding mechanism, with no reference I dont know how it should be. I need to have a crack at another one...............but which ?3 points

-

Another weekend and another chance to work on this beautiful movement which came back to life again today. For anyone interested, I've uploaded more assembly pictures. The calendar and automatic works remain to be assembled. It's getting close https://1drv.ms/f/s!AnVrKJ9agkNWkokVhogLYtvc6xAqdQ?e=qjlJ4w (sort by name in ascending order)2 points

-

2 points

-

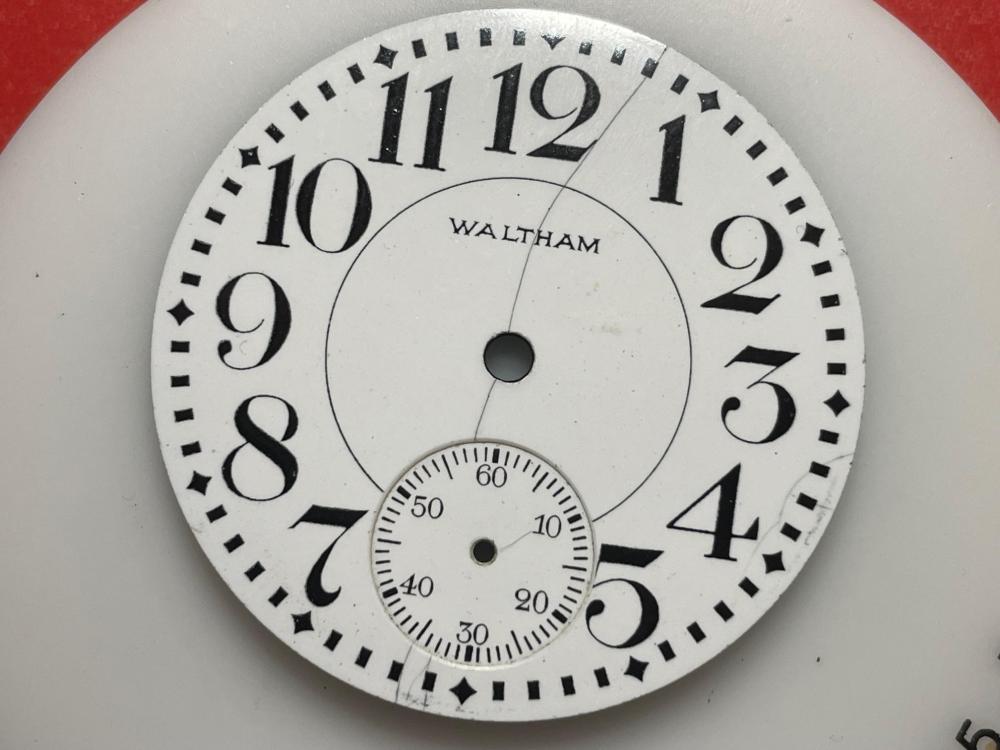

Well, I was not going to buy anything else until I got the existing ones done, but when I was searching for info on someone else's watch, I came across this one at a rather good price..... It's a lever set "Crescent Street" grade, listed as a Railroad type watch. The price was possibly due to the crack in the dial, which is rather obvious! One of the dial feet is missing - possibly someone assumed it had two and tried to pry it without loosening the third, resulting in the dial crack? The movement is generally pretty good, though it has been messed with & one part is missing! The yoke should have a spigoted washer as a cover plate; it just has a semi tightened screw from something in it instead. That part looks to be similar to a cover/retainer disc in the normal crown set movements - but the spigot in the part for those is larger than the hole in the yoke. I found a shouldered screw in a screw assortment that was a perfect fit for the yoke, though that now leaves the yoke spring reliant on friction to hold it in place. Other than that, just mismatched case screws; it looks like someone has had problems with one screw there. I got some Polydent to try and clean the dial, but that had little effect overnight. Then a few drops of bleach - still no effect. Bleach in the ultrasonic cleaner finally got the crus cleared out, then a few rinses & and ultrasonic blast in deionised water to ensure no bleach, and Renaissance wax after drying thoroughly. The result is not quite perfect, but it's no longer an eyesore!2 points

-

HWGIKE#18 Oris 451 Full service. Mixed two wheels on the rocker bar, took me 2 hours to realize. Kept the time overnight. Pin pallet. I relumed the hands and the numbers on the dial next time I might play with the color of the lume. I can use it as a reading lamp now. It should have received a new mainspring but I have not got one.2 points

-

2 points

-

1 point

-

All stainless steel case and does look all original including the nice crown. I was shocked at the price as I had to ask as it was on a sticker on the back. Weird thing is that the stall next to this one had some nice Seiko chronographs all priced at around the £500 mark. It did stop running on the way home and looks terrible on the timegrapher. I am sure I can do a good job on it though. Found a very informative website on ATP watches https://af0210strap.com/blogs/news/the-atp-watch-on-an-a-f-0210-strap1 point

-

1 point

-

1 point

-

1 point

-

I've done a couple now: one 5.5mm (custom size) and one 14.0mm. They work fine. I had previously made one from brass tube with a 3D-printed plunger for a tiny ladies watch (Seiko Rainbow with cal 1104A movement) with a 6mm diameter barrel that was too small for any of the winders in my cheap Chinese set, using an arbor from the set, but when I was trying to coax the tail into the tube it caught on the edge of the cutout and broke off. The RS winder was more successful. It may just be that it was easier to hold than the 5.5mm tubing so I had more control. I'm not sure. By the time I had received a donor movement for that watch (which was needed for multiple parts) I had made a suitable RS winder and had no problems with it.1 point

-

While i'm sorta skeptical that lubeta is the ONLY solution as it seems many just use a tiny bit of 9010 on the pawls inside the wheels i am trying to stick to best practices and those parts already have a lot of wear inside i noticed. (I'm prettys ure this watch predates the existence of lubeta by many decades but don't quote me on that.). The lubeta was delivered and i'll be applying it this weekend. Also despite the 1ms beat error and poise issue the watch has only lost 8 seconds total since i got it together. Very pleased with that!1 point

-

A recently cleaned up Swatch Irony "Big Feature" Steel YGS737 gets a fresh cell and an airing today. This was one of several in a job lot of spares or repair Swatches I picked up ages ago. The case still needs a little work, and it is on a band borrowed from a different Irony, but I have a replacement band on order and I hope to get a chance to polish the case this evening.1 point

-

1 point

-

this would actually be the best plan for both you and the customer. Attempting to fix a watch that was never designed to be repaired leads to lots of problems for you. Then if you can't quite get it right the customers going to be unhappy with you not the people who made the watch. It's best to explain to the customer that it's not a real watch it only looks like a real watch and it's really cheap is is not meant to be repaired. the problem with watches are people only see the outside they somehow think it's real and the just don't grasp what they have at all. so education of the customer explaining the outside looks real but the inside is not and it can't be repaired ever is the best option.1 point

-

you're doing exactly what I was taught in both schools grease. Then my favorite current grease is 9504. I really do not understand why some of the watch companies not all of them but some of them insist on using oil which with time is been getting heavier but still oil and epilam makes no sense to me.1 point

-

1 point

-

If you buy from a reputable supplier and not eBay then they'll have already done this. Edit Unless it's a reputable supplier that also has an eBay listing. https://www.ebay.co.uk/itm/2542020982831 point

-

1 point

-

It would probably be impossible to learn everything from this forum. There are many good watchmaking books available from Amazon and Ebay. Do get some of them to build up a sound foundation first. Jumping headlong into everything is not the best way of doing things. First learn the science behind metal working and machining. Learn the reasons why things are done the way they are. When you understand the science, then you can start to appreciate the intricacies of horology. Then you can start bending the rules and coming up with your own techniques of doing things. When you do get a lathe, don't go and try cutting a balance staff as your 1st project. Start with simpler things. Start with softer materials like brass and soft steel, then work your way up to blued steels and stainless steels. Be prepared to throw away many failures. Or keep them in a showcase to see how far you have come along in your journey.1 point