Leaderboard

Popular Content

Showing content with the highest reputation on 09/24/24 in Posts

-

3 points

-

Absolutely no adhesive. Ever wonder why glued ones are for sale? On ebay or else? Someone had thought of gluing as a quick fix, look where the watch ended up, FOR SALE ON EBAY. You are learning an art so fix each watch as though a patek phillip. Rgds2 points

-

I use them for automatics. As you get close to the reverse bend, you just feed it in...being careful. I do not know how many I have done, but I recall having broken one once. It was an old spring that was probably already fatigued.2 points

-

2 points

-

Unlike so many others here I'm not "mechanically inclined" but love watches so much that several years ago I decided to take them on. So, at age 55, I decided to learn how to operate screwdrivers and tweezers, and I've come a fair bit since and still love it (except when I lose or break something or can't get it to work). Welcome to the forum Jake!2 points

-

Finally got this little Oris tank back on my wrist ( after fiddling with the Westclox) with a half decent strap. I went with Frank's ( praezis ) idea of drilling a hole in the top of the cannon pinion so i could then tap the broken cw arbor out from the top end, thanks for the suggestion Frank it seemed like the safest option. And Nev's idea of gluing an iron tapered pin to fill the hole, in fact it was a stainless steel panel pin that i shaved down with a mini sanding disk on a low powered rotary type tool. Filed down and polished up, the join is visible but only under good light and magnification . Running solid up to now , 28 hours and it doesn't appear to have lost any time. This watch goes back around 2 years to my initial attempts at restoring it,this cannon pinion with jammed cw arbor inside it, broken hairsprings a balance staff , a dodgy overpowered mainspring, a new crystal that i put off buying then aquired a big stock of fancy crystals that was just over the cost of the one i nearly bought for it. And last night closing the minute hand hole, it still needs the hands restoring , bluing and luming but I'm happy to wear it for a while as it is, luming is something i haven't even tried yet, mostly because i enjoy originality, a watch's history, it's age , its life and its deterioration unless something is needed to protect and prolong it. Just as we should embrace growing old gracefully , the aching back, the dodgy knees, hair loss, hair growth in the wrong places , stiff hands, failing vision, I'll stop now before we all get depressed about the inevitable . Time can be short ,so make the most of what we have, grab any opportunities that come our way to make life more enjoyable. Signing out people, have a great day and make the most of it. Rich X2 points

-

1 point

-

Yep thats what i have mb, my description probably misled . I wasn't sure how well the movement would come out as the spring has a lot of tension, the copper spacer hoop kept the two pieces of the stem and pendant seperate, all i had to do was lift the case up free once the four securing screws were removed.1 point

-

Oh that's unusual. The older ones had a similar design (if I get your description) but the pendant just had a wide protrusion that fit loosely into a slot on on the springy winding pinion, like a fat screwdriver blade. So the movement could be dropped right out because the two were not affixed, and to put it in you just turned the crown until the two slotted together.1 point

-

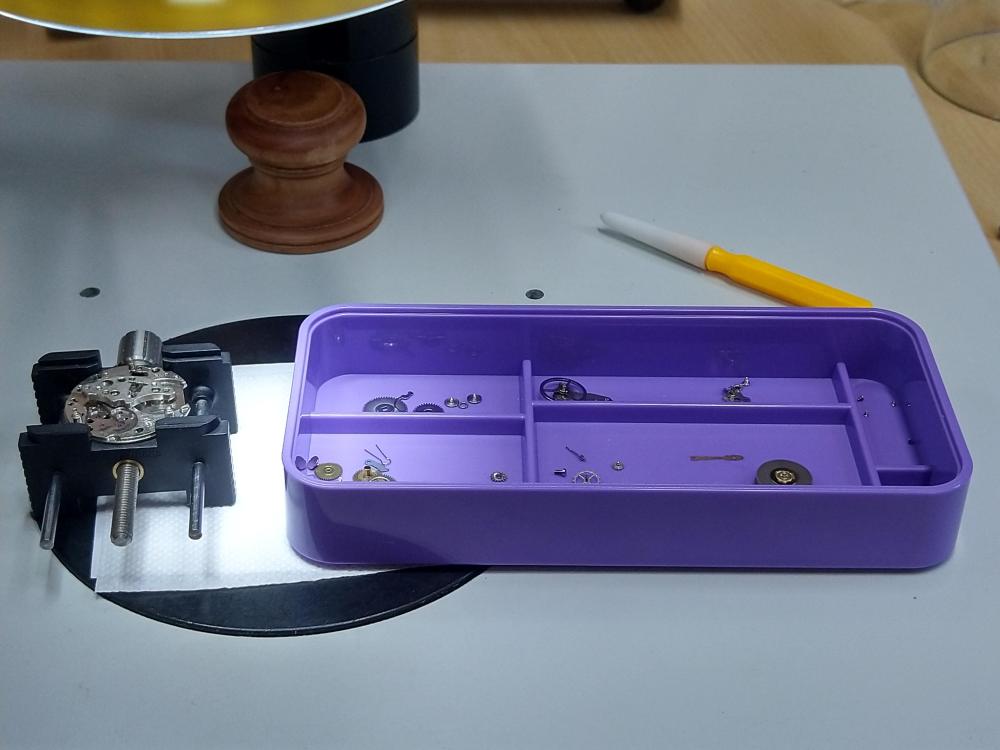

Can I see the complete set ups please. I need to see what the movements are.1 point

-

The easy way is to fix some weight 2 to 3 oz where the pendulum hangs set it to time and see how it goes for a few hours, if you see a significant change in time in the two hours adjust weight accordingly. You need to make sure it has a nice even tick tock.1 point

-

33 years old I am from the US and I've been lurking for 6 months learning a lot, this is a fantastic forum! I am very new to watchmaking, I have a small collection of vintage watches mostly from the 70s. As they slowly began to run poorly or stop all together I decided I would learn how to service them myself "how hard could it be?" I have purchased a ton of tools and too many parts movements but have successfully gotten one Tissot 2571 from non runner to runner! I am mechanicaly inclined I enjoy working on car engines where the parts are easily found when dropped. Old cars. Old watches.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

I was a Volvo mechanic before going to watchmaking school. Not a factory mechanic- I worked for (initially and then closely with) a Volvo junkyard. We built some pretty good rally as well as demo Derby cars. The rallys were usually English two seaters with tricked out Volvo motors. The demos were _always_ Chrysler Imperials!1 point

-

1 point

-

1 point

-

Its used to set the dive time, various factors determine that, in the main the amount of air the diver is carrying, depth also plays a part, further down the more air the diver needs to return to the surface, but yes you're right decompression times would also need to be accounted for when setting the dive time. A traditionally marked bezel can be used for both time elapse and time remaining were as this one is really only time remaining without causing confusion.1 point

-

As a diver I know that almost without exception everyone uses a dive computer. However, in the past you used to use dive tables to calculate your maximum bottom depth duration. For example if you knew the dive was 30m then you would use the table to have it tell you that you could safely remain at this depth for 15 mins. So I assume you could use this bezel once you get to 30m to let you count down from 15 to 0 mins before you have to make your way to surface with the standard type of stops. However, if you over-stay your time at depth then you run the risk of accumulating too much nitrogen in your blood and returning to surface would require additional and prolonged stops to allow the nitrogen to exit your blood and other soft tissues. Failure to make these additional stops could result in a nasty case of DCI, also known as the bends and in extreme cases death. You would have a pressure gauge on your tank so you dive on pressure, not time. However, if you overstay your bottom time, then you may have to make more and longer periodic stops on your way to the surface (known as decompression stops). Normally you dive and plan not to have these decompression stops and only regular 3 minute stops at set intervals. Decompression stops could be as long as 10-20 minutes each and several of them (depending how deep you wend and for how long) and you better hope you have enough air left to make these longer stops, or you have to come to surface and hope for the best.1 point

-

I also thought it seemed high but yes Andy visually to 180° with marks on the balance wheel and the plate and then adjust the tg LA to meet the same 180° amplitude that i concluded visually. If the balance wheel has 2 spokes this makes marking up easier. This is at rest obviously and check to see that the impulse and fork are lined through so the movement does need to be in beat. I choose one of the spokes as a register then place a dot of ink ( fluorescent would be lovely ) on the rim at spoke center ( i find the bottom edge of the rim works best sometimes depending on where the spokes are positioned in relation to the plate or a bridge. At the opposite spoke ( 180° ) i then mark whatever is next to it , be it a bridge or the plate ( you choose which spoke works best for marking up ). All that remains is to slowly wind up and watch the two mark reach alignment, its kinda fun seeing the approach take place, fluorescent ink and uv light . When the marks get close winding up needs just a click at a time and with time to settle between each click so this part shouldn't be rushed, its easy to overshoot if you lose concentration then you either have ho start over or just guess it. I'm sure you know all this Andy so no offence i just thought anyone else beginner wise reading can pick the bones of the idea and make use of it. Now if someone has an Oris 291 in running order check its lift angle for me1 point

-

Normally the canon pinion cannot rob power or reduce vertical play as it sits on a step of the center staff. Repair: how about drilling a smaller hole into the closed top, push the broken part out, plug and polish the top again? Clamping will be a bit tricky.1 point

-

This is how i fit the brass hairspring pin in the stud. Assemble all of the balance and install it in the movement, fit the movement into a movement holder. Slide the hairspring into the stud and fit the brass pin using fine tweezers. I stand the movement holder on it's side so that the movement is in a vertical position, this gives better access to the stud hole. Voilà1 point

-

OK, you probably all know this wrinkle, but it was new to me. I've been trying to adjust the last coil on a Breguet overcoil so that all the various bits lined up. I was doing this on the upturned balance cock (with the spring removed from the balance of course). I saw a video where the watchmaker took an impression of the bottom of the balance cock on a thin sheet of rodico, which captured the location of the curb pins, the stud mount position and the jewel hole. This is carefully removed from the cock, and the holes transferred to a piece of paper with a pin poked through the rodico. I repeated this 3 times to get a sense of 'repeatability'. I then drew the curb pin circle from the centre with a pair of compasses. You can then drop the hairspring on the diagram and see where everything needs to be, and tweak accordingly. Much easier!1 point

-

if you have the snow globe affect like this then all the numbers will typically be invalid. towards always really important that visually the watch should agree with the timing machine and the timing machine numbers in the graphical display should all be similar and when things are this bad of the graphical display well everything else is worthless. basically all reverser wheels have to be treated in a specific way for each the various types otherwise undesirable things will occur. typically on the Rolex am attaching some images they have to be epilam. That's to keep the oil from going where it's not supposed to be. Then you can see it's only on the post at the wheel goes on nowhere else.1 point

-

Thank you for the kind comment. Many years ago my dad was a watchmaker and showed me the basics, but I followed a different career path. A couple of years ago I picked it up again and started seriously studying and setting up my bench. Along with my studies, I am trying to spend a bit of time on the bench every day to gain experience. There is much to learn!1 point

-

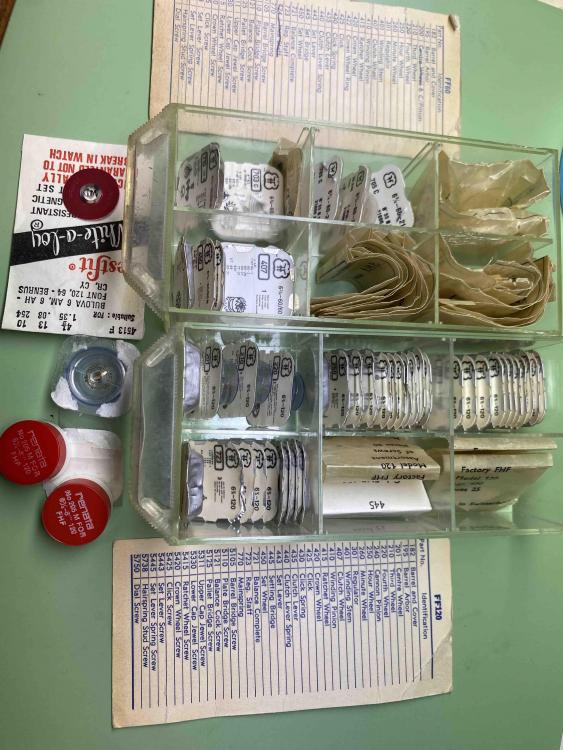

Hi clockboy, thank you for that very valid grounding comment, and I would normally agree with it. However, I have trays of spare FHF120 /60 parts on hand that may never be used so there were no out of pocket expenses in this instance. However, time was spent for the cost of experience. This was the first time I had done many of these repairs. I had to get into the frame of mind to analyze what was causing the problems and the logical steps of what to check first, and putting theory into practice. Next time I get a job that requires any of these tasks it will hopefully take me less time, and I will have a better understanding of what I should be charging for the repair. Thank you kindly for your feedback , I appreciate all comments.1 point