Leaderboard

Popular Content

Showing content with the highest reputation on 09/25/24 in all areas

-

nevenbekriev, based on all the input I have received and my own ongoing consideration of this question, I have also now come to the conclusion that my recommendation in my initial drawing was incorrect (see my updated skilled artwork). The red is the jewel and the gold is the spring washer. This position makes the most sense. The spring washer will push the pinion gear down toward the baseplate to ensure better engagement with the gear and allow the wider part of the cone of the washer to rest on the underside of the center second bridge with no chance of interfering with the mesh of the gears. Broken would have been a better choice of words when describing the jewel. When observed through a loupe, the opening has a somewhat irregular shape from either a crack or chip. Thanks for your input. New spring washers arriving on Friday.3 points

-

Yes, indeed! I’m pretty sure I used a bit too much force but was saved by my newly acquired brass hammer. The next time I know I can use a bit less force. I should have bought two axles. One for practice (without the rotor attached) and one for the actual job. I do recommend getting two axles because it is difficult to assess the force needed when you’ve never had the chance to try it.2 points

-

So, my watch repair friends, the agony is over. The new axle has been riveted! As I lifted the brass hammer to whack the punch, @Jon's words suddenly came to mind: "I'm sure you will ace it. What you believe, you become!" I haven't yet had a chance to test it, but as far as I can tell it looks good. Thanks for the practical advice, explanations, videos, articles, and encouragement. Invaluable! Feeling pretty good about myself tonight!2 points

-

2 points

-

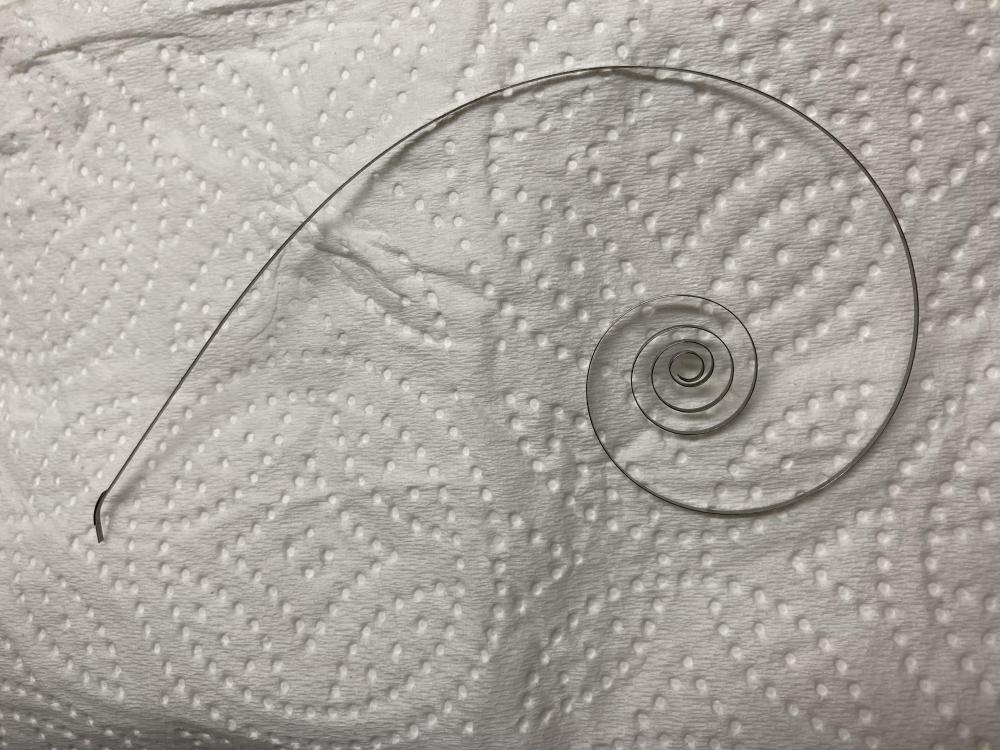

A belated update as I’ve finally got round to looking at this one. I closed up the hole in the barrel bridge to reduce the sideshake but the amplitude wouldn’t exceed 150 degrees. The next step was to remove the ‘new’ GR mainspring from Cousins and it looks rather tired! I’ve fitted a new one from a different supplier and immediately the amplitude increased to 230 degrees. Rather more respectable for this type of watch. I think another service (there is oil in the lever pivot holes) will improve it further…1 point

-

1 point

-

Not impressed. The Kluber P125 (or whatever it was) should be thinly spread around the barrel rim but not in the notches. When using oil (HP-1300) I prefer to lubricate the barrel bearings when the arbor and spring have been mounted and the lid has been closed. I am unsure what calibre this is but I would choose Moebius 9504 (instead of Molykote) for the barrel bearings which I believe is fairly close to Rolex's MR4 grease. Did I just start a fire!?1 point

-

1 point

-

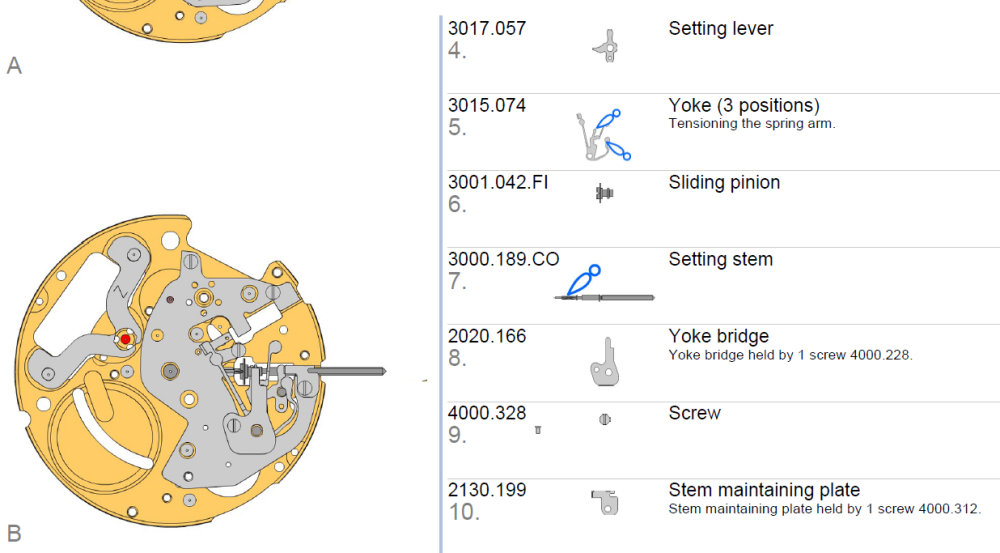

I don’t think it will be a “retainer “, it would normally be held in by the setting lever. This may have become dislodged. To check you would need to remove the complete movement from the case, then remove the hands and dial to access the area. You would need to have some knowledge and basic experience along with tools to investigate. If it was a cheap 10 quid watch from the local market I would say give it a go, but this watch is not. Any independent watchmaker could have a look at it and quote for repair, otherwise I would suggest enquiring about the TAG repair. Tom1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

I have stopped buying pegwood. I make my own. I have several large French Lilacs in my yard, and the pruned and dried branches and twigs once liberated from their bark make great pegwood shafts. The wood is hard and dense, and sharpens down to a very fine point. I practiced on old donor movements to ensure that it does not scratch the finishes or damages the jewels. I then run the pegged movement pieces through my cleaner after getting the larger pegwood remnants off with Rodico or a blower.1 point

-

Welcome to the forum, from Fraserburgh east coast. Added a couple of files for you to read. TZIllustratedGlossary.pdf TM 9-1575.pdf1 point

-

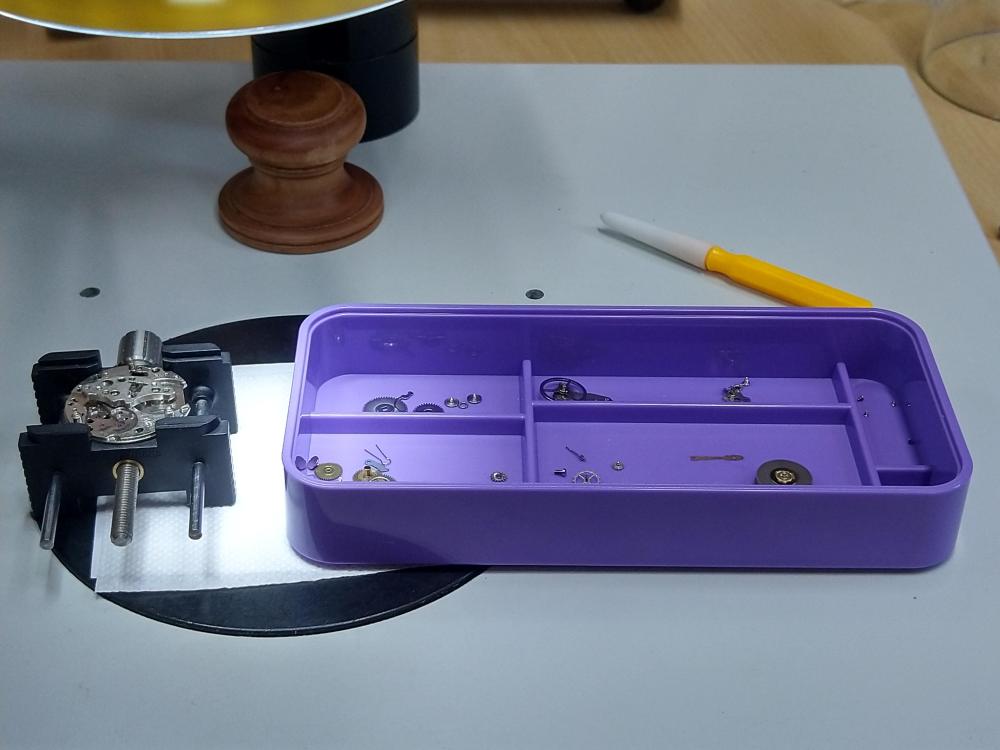

Neverenoughwatches.... thx for the pic grab!!! Mine has been sitting on corner of 2nd bench/storage area and couldn't find the blame thing right off.!! Man I need to tidy up things!! Not showing my bench off for a bit!!!! I'll get this Hammy sorted and poss one other prior to show and tell!!!1 point

-

1 point

-

I use them for automatics. As you get close to the reverse bend, you just feed it in...being careful. I do not know how many I have done, but I recall having broken one once. It was an old spring that was probably already fatigued.1 point

-

1 point

-

Finally got this little Oris tank back on my wrist ( after fiddling with the Westclox) with a half decent strap. I went with Frank's ( praezis ) idea of drilling a hole in the top of the cannon pinion so i could then tap the broken cw arbor out from the top end, thanks for the suggestion Frank it seemed like the safest option. And Nev's idea of gluing an iron tapered pin to fill the hole, in fact it was a stainless steel panel pin that i shaved down with a mini sanding disk on a low powered rotary type tool. Filed down and polished up, the join is visible but only under good light and magnification . Running solid up to now , 28 hours and it doesn't appear to have lost any time. This watch goes back around 2 years to my initial attempts at restoring it,this cannon pinion with jammed cw arbor inside it, broken hairsprings a balance staff , a dodgy overpowered mainspring, a new crystal that i put off buying then aquired a big stock of fancy crystals that was just over the cost of the one i nearly bought for it. And last night closing the minute hand hole, it still needs the hands restoring , bluing and luming but I'm happy to wear it for a while as it is, luming is something i haven't even tried yet, mostly because i enjoy originality, a watch's history, it's age , its life and its deterioration unless something is needed to protect and prolong it. Just as we should embrace growing old gracefully , the aching back, the dodgy knees, hair loss, hair growth in the wrong places , stiff hands, failing vision, I'll stop now before we all get depressed about the inevitable . Time can be short ,so make the most of what we have, grab any opportunities that come our way to make life more enjoyable. Signing out people, have a great day and make the most of it. Rich X1 point

-

This is my "no more watches for me" watch. I hope. At least for a while. I've been very fond of all things Japanese lately, especially vintage LM and KS Seikos. And old Seiko tools. I just put together a complete set of S-220 crystal presss. Anyway here's the watch. KS 4502-7001. Manual wound and originally chronometer graded according to the serial stamped in the bridge. 36000 bph. I hope the parts are ok. The crown is a diver type so there's a little struggle to change the gasket.1 point

-

I started off using ultrasonic cleaning and water based degreasers. I also experienced rust on screws and steel pinions. The strange thing is it doesn't happen to every watch. Some go through the cleaning process and come out absolutely fine. It might be due the composition of the steel used. I also ranted about water based cleaners on this forum and promptly got chided by several professional watchmakers. They said that they have been using water based cleaners for years and have never had any problems. So I moved on to using water free solutions but these are frightfully expensive here in Singapore. A bottle of L&R #111 and Rinse #3 comes to a whopping $300. You'll have to do a lot of explaining to justify spending that kind of money. But I never stopped thinking about why I was getting rust sometimes and why other watchmakers don't. Some of the points I've identified are:- 1) They are using professional water based watch cleaners. I think these professional cleaners contain rust inhibitors that are not listed in the MSDS. 2) They use rotary type cleaning machines. At the end of the cleaning cycle, the basket is spun at high speed to throw off any water trapped in narrow gaps such as screw slots and leaves of the pinions. 3) They use hot air to dry their parts. I think air circulation removes water droplets faster than waiting for parts to heat up via radiation and conduction in an oven and letting evaporation dry up any trapped droplets. AND heat speeds up chemical processes, which includes rusting.1 point