Leaderboard

Popular Content

Showing content with the highest reputation on 09/26/24 in Posts

-

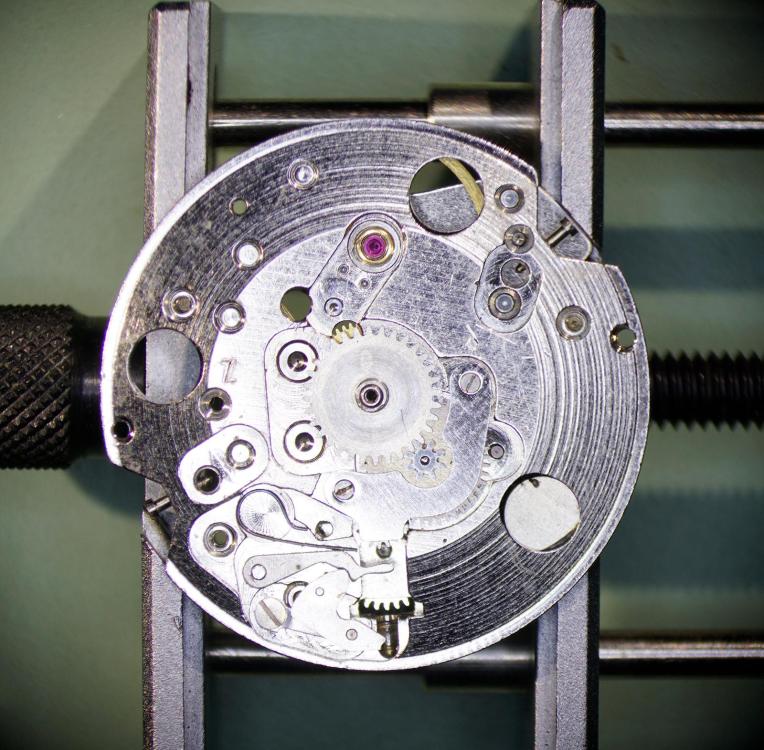

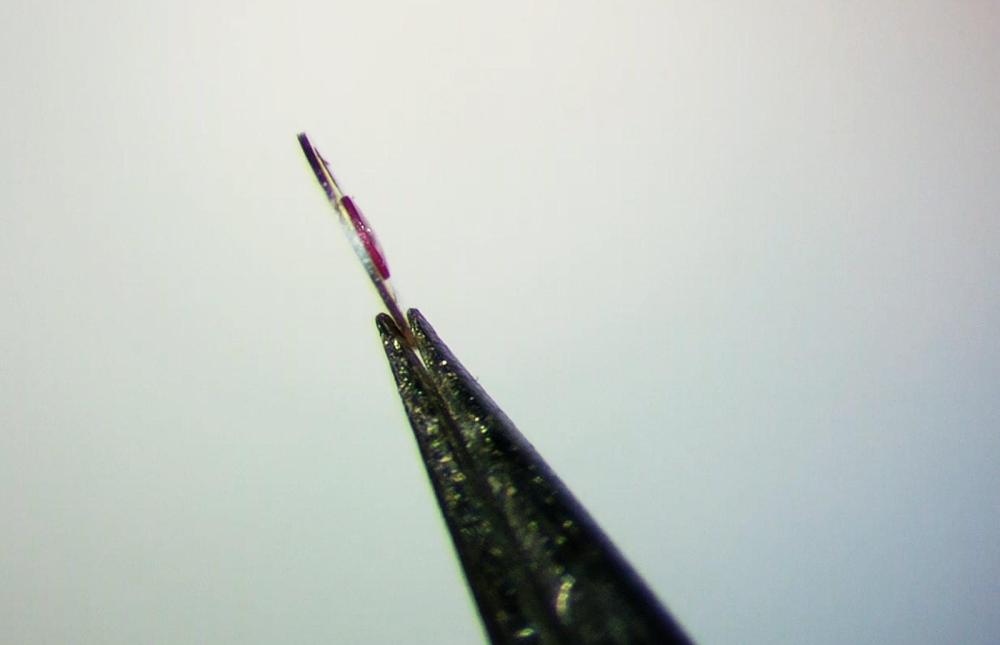

A little over a week ago I tried making something resembling a balance staff for the first time. It wasn't for any specific watch, just trying to get a feel for how the gravers and steel "worked". I got encouraging feedback , so today I decided to try again. Now for an actual project, a Junghans J47 with both balance staff pivots broken. I do actually have some new balance staffs for this specific movement, so that made it easier to get good measurements. I won't ask you to spot the differences between the DCN staff and mine (my wife sometimes says I'm snotty enough already), but any feedback is greatly appreciated.. Tonight I'll fit the wheel, finish the pivots on the jacot tool and see if it will actually work..7 points

-

Seriously, we sometimes have a watchmaker make a staff as part of their bench test. Most, who were recent multi-year watch school grads, failed. These are folks who spent months doing supervised turning. What you've done is super impressive.3 points

-

I still have difficulty when there’s an english and an english for the same part or an archaic term for same…3 points

-

2 points

-

I often do, by mistake. Words with "ou" (colour, flavour, honour etc) are from the old French when it was the main language in England. The differences are usually blamed on Mr Noah Webster. " the American lexicographer. Seeking to establish American independence and identity in language, Webster implemented a number of spelling reforms in A Compendious Dictionary of the English Language, which he published in 1806". I find it interesting the way words and pronunciation change, The one that amazes me is the spelling of Knight. I believe the scene in Holy Grail with the French knights in the castle has the pronunciation about right : "you silly English "cuh-nikt" "2 points

-

ETA lists the same spring for the 6497-1 and -2, at a thickness of 0.175mm (GR 4307-1). It's not uncommon though for a maker to use a stronger spring when going to a higher frequency on the same base caliber. The 6497-1 is 18,000bph, the -2 is 21,600. Perhaps the ST36, which is 21,600bph, does use a stronger spring. It doesn't take much to cause rebanking. An old Unitas 6497 that's hitting 275 in horizontal really shouldn't see more than 40 degrees drop in verticals. Could be a pivot issue with the balance, or if the locks on the escapement are a bit heavy that shows up more in the verticals. Curious what the size difference is between the mainsprings.2 points

-

Old books usually call it "knocking" or "galloping" due to the telltale sound it makes on a large pocket watch.2 points

-

I'm the same without a standard language for watchmaking it can get confusing, in particular for beginners, 2 or 3 people advising using or 2 or 3 different names for the same part. I admit to liking the older English names and terms going back to traditional watchmaking ie. The lever ( its function ) as opposed to the pallet fork, its less spelling for starters and use pallets or even anchor ( depending on the particular part of it in question )to describe one end of the lever and fork for the other end. Sometimes its function related and other times a lookalike description .2 points

-

2 points

-

So, my watch repair friends, the agony is over. The new axle has been riveted! As I lifted the brass hammer to whack the punch, @Jon's words suddenly came to mind: "I'm sure you will ace it. What you believe, you become!" I haven't yet had a chance to test it, but as far as I can tell it looks good. Thanks for the practical advice, explanations, videos, articles, and encouragement. Invaluable! Feeling pretty good about myself tonight!2 points

-

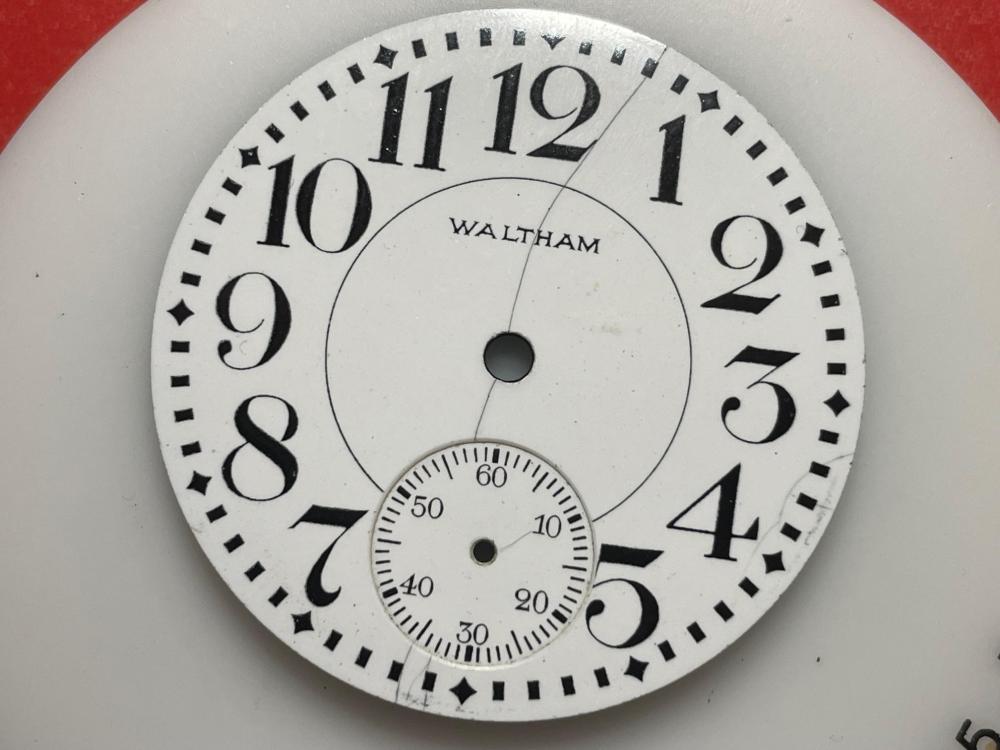

Greetings All. I'm an amateur watchmaker who first took up the hobby about a year ago and who has since dived in with both feet. I have been restoring vintage watches of various types in need of service or repair. I've attached a photo of my growing collection of self-restored watches. Most of these where purchased in non-running condition. Some came back to life with a simple service, while others required a lot more work, but they all run well now. I've also done case restorations on some of these (metal plating, etc.), although I tend to avoid it unless the case is in truly terrible condition. I look forward to picking brains around here when I get stumped, and sharing what little I've learned so far!1 point

-

Something to say here. The losses in balance system increase proportionally to the square of the amplitude Thus, there is effect of limitation of the amplitude due huge increase of losses, while the income of energy is constant, and this leads to smaller differences vertical/horizontal when bigger amplitudes1 point

-

I can't see them on your new photos either, so either the light or left over Rodico. Again, nothing but respect from me.1 point

-

Yes, if there is a poise error - and there always is. We had discussed this in several threads about dynamic poising or just poising. Frank1 point

-

… but not too much, just slightly, after having them ground flat with the Arkansas first.1 point

-

1 point

-

Hello, a stronger mainspring cannot heal a too big difference between flat and vertical amplitude, it will just shift values to a higher range. Reasons are elsewhere as mentioned by nickelsilver. And you do not want 275 deg vertical, for you will get differing rates in the vertical positions then - 220 is optimal. Frank1 point

-

On mine, the dial does appear authentic and the lume under the scope is old and degraded but not curently radioactive (based on an inexpensive but functional Geiger-type detector) which would rule out radium. So, it's likely relatively short-lived tritium lume which matches with the rest of the watch that dates to the 70's. So yes, radioactive at one time but mostly decayed by now and not at all the kind of exposure you could get from working on a radium-lumed watch if that is a concern. You need a different type of detector to actually measure tritium, but enough half-lives have gone by that you can assume a low risk just with math, and it doesn't produce deeply-penetrating rays or particles in any case. If I read the dial correctly, yours is a "Keepsake" version which is also a later-years model so I think it would be very unlikely to be radium, but I'm not a West End expert.1 point

-

1 point

-

That raises a question for me - why don't all you UK folks spell it "barrel arbour" like you do with your "colours"? (apologies for my humo[u]r)1 point

-

R, you're exactly right about that! I practised pulling the spring back (right hand) and holding it (left hand) while also controlling the movement holder (left hand) about 5 to 10 times before I felt confident to do the job. Practice makes perfect, and sometimes practice is a must not to make a mess. Lovely movement holders! Thanks for sharing the pictures!1 point

-

One of these is destined for my bench in a few months. Your’s looks great!1 point

-

Haha, I'm probably sticking up for him now , i think he's shortened mainspring barrel to just main barrel lol, why not just barrel ? I guess alarm watches have alarm barrels ? But again as pointed out by Klassiker, english is not kalle's first language so allowances have to be made, but yes i like him too Yey day at home today in my watchroom, radiator fitted in there last week so nice and cosy now. After spending all day yesterday climbing around like a monkey on scaffolding, this is heaven , the smell of coffee percolating in the corner and fresh homemade walnut and fruit loaf and its raining outside, i ask what could be better ? No its not coffee , its camomile tea I've had my one morning coffee, i just love the smell of coffee brewing. Not trying to make anyone jealous or anything............well maybe...... just a little..... That would affect word order, grammar and such which is totally understandable but not terminology. https://youtu.be/vQBGA_oJlhI?si=GSMsYe88Ruzdn-1k1 point

-

I like Kalle, who wouldn't, but using his homemade terminology, like "main barrel" takes a lot of focus away. I always wanted to ask him where I could find the secondary barrels. "knocking" isn't bad as a synonym for re-banking! The impulse pin "knocks on the door" (the outside of the fork horn). Yes, there is a distinct and important difference so I couldn't agree more. That would affect word order, grammar and such which is totally understandable but not terminology.1 point

-

Nice, yours looks a bit happier than mine. Any idea if these are radioactive lume? Edit: after a bit of reading, pretty sure it is. Movement pic and probably away in a drawer or sold then... Pretty pleased with the strap though... And (while I imagine there are loads of them) I've never seen an acrylic like this before...1 point

-

Haha I've been mentioned in a few of his videos, i figured the language barrier could be the reason, it was pointed out to him a couple of times in the comments, be good to hear kalle correct this mistake, i have a lot of respect for folk that hold thier hands up to say sorry i got something wrong.1 point

-

Ok so I'd be careful with this idea, i think there are other devices specifically designed for that , you just need to find the correct outlets for them1 point

-

He didn't mention rebanking at all just knocking as overbanking , which are two different terms1 point

-

I guess it is raining Primas - I just received one that I had taken a chance on from an Ebay seller in Pakistan. Seems to run quite well, but when in setting position things are a bit stiff so that will be reason enough to open it up and take it apart! Edit- Looking at the photo I think I'll look examine it more closely to see if it's a redial, but that would be OK because I really didn't spend any more than you might on a Mumbai special Seiko.1 point

-

The 11DP uses Parashock shock protection. The cap jewel is fixed to the setting which has a spring. That spring shouldn't come loose, but I have had it happen to me once. It's possible that you may be able to press the spring back onto the setting. Attached is a tech sheet discussing the shock system for the 11DP (Citizen 0241). Note that there is an orientation to the hole jewel, the side with the jewel sitting proud of the spring faces up. I've also noticed that the movement isn't as easy to fix in the holder dial side up as it is dial down. Below is how I orient mine. There was some other issues discussed regarding the 11DP in this thread which you may find useful. Bulova_11DP_TECH_1971-11.pdf1 point

-

I believe he always calls rebanking/knocking/galloping "overbanking". I have heard it several times.1 point

-

Poor Kalle is getting ragged about, i did watch one of his videos yesterday, first time for ages. I had to end it though he had rebank and overbank completely mixed up . I read the comments and only a couple of people had picked up on it, proves that beginners are picking up incorrect terms, not good.1 point

-

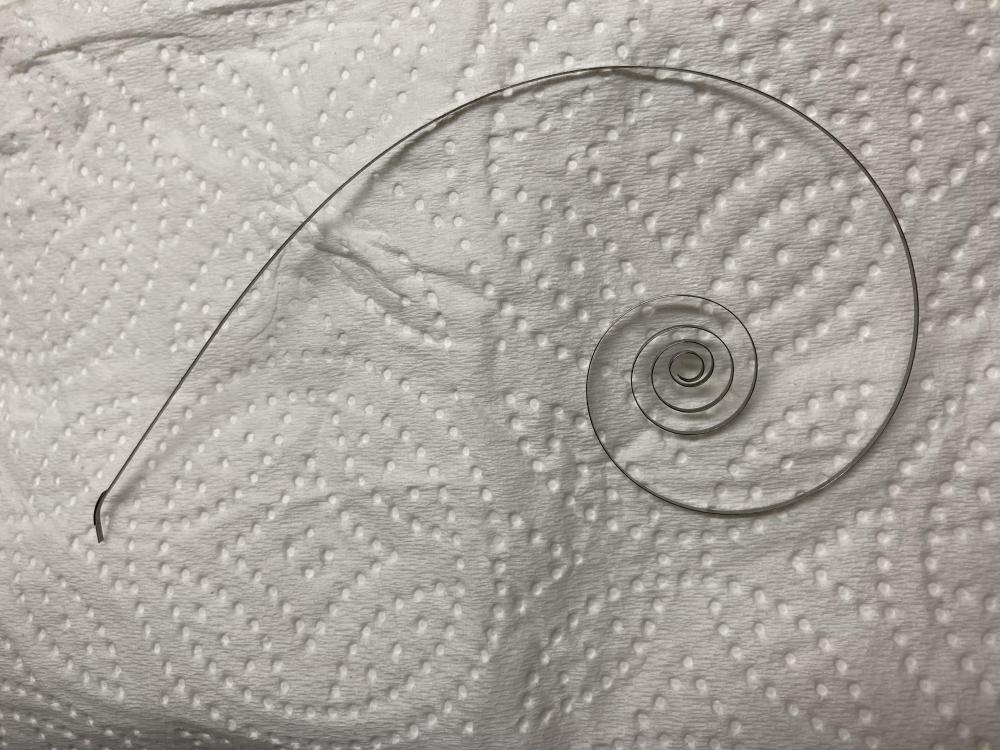

A belated update as I’ve finally got round to looking at this one. I closed up the hole in the barrel bridge to reduce the sideshake but the amplitude wouldn’t exceed 150 degrees. The next step was to remove the ‘new’ GR mainspring from Cousins and it looks rather tired! I’ve fitted a new one from a different supplier and immediately the amplitude increased to 230 degrees. Rather more respectable for this type of watch. I think another service (there is oil in the lever pivot holes) will improve it further…1 point

-

1 point

-

Yes Paul you will have that exactly right when the springs arrive, carry on. Anyone have an idea how to make these spring washers, the usual flat fork springs look simple to make. Paper thin brass sheet and a paper punch ? Found 0.3mm sheet brass, large dial washers ? Thick tin foil ?1 point

-

I like tools on my bench, not good if anything pings off, rarely happens these days. Now that it doesn't happen i dont get to dust and that builds up quick so bench clearances have become a necessary weekly routine. Jeez if the missus found out that dusting is one of my forte I'd have less bench time .1 point

-

Wow! That's really good. I could see that hanging on the walls of a modern art gallery.1 point

-

Getting into watch repair and servicing is long journey. Tackling a Rolex without experience is really not a good idea. Fittings after market parts is another bad decision .Rolex genuine parts are always fractionally different to the aftermarket parts in terms of size and build quality.1 point

-

Another weekend and another chance to work on this beautiful movement which came back to life again today. For anyone interested, I've uploaded more assembly pictures. The calendar and automatic works remain to be assembled. It's getting close https://1drv.ms/f/s!AnVrKJ9agkNWkokVhogLYtvc6xAqdQ?e=qjlJ4w (sort by name in ascending order)1 point

-

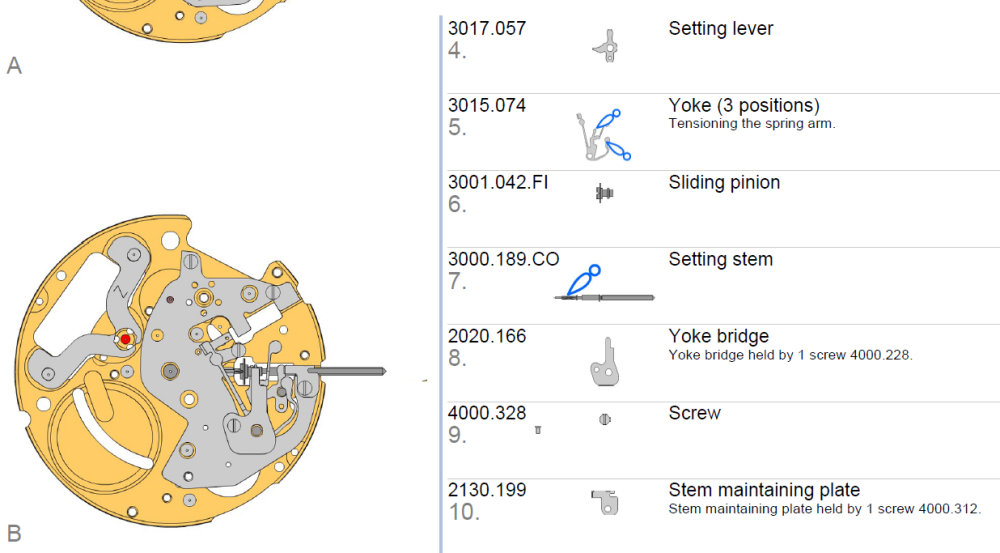

Well, I was not going to buy anything else until I got the existing ones done, but when I was searching for info on someone else's watch, I came across this one at a rather good price..... It's a lever set "Crescent Street" grade, listed as a Railroad type watch. The price was possibly due to the crack in the dial, which is rather obvious! One of the dial feet is missing - possibly someone assumed it had two and tried to pry it without loosening the third, resulting in the dial crack? The movement is generally pretty good, though it has been messed with & one part is missing! The yoke should have a spigoted washer as a cover plate; it just has a semi tightened screw from something in it instead. That part looks to be similar to a cover/retainer disc in the normal crown set movements - but the spigot in the part for those is larger than the hole in the yoke. I found a shouldered screw in a screw assortment that was a perfect fit for the yoke, though that now leaves the yoke spring reliant on friction to hold it in place. Other than that, just mismatched case screws; it looks like someone has had problems with one screw there. I got some Polydent to try and clean the dial, but that had little effect overnight. Then a few drops of bleach - still no effect. Bleach in the ultrasonic cleaner finally got the crus cleared out, then a few rinses & and ultrasonic blast in deionised water to ensure no bleach, and Renaissance wax after drying thoroughly. The result is not quite perfect, but it's no longer an eyesore!1 point

-

so far so good, i managed to make a working one,(that paletfork is a real pain to install). it is still running a bit slugish so i wil probably need to still give it a good service but we are one step closer to having a watch on my wrist.1 point

-

Hi Guys, Today I have a huge sense of accomplishment and relief after finally finishing restoration of this Ball 999B 16s 21 j railroad grade pocket watch. I started it in April, so it only took me five months to complete; as life got in the way. It also had a lot wrong with it. Broken jewels, broken staff, bent wheel, broken hands, well, you get the picture. It's running great in my estimation. The fact that it's running at all is proof, not of my workmanship because heaven knows it's lacking, but of the high quality of workmanship that went into the watch's manufacture. I feel very lucky to have gotten it back into shape. My only regret is that you can see some of the glue used to adhere the crystal. I thought it was supposed to dry clear. I might retry with some UV glue to see if that's better. Thanks to all the people who gave me input along the way. I couldn't have finished without all their help. Arron.1 point

-

Yes, we need each other's support because there are days when you can feel very down and start thinking about giving up. It's easy to feel inadequate when you see the pros on YouTube, but then you have to remember that there is a lot of editing. A step that might take an hour, two, or even three in real life is often done in a few seconds in a video.1 point

-

Even the professionals on here are humbled at times. Very few never require help.1 point

-

1 point

-

Picking up this side-tracked post again as I just removed a balance staff of a 1920's Omega (35,5L-T1) I was impressed by the way @Delgetti had his setup when he had to change out a balance-staff (https://www.watchrepairtalk.com/topic/28854-new-balance-staff-not-riveting-to-balance/page/2/#comment-244054 Not only that, but also the idea of removing the seat first before punching the staff out from the seat-side, avoiding the whole discussion of the rivet yes/no enlarging the hole. I didn't have the fancy clamps & tools Delgetti has, so I used my screw-head polishing tool. Initially I used #1500 grit diamond paste on the steel wheel, which kinda worked, but very slow. I changed to #800 grit diamond paste, which worked better, but still slow. Then I glued #240 sanding paper to the steel disk; That worked and the disk was hand-driven. Once close to the balance wheel, I took the sanding paper off and continued with #800 diamond paste. One can only do this when the balance wheel sits true on the staff and has no "wobble". I went on grinding until I saw some diamond paste on the rim of the balance wheel. This was as far as I could grind and it seemed that at that point there wasn't much left of the seat. Carefully, with my staking set, I knocked the staff from the seat-side out. Turns out that the thickness of the seat left, now a small ring, was only 0.1mm. The balance wheel hole is in perfect shape and no damage done to the wheel at all. Of course, if the wheel has a "wobble" or isn't seated true on the balance staff, you can't get as close and there will be more left of the seat. In my case, it worked perfect I'm very happy how this method worked out !1 point

-

But that is a different pair of shoes, I never talked of that. I assume that the tool will not reach the hole, no matter what you use. Easy with simple stake, too, if you keep the stake between your fingers while hammering. When I push the staff out after removing the hub, I use a stake with cylindrical pivot, a bit smaller than the hole. As I said, no punching method or tool can protect the hole - from widening by the distorted staff - from distorting hole and balance arm to a funnel-like shape if the rivet is too thick (happened to me decades ago). I apologize if I seemed to be condescending, tried to say it friendly, but meanwhile I am tired of repeating the facts. But I know now, we had different issues in mind. Regards, Frank1 point

-

Update: After giving up hope that I could get the staff riveted to the balance, I got to musing over the above advice. I decided to just play around with different methods of attaching the staff using a junker staff and balance. I used liquid shellac first and I thought it held moderately well initially, but then with a bit of wiggling from my tweezers, the joint failed. I then tried the solder. Oh what a big blob of mess that made. I could see, however, how a skilled jeweler could make that work quite well. Finally, I tried CA glue (super glue). It took two tries but ultimately it turned out quite well. I got the watch back together and it's still running. I realize this is just a temporary fix, and is probably considered blasphemy by the real watchmakers here (i don't include myself under that esteemed label), but it's super cool to see and hear this 19th century timepiece chugging along again. It's nice to have an occasional small victory to offset the frustrations with this hobby. PS I appreciate everyone's kind advice. I do think that next time I am going to give my lathe its maiden voyage and try cutting off the hub to remove the staff. That seems like it's do-able for a novice, whereas making my own staff seems daunting at this stage of the game.1 point

-

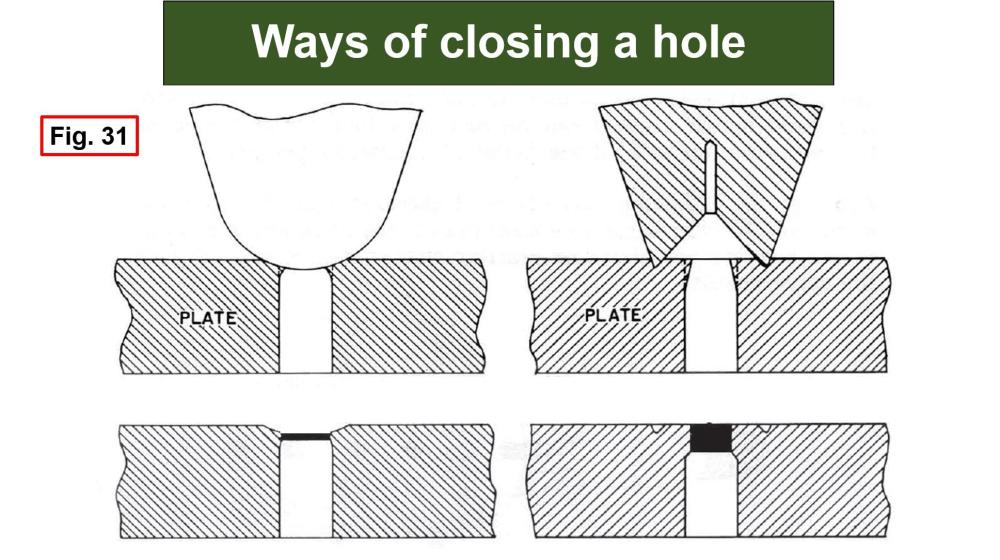

I concur with @nevenbekriev and @nickelsilver. It is a better and safer method to cut away the hub before removing the balance staff. The rivet can be cut back, but I find the hub is a better way to do it. If someone decides to use a platax tool and knows there is a real risk of enlarging the hole in the balance arms, that seems a little foolish to me, regardless of who they are. If you don't have a lathe, then I can see why punching the staff out is the only option I knew of a client who he always asked a potential watchmaker who he wanted to do either repair or servicing of his watches, how they removed the balance staff from the balance, and if the watchmaker said they punched it out with a platax tool or similar, he would walk away and find someone who cut the hub or rivet first. There are obviously more than one way to skin a cat and watchmaking is a very subjective matter based on experience, but I'm sure that anyone who has the experience of cutting the hub off first before removing the staff will realise it is the better method, which is infinitely safer. I would try closing up the hole, because if there is a gap the rivet isn't going to alleviate that. You can use a domed stake on both sides if you have an inverto staking tool, but make sure the domed stakes are the correct size, so when the work is gripped between the stakes, the work doesn't turn and the stakes don't touch each other. Be incredibly light with the hammer! Once the staff is fitted, because you have closed the hole, you may find the staff might not be true to the balance, but you would put it in calipers anyway to true it up so it spun without a wobble1 point

-

Yes, there’s a noticeable tilt in the barrel and there’s a lot of play where the barrel arbor comes through the barrel bridge. I’ve found a replacement bridge which hopefully won’t have the same issue. I’ll report back with an update. I’ll put the worn bridge to one side and return to it when I’ve learnt the art of rebushing. These are nice watches, and relatively easy to work on.1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)