Leaderboard

Popular Content

Showing content with the highest reputation on 09/29/24 in Posts

-

Spent a nice Saturday morning on this nice Helbros that I picked up at the beginning of the month in a lot for $5US. Did not work, could barely get the minute hand to turn and was dingy. Stripped it down and had a bent 3rd wheel and it looked like someone tried to make an overcoil out of a flat hairspring. Has an AS 1660 with only 7 jewels so did not want to have to put any money into it. I did have a new acrylic and watch strap that fit beautifully and the dial cleaned up a bit with just IPA and water, carefully and gently of course.4 points

-

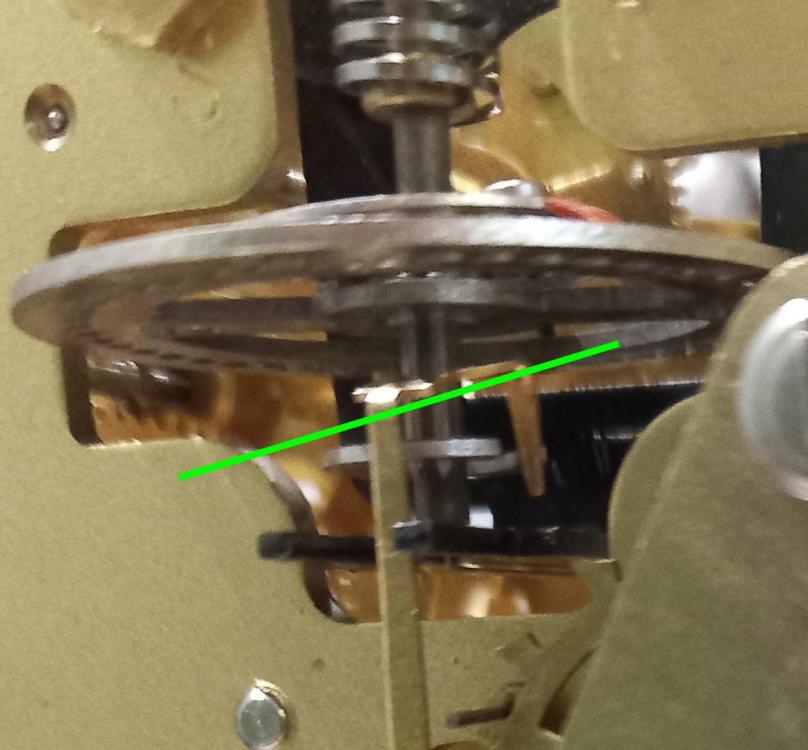

What You describe - that the second hand jumps when setting hands backwards is normal for this layout of train with double third wheel. Happens when the real cannon pinion(which is on the offcenter 2nd wheel) is tight. Pay attention exactly on this cannon pinion - probably somehow it has moved up on the wheel pivot and thus killing the axial free play of the wheel and rubbing on the bearing in the main plate2 points

-

Hi Rixy, See, the balance is on a separate platform, but the lever is not on it, it is on the movement together wit the escape wheel. The special thing here is that there are banking pins, and they are on the balance platform. The problem You describe is because the banking pins are shifted (together with the entire balance platform) from their correct position that will allow normal work of the lever. Now it is clear seen that when the lever top is moved right and has rested on the banking pin, the downside pin is still on the impulse surface. This means that the entire balance platform must move a little right, just enough to allow the pin to leave the impulse plain. So You must untighten the nuts that fix the balance platform, find the platform correct position that gives normal lever action (this is when 'run to the banking' is equal in both sides) and then tighten the nuts.2 points

-

2 points

-

This is an American watch, so the "normal" position of the stem in the keyless is the "out" position where the spring is pushing it outward. The case must hold the stem inward to keep it in winding mode when it would otherwise want to pop out to setting mode. The stem is not split. It will be held in probably by a threaded case sleeve, and the case sleeve is responsible for adjusting the depth of the stem into the movement. If it is adjusted out too far, the stem will never engage deep enough to put the watch in winding mode. If it is in too far, it will never leave winding mode. Don't try to pull the stem out as it is, you will probably break the sleeve. A sleeve looks like this, though with variations in the number of slots in the big end. It holds the stem, allowing it to slide over its detent. With the crown unscrewed and removed, look into the top of the pendant tube. You should see threads and also 4 or perhaps 2 slots or divots. Those are meant to engage with a "sleeve wrench" which is used to turn the case sleeve in and out. It's a tool that looks like this, with many different sized and styles of tips: Probably you just need to turn in the case sleeve 1 or 1.5 turns and it will engage the movement's winding correctly. Here's a video of JD Richard adjusting one.https://www.youtube.com/watch?v=ugiH0FvERqc2 points

-

2 points

-

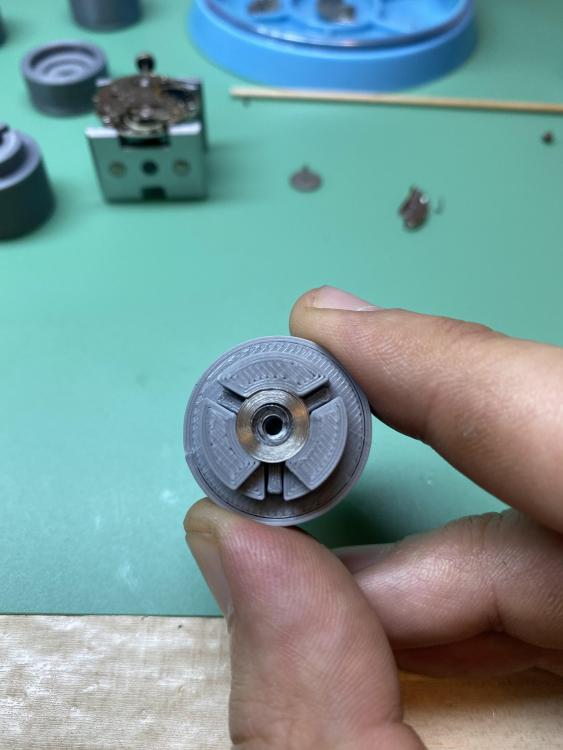

Hi guys, I have started a project in Github to generate all the possible types of mainspring winder sizes from a single base design using a Python script. https://github.com/vishnu350/rs-mainspring-winder The STL files can be downloaded from the release section: https://github.com/vishnu350/rs-mainspring-winder/releases This project is a 3D printable "Rising Sun" watch mainspring winder for hobbyists. Mainspring winding for hobbyists has always been a problem, as most of us cannot afford the $1000 Bergeon set. Or sometimes, the appropriate size just isn't available. This forces most casual hobbyists to resort to handwinding or other similar stunts, which is not ideal. This mainspring winder is designed using FreeCAD to be easily 3D printed with no post-processing/finishing required. It will approximately cost $5/set by most 3D print service providers (use eBay to find someone near you). The design is parameterized, allowing you to dynamically change the size/dimensions of the winder and the entire design will be recalculated accordingly. The RS mainspring winder is a pleasure to use when constructed correctly, and can wind in both clockwise and counter-clockwise directions. I have uploaded a video describing the 3D printed RS winder parts and how to use it. Will appreciate any help or feedback as to further improve the design, as I actually do not own a 3D printer (I pay for each print). I also do not know the complete range of sizes that is required to be uploaded into the release section. Also, the optimal design parameters may still not be perfect, but it seems to work pretty well for me at the moment. Thanks.1 point

-

Since the impulse pin is way off it may be easier to remove the balance spring, then replace it approximately in the correct position and fine-adjust using the stud arm. Use hand levers under the collet to remove the balance spring. Use a rocking motion. I'm sure there is a video showing how it's done. Use a staking set to reinstall the collet. Do not use a hammer on the punch. Just gently press the collet down on the balance staff. After removing the balance spring, replace the balance wheel on the movement with the impulse pin centre between the banking pins. Now mark the balance wheel's rim right under the stud holder. Then replace the balance spring and fine-adjust using the stud holder arm. BTW, I don't think you can replace just the balance spring. It has something to do with the spring having to be vibrated with the balance wheel. Anyway, I know way too little about it to go into any details.1 point

-

Thanks Frank. I I would like to live a little longer, if possible, so your advice will be followed to the letter!1 point

-

I hate coming late discussions like this where a lot of confusion this is a standard American pocket watch case. American pocket watches came into existence before the modern split stem. Or basically the modern stem altogether. In fact they came into existence there are no stems at all. If you look The message of @mbwatch He shows the components or the main component of what's holding the stem in which is the sleeve. Sleeves can be a real pain in the ass if there's a problem here as the really hard to find and yes there are lots and lots of different shapes and sizes. Ideally we need to determine whether the problem is with the sleeve or the watch. So for instance if you push in on the crown and rotate does the watch wind at all? Plus when the watch was incoming was their winding and setting problem in the first place? The stem is held in the case with the sleeve which is pictured up above. We do need to figure out whether the problem is a sleeve problem or a watch problem this is where it be nice if you had your bench keys. Sometimes if you're lucky they can be purchased on eBay otherwise you'll have to make something but you really need to have these to figure out what's going on with your winding and setting1 point

-

1 point

-

Thank you both for your replies. After some adjustment I finally have managed to get it running. Every problem is a learning opportunity. Cheers!1 point

-

1 point

-

Yes 4 pivots to fit plus the barrel! That last one and the jump hour were 2 of the 6 watches i picked up at a local monthly vintage fair for $30. Next one up in the bench is the lower right. A Gruen Precision with an auto 460 with a bumper rotor. The dial is too far gone. I replaced the acrylic, but ordered a new one with a tension ring as was in here. Also added a SS crown. A lille large on this 32.6mm case, but gives it a kind of a field watch vibe. SS case with drilled lugs. The sides are brushed vertical instead of horizontal. I still need to strip and service, but this Veri-thin movement has an incabloc shock system and a Breguet hairspring. Looks okay on the dark brown nato, but probably better on a tan/Khaki with SS rings. Last 2 pics after a US bath of the case and caseback. Edit: Oh and it is currently running!1 point

-

I had not conteplated that but seems to be a valid conclusion. I will have to check it out! This also has no yoke clutch in the keyless. Yes just IPA on a foam swab gently then distilled water to remove anything loosen up but not aggressive or on the printing.1 point

-

That and the faux bridges. It's 3/4 plate, but doesn't look like it until you really look close. That removable barrel would simplify things a bit during reassembly. That dial side winding setup came up this morning as well in the Venus 170 Thoughts thread. Very interesting movement!1 point

-

Hi Razz, good show, specially like how well dial has cleaned up, will you elaborate on details, I guess ISP/ DRY first ! then wash away the residue with water. TIA Oh, beeauty full dial.1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

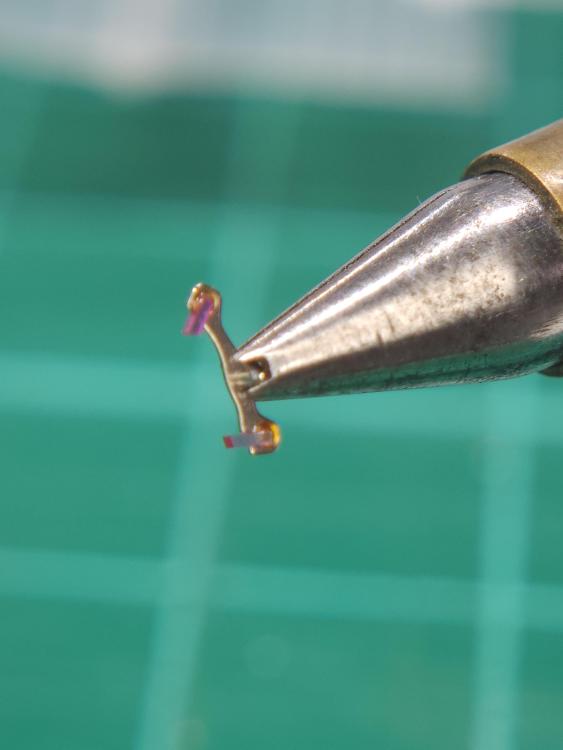

Cool! I was actually quite impressed that you know what tissue forceps look like. It's not common knowledge. We use them for wisdom teeth surgery when we need to pull the gums back together to suture up the wound. Not most people's favorite surgical instrument. I actually knew what @Neverenoughwatches mystery tool was because I came across a photo of it when I was researching a strange tool that I got in my set of balance screw holders. It looked a lot like a balance screw holder but it had a strange channel cut in it and two notches in the jaws. I think it's a pallet fork holder because my mentor has a Bergeon pallet fork holder of a similar design. I could be totally wrong but that's what I've been using it for.1 point

-

1 point

-

https://www.scienceservices.eu/dumont-tweezers-style-25b-h-p-grade-inox-02-inventory-sale.html Have a look at the above link. Does that look familiar.1 point

-

Don‘t connect wires blindly and don‘t rely on colors! Check first if the wiring matches the schematic! Frank1 point

-

You need to rotate the hairspring. You can usually do it by pushing something sharp in to the gap in the collet, and rotating it. See here for how to get it the correct position (you don't need to be exact as you have an adjustable stud holder)1 point

-

Thanks for the info - I've already caused mine a mischief, in that the stem now pulls right the way out of the case. Think there's something threaded...1 point

-

On mine, the dial does appear authentic and the lume under the scope is old and degraded but not curently radioactive (based on an inexpensive but functional Geiger-type detector) which would rule out radium. So, it's likely relatively short-lived tritium lume which matches with the rest of the watch that dates to the 70's. So yes, radioactive at one time but mostly decayed by now and not at all the kind of exposure you could get from working on a radium-lumed watch if that is a concern. You need a different type of detector to actually measure tritium, but enough half-lives have gone by that you can assume a low risk just with math, and it doesn't produce deeply-penetrating rays or particles in any case. If I read the dial correctly, yours is a "Keepsake" version which is also a later-years model so I think it would be very unlikely to be radium, but I'm not a West End expert.1 point

-

Nice, yours looks a bit happier than mine. Any idea if these are radioactive lume? Edit: after a bit of reading, pretty sure it is. Movement pic and probably away in a drawer or sold then... Pretty pleased with the strap though... And (while I imagine there are loads of them) I've never seen an acrylic like this before...1 point

-

See if this helps. https://www.watchrepairtalk.com/forum/5-watch-repair-tutorials-information/1 point

-

1 point

-

Aannd we have a winner, good gyime good gyime, Isla can you take Richard to the conveyor belt please, dont forget the cuddly toy now. Aye sir it is indeed. I took a risk as it looked a bit pants on the sellers photo and i thought it might be cheap chinese but there were other items that boosted the sale. It is made by the Farco tool company so it is actually cheap Italian . Chill amici joke. The quality isn't bad at all .1 point

-

1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)