Leaderboard

Popular Content

Showing content with the highest reputation on 10/08/24 in all areas

-

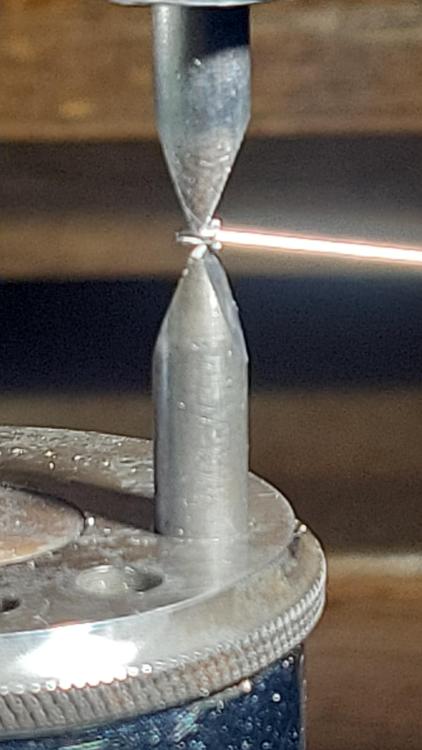

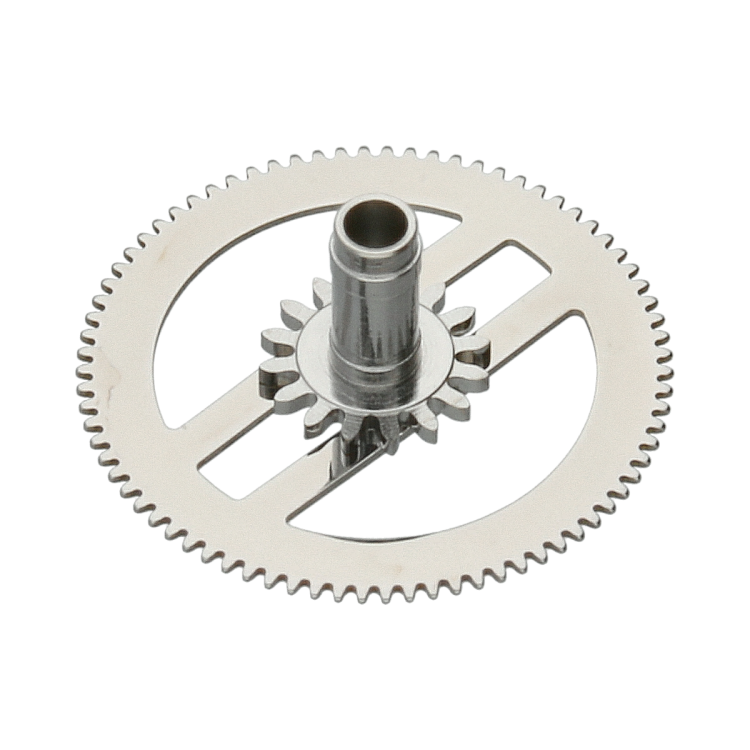

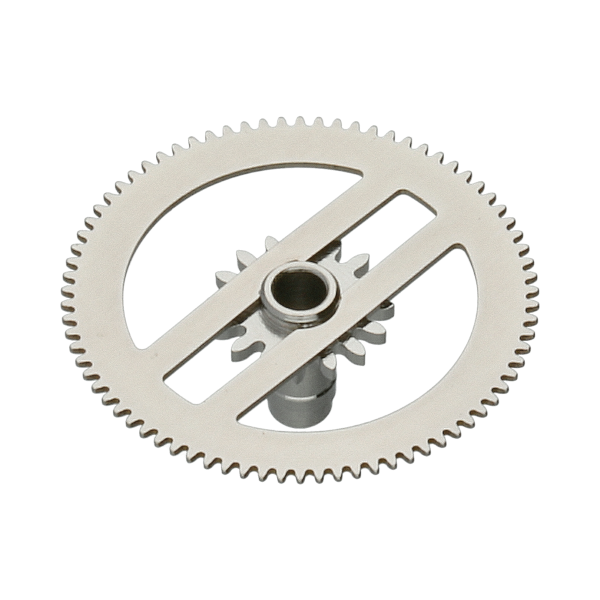

Okay, the problem was the center cannon being too loose on the wheel. I didn't have a cannon tightener, so I ground two broken stakes on my little belt sander, then stoned them. I didn't have a rod that fit inside perfectly, so I had to just be extra gentle with my tapping. After a couple taps, it popped right on with a good amount of friction. That's as much stress as I have in me tonight, so it's red wine time until I find another free hour.4 points

-

One of the things I've discovered is that restoring old watchmaker's tools is almost as satisfying as restoring a vintage watch. Using the restored tool to restore a watch is like winning the lottery the day after they repeal capital gains taxes. The Mrs. has progressed from saying "what, ANOTHER watch video?" to rolling her eyes when the packages show up with "what did you order now?". I fully expect any day now for her to say "what can't you just watch porn like the other husbands?" Welcome to the obsession.3 points

-

2 points

-

oh you're going to need something to go with fewer tool which is when you're moving the pallet stones you need to heat up the shellac which means the entire tool has to go on a small heater.2 points

-

2 points

-

I am getting quickly to the belief that watch fiddling is only a cover for our tool addiction Tom2 points

-

2 points

-

This kind of cannon pinions are quite common and can be a pain sometimes when it pops off when levering off the hands. I usually put a small drop of hp1300 in the groove.2 points

-

Nicely done msb, accurate grinding of your stakes Did you also broach it out to size with a mini lightsaber at the same time ? It takes a lot to impress me , but you achieved it matey.......Very Cool indeed2 points

-

2 points

-

I looked at a drawing I made for an old Patek fork, and measured 325 or so rebanking. Newer stuff might hit a bit higher due to less ornate fork horns, but not a lot. Once you're over 300 for me that's a bit risky. Especially with an automatic watch.2 points

-

What spring did you fit? Do you know the GR number or the dimensions of the spring? Did you use breaking grease on the barrel wall? Was just the mainspring replaced or a full service done on the movement? I have found that if the amplitude is low, the timegrapher can double it up, or if it doesn't hear the first impulse and makes stuff up. If it does have a low amplitude, you should be able to see it pretty clearly, or put a mark with pen on the balance and you'll know if it really is that high an amplitude, which it isn't. No watch movement would show 348 degrees and not be knocking (rebanking). In fact, no watch movement could spin 348 degrees, as it is impossible. I've just serviced a Rolex 1200 from 1950's and used a mainspring a strength too much, which was 0.11 mm thickness instead of 0.1 mm and it started to knock at 332 degrees. With the correct spring the movement now achieves 285 degrees. I find that if the amplitude goes beyond 330, it will knock.2 points

-

this is one of the reasons Rolex watch repair is so expensive as typically refinishing the case is included in the repair.. then if you really obsessed with case refinishing often times typically the band and sometimes the case will have satin finish with shiny finish. but yes looking at your picture refinishing or polishing the case makes it look better and that's all the customer typically sees anyway all the work that you did inside they're not going to see other than as long as the watch keeps time. So making the outside looks nice makes the customer happy. I think you would have noticed by now if you had needed to regulate. As the timing machine in the shop sits behind me I get to see all sorts of bizarre things like Rolex watches that people of played with. typically a Rolex watch will keep phenomenal time but often times people without timing machines or possibly functional brains. We'll play with the regulating weights and you end up with like horrible positional errors which is very noticeable of course the timing machine. or briefly when we were short a watchmaker we set work out and one day when the persons bringing the watches back I did ask whether he had a timing machine. Yes he assured me that he had a timing machine but based on what we were seeing he never looked at the timing and more than one position. Plus I asked about the lubrication a pallet fork pivots and somebody told him that was a good thing to do. Fortunately we got a better watchmaker in-house and this person went away. Because that meant the owner would spend a lot of time regulating the Rolex watch to the way it's supposed to be regulated which kinda canceled out the effect of sending a watch out to be serviced if it didn't keep time when I came back depending upon the size of the watches you work on the movement holder is below are very nice to use. what makes the holders interesting is one side is for holding one side of the movement and the other side has a slightly different sized to hold the dial side. Typically on Swiss watches the dial side will have a lip that's a slightly different diameter than the movement size. In other words these were designed for specific size watches. Then as nice as they are cousins does not have a nice price at all. I thought they were expensive many years ago where I purchased mine but not as expensive as this. Maybe the Chinese have cloned them now. But still if you're working on similar size watches I found they were really nice. https://www.cousinsuk.com/product/by-size-bergeon-5914?code=M431052 points

-

Yes, it is a detecting issue. Cause: the machine misses the 1st (too) small impulse of the tic noise. It uses the next pulse in the noise as start. Because amplitude is calculated from the time interval 1st to last pulse of the noise, this is too short and so amplitude too high (as explained several times before ) Frank2 points

-

Those movements should run like chronometer beasts; the wavy funky line isn't very chronometer-y. In some cases the machine will pick up a bad/dirty signal and double the amplitude. This is how you can end up with 350+ and it not be rebanking. I would be curious to see how it does if you clean the fork, balance, and balance jewels, oil it carefully, and recheck. 348 degrees shouldn't be possible, there just isn't room for the impulse jewel to swing that far without bumping the fork horns.2 points

-

Hi guys, I have started a project in Github to generate all the possible types of mainspring winder sizes from a single base design using a Python script. https://github.com/vishnu350/rs-mainspring-winder The STL files can be downloaded from the release section: https://github.com/vishnu350/rs-mainspring-winder/releases This project is a 3D printable "Rising Sun" watch mainspring winder for hobbyists. Mainspring winding for hobbyists has always been a problem, as most of us cannot afford the $1000 Bergeon set. Or sometimes, the appropriate size just isn't available. This forces most casual hobbyists to resort to handwinding or other similar stunts, which is not ideal. This mainspring winder is designed using FreeCAD to be easily 3D printed with no post-processing/finishing required. It will approximately cost $5/set by most 3D print service providers (use eBay to find someone near you). The design is parameterized, allowing you to dynamically change the size/dimensions of the winder and the entire design will be recalculated accordingly. The RS mainspring winder is a pleasure to use when constructed correctly, and can wind in both clockwise and counter-clockwise directions. I have uploaded a video describing the 3D printed RS winder parts and how to use it. Will appreciate any help or feedback as to further improve the design, as I actually do not own a 3D printer (I pay for each print). I also do not know the complete range of sizes that is required to be uploaded into the release section. Also, the optimal design parameters may still not be perfect, but it seems to work pretty well for me at the moment. Thanks.1 point

-

1 point

-

This popped up in my FB feed this morning. An auction of stuff from a clock centre in South Australia. Knowing how hard it it to find stuff in Oz I thought I should put it up here. https://bid.adeyauctions.com/?fbclid=IwZXh0bgNhZW0CMTEAAR3tABfnRCdRvM5eTgDi2_qGkaLhHZn952RTOU7mJhsfg7dbzQ7k3KS5-tw_aem_mVgnAG0UY-nTfX4bE3DN6w no affiliation or any connection to this Tom1 point

-

1 point

-

Aw JerseyMo.....that looks like a lifetime of work and dedication. You're so passionate about Timex and this hobby....how'd you feel about your decision?1 point

-

1 point

-

I'm looking forward to receiving it and mess about with it some. Getting a bunch of tools in the mail always feels like chrismas.. I'll try posting some pictures and a walk-through when i figure it out.1 point

-

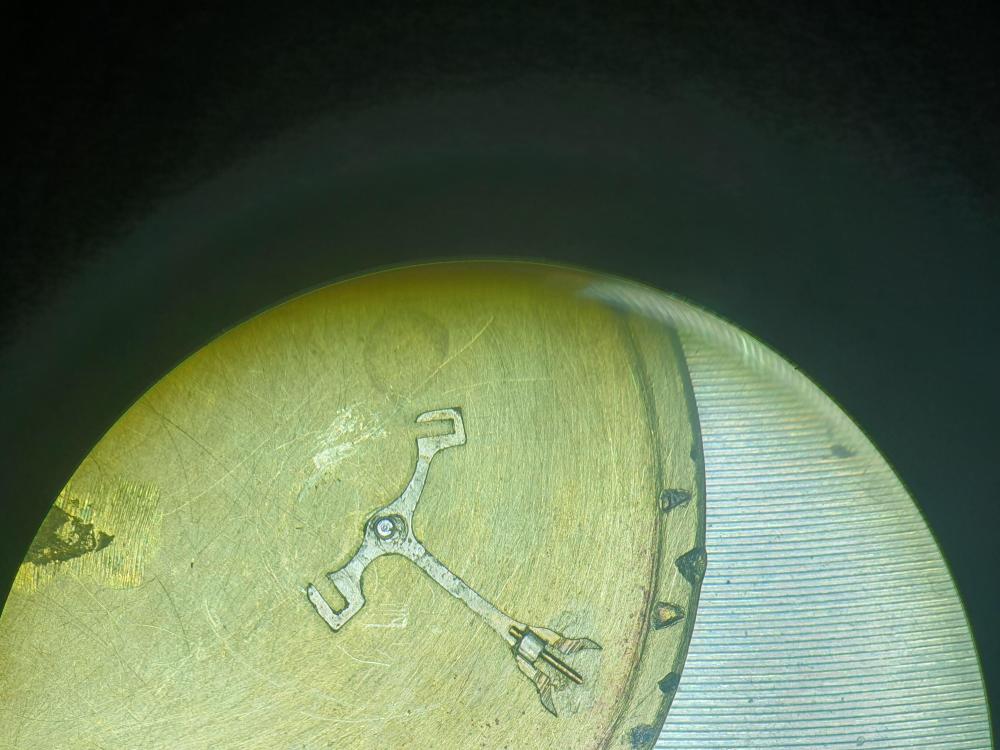

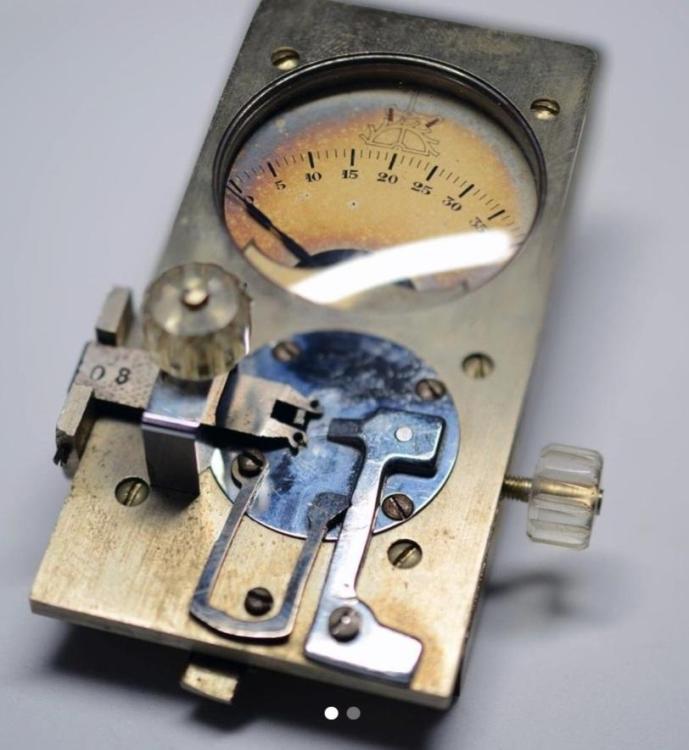

What a gadget ! Checks and adjusts pallet stones. Makes that process of setting up the escapement easier and accuate more quickly than is possible without it. Depends what it cost.1 point

-

If you could post the width of the tension ring this may be of benefit to someone in the future.1 point

-

It looks to be quite effective at scamming people, from the 4.3 stars feedback! It cannot do anything useful beyond that though. Mobile phones just do not have any receivers capable of tuning through the full radio / magnetic spectrum for any real EMF sensing, and definitely zero capability for ionising radiation detection!1 point

-

I got to be very tired to miss the opportunity for making sarky comment Aren't we all sunshine.....aren't we all1 point

-

It matches the two brain cells I have to rub together, apparently I'm a little dense these days.1 point

-

I wondered what the light sabre comment was until i looked at the photo again. Hehe.1 point

-

Well you must have two then, i can see one poking the cp in your photo1 point

-

1 point

-

timing specifications for watches is always interesting. Like for instance maximum amplitude for this watch fully wound up in the dial up position is maximum 315°. With the definition of fully wound up after 1 to 3 hours of winding it fully up. which is interesting because this is a much longer time that I typically see a lot of times it be 15 minutes minimum. then the classic of after 24 hours vertical 6 o'clock up no less than 210°. I would be really curious what this watch is doing at 24 hours. then for the rest the timing specifications which your watch is not meeting at all like the beat you're supposed to have a maximum of 0.6 ms. Then for timekeeping often times the express it an interesting fashions such as +5 with a variation of -5+5. this would basically translate that the watch should keep time between zero and 10 seconds worst-case never be running slow like your watches. then nice for troubleshooting as you have a microphone that rotates and thinking about that how are you holding the watch in the microphone? Some people like to hold their movement holder in the microphone and that's not a good idea. As you need a good signal and the watch itself ideally should be in the holder. Then a timing procedure like in this watch wind it up wait an hour minimum and give us a picture of dial up, dial down and crown down would be nice. I've never really paid attention as to whether it's actually a double amplitude. Typically what I've seen is with super low amplitudes the waveform gets stretched out and the timing machine will trigger off something in the middle confusing that with the locking signal. Then you end up with a nice happy amplitude but I don't think I've ever seen an amplitude as high as this one? this of course is why you should always visually look at your watch and see if the visual confirms what the timing machines trying to tell you. typically I don't see this but most the timing machines that I have either have automatic gain control or limited choices. for which this timing machine does have a gain adjustment I wonder if it's set correctly? this is where we also run into the unfortunate that we don't have in our oscilloscope as you have a better idea of what's going on with the signal. then the breaking grease was something I was curious about because of that's not slipping the way it's supposed to you can definitely have too much power. but? But still let brings up questions? then I guess I get to make wild assumptions like you service this watch and this is what it's doing? There's a lot of unknown things in this discussion and things that are quite right for instance as the watch been demagnetized? Plus what was a condition like before you service it? Or for that matter why did you service its a lot of times pre-existing conditions could be an influence. Then?1 point

-

1 point

-

Ok, hope the following helps seeing a bigger picture. Vegetables, fruits grown in Hiroshima or Nakasaki contain more radioactive nucli than European produce. as the soil in Hiroshima contains more radioactive nuclei. Beware, don't eat your watch. Glue a Geiger to your stomach instead. lol1 point

-

Well, I did manage to pull the canon pinon off of the wheel, before realizing that they were pressed together. I was able to press the wheel back on with my staking set. I do think that a grease would be appropriate. I have Moebius 9504.1 point

-

It's metal sliding on metal, so I'd also use a grease. I'm not familiar with many Moebius products, but the ones in the know seem to prefer 9504 to 9501. If you have it already, use that.1 point

-

Suggest reading this thread from the begining. TOO MASSIVE TO PENTERATE HUMAN SKIN. Shall I return couple of my college degrees in nuclear science? Rgds NUCE JOE1 point

-

1 point

-

Ok, I get it now. I've always wondered why Bergeon didn't standardize the tip of their winding arbors so that even biggest arbor can fit into the smallest barrel.1 point

-

1 point

-

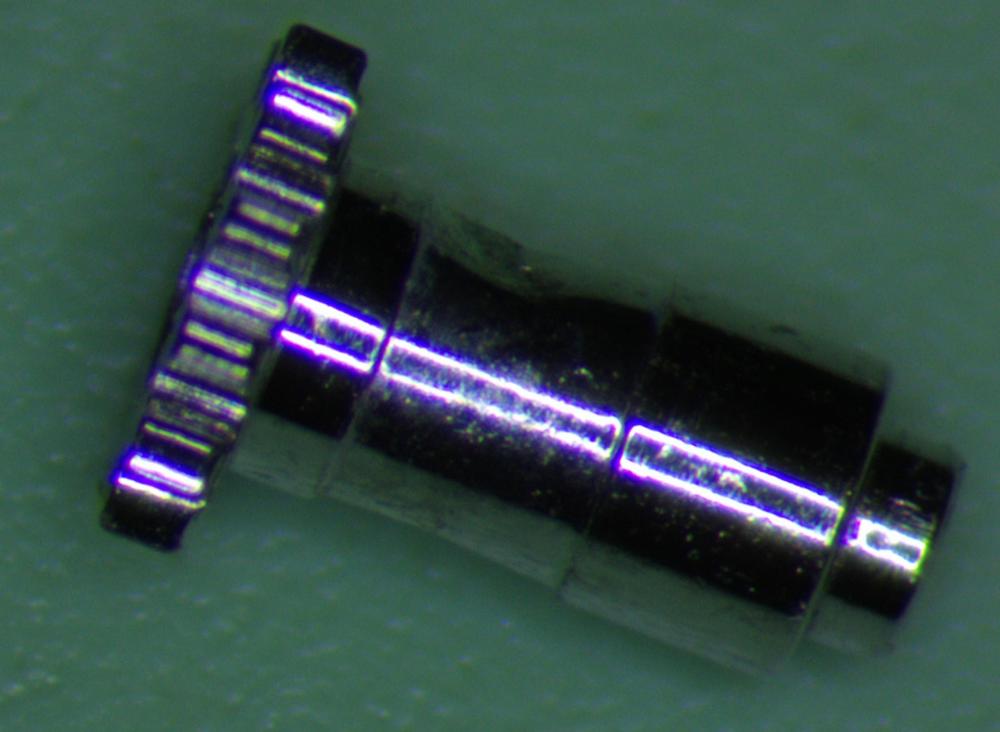

There's a scene in MIB about little Tiffany about to start stuff. That's men with brass tubes in a drawer. In case anyone is curious, I managed to break my winding barrel. I thought others would like to see just how it's constructed. The moving parts are apparently made in two pieces. It seems I managed to separate the table from the plunger. The tube that's left in the table is only 0.5mm wide. Hopefully a little filing and Locktite is all it needs.1 point

-

Though- rarely does a watch sit perfectly horizontally for a period of time, motionless*. I've done pieces for companies that accepted 7h after full wind for no rebanking. *With the exception of one placed face down at bedtime, and in the case of an auto possibly at full wind.1 point

-

Not hailing from east of the Pennines, (and without the required skills in any event) I've gone large and splashed out the £3.95 for a lever and screw as suggested by AndyGSi. I only found out yesterday, whilst feeding my nightly dose of insomnia with a Chronoglide video [correction it was a Vintage Watch Services video], that Oris were restricted to pin pallet movements by some obscure Swiss regulation. This restriction was removed just in time for them to stumble into the quartz crisis; how's your luck! The result of this was Oris made an art out of making these movements. I personally think Oris are underrated as a brand, just my opinion. Video link below-1 point

-

I'm almost certain it was @JohnR725, because he helped me with a similar trace. In my case it was magnetism. Has the movement been demagnetized?1 point

-

So finally, mission accomplished! Preliminarily everything looks very good and I am particularly pleased with the repair of the rotor. It was undeniably a bit nerve-wracking to rivet the axle to the rotor but it now seems to work as well as when the watch was new. Who would have thought that you could repair a Rolex by hitting it really hard with a hammer? Although the owner did not ask me to do so, I polished the case and the bracelet. I was cautious with the case so as not to jeopardise its shape. All I did was polish with Polinoxx polishing compound on a Felpato mop to bring back the lustre. The bracelet I fully polished and brushed as it was very scratched and dull and lost most of its lustre. I got the impression that Rolex stainless steel is extremely hard compared to other watches I polished. It now remains to test the watch properly for a few days. It is currently spinning on my cyclomat. Preliminarily, the precision seems to be according to specification. I have adjusted the beat error but lack the Rolex special tool to adjust the rate. We will see if it is needed. In many ways, servicing and repairing my first Rolex has been educational and a lot of fun, if a little nerve-wracking at times, and all the help I've received in this thread has been invaluable. So once again a big warm thank you!1 point

-

usually this question comes up with vintage pocket watches but the answer is still the same. Lift angle is only important if you have a newfangled timing machine to measure amplitude. So when watches were made without those newfangled timing machines there was typically no reason to list a lift angle. Then have you ever noticed how the timing machine defaults to 52°? It should be just fine. It's only when visually whatever you're seeing with the balance wheel does not agree with the timing machine if you're concerned then you can figure it out. It's actually very very easy to do you don't even need a smart phone or anything. There's even a video that explains you just need to put a Mark on the balance wheel that you can see. Then you slowly wind the watch up to 180° and set the timing machine to agree with whatever you're seeing. Personally I like to put something that fluoresces under a UV light as I find that a lot easier to see than a dark Mark on the balance wheel then the other weird mystery of lack of parts list sort of? I have a link below which does list all the parts and gives you cross references for those parts. If you had access to a US material house and were friendly with one of them you could ask about the bestfit part number as they typically don't list those online you would have to ask. but even without that it's still nice as it gives you cross reference of parts. Then cousins was unhelpful as we do get PDFs but no parts list or pictures of parts. Then don't even think about a service manual more than likely it never existed in the first place but there must of the parts list if the parts are available or were listed at the link below. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=CORT_677 2567_Cortebert 429,451,571,575.pdf1 point

-

How i clean and dry watch parts... cheapy cheap diy fashion, spinning inside a US. Speed controlled CW + CCW... DC motor and mini US machine, a lab stand, some bean tins, a modded make up lid,a bit of door panel plastic and a few nuts and bolts, the wing nut acts as a small impeller...it will when i bend the wings over. How rather very simple of me1 point

-

Forget all this fandangled stuff, cleaning watch parts is just like cleaning your clothes. Spin them backwards and forwards in good cleaning solutions with some added agitation if required, spin off the excess fluid and hang em out to dry........ah the random shite that us penny-pinchers do to get by .1 point

-

1 point

-

What I find the 3D housing, plunger and setting bowl really useful for is changing the spring orientation. I have a set of Bergeon right hand winders but don't want to pay almost £40 a pop per left hand arbor. I've tried reversing springs by using an empty mainspring ring but 9 times out of 10 I end up with a jack in the box and lots of swearing The 9.5, 10 and 11mm 3D housings fit my number 6 and 7 winders and make changing the spring direction a doddle and for strange barrel sizes you can always scale the print. Not had a 3D printer for long but it's a fantastic tool, especially if you put the effort into learning a CAD program and designing your own parts.1 point

-

The problem is the average Joe nice watch buyer probably has no idea what is coming. Good information thank you nickelsilver. I can see why you might have a need to be worried. Striving towards being able to make any watchpart must be on the minds of many pros to be able to survive. There must be others just waiting to step into the big boys shoes and I'm not saying its that simple, very far from it. But some hope maybe ?1 point