Leaderboard

Popular Content

Showing content with the highest reputation on 10/10/24 in all areas

-

Thanks for the suggestion! It was helpful in pinpointing the problem. It appears I had installed the gear under the intermediate date change spring upside down. Flipping it over solved the issue.4 points

-

4 points

-

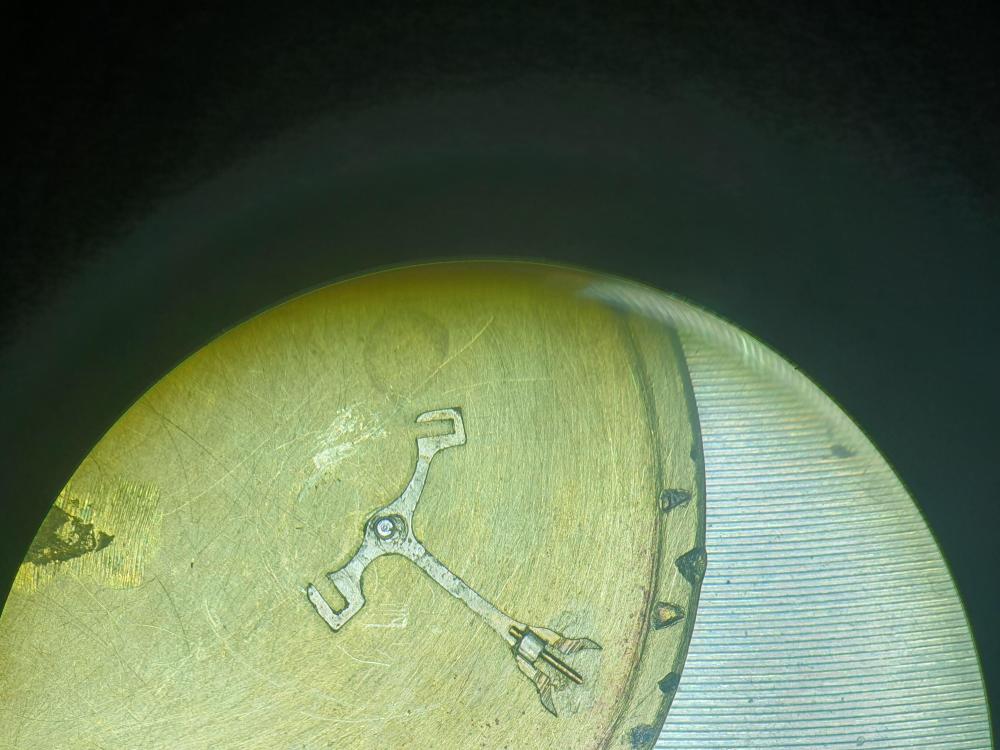

That little spindle tool in your second photo looks to be the tool used to grab punches out of the box. They are surprisingly difficult to grasp with fingers because they are so small, smooth, and close together, so you poke that tool like a sleeve over your selected punch and pull it up.3 points

-

I do too...we are all different and we have no idea why that person behaves the way they do. I had a shitty upbringing and my dad was a drunken bully a lot of the time ( major issues god rest his soul, i know he had some good in him ). I wont let that taint my behaviour towards folk and i try to get on with everybody because life is too short, i act the fool, mostly because i like to see folk laugh but i have a very serious mature side when it's required and i absolutely detest bullies and drunks , i give folk the benefit of the doubt but only for so long, i can be real sod when someone rubs me up the wrong way. I remember some of the comments that " he who shall not be named " would make to beginners.....my tolerance ceiling used to instantly drop3 points

-

Who likes rust ? I hate it, been busy with an old rusty green tinged movement pass couple of days, mostly using vinegar and WD for a quick dip deactivating delaminating solution. It quickly gets to work lifting the light surface rust into the solution...but leaving the parts in vinegar for too long to deter the deeper stuff can have a detrimental effect on the steel, i try to stick to half an hour at most. This then leaves mechanical options available, pegwood even tougher bamboo can struggle to touch deeper rust and bits of timber end up stuck in bearing holes that then need poking out. fibre glass pens work well at rubbing off rust but they scratch brass and steel and the fibres go everywhere, plastic chisel edged probes are ok but still pieces break off. Sharpened knife blades and needles....still need to careful as they scratch will scratch so i thought i would try some softer metal, titanium , bronze, brass and copper. Heres a few scrapers i made. The copper is from a sheet copper canopy roof i replaced.. thats probably the softest, then brass from a big ol barrel lid, then bronze...this is cut from an old pre 1990s UK penny, technically its a mild bronze as apparently copper uk couns were 97% copper but a spec. list i found labeled them as bronze...then last is Titanium cut from the handle of my tweezers. The hardness order i have mostly guessed so if anyone want to correct that....feel free to.2 points

-

That would be very interesting and much appreciated! Amen! Happy daddy => Happy wife => Happy kids => Happy society => Happy world => Happy future! Congrats!2 points

-

Good to know, but actually not important unless You really know how exactly hundreds the pallet has to be moved. Well, I made my first attempts in escapement adjustments when I was 13-14 years old. There was nobody then to tell me how to do it, so I did it the way I figured. This way proved good for me, and I still use it. For sure it doesn't need special tools and equipment and all happens pretty fast. Sometimes people don't believe me, but actually I don't have microscope, timegrapher, Horia tool, Platax or whatever of that sort. This is not because I am poor, actually I am not. I just don't need such things. When I learned, it was not possible to get to such things so i learned to do without... I have several lathes with different milling attachments, plenty of different files, plenty of simple tools like tweezers and screwdrivers. About 5 years ago I even got staking set...2 points

-

Not difficult to verify: I did it, units are 1/100 mm . My compassion for the next repairer!2 points

-

The things in the bag are countersinks, for cutting radiused sinks in holes. Looks like you have a couple of 8mm collets there next to it too. The table with clamps is a little faceplate, you would center a part in it with a point in the spindle, then clamp it in place to work on it. The collet that's in the spindle should be a 2.2mm; they used this odd diameter for the reamers for some reason. These are great tools, nicer than Seitz, and only equalled by Chatons SA (their later sets were amazing).2 points

-

Are you actually winding the watch? That sound very much like giving it just a tiny amount of wind, rather than fully winding it??2 points

-

Yes, it was really painful to watch. I clean old shellac off ethanol. Comes off in seconds. I don't use shellac anymore. Once I confirm that I'm getting good amplitude, I just put a couple of drops of UV glue and zap it. It will never come off again.... unless you wash it in acetone. If you really want to measure the distance of the face of the pallet to the back of the fork, a digital microscope could be used, with less chance of damaging or accidentally changing the distance if the jewel was already loose. The measurements mean nothing. Ultimate test is the amplitude.2 points

-

Oh Lordy, again? Just sitting here questioning my decision to volunteer as a moderator, just had a shiver down my spine of realising you are approaching retirement Rich!!! enjoy ️ Tom2 points

-

I watched the video (diagonally). Oh, what a sorrow! Why a man will make video about using a tool when He has never used this tool before? Hi put the pallet backwards in the first attempt, this shows He has no idea what He is doing. My respect, He didn't loose or lounge the pallet, thou He hunted for it with the tweezers for several minutes... Well, this tool doesn't measure anything and doesn't help to adjust the escapement, all it does is to show how exactly You have moved the pallet, but in some kind of unknown length units, thus helping to be sure the pallet has actually moved in needed direction and gives relative idea for the movement length. I made simple video to show how I put the pallet in place and correct it's position. You can see that I do it with bare hands and one brass tweezers. The tweezers need to be rigid - I use these for straightening pivots. You can see the oscillating movement I do with the tweezers when moving the pallet out or in. It helps to move the pallet gradually and in small steps. Of course, You have to put the pallet fork in the movement and try it in every step When the pallet has to be moved out (to the wheel), it is not needed to remove the shellac. It's presence actually helps, as You can observe the gap that appears behind the pallet end and thus know how much has the pallet moved. And, pressing it in with the tweezers as I do in the video resets it in the position before the start. When adjustment is done and all the checks show it is correct, then only heating the pallet fork is needed to soften the shellac, if enough of it is sill there.2 points

-

Billy it could be one of many faults. It probably needs a service.2 points

-

Hi Billie we need a bit more information with this such as which watch is it, is it valuable...either monetary or sentimentality...and some photos of the watch, from outside and inside. Also about yourself....your capability to repair watches. An introduction would be helpful Billie..for us to know what you are about.2 points

-

2 points

-

Same reason as any watch part Rich, sweat salt on your fingers. Finger cots And potential short circuit, salts conduct electricity2 points

-

...a Lemania WWW cal 27A. Even compared to the other DDs this is a simple movement but unsurprising this one has the requisite broken detent... ...the other DDs often have simpler finishes on parts and I'm wondering if this broken piece could be a replacement bridge from a civilian variant of the calibre 27A. Shouldn't it match the finish on the other parts in the keyless works? I suspect finding just the specific military version part is a long shot. After Borel leading me a bit astray on compatibles I think I've found NOS available (if anyone is ever in the same position, skip looking at the Lemania and focus on the Tissot and Omega versions of this movement)... ...as authenticity is a concern I'm wondering if anyone has an image displaying the genuine WWW piece? Christian the Watchguy is usually my go to for great photos of these and he does have a fuzzy photo but it is of the underside of the bridge. I'm wondering if the straight graining should be there or if it is supposed to be unfinished?1 point

-

What does the description say, i honestly think the guy might be lifting your leg. Let me dig out mine and show you. Yes the staking set may be for a combo tool but the frame with it is wrong, this is mine and it has a spindle that takes the stakes. Ask about the spindle . Ask the seller to show you the sprindle in the frame and a stake in the receiving spindle, then theres the difference of the rotating anvil with reduced holes for replacing staffs. The main thing you need here would be the spindle, its the end that you need to see. The sellers looks a bit like this which i use for holding drills. You might be ok, but just be sure whats you have coming.1 point

-

I’ve had the same comment too! I’m just now of an age where tools and titties share equal interest!1 point

-

Sorry to inform you but I'm pretty sure this staking set youve just bought cant be used with your jewelling tool. 2 completely different tools. Your jewel press has no staking anvil. I would think quickly about cancelling your second purchase unless someone knows differently. There are staking/ jewelling combos , i have one but its nothing like what you have with your press.1 point

-

We can all add our little bit to that simple solution H, so sad the whole world doesn't implement it. I would much sooner make what i want than buy it.... and do to some extent....you get something to your own specifications. Just something ive learnt from bespoke construction.1 point

-

I think about that person sometimes and honestly hope he's doing well. No hard feelings. We're all different and sometimes there is a connect and sometimes a disconnect. That's just how life is.1 point

-

I actually have 4 jewelling sets and an extra tool making 5 in total and i still want yours , i don't have a Favourite . Been searching for a complete Chatons SA for well over a year since Nicklesilver recommended one1 point

-

I agree with all, but the last one. Nop, amplitude is not the ultimate test. There are several factors that the movement must comply with. Good amplitude is result of the efficiency of the escapement. Efficiency is one of the factors. But, the other factors are reliability and isochronism. Amplitude will increase with reducing the 'depth' of the escapement. But, with reducing the depth, at some point, the reliability will get bad. There are cases when the movement will work fine on the table, but when worn on wrist (shaken hit...), it will tend to stop with escapement locked. And the best isochronism sometimes do not coincider with the best amplitude...1 point

-

1 point

-

Hi Rich, I am not quite sure what you’re looking for here? You have already posted this in the watch movement identification dedicated area of the forum. As there are 10’s of thousands of movements/variations the only really useful thing would be a comprehensive database like ranfft was and I think that was a lifetime’s work with lots of extra information and input from users globally. If you look at emmywatch it’s a fair attempt but has a lot of inconsistencies and inaccuracies which whilst maybe giving a starting place we still need to do further research as often as not to confirm identities that are towards the obscure end of the scale. just my tuppence Tom1 point

-

I don't know why I was limited to a 3DPrinting forum, but oh well. I managed to grab a much coveted Meyer's No.58 Movement holder off ebay, but it only came with the second to smallest jaw inserts. Not to be detered I reverse engineered how to machine the jaw inserts. Here is the Flickr Album. https://flic.kr/s/aHBqjAGuFJ I made a small insert set as a test and then made a set for size 16s pocket watches. I'll make a few more to fill out the set. I made these from Aluminum, but might try glass-filled Delrin as an experiment The drawing could easily be used to design the jaw inserts for 3D printing in Nylon or a hard Urethane1 point

-

1 point

-

That was going to be my next question....if you were leaving the forum. Your Timex knowledge is unrivalled here... someone has a Timex issue or question is directed straight towards you. So pleased you are staying , losing such a valued member as yourself would leave a big hole in the forum.1 point

-

Cleaning method varies depending on movement type. For the basic M24 platform it is ammonia - water rinse - dry - lighter fluid - dry - lubricate. the WD - 40 is never used to lubricate, rather I use it as a rust remover yes, I'm still going to help1 point

-

1 point

-

Sternkreuz is the make and T 170x110x is the size. As you are in America you need to find a watch material supplier near you. It doesn't have to be Sternkreuz all you need is the size. That type of watch is known as a Ladies dress watch probably from the 1920's to early 1930's1 point

-

I'm sure i started a thread for this about two years ago, no eyed deer where that went to ( ok so its a goat, what ya gonna do ? Shoot me ? ) . I'll try again. A new place where we can post wacky ideas that work ( i have lots, they dont always work, but then neither do i if i can help it ). Heres one - so i dont get the typical ultrasonic cleaning thing which goes something like this, parts in a mini mesh basket in a lift out basket in a glass jar in the US. ( see picture 1, yes i have pants on today so lets not get too excited ) This seems like an awful lot of barriers for the cavitations to penetrate before they reach the actual part, 3 in fact. We can eliminate two of these very easily, like so by putting the parts directly into a small tin that will float. A tin with a lid is great , i have a few that i use that float very well in fact. An alternative is one of those tea lights after the candle has burned out. Dome the bottom of the foil to create a keel to stop it tipping over, the watch part also settles in the bottom to give it more stabilty. I use a small US occasionally, next to where I'm working if things just need a quick rinse, gives you a good example of how i do things sometimes, part goes in the foil tub placed in the water then i drip a little cleaner into it. Works a treat though the US could do to be upgraded. For plates and bridges you can also hang them off copper wire draped over the side of a glass jar or tin. A little tip or trick can often save stress when tryin to get our heads around something, like parts that are just not cleaning well enough, that has just a very simple answer to it. More ideas people please, teamwork makes the dream work an all that Another quick one folks, this time for drying parts. I feel this needs to be quick to stop that white ring staining that often happens when the part is removed from an IPA rinse, commonly seen around the jewel holes. This involves 2 pieces of apparatus besides the dryer. 1 x wire egg cup and 1 x half of one of those spring loaded 2 part tea strainers. The wire egg cup allows the warm air to pass through the mesh basket. This basket is suitable for plates, bridges and a few other parts that have enough mass not to blow away , although as you can see my dryer is speed controlled .Obviously if you are drying small parts leave them in the mini mesh baskets that have lids and use a bigger basket holder. Hairdryer is fitted to a small microphone stand.1 point

-

Ok victorian grandpa you can keep that thought but I'm gonna treat myself everyday if i can cos nobody else will, you got to look after no. 1 in this world. Someone somewhere sometime somehow is planning to shit on you, call me cynical but ita something you dont want to forger...ever1 point

-

1 point

-

1 point

-

1 point

-

I'm looking forward to receiving it and mess about with it some. Getting a bunch of tools in the mail always feels like chrismas.. I'll try posting some pictures and a walk-through when i figure it out.1 point

-

I am getting quickly to the belief that watch fiddling is only a cover for our tool addiction Tom1 point

-

Welcome Jason. I was already one who likes good tools, as I do handyman jobs on the side. What's worse, is that I have had the attitude that I should gather tools that I might need in the future, as opposed to what I need for the current project. I like having the right tool on hand, when I need it, and not having to put a project to the side while I hunt for a deal on a tool. Some of vintage tools are projects in themselves, as they need some cleanup and restoration. My staking set was a good deal of work, to meticulously clean and lightly oil each piece. Find some missing pieces. Refinish the case. It's now a thing of beauty that I love grabbing when it is needed. Then there was the Seitz tool set... The expense is the other thing. Fortunately, my wife knows that whatever hobby that I get into I will try to make some money off of. So far, I've been flipping some tools (while keeping the best for myself). Hadn't started selling any of the watches that I have serviced, but I'm sure that is coming. Though, sometimes I do try to secret away the latest package to arrive, before my wife sees it so I don't get that "what did you buy now?" question.1 point

-

One of the things I've discovered is that restoring old watchmaker's tools is almost as satisfying as restoring a vintage watch. Using the restored tool to restore a watch is like winning the lottery the day after they repeal capital gains taxes. The Mrs. has progressed from saying "what, ANOTHER watch video?" to rolling her eyes when the packages show up with "what did you order now?". I fully expect any day now for her to say "what can't you just watch porn like the other husbands?" Welcome to the obsession.1 point

-

1 point

-

You also get to hear him when he becomes frustrated & has to put a watch aside for 6 months, and you even get to see him with a dead end watch once or twice.1 point

-

1 point

-

Another little idea , for a movement cushion this time. Always made my own cushions but i like this one it has built in features. The pot is from cousins , add lead circles for weight , light cushions move far too easy for my liking, a foam mat cushion, yoga mats and those click together floor mats are about the right density punch out the center. The lid acts as a dust protector when you want a coffee break, saves on those glass movement covers.1 point

-

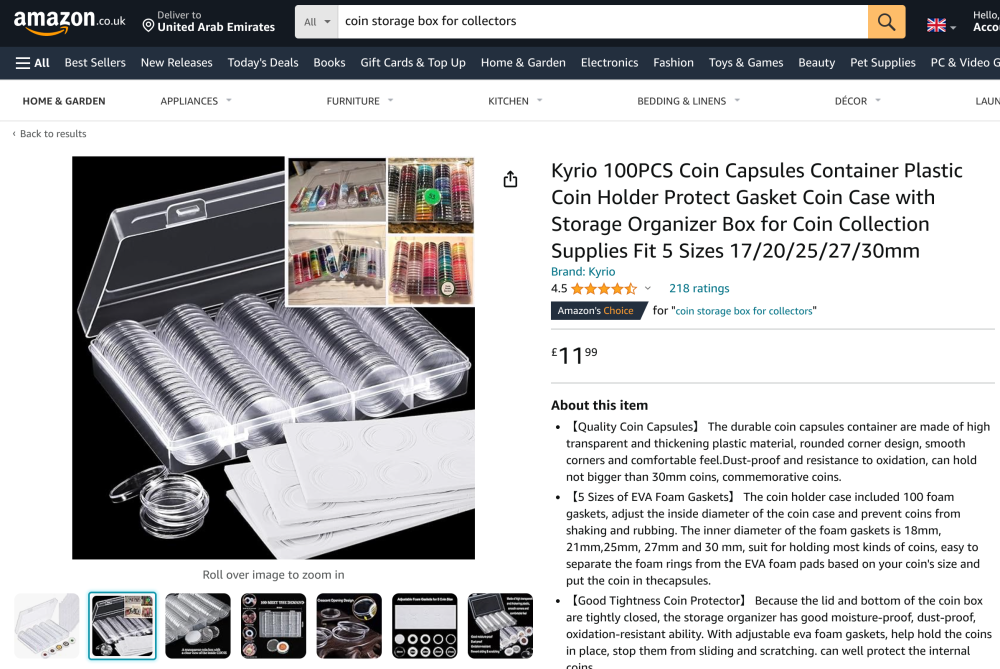

A lifetime of pegwood Scott, whats the timber like, my first lot of pegwood from cousins was really bitty, dipped in cleaner it was a little better. I do prefer bamboo its harder and breaks up less, there where whispers that its silica content can scratch but i havent experienced that to date , i always soak the wood in cleaner ( paraffin now ) when pegging anyway so that it softens it. My favourite probe at the moment is a burger bun stick , its really thin, instead of holding a bridge down by pushing from above with the tip ( the usual technique ) , i use the side of it, the stick has some flex in it so its difficult to press too hard and risk popping a pivot , it also cant slip holding it that way, coffee stirrer sticks have that same flexibility to them. Not so keen on the delrin or plastic type probes.1 point

-

1 point

-

1 point

-

Ha I used to see these by the dozen, probably have one in a drawer somewhere. Won't spoil the game though!1 point