Leaderboard

Popular Content

Showing content with the highest reputation on 10/11/24 in all areas

-

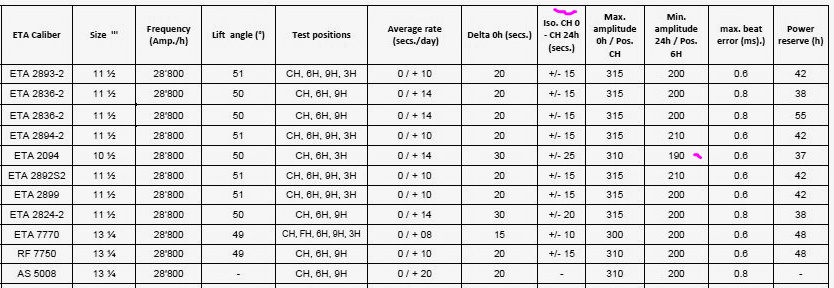

someday in the future some unsuspecting watchmaker attempts to adjust the pallet stones, does the UV glue soften in or with heat? the unfortunate problem of timekeeping is you do have to have a functional escapement. the amusements I have with this and other groups is the obsession with some sort of magical target amplitude or you're a failure in watch repair. On a different group somebody with a pocket watch had way too much amplitude and tried everything except the logical solution. The groups decision was put the proper mainspring as typically American pocket watches even Rolex has differing strength mainsprings for the same watch. But this person was so scared the new mainspring it might take the amplitude too low and he would be I guess a failure. I am wondering if maybe YouTube personalities are spreading this bizarre obsession? then using the term timekeeping is too simplistic we need numbers. So I snipped out something with numbers something may be easy to recognize that Omega numbers ETA numbers of various watches. then I did not snip out the fine print which I assume everyone knows for proper timing procedures. In other words fully wound up at zero is fully wound up but a settling time. typically at least 15 minutes to about an hour it varies. This way with a any watch or not wound up at the absolute peak of too much power. then notice test positions it depends upon the grade of the watch but this is only for ETA specifications ideally for troubleshooting you should really look at six positions. Then you get the average rate once again it depends upon the quality grade of the watch. The Delta of the various tests positions. Then? isochronism? True they abbreviated it but that's the word. Just think if you had a properly adjusted escapement a properly shaped mainspring with the nice back curve producing linear power may be little watch fully wound up doing 245°? On this group you would be a failure and you should leave. But if it met all the timing specifications and at the end of 24 hours it was within the timekeeping specifications especially the isochronism and still had the minimum amplitude on the spec sheets you would be fine except on this group where you would be a failure because you were supposed to get that magical amplitude whatever the heck it is yes I really do get annoyed with the target amplitude or death attitude on these graphs so isochronism the effect of amplitude. This is where if you hit some magical 300° and your mainspring sock and other factors in your crashed 200° you would be extremely unlikely to ever get this isochronism number you do much better with a consistent amplitude over the running span. This is also why the power reserves become important as you tend to get more linear timekeeping with longer power reserves as it gives more even mainspring power oh and then for those of you recovering from your heart attack over minimum amplitude of the 190°. But notice at that lower amplitude the isochronism number is much bigger there only timing and three positions Delta's bigger. Plus a slightly shorter power reserve. So customers only care if their watch keeps time they don't typically care about amplitude. Although I see on the Rolex discussion group for some of them of timing machines and they are concerned about their amplitude. But typical people don't have timing machines they just care of the watch keeps time. Watch companies as we'd see below have timing specifications and timekeeping is the most important. With unfortunately you still have to have a functional escapement and enough amplitude consistent amplitude to keep the timekeeping.2 points

-

for this particular Seiko movements there is a special movement holder specifically for the sweep chronograph hand. It allows you to push the button in for returning to zero and hold it in place. While pushing the second hand on it the proper location. It also provides support underneath C don't knock the jewel allowed because it requires a lot of force to put the chronograph hand on. For instance this is why a lot of Swiss chronograph watches when you go to remove the hands they will disintegrate because they been put on with so much force that they basically are considered non-removable and in the service centers they would get an entire replacement hand kit which we do not get so chronograph hands need to go on typically very very tight as others have mentioned there's a lot of force on them when the returning to zero.2 points

-

2 points

-

I can't believe the number of people bidding on this. Although saying that, most look like newbies who probably haven't got a clue!!!2 points

-

Or possibly a "frankenstein" with the case originally from a different make, plus a Cartier movement & dial? There are quite a few movements about at reasonable prices. One here that looks built from parts - what looks like a Rotary logo on their version of the movement, plus a Cartier dial and with an unbranded tank case: https://www.ebay.co.uk/itm/2357770378992 points

-

What !.....Just today ? Och aye Tommy thit soonds leek a reite gud idea,"Kirk to engine room make it so Scotty " .2 points

-

The various individual identification threads can sometimes end up each several pages long. I just do not see how it could work with everyone posting all requests in a single thread. What could be a useful one (which I thought you may mean, when you started this thread), is a moderator- or advanced-member only sticky "index" type thread with a thumbnail image, calibre type & a link to the relevant full thread, for each identified movement. That could work as a quick reference that can be browsed through easily for known movements without hours of looking through many old & long threads? It would need someone with a lot of spare time to initially compile it, but then only one or two new entries a week, if that?2 points

-

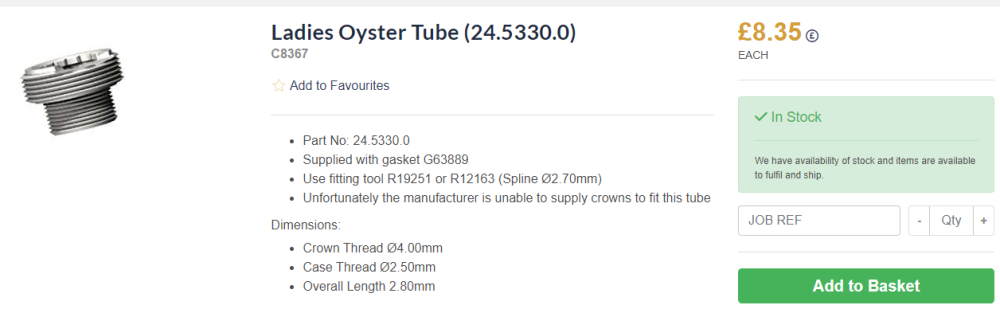

That's a bit of an overkill. If you look at the beginning of this thread, a nail clipper would have been sufficient for the job. But having the smoothing broach in the centre of the cannon pinion to prevent the tube from getting over compressed is important. But even if you do everything right, sometimes the tube may crack due to metal fatigue.2 points

-

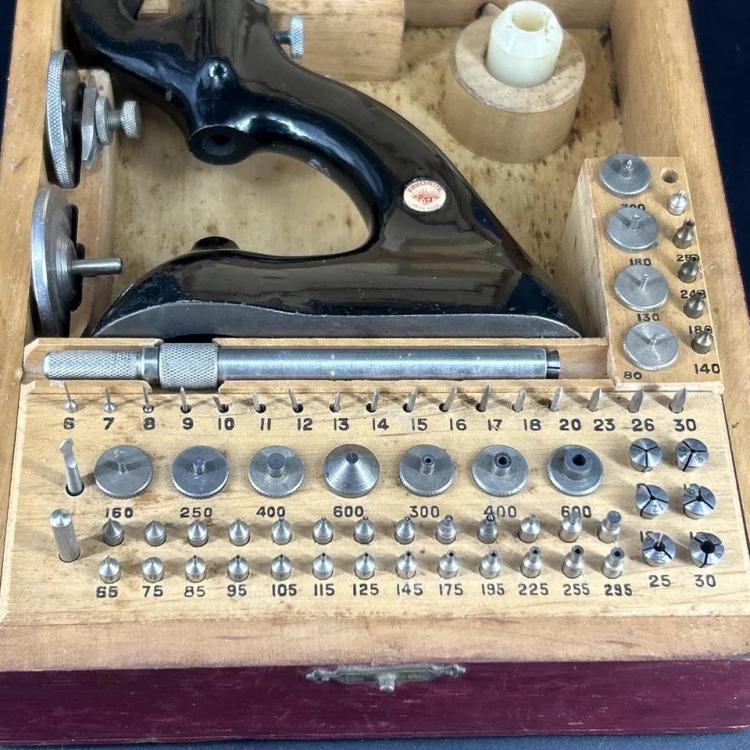

I impulse bought a fairly complete looking Favorite jeweling tool, without really knowing what on earth I am doing. I know there's a set of collets and reamers that seems to be one of the big advantages of these, and have also read that they use 4mm anvils/pushers, that should be compatible with horia pushers (is that right?). I've read on here somewhere that the two "spade" shaped tools are for deburring edges. What is the odd table thing with the "claws" underneath and what looks like a thumb screw on the top? Anyone know what the things in the bag might be? (I don't have the set in hand yet). How about the big white plastic thing? I've read that Favorite did a staking set for their jeweling tool, so am thinking of keeping an eye out for that. Any information at all would be welcome.1 point

-

Well, then may be X-ray film (this days they print them on digital printers), Coca Cola can... Just look around. I don' know much about purchasing watch parts, but doubt that there are such square gaskets for sale.1 point

-

Looks to me like standard Sternkreuz R or Rr Acrylic.1 point

-

1 point

-

Is there no fluting at all in the tube even part way down? Edit Think this is probably what you'll be needing or maybe the 24.5300.0 Double Edit Think this confirms my above. https://perrinwatchparts.com/products/generic-not-genuine-case-tube-a-type-to-fit-rolex-style-530-mm-crown-supplied-with-case-tube-gasket-see-all-case-numbers-in-description1 point

-

According to my own understanding of the matter, this watch has only one subdial and it is of the minute register. And, it has central chrono hand, which is not on subdial. So, You problem is the chrono hand... The most probable reason is that the hand is not firmly seated on the shaft. This is a regular problem of such hands as the shock when resetting is huge so the friction between the shaft and the hand's bush sometimes gives and the hand's position on the shaft changes. The hand must be pressed really tight. If the hole of the bush is enlarged, it is possible to shrink it. The best way to do it is in a lathe's collet. In the service centers they often don't reuse the hands, but rather replace them in order to avoid such problem. Another reason may be the bush is loose in the hand. And, of course, the movement may be out of order.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

1 point

-

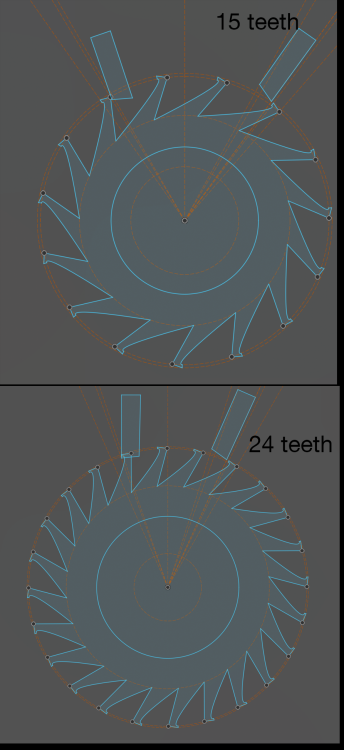

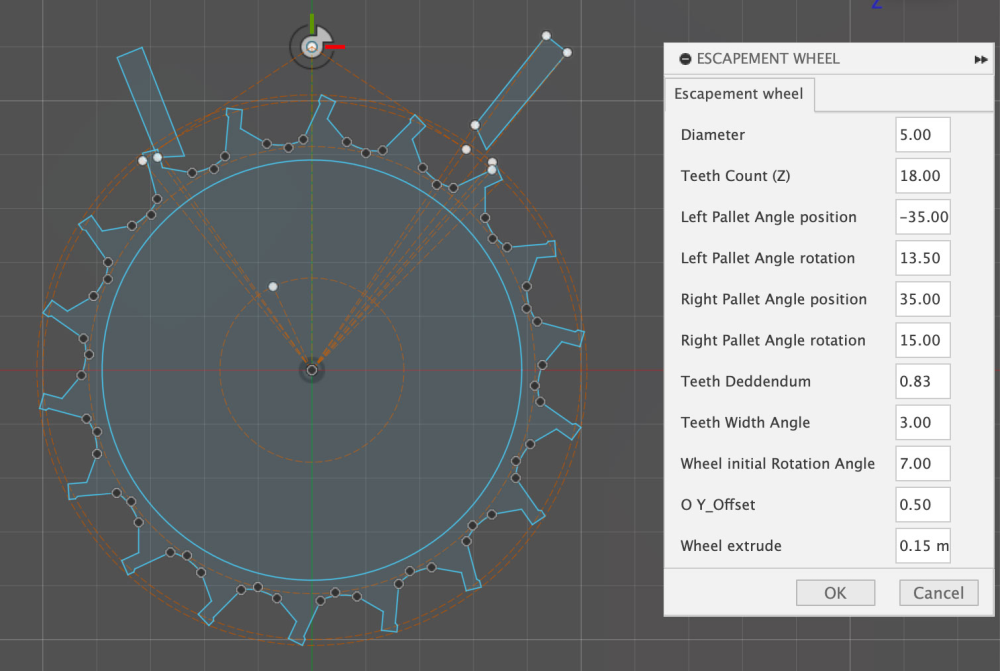

Hi! First of, Im not an expert I've exploring making my own movement, been making a script that follows George Daniel's Watchmaking, particularly the "Semi Equidistant Club-Toothed escapement" (which I think is a good option?), and it works great for 15 teeth escapements, but, for a movement Im working on, I need 24 teeth, Im mostly having trouble calculating the Locking face angle and the position of the left jewel. People who know how to design these guys seems to be ultra hard to find... anyone knows some resources I can follow? (books, papers, NIHS rules, etc) or if someone has an hour or so, I'd be happy to pay for your time. example Thank you so much! Felipe Zuleta https://fezuone.co1 point

-

Hi, just a bit of an update Kept working at this escapement+pallet drawing tool, reading more books, and experimenting a bit more, and reached some deeper understanding, Im actively working on this script for fusion360 (adaptable to any software) that can modify angles, which when animated allow me to see if the wheel will work or needs modification (takes less than a minute). Basically I couldn't find a function for all scenarios, but rather manual tweaks that paired with fast animation, allow me to find an escapement wheel. e.g on the NIHS rules vph of 18000, 21600 28800 are suitable, but 25200 is not (I dont know why), so based on the train of wheel ratios I decided on, a 18 tooth wheel is ok for 21600 vph, and 24 tooth for 28800, but 24 tooth is considered super high, so Im gonna give it a go at 18 on the initial prototypes.1 point

-

1 point

-

Managed to get batteries, put them both in and working again many thank for all the help from this forum A*1 point

-

mikepilk, that Longines is a beautiful looking watch, I'm now on the look out for one. What's on my wrist today ... I present this Fero with the 15j EB 1344 movement. Well to be honest, it's not really my cup of tea but I chose to give this a chance really to have a bit of practice on smaller movements. I was a bit taken back when I realised it is a pin pallet, I assumed out of those 15 jewels two would be on the pallet, but even better for my practice. Thanks to the exhibition caseback enabling spectators to marvel at the movement, visible was the second wheel rattling about loosely and could see the balance seemed ok and trying to go. The acrylic with the hour markers is basically a movement ring so all comes out as one. Stripped down and cleaned up really well, bit of wear on the movement plate centre hole, but what I did notice was that some of the jewels holes seemed way too big for the pivots, they didn't look worn at all, nice clean crisp lines and symmetrical holes, was this sometimes the case for cheaper grade movements? The balance hairspring is fixed post and I didn't look forward to messing with this if the beat error was way out, visually it didn't look too bad. Put on the timegrapher expecting poor readings, amplitude 260+, beat error 0.4, I'll go with that but running way too fast. Achieved +3 seconds but this was going up and down, I'm thinking this will settle down when the oil makes its way around the escape? Like I said, not really my style but seeing as it's running fairly well, I'll give it a wear for a couple of days. Timex next, pulled all the ones I've got out for a post yesterday, never done a Timex but now they're out, now is a good excuse. So if you read this JerseyMo, know that someone in Lancashire UK is scratching there head attempting a Timex automatic with a rotor with about 3mm of play1 point

-

The lack of information on the case back would lead me to believe it's a fake. Edit I think this is what a genuine one should look like. https://www.ebay.co.uk/itm/3356104499911 point

-

This site sells Cartier gold plated watches and I have been reading about counterfeit on there page. According to Cartier they do not make gold plated cases. Do we have an expert here that can clear this up? https://www.chrono24.co.uk/cartier/gold-plated--cm20.htm1 point

-

You’re in a funny mood today a topic that is pinned always appears at the top of a forum section and any new posts are automatically added below it. In this case it should be the fist post in this forum giving a guide on what you should include in a request for help in identifying a movement. This would be a “how to” for submitting the request. An admin or moderator can pin a post, I suggested submitting it to Mark for his approval as it’s his site. sorry I don’t speak English, I am a jock after all Tom1 point

-

I can see a few problems Rich 1. Every question is essentially the same, “anyone know what this movement is?” Albeit phrased differently. 2. Forum software is designed to operate as a repository of conversations held in chronological order, not alphabetical or any other ordering 3. Deleting post after identifying the movement would be an administrative burden and also remove potentially useful information an idea which could be helpful would be to create a pinned post outlining what information, photos etc. that would be useful to have in any request. Write one up mate and submit it to Mark as an idea. Tom1 point

-

Seems a fair bet , you'll know soon enough and if you have 4 week to return it, if its all good then i think you have done ok with the two tools. You then just need to parcel them up and send them to me1 point

-

You mean, is it a genuine Cartier, or a fake? The photos are not great, but I would guess genuine. Off the shelf movement with no decoration. Plated case? Nothing special in watchmaking terms, and in poor condition, so not worth much either. Have you handled it yourself, or only seen these photos?1 point

-

I've got 4 weeks to return it, should arrive in the next few days. In one shot of the frame there appears to be a stake mounted. It might be that the spindle is mounted in the frame (pictured in the Pennyfathing link, which does say its for the "jeweling" tool explicitly, and they seem to know their stuff), or it might be that the spindle is total nonsense and is just the picker thing pictured, wobbling around in there. I should have both in hand in the next couple of days.1 point

-

1 point

-

What does the description say, i honestly think the guy might be lifting your leg. Let me dig out mine and show you. Yes the staking set may be for a combo tool but the frame with it is wrong, this is mine and it has a spindle that takes the stakes. Ask about the spindle . Ask the seller to show you the sprindle in the frame and a stake in the receiving spindle, then theres the difference of the rotating anvil with reduced holes for replacing staffs. The main thing you need here would be the spindle, its the end that you need to see. The sellers looks a bit like this which i use for holding drills. You might be ok, but just be sure whats you have coming.1 point

-

Welcome to this forum and good luck with your journey. Oh I mean your journey in watch repair, not space.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

We can all add our little bit to that simple solution H, so sad the whole world doesn't implement it. I would much sooner make what i want than buy it.... and do to some extent....you get something to your own specifications. Just something ive learnt from bespoke construction.1 point

-

I do too...we are all different and we have no idea why that person behaves the way they do. I had a shitty upbringing and my dad was a drunken bully a lot of the time ( major issues god rest his soul, i know he had some good in him ). I wont let that taint my behaviour towards folk and i try to get on with everybody because life is too short, i act the fool, mostly because i like to see folk laugh but i have a very serious mature side when it's required and i absolutely detest bullies and drunks , i give folk the benefit of the doubt but only for so long, i can be real sod when someone rubs me up the wrong way. I remember some of the comments that " he who shall not be named " would make to beginners.....my tolerance ceiling used to instantly drop1 point

-

I got a 7j 610 grade movement for about 20 bucks, which is the same Waltham Model 1908 as the Crescent St. but in hunter configuration. The ratchet wheel screw was in fact the same diameter/thread pitch, but the barrel dimensions were slightly different so the screw was a little long. I filed it down and now it's working perfectly, you can't tell it's a replacement at all. I needed a few other random screws from the donor movement (dial screw, one of the balance jewel screws), and those were all identical and worked perfectly. With the new mainspring the Crescent St is humming along nicely, though running too fast, so I still need a few balance adjustments before wrapping up this project1 point

-

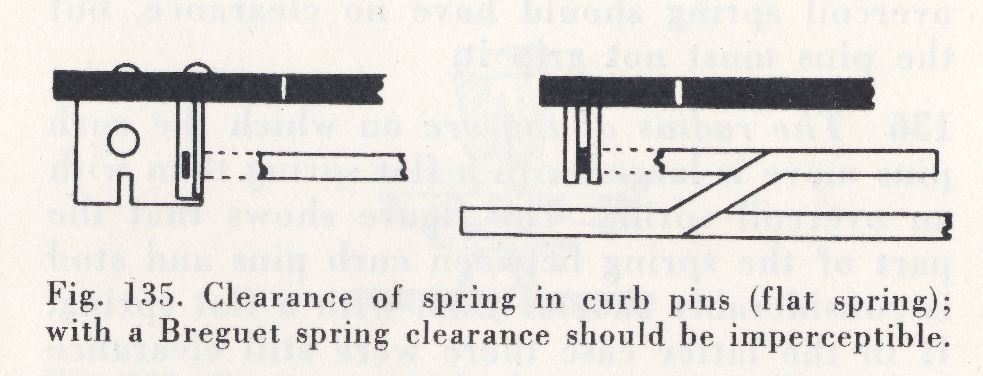

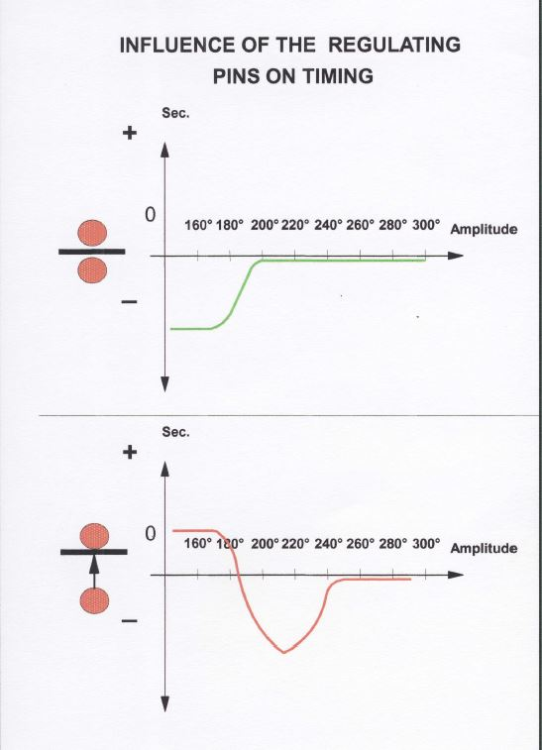

Here's a very good reference and a review of the reference. But minor problem with reference material like this and he even brings this up but he doesn't pointed out as a problem. Reference books like this cover a lot of stuff from manufacturing point of view. So he talks about using it to make hairsprings. You have an existing watch is not going to redesign the watch so it's going to have design flaws. Even if the watch does keep really good time. https://youtu.be/op68gwVvsCo?si=7-jq6k3mRsgTqUeZ Interesting wording let's look at what Wikipedia says https://en.wikipedia.org/wiki/Isochronous_timing Let's see what Wikipedia has to say watch is isochronous if it runs at the same rate regardless of changes in its drive force Notice the reference to drive force the watch should keep the same time regardless of amplitude unfortunately amplitude does affect timekeeping. Another Wikipedia entry let's look at mainsprings https://en.wikipedia.org/wiki/Mainspring Notice the pictures the mainspring is like the top right out of the package and then the lower left the Elgin Springs. Reference to the interesting curvatures designed to produce more even force as the mainspring unwinds. Unfortunately if you take mainsprings out of the ring you find that they don't always have this really nice curvature like they're supposed to. I find a lot of times with modern pocket watch Springs the most amusing was one that basically had the center curve and went straight out and had basically no curve at all that is going to produce very uneven power. Other Springs look almost set but the brand-new and some of the later generation both Hamilton Elgin tend to be some of the nicest looking mainsprings because they do have the proper curves versus the modern Springs which often don't so if you don't have a mainspring of the right shape you're going to have an even power so if there is manufacturing inconsistencies that can be an issue especially when we want to be super nitpicky on timekeeping down to the second. Did you notice this question why do you think I ask this? If you looked at your watch dial down which most people is the only position they looked at the regulate the watch and then move it to crown down what happens for timekeeping? Often times people love to have amplitude and if you around the end your pivots you'll get lots of amplitude but ill have a problem as soon as you go to the crown positions is more friction you lose your amplitude. It's why typically the ends the pivots are flattened to make their amplitude more even with the pendant positions. Basically looking at the watch in more than one position can show the effect of amplitude changes from dial positions the pendant positions and then 24 hours later with the timekeeping look like you also find related the mainspring is our watches that will run 48 hours and 56 hours another attempt to get a more even powered mainspring. So usually not necessarily at the extremes at least at the extremes of running out of energy like you would be of it had a watch that only ran for 30 hours for instance then those pesky hairspring regulator pins it would be nice if we just break them off and not deal with them at all as timekeeping would be so much nicer. Regulator pins spacing depends upon type of hairspring you have. Here's an interesting image obviously a flat hairspring. So we can see the effect of the hairspring bouncing off the regulator pins as long as it's doing that it should keep relatively linear time. But as the amplitude drops basically the regulation point moves and the watch slows down. Opening the pins up will make this worse and closing has issues because flat hairsprings are supposed to have some spacing. Basically if you took the thickness of the hairspring multiplied it by two that's the spacing between the pins. But like everything else that can be some minor variations here Then what happens if you're not centered between the pins. This will also depend upon how strongly are pushing the hairspring out of between the pins. For instance I once worked at a shop where we were instructed to bend a hairspring so it always touched one of the pins. Which would work fine as long as they hairspring never got enough amplitude the liftoff.1 point

.thumb.jpg.597a6d299b2710da1329e25911a036c9.jpg)

.thumb.jpg.ba6bea577ccb81423d486e711b5cd683.jpg)

.thumb.jpg.bf69838fac17ad69c0a86a9d9ee1c1c0.jpg)

.thumb.jpg.3a4938ad05d04a7cda04be1ebf027033.jpg)