Leaderboard

Popular Content

Showing content with the highest reputation on 10/13/24 in Posts

-

Today on this fine Sunday morning in the North of England, adorning my wrist, I give you this 1968 Citizen Dandy Seven Custom, with the 27 jewel 5204 movement. I've had this for a while now and it gets fairly regular wrist time and keeps excellent time. I had been on the look out for a dandy seven for a long time, there doesn't seem to be many around in europe sales, a few in Japan and they are normally quite pricey. Then this appeared on ebay and it didn't look good, but I risked the gamble. When it arrived it was even worse than the listing photos showed, a real sorry state. Removing the caseback revealed a completely green movement accompanied by a strong smell of old perfume. I can only guess that someone thought perfume might free up the movement, the setting lever spring was broken so not much achieved with the perfume rinse. This contamination took its toll on the movement and dial though, a lot of plating lifting and a furry crust around the dial. So this will never be a showpiece but I saw it through. Everything cleaned up well but there are scars, eventually sourced a replacement setting lever spring. When the balance dropped back in, fired straight into life, regulated very well and as said previously, keeps excellent time. So although it's a bit scruffy, I've got my dandy seven and I love it. Timex coming on well, movement ticking away working the oil around the escape, but my word ... that escape wheel and pallet. Let me tell you there was some adult language at my workbench getting those two back in.4 points

-

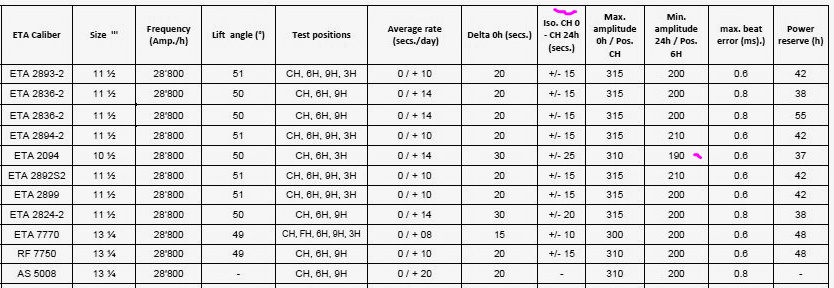

If you want to translate the positions names yourself: H = haut = up F = fond = back C = cadran = dial French language has the problem of same 1st letter for dial and crown, so they have to use 3,6,9… Re amplitude: don‘t make yourself too comfortable with John‘ s words. Horizontal considerable below 270 should at least make you frown and think about the possible reason. Frank3 points

-

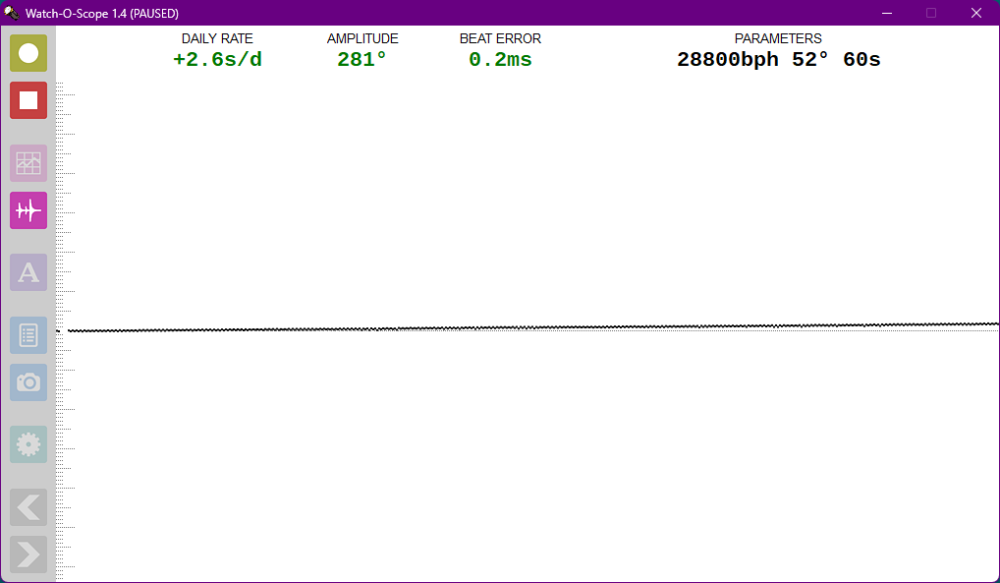

Thanks for sharing! How should the abbreviations under "Test Positions" be understood? Let me guess and then you can confirm or correct me if needed. CH = Dial up FH = Dial down 6H = Crown left (dial facing user) 9H = Crown down 3H = Crown up It happens on occasion, but it's not too bad. It has been mostly on WRT, especially by a moderator who's no longer here (thank god). If your amplitude fully wound dial-up was below 270° you were a total failure. I did feel like a total failure and almost gave up on this beloved hobby of mine. Fortunately, "a pro" here on the forum insisted that amplitude was not the be-all and end-all and that there were more important things to focus on. So I have been a lot happier since.3 points

-

Maybe a daft question but is the click in correctly?2 points

-

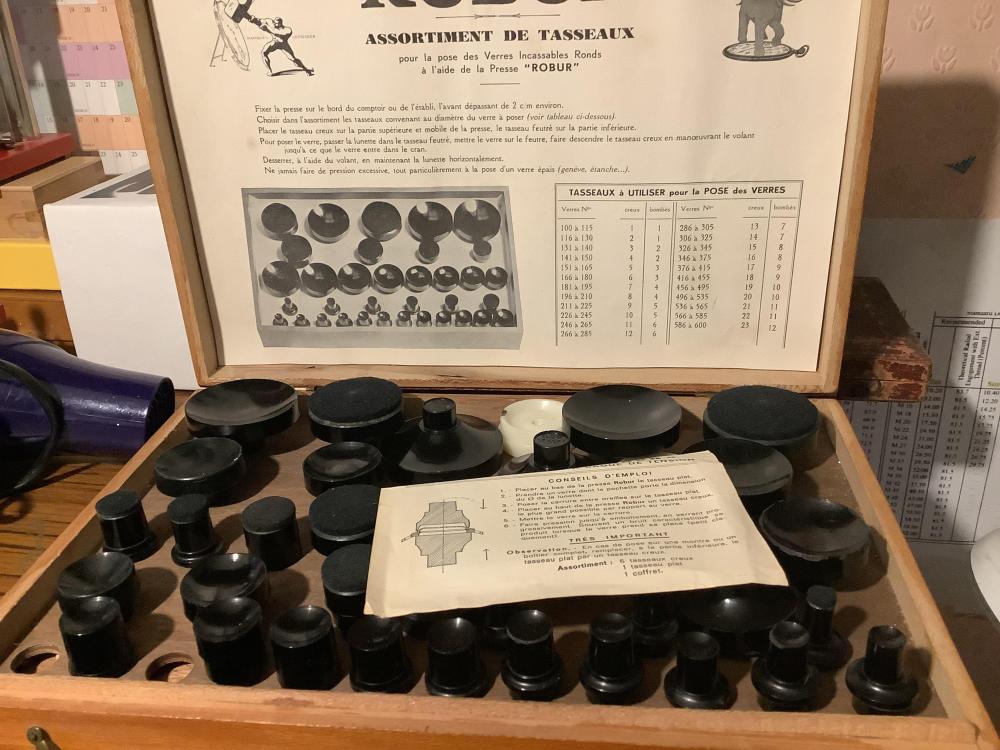

The torure devices the creepy little guy lays out on a table to help get our hero to talk?2 points

-

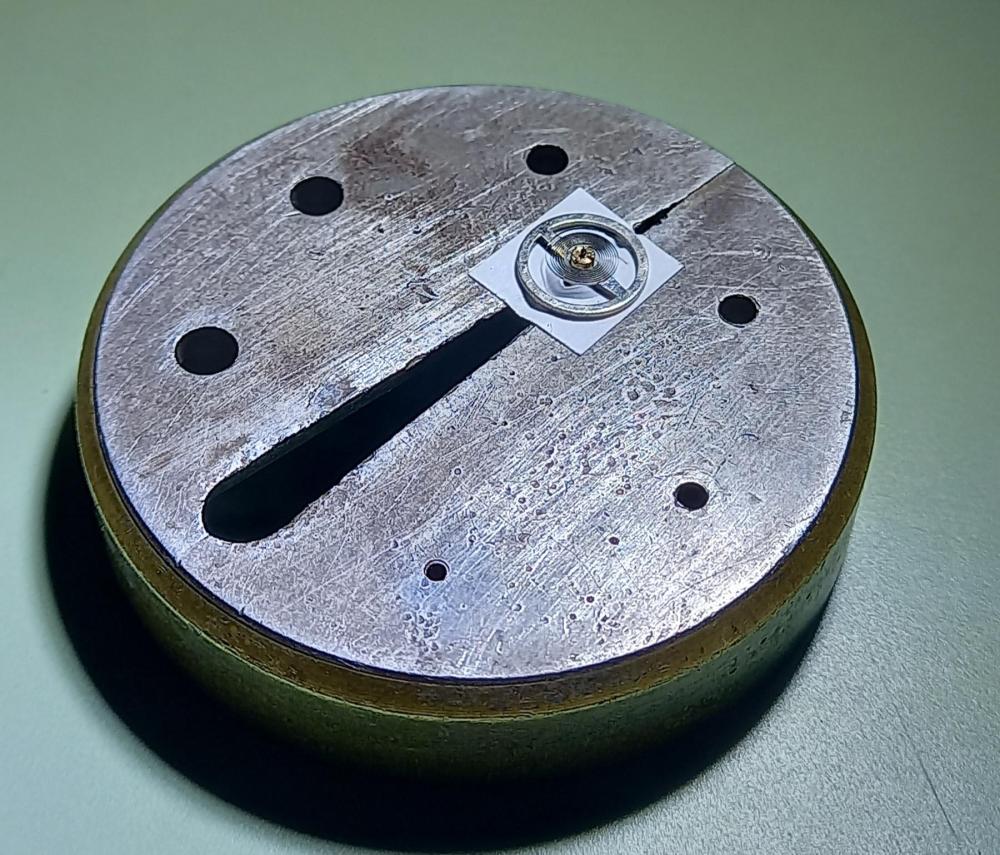

Hello everyone! This is my first post here on WatchRepairTalk, and I wanted to share a project I've been working on—a DIY Watch Cleaning Machine that I designed and built myself. Since it's difficult to find a good-quality machine at a reasonable price, I decided to use my engineering skills and create one. Why not, right? Look at a demonstration video on my instagram page. You can follow this page if you are interested in my watchmaking journey! Demonstration video of Akrid the Watch Cleaning Machine I named this machine after my alias from the Dutch watch forum, Akrid (which is also my alias here). It features three stations: one for cleaning and two for rinsing. The final cycle is for drying the watch parts, allowing the movement to be reassembled immediately after the cleaning process. I've been using it for two months now, and it's been working flawlessly! The cleaning results are far superior to what I used to get with my ultrasonic cleaner. See the cleaning results here: Cleaning results of Akrid I'd love to hear your thoughts on the design!1 point

-

1 point

-

1 point

-

All i can think about is how I'm gonna aquire that small leather bound Estwing chipping hammer on your desk1 point

-

It sounds like something wrong within the barrel? If the movement spins from touching the ratchet wheel screw with no pallet fork, the wheel train appears to be OK - but the mainspring or arbour is presumably somehow seized in the barrel, so cannot be wound?1 point

-

1 point

-

I have a crystal on order from Cousins, hopefully is tall enough. I like the idea of cutting a gasket from rubber, I see Amazon sells thin sheets, I'll probably give that a try.1 point

-

you could maybe find a suitable spring bar spring to work in the crown, a lot of times both the crown and tube are worn and will not function, especially when you put the flat gasket in the crown, if you have some tapered reamers you can use those to remove the damaged tube, after-market tubes are everywhere, use the 5.3 crown and tube, there are different 5.3 tubes, you should get the style that uses the tube wrench, there are endless tube tools on eBay for you to look at for reference......there are also taps to fit the case case1 point

-

I compared it against a photo I had of a disassembled ETA1080 and it isn't a match. The 1080 had placed balance directly across from the winding works. However, the setting lever spring and minute wheel cover plate are almost identical so ETA is where to keep looking.1 point

-

The name Grafton i dont recognise or the movement as being Ingersol. There is more to the barrel than just the number of teeth and size. Lots of sizes need to correct, lid height, the inside barrel height has to be right for the correct mainspring, both holes for the arbor the inner raised lips, teeth modulus for the cw pinion mesh. I wouldn't like to guess at how many differences there would be between 10.5 ligne movements . But we can make a start with the identity, help folk by removing the set lever, yoke and set bridge, lay them out and post a good picture of them. You dont always need identify markings. Closest I'm getting up to now is an ETA 1080, but I'll keep looking.1 point

-

I found this https://www.watchprosite.com/horological-meandering/on-request-the-rolex-microstella-tool/17.1179526.9410911/ https://youtu.be/3V7bVkqJuOQ?si=9XgfuB3TC_5nvRoV1 point

-

Just to loop back to this. I got back from a week's holiday and got back around to reinstalling the old mainspring. Comparison with the new but stronger spring shows that the old spring was quite set considering that they are supposed to be the same length. A full wind and onto the timegrapher - 200 degrees amplitude. Definitely no knocking! Thanks for the tip about Dennison sizing @JohnR725. I have ordered a new white alloy spring in the 711K size.1 point

-

Love the integrated bracelet and round dial. I found an advertisement from the time period somewhere touting the high beat and the first of its kind integrated bracelet of this watch. I have the square dial version and the case has 4 screws and much harder to do simple rate adjustments without taking it completely out of the case.1 point

-

Have a search for seiko-mod dial maker, they are on Facebook and I think they have a website Tom1 point

-

Just takes some extra careful attention noting any chamfered edges to lock into the case lips and dont rush it, the finish is then back as the original . Get close to the size with a fine file then fine grit lapping film or sand paper to achieve the goal, the end result is far above gluing the crystal imho.1 point

-

1 point

-

The hands clear fine, the watch has been running for a couple of days. I'm trying to sort the crystal issue. I'm OK with how the hands are as the watch has been running for 2 days and they do not foul one another. And yes, I do believe the crystal is the wrong type. As per my original message I am trying to get help on two items: 1. I’m guessing I won’t be able to source a replacement crystal, but if anyone knows where I can find this style of crystal can you give a link to them? 2. If I can’t source a new crystal then I guess my next best solution is to try and add more or replace the current gasket with something thicker to get the crystal off of the seconds hand. Any suggestions as to 1) What kind of gasket should I use and where would I source it, and 2) would I need to glue it to the crystal like it currently is or can I just lay the gasket on the case and fit the crystal as normal?1 point

-

someday in the future some unsuspecting watchmaker attempts to adjust the pallet stones, does the UV glue soften in or with heat? the unfortunate problem of timekeeping is you do have to have a functional escapement. the amusements I have with this and other groups is the obsession with some sort of magical target amplitude or you're a failure in watch repair. On a different group somebody with a pocket watch had way too much amplitude and tried everything except the logical solution. The groups decision was put the proper mainspring as typically American pocket watches even Rolex has differing strength mainsprings for the same watch. But this person was so scared the new mainspring it might take the amplitude too low and he would be I guess a failure. I am wondering if maybe YouTube personalities are spreading this bizarre obsession? then using the term timekeeping is too simplistic we need numbers. So I snipped out something with numbers something may be easy to recognize that Omega numbers ETA numbers of various watches. then I did not snip out the fine print which I assume everyone knows for proper timing procedures. In other words fully wound up at zero is fully wound up but a settling time. typically at least 15 minutes to about an hour it varies. This way with a any watch or not wound up at the absolute peak of too much power. then notice test positions it depends upon the grade of the watch but this is only for ETA specifications ideally for troubleshooting you should really look at six positions. Then you get the average rate once again it depends upon the quality grade of the watch. The Delta of the various tests positions. Then? isochronism? True they abbreviated it but that's the word. Just think if you had a properly adjusted escapement a properly shaped mainspring with the nice back curve producing linear power may be little watch fully wound up doing 245°? On this group you would be a failure and you should leave. But if it met all the timing specifications and at the end of 24 hours it was within the timekeeping specifications especially the isochronism and still had the minimum amplitude on the spec sheets you would be fine except on this group where you would be a failure because you were supposed to get that magical amplitude whatever the heck it is yes I really do get annoyed with the target amplitude or death attitude on these graphs so isochronism the effect of amplitude. This is where if you hit some magical 300° and your mainspring sock and other factors in your crashed 200° you would be extremely unlikely to ever get this isochronism number you do much better with a consistent amplitude over the running span. This is also why the power reserves become important as you tend to get more linear timekeeping with longer power reserves as it gives more even mainspring power oh and then for those of you recovering from your heart attack over minimum amplitude of the 190°. But notice at that lower amplitude the isochronism number is much bigger there only timing and three positions Delta's bigger. Plus a slightly shorter power reserve. So customers only care if their watch keeps time they don't typically care about amplitude. Although I see on the Rolex discussion group for some of them of timing machines and they are concerned about their amplitude. But typical people don't have timing machines they just care of the watch keeps time. Watch companies as we'd see below have timing specifications and timekeeping is the most important. With unfortunately you still have to have a functional escapement and enough amplitude consistent amplitude to keep the timekeeping.1 point

-

1 point

-

Managed to get batteries, put them both in and working again many thank for all the help from this forum A*1 point

-

Hi. Two batteries one for the analogue and one for the digital. Too much use of the back light drains the CR 2025 quicker.1 point

-

Looks like there's 1 removable link on each side. Even if all the links had been removed you'd still be able to break strap to add links back in.1 point

-

Same reason as any watch part Rich, sweat salt on your fingers. Finger cots And potential short circuit, salts conduct electricity1 point

-

Not hailing from east of the Pennines, (and without the required skills in any event) I've gone large and splashed out the £3.95 for a lever and screw as suggested by AndyGSi. I only found out yesterday, whilst feeding my nightly dose of insomnia with a Chronoglide video [correction it was a Vintage Watch Services video], that Oris were restricted to pin pallet movements by some obscure Swiss regulation. This restriction was removed just in time for them to stumble into the quartz crisis; how's your luck! The result of this was Oris made an art out of making these movements. I personally think Oris are underrated as a brand, just my opinion. Video link below-1 point

-

always nice when describing a watch would be to give us a movement number. On a watch repair discussion group we tend to be movement oriented versus name oriented. yes the classic problem of starting watch repair was something that a newbie shouldn't start with. Because things like Rolex Omega and all sorts of other brands the parts are dreadfully expensive. So if you have an accident not the newbie would ever have an accident. After all if you look at the YouTube videos watch repair does look insanely easy so but just in case you did have an accident like on the mega it would be dreadfully expensive. Then just the availability of spare parts altogether especially was something expensive. Then yes eBay is filled with all sorts of inexpensive watches to start with.1 point

-

1 point

-

Replacing this BALANCE COMPLETE with a new one is your best bet.1 point

-

Pictures of the tg readings in different positions will help, also a few of the escapement and balance might shed some light on the matter1 point

-

Well not my solution I found a little watch and jewellery shop that advertised watch repairs available. So I went in and thought maybe I can get some advice The old chap took it into his workshop area which I could see from the counter. I saw him turn on his desk lamp and put his magnifying headset on and pick out a tool but that's all. 30 seconds later he came back with the end links removed without a mark on the watch or links. Even the spring bars were undamaged. It was like magic I don't know what he did but he didn't even charge me. I gave a donation to my favourite charity, cancer research, of £20 and e-mailed him to let him know.. He replied to say "anytime"1 point

-

Thanks, all. The confirmation that this is normal was what I needed to go ahead and use the press. It popped right out. The crystal's thicker than I thought. I measure it as 2.4mm thick in the centre. Makes sense for a diver's watch. 6217-8001.1 point

-

Looks like a diver's bezel has already been removed and the crystal just needs pressing out or fit a die inside from the back and tap it out with a hammer . Nothing to lose as the crystal looks shot.1 point

-

Polishing this crystal won't do any good. It looks like there's a bezel around the crystal. Use a razor to open up a gap between the bezel and watch case until a case knife can be inserted to pry off the bezel. The crystal should then be able to push out easily. Unless it has been glued in.1 point

-

I hate coming late discussions like this where a lot of confusion this is a standard American pocket watch case. American pocket watches came into existence before the modern split stem. Or basically the modern stem altogether. In fact they came into existence there are no stems at all. If you look The message of @mbwatch He shows the components or the main component of what's holding the stem in which is the sleeve. Sleeves can be a real pain in the ass if there's a problem here as the really hard to find and yes there are lots and lots of different shapes and sizes. Ideally we need to determine whether the problem is with the sleeve or the watch. So for instance if you push in on the crown and rotate does the watch wind at all? Plus when the watch was incoming was their winding and setting problem in the first place? The stem is held in the case with the sleeve which is pictured up above. We do need to figure out whether the problem is a sleeve problem or a watch problem this is where it be nice if you had your bench keys. Sometimes if you're lucky they can be purchased on eBay otherwise you'll have to make something but you really need to have these to figure out what's going on with your winding and setting1 point

-

You need to rotate the hairspring. You can usually do it by pushing something sharp in to the gap in the collet, and rotating it. See here for how to get it the correct position (you don't need to be exact as you have an adjustable stud holder)1 point

-

1 point

-

1 point

-

I just found 2 things about this topic: 1) from personal testing with aluminum foil in small jars of both the cleaner and the rinse, I found no reaction; 2) I reached out to Zenith Solutions corporate contact information and they confirmed that their products do not react with aluminum.1 point

-

1 point

-

1 point

-

I doubt that's rust as the main plate is unlikely to be steel or any other ferrous alloy, it's most likely plated brass. Unless something else has been deposited onto the surface it looks to me like the cleaner has started to strip the plating off the brass. How long did you leave it in the cleaner, and at what temperature?1 point

-

The hairsprings in contemporary watches practically doesn't get rusty. If You see rust on such hairspring, it probably is due rusty water that has dried on the hairspring, but the source of the rust is something else, made of steel. The old steel hairsprings (black or blued color) do get rusty, but... If you see real rust on such hairspring, then it is gone. The problem is that actually spring gets thinner in the rusted places and timekeeping is gone, the spring can 'breath' in strange manner.1 point

-

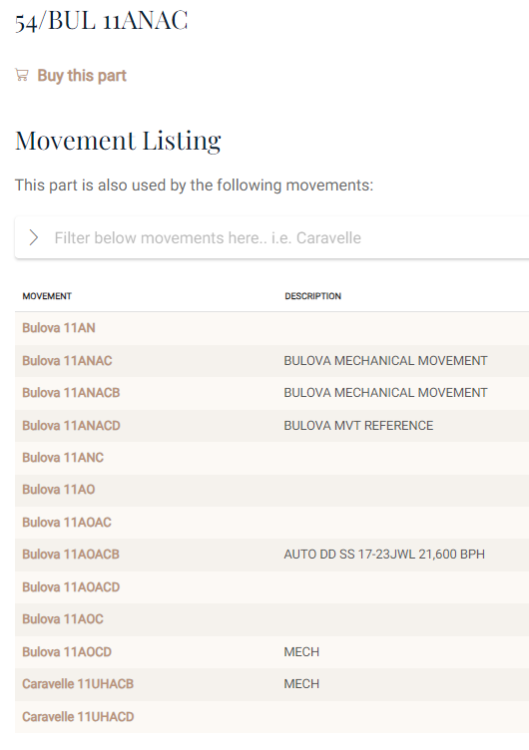

The problem is we end up with way too many variables here. For instance how is or was the original one dip marketed in other words what is its true purpose if anything? So advertisement from 1957 the basically has two purposes one to prevent rust and clean things like your hairspring. So in other words if you're cleaning machine didn't do a good job of cleaning in the first place this would be something you would use. YouTube is always interesting I've seen two separate videos on ultrasonic is evil and bad it will destroy your watches. Yet both of the schools I went to had ultrasonic cleaning machines. The cleaning machines were cleaning all day long watches. It seems like we might and noticed the destruction of the evil ultrasonic but I guess we weren't paying attention. Then if the shellac was disintegrating I think we would've noticed that too. I think all the shops I've worked in except one had ultrasonic cleaning machines. So my experience in real world differs from YouTube. Then the ongoing and listed debate of how can you dissolves shellac is probably just about everything in the universe if you leave it in their long can. That does appear to be that alcohol will dissolves shellac so it is forbidden under penalty of death of ever using alcohol except variables again. As I said I used alcohol that will dissolves shellac the can was very clearly labeled that it will dissolve in sin shellac and yet it never was a problem because I didn't leave it in there all day long I only used it for the final final rinse. As I said the cleaning machine at work at the recommendation of Elma you would think they would understand about cleaning machines after all they make them their recommendation was ipa once again as the final rinse. Then as I said too many variables and too many stories. For instance the Chinese 6497 clone I think I cleaned it twice in commercial watch cleaning products and Of course the evil alcohol rinse and they hairspring cam free from the stud. So let's see the conclusion would be don't use ultrasonic cleaning machines don't use commercial watch products and definitely don't use alcohol as poorly glued Chinese studs will disintegrate. We also don't know in your chronograph example which chronograph it was how long did it stay in the solution and whether was any other solutions involved at all too many variables. Now we get to the peculiar problem of chemistry the formulas of course have changed. Then I suspect that probably all solvents that evaporate which is a nice characteristic unless we like wet parts probably are bad for our health. I know one of my coworkers was using of the one dip for cleaning off glue on a display case and it was definitely not good for her system at all. Although it she does seem to react way more to chemicals and things than most people. But definitely having it on a cloth breathing in the vapors and this would be the newest stuff was not good at all.1 point

-

Actually from time to time I would like to blow up the parts preferably in the assembled watch. Or specifically I was thinking of the can it be nice to make my problem go away in a spectacular fashion but for a variety of reasons Debbie very very bad in my location to do that. I'm always puzzled by why a different procedure for parts that have shellac? Because I run all of my parts through the cleaning machine and they come out nice and clean. Contrary to the YouTube gods to claim that ultrasonic alcohol cleaning fluids and probably just about everything else in the universe is bad for the shellac it seems to work just fine. Then there is a universal concern of Rust the way you describe by you didn't mention something? I've seen several references to using epilam can lead to rust. There used to be a website that had pictures and I was at a lecture once with a described the exact same concern. The solvent used with the earlier batches of epilam well basically think of it like Freon it wasn't Freon but it was something else. So what happened is as it was drying of that operating it would produce a chilling affect and depending upon your location humidity in the air you would get the moisture in the air to condense on the steel parts the pallet fork and escape wheel. Then ultimately that would lead to rust and on the website the person showed the rust damage and the damage it was doing. This is where I was at a lecture in some I was concerned about this so they had a hairdryer and yes you can hold the parts in your tweezers it works fine they would put it in The epilam and immediately warm air dry. The newer epilam is supposed to be less volatile so I don't think that's as much of an issue. I suppose it's conceivable though whatever your solvents is if you blow what sort of apparatus really fast could produce a chilling effect I think basically when anything evaporates it produces a chilling effect and if you have enough humidity in the area will have condensation1 point

-

I am reminded of the saying, "If you have nothing good to say, then say nothing." Seems rather apt here. I did my time with other apprentice fitter and machinists. I have since worked with other fitter and machinists. How one turns out is directly related to how much one listens, learns and applies oneself. (from someone considering doing the DLC course via BHI)1 point

-

1 point