Leaderboard

Popular Content

Showing content with the highest reputation on 10/14/24 in Posts

-

I don't really see many Seikos (like 1 every 3 or 4 years?) but they seem to be known for running lower than 270 amplitude. Likewise, I might have worked on one Russian movement years ago. But for other stuff, regardless of age, I do go for a healthy 270 horizontal. I am doing this for paying customers though. If I am under, I will figure out a way to get it up (and 99 times out of 100 a new mainspring isn't the answer). That often entails adjusting the escapement, which I do very frequently. There are exceptions; for example I had a nice little Piaget 9P in last week, which hit 255 or so horizontal. However, it only dropped to 240 in vertical, and had a 15 second delta over 6 positions, going to 20s at 24h and amplitude staying above 200. So I let it go at that.7 points

-

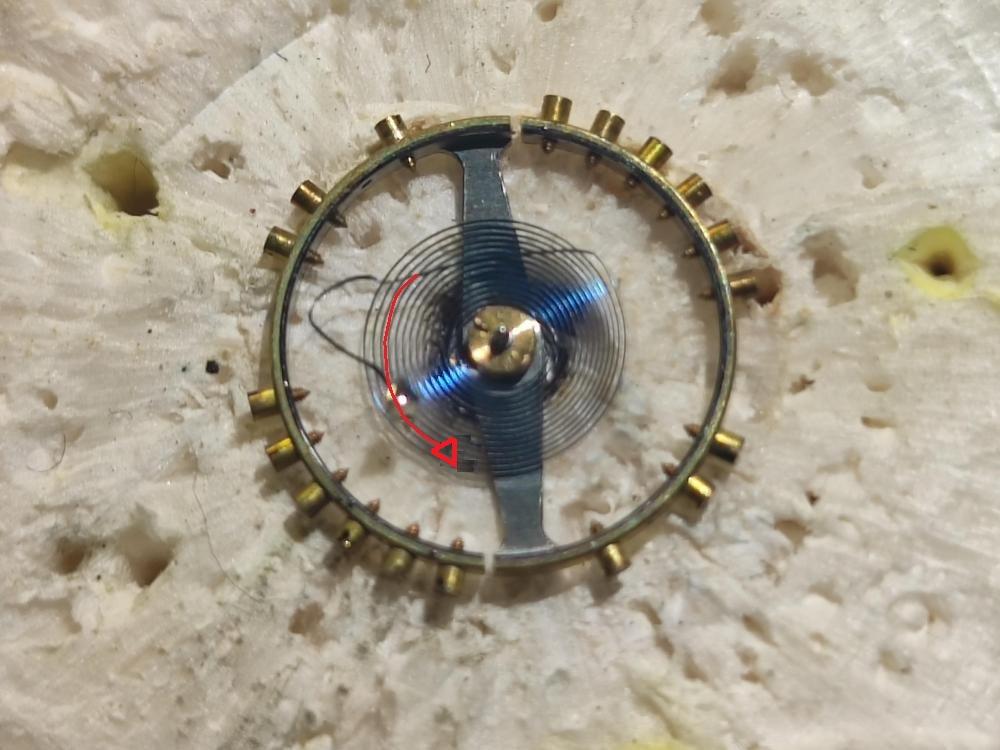

OK, just shape the end of the overcoil like I have drawn with red. The shape of the beginning is correct and don't do anything there but (if needed) bringing it in plain which is parallel to the hairspring body. It depends on how many it has been bugled before, but seems like it will straighten with no problems.5 points

-

Fear of what MIGHT happen DUE to actual bad experience . Not all ultrasonic cleaner are equal, i think mine has shellac rage I swear i could feel one of my front teeth slowly coming loose while i was stood over it yesterday3 points

-

Not told but quietly assumed: the spring is correct for the barrel, i.e. thinner then means longer concurrently. Remember: the optimal mainspring occupies half of the free area inside the barrel. Frank3 points

-

I've never put a pallet fork anywhere near a machine, always just dipped and cleaned by hand.3 points

-

Sounds familiar, I'm pretty fluent in multiple four letter worded Timex related Anglo Saxon phrases myself.2 points

-

Yes, thou shall not worship the holy timegraph machine but in my experience praezis alert is quite correct. If you are working on a quality movement in fair condition and don’t see the magic amplitude number it may be telling you something is amiss… Something amazing happened to me in my watch journey- as I learned to discover more defects and faults and my skills improved at correcting them and I learned a few tips and tricks to easily improve amplitude…amazingly! the quality and condition of my movements improved AND when they don’t meet or exceed the magic number I almost always discover a reason why. Sometimes the reason is ‘because this is a Seiko’. More often it’s because there’s something I missed or something I could improve… …In conclusion: take the number as a hint…2 points

-

Hey, congratulations! Downsizing is, well, a PITA. We've been through several rounds both before and after I retired, and I've had enough of that. In our current abode, I'm too crowded to function and haven't been able to do much with watches since moving, so, what to do? Build more space! We are just finishing an oversized garage with a a partitioned space in the back, with the whole thing heated and cooled, this should provide enough additional room so that I can get everything set up and get back to work. Unfortunately, the nice new garage space is not for me. It's for my wife, the artist But, I will have storage space for all the stuff that is cluttering up the room that I want to use for watch repair. It will be interesting to see how it all works out. Please, keep us updated on how things are working out. I think there are enough of us around here close to or past retirement age, that sharing experiences could be helpful. Good Luck!2 points

-

1 point

-

now that it's out for future reference can you give us a picture of the case without the movement so everybody can see the locking ring. then a picture of the back side of the movement so people can see the locking tabs on the movement themselves. probably warped because somebody was trying to pry their movement out not recognizing that its locked in place with the ring.1 point

-

I have done dozens of them and never had a significant issue with the fork & escape wheels beyond my first 2 or 3. Until a field watch I worked on 2 weeks ago, where I bent 2 forks and mangled 2 escape wheels getting it back together. Had to open up 3 different donors to make a ticking watch that time.1 point

-

@all of the people saying "never in the machine", is that because of fear of what you imagine might happen, or due to actual bad experience?1 point

-

That's what I do for pallets. But with shock protected balances, I clean in the ultrasonic with the balance fitted to the mainplate. The caps/chatons also get the ultrasonic treatment - they go in a contact lens case with cleaning fluid. For non-shock balances, I put the balance+hairspring in it's own little basket, then normal ultrasonic clean. In fact, the only things I don't put in the ultrasonic are the very tiniest screws, and small springs which can escape through mesh baskets.1 point

-

Balance jewels can go in ultrasonic. Pegging cap stones, drop flat face of the stone on a piece of rough surface cardboard, push down on the stone with finger, pour some lighter fluid on it, scrub till you get a perfect shiny surface & rinse. I know of no trick to clean inside of chaton, other than ultrasonic. Much depends on how expensive of a piece your working on, spend as much time as neccessary to clean Grand Seiko fork. Rgds1 point

-

Considering the extra run time, my guess is it has a slightly weaker than normal mainspring.1 point

-

I totally rely on TG machine for BE adjustment. Deforming force was applied near the stud and adjust arm, so not much deformation is expected to have occured on lower coil. Hello neven, please don't ask me how many overcoil I have destroyed to gain the dexterity to sort out overcoil in place and have to agree with you, a newbie might be better off just seperating the hairspring. Didn't know Simeon is a newbie, newbie working on overcoil ? A brave newbie. Rgds1 point

-

One thing you can do if you remove the spring is to place it on the upturned cock, centering the collet over the jewel, and observe where the regulator pins are in relation to the coils. Now you can form the curve over that coil (or between two), sort of a built-in guide. When you're happy with the curve, most of the final adjustment should be right near the stud- and you can check this with the spring off as well.1 point

-

I've been reading this forum regularly for a few years now, and I'm really not aware of any such "camp". Certainly @praezis doesn't belong in it, not judging by the comment above anyway. It's just a rule of thumb, useful as a quick and easy check, with a good foundation in theory and practice. It should be seen as an aid to achieving good timekeeping, not as an end in itself.1 point

-

I refuse to go back to the camp where an amplitude below 270° is considered a failure. It just doesn't bring me any joy or better-performing watches. I'm afraid stating "considerably below 270°" doesn't say much if anything at all. All we see (again) is the dreaded number 270°.1 point

-

I have an Omeag just like your watch, used watch when I bought it, dial was warped . Just want to inform you , these dials warp real easy, hate to see your next image with warped dial. Beautiful watch you have.1 point

-

You should be able to turn the dial and movement as JohnR725 said so you can see the two steel tabs it should then just come out turn it on its side.1 point

-

Ronsonol lighter fluid is what I always used it doesn't harm shellac. You need a small pot with a screw lid as it evaporates very quick. You could leave parts in it for days and it will not harm them.1 point

-

Here is a previous discussion on amplitude. Importance of amplitude. To avoid repetition.1 point

-

Exciting times ahead David . Ive been planning my new watchroom for 18 months now , the hard bit is becoming motivated enough to actually make a start, having a completely fresh and finished space to work with is the first step that we all want to skip...definitely....definitely not advisable, and i have 10 years before i retire. Interesting to see how other folks design and plan, before and after pictures see the space come together, this stage fascinates me.1 point

-

the ring you talk about is a locking ring it's not supposed to move very much at all. It basically goes in one direction to lock and the other direction to unlock. On the top your image I put marks that's where you would push in one direction or the other for locking and unlocking. Then we need to see something that we can't see which is the metal tabs. I put the marks where you can see the openings which have to be in the right place for the tabs on the movement they come out. so if you're lucky you may be a look at with bright lighting as you push on the locking ring one direction or the other and I don't think it has to pass the stem you should be able to see the tabs underneath.1 point

-

1 point

-

Maybe a daft question but is the click in correctly?1 point

-

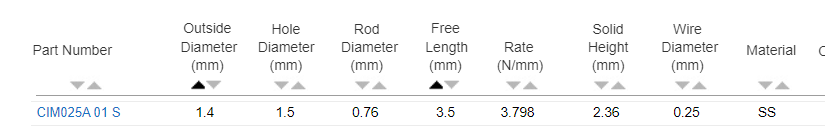

It seems that the springs breaking is a common occurrence in these crowns. If you don't realise you can disassemble and change the spring, you can waste a lot of money on a new crown. I measured the spring as : Outer dia 1.35mm, Inner dia 0.85mm, length 3.5mm, wire thickness 0.25mm. I managed to find a close match on https://www.leespring.co.uk/compression-springs Outer dia 1.4mm, wire diameter 0.25mm, length 3.5mm1 point

-

It sounds like something wrong within the barrel? If the movement spins from touching the ratchet wheel screw with no pallet fork, the wheel train appears to be OK - but the mainspring or arbour is presumably somehow seized in the barrel, so cannot be wound?1 point

-

have you tried with the crown wheel removed, maybe it is binding, I can't see how the pallet/bridge causes the ratchet wheel to freeze up, make sure the square of the barrel arbor is in the square of the ratchet wheel properly1 point

-

I have a crystal on order from Cousins, hopefully is tall enough. I like the idea of cutting a gasket from rubber, I see Amazon sells thin sheets, I'll probably give that a try.1 point

-

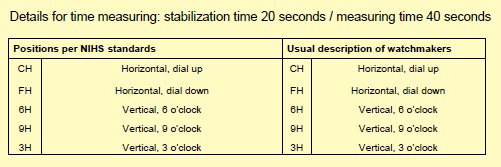

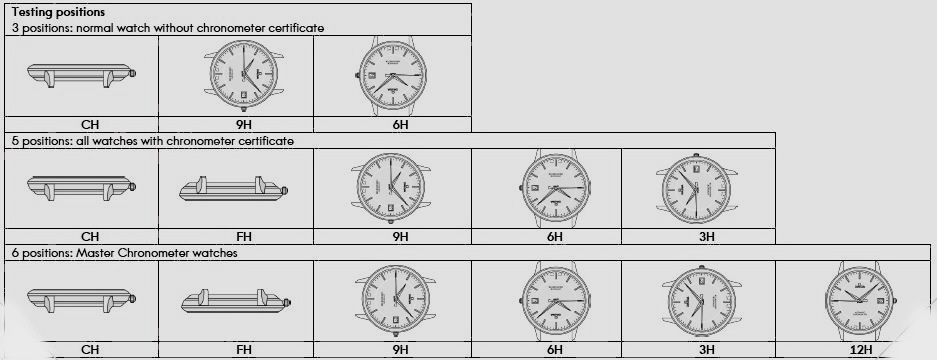

it's interesting with this particular chart is the minimum is three positions the maximum is five. Here's the translation and the stabilization time is more or less standard. So is when you rotate your microphone you have to wait 20 seconds and then they usually average the measuring over in this case 40 seconds. thinking about this magical number I have attached a PDF. On page 4 all sorts of amplitudes and then you get the extra the average which is 269° oh dear maybe it's close enough to be acceptable. But some of the other positions are below the acceptable fortunately most people in this group only test in one position anyway so there is always that. then starting on page 9 interesting of the maximum amplitude changes between automatic and manual wind don't think I'd notice that before? In a case they go on a talk about the maximum for a few more pages was looking at some of the other documents I do see another watch company that had only two positions most a minimum is three. Here's what Omega things on the number of positions typically that be three. Chronometer five which agrees with Rolex and master chronometer get six positions. the testing positions of course does bring up an amusing problem of having a witschi timing machine that checks the watch and six positions when as far as timing specifications go we really wouldn't have to other than it's nice for evaluation purposes. 8643_WI_81 BASIC CHECKS AND SETTINGS OF A MECHANICAL WATCH_EN cousins UK.pdf1 point

-

Today on this fine Sunday morning in the North of England, adorning my wrist, I give you this 1968 Citizen Dandy Seven Custom, with the 27 jewel 5204 movement. I've had this for a while now and it gets fairly regular wrist time and keeps excellent time. I had been on the look out for a dandy seven for a long time, there doesn't seem to be many around in europe sales, a few in Japan and they are normally quite pricey. Then this appeared on ebay and it didn't look good, but I risked the gamble. When it arrived it was even worse than the listing photos showed, a real sorry state. Removing the caseback revealed a completely green movement accompanied by a strong smell of old perfume. I can only guess that someone thought perfume might free up the movement, the setting lever spring was broken so not much achieved with the perfume rinse. This contamination took its toll on the movement and dial though, a lot of plating lifting and a furry crust around the dial. So this will never be a showpiece but I saw it through. Everything cleaned up well but there are scars, eventually sourced a replacement setting lever spring. When the balance dropped back in, fired straight into life, regulated very well and as said previously, keeps excellent time. So although it's a bit scruffy, I've got my dandy seven and I love it. Timex coming on well, movement ticking away working the oil around the escape, but my word ... that escape wheel and pallet. Let me tell you there was some adult language at my workbench getting those two back in.1 point

-

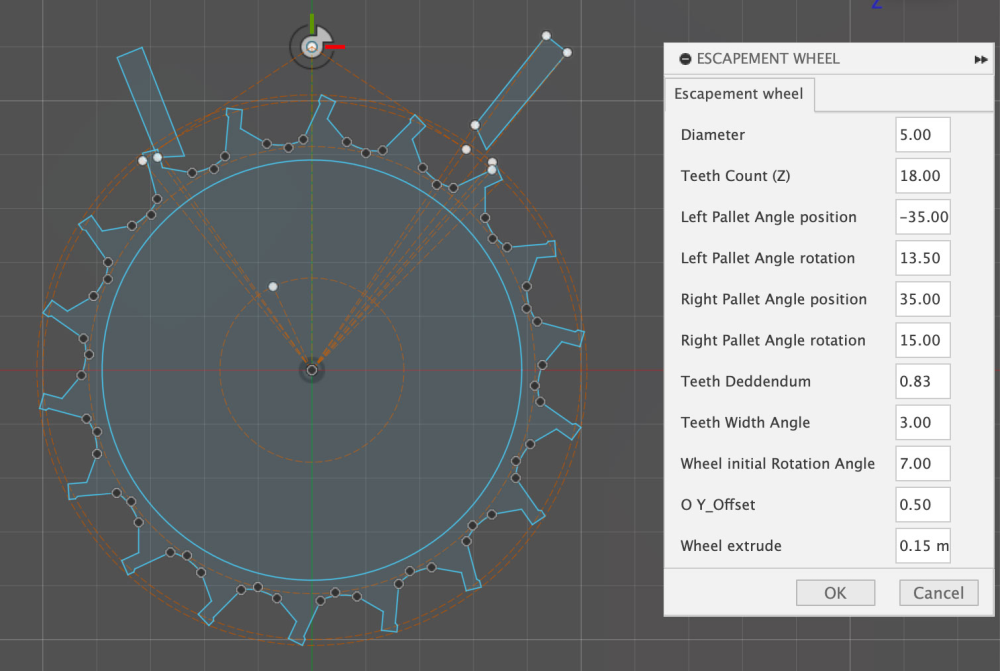

Hi, just a bit of an update Kept working at this escapement+pallet drawing tool, reading more books, and experimenting a bit more, and reached some deeper understanding, Im actively working on this script for fusion360 (adaptable to any software) that can modify angles, which when animated allow me to see if the wheel will work or needs modification (takes less than a minute). Basically I couldn't find a function for all scenarios, but rather manual tweaks that paired with fast animation, allow me to find an escapement wheel. e.g on the NIHS rules vph of 18000, 21600 28800 are suitable, but 25200 is not (I dont know why), so based on the train of wheel ratios I decided on, a 18 tooth wheel is ok for 21600 vph, and 24 tooth for 28800, but 24 tooth is considered super high, so Im gonna give it a go at 18 on the initial prototypes.1 point

-

mikepilk, that Longines is a beautiful looking watch, I'm now on the look out for one. What's on my wrist today ... I present this Fero with the 15j EB 1344 movement. Well to be honest, it's not really my cup of tea but I chose to give this a chance really to have a bit of practice on smaller movements. I was a bit taken back when I realised it is a pin pallet, I assumed out of those 15 jewels two would be on the pallet, but even better for my practice. Thanks to the exhibition caseback enabling spectators to marvel at the movement, visible was the second wheel rattling about loosely and could see the balance seemed ok and trying to go. The acrylic with the hour markers is basically a movement ring so all comes out as one. Stripped down and cleaned up really well, bit of wear on the movement plate centre hole, but what I did notice was that some of the jewels holes seemed way too big for the pivots, they didn't look worn at all, nice clean crisp lines and symmetrical holes, was this sometimes the case for cheaper grade movements? The balance hairspring is fixed post and I didn't look forward to messing with this if the beat error was way out, visually it didn't look too bad. Put on the timegrapher expecting poor readings, amplitude 260+, beat error 0.4, I'll go with that but running way too fast. Achieved +3 seconds but this was going up and down, I'm thinking this will settle down when the oil makes its way around the escape? Like I said, not really my style but seeing as it's running fairly well, I'll give it a wear for a couple of days. Timex next, pulled all the ones I've got out for a post yesterday, never done a Timex but now they're out, now is a good excuse. So if you read this JerseyMo, know that someone in Lancashire UK is scratching there head attempting a Timex automatic with a rotor with about 3mm of play1 point

-

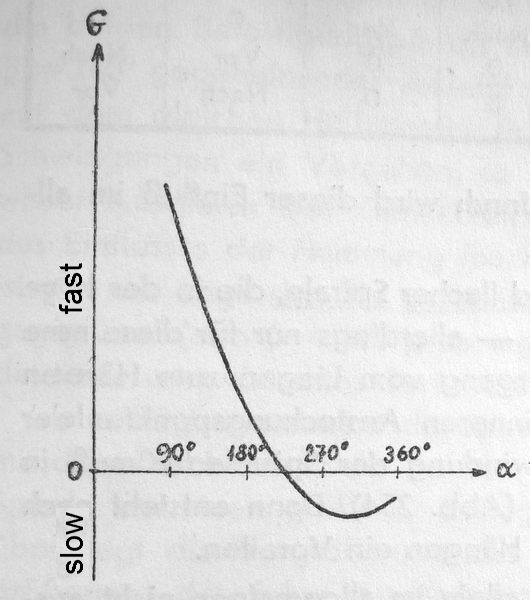

The higher the amplitude, the more stable is the swing regarding timing. Shocks have less influence on timing, and escapement action is a series of pos. and neg. shocks, too. With standard value 270° flat you will get near 220° vertical, at least after some hours. This is a magical number, as poise errors have zero influence at 220. So choosing 270/220 was quite clever. Frank1 point