Leaderboard

Popular Content

Showing content with the highest reputation on 10/15/24 in Posts

-

As an enthusiast, I have limited access to official documentation. Still, from what I've observed in the documents shared by @JohnR725 and others (Thank you!!!) from some major manufacturers, such as Omega and Rolex, I never saw any documentation stating the 270° magic number for amplitude at full wind in the horizontal positions. Hence I don't pay much attention to the 270° idea. In these documents amplitude is typically given as a minimum in some vertical positions after 24h (often 200°) and as a maximum in the horizontal positions at full wind (usually around 300°). Trying to achieve these numbers has kept my sanity intact and I have been a much happier enthusiast ever since. Just seeing the number 270 makes me feel slightly depressed as it almost made me give up on this wonderful hobby before I knew better. I think this quote says most of it!3 points

-

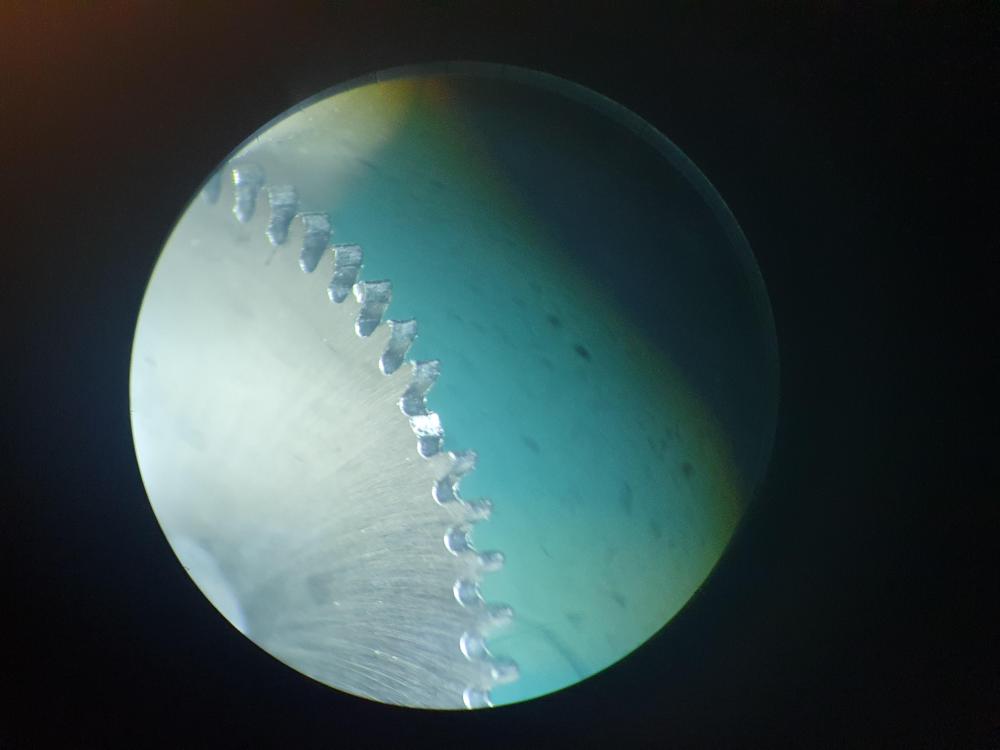

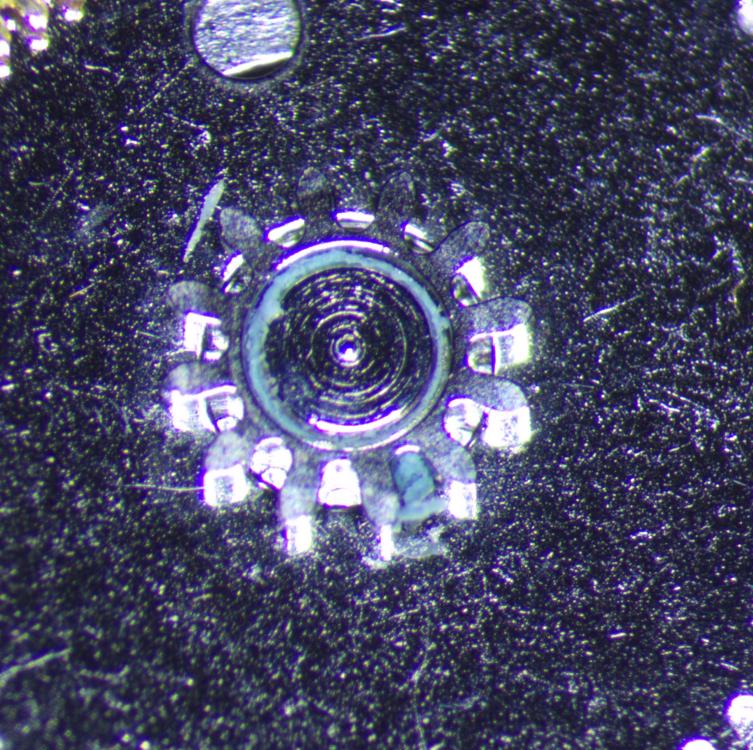

Repairing the ratchet wheel is possible, but it will look ugly no mater how many painstaking applied. Making new one is the solution here. Of course, the best solution is to leave as it is. But the main thing to know here is how this teeth break so to avoid breaking them here and in other movements in the future. When winding, never release the crown to turn back until the click locking suddenly by the spring force. Move fingers to rotate forward and back without releasing the crown2 points

-

2 points

-

I see the problem that you don‘t have any immediate reference how well your movement is doing. < 300 is trivial. Else you will have to wait for 24 h after each measure?2 points

-

Do you know that an ultrasonic cleaner can generate more than 120dB of sound in a enclosed room? I think most of us here are over fifty years old and the natural decline in hearing of high frequencies allows us to be in the same room as a working ultrasonic cleaner. When I was still working as a dentist, whenever I had a young child in my surgery and the ultrasonic cleaner was turned on, they would cringe and clap their hands over their ears. I tested the noise level in the room with the ultrasonic cleaner and was shocked. My cheap Radio Shack sound meter went off the scale, even as far as 6 feet away. Even the tiny ultrasonic scaler that we used for cleaning teeth can generate more than 120dB at a distance of 1 inch away. I can't imagine the actual sound level the patient is subjected to when the tip of the scaler touches the tooth and the sound is conducted through flesh and bone to the eardrums. No wonder patients never like going to the dentist. And why most dentist are hard of hearing. But coming back to the topic, ultrasonic cleaners come in different powers. My mentor uses a 60W and he throws everything into it, including pallet forks and balance wheels and never had any problem. I have a 120W model and have lost shellac after a 10mins of cleaning. So now I only clean the pallet fork by hand.2 points

-

1 point

-

1 point

-

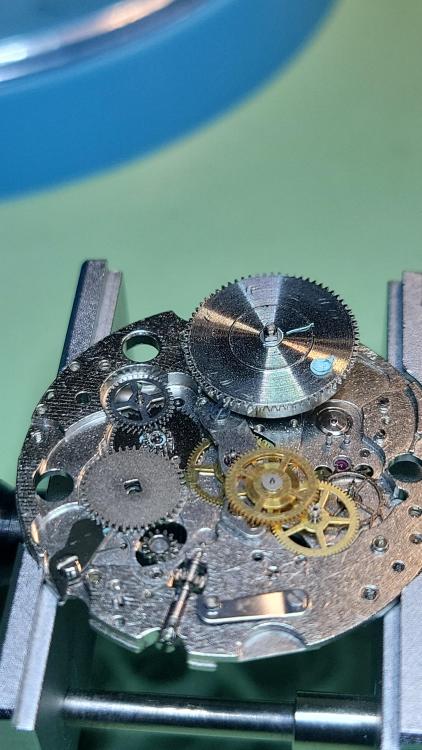

Well, I've made and fitted a new pallet fork staff, replaced the pallet jewels and straightened the seconds hand pivot. The pallet fork locks and unlocks the escapewheel so I'm itching to see if she'll actually run, but there's another thing that needs fixing first. The ratched wheel is missing a tooth. Yes I know it will still work without it, but what's the fun in that..? Can anyone tell me what the recommended method for this is? Making a slot with a small saw, solder in a new piece and file it in shape? If so, brass or steel?1 point

-

1 point

-

1 point

-

The barrel may have been roughed out, then later machined for the lid (for example). That would open the possibility of the lid mating surface not being perfectly concentric with the barrel hole. A lid would be fabricated, fit to the barrel, then the barrel centered up in the lathe, lid fit, and hole bored. They had techniques to center up stuff really well, but it's time consuming so they might cut corners on lower end stuff, or if there was a way to make a certain eccentricity a non-issue. Some books show boring the mounted cap and barrel in the same operation.1 point

-

The setting lever is a complete unit with the 3 pointed star gear so isn't available as a separate item. The 5 pointed star is part of the calendar plate so again not available as a separate item.1 point

-

What is seen on the first video (by the hairspring breathing) is that the amplitude is really high. The other thing seen is that when expands, the hairspring probably touches the stud. So, what You can do is center the hairspring better as it will stay a little away from the stud. Then, check You amplitude. One way to do it is to put a dot with marker on the balance rim and observe it's movement. The other way is to check if the lift angle for the movement is different from the magical number 52 and insert the correct number in the timegrapher. And if really rebanking happens, then You can return the old spring and check what will happen then. Yes, You can close a little the regulator pin. But it will not solve the problem.1 point

-

If you get a new crown tube it comes with a gasket. Sorry but once again the 7935 appears to have fallen into a black hole when it comes to back gaskets. I've got various sites where I've varying rates of success. The 7965 back gasket details were found here. https://perrinwatchparts.com/products/generic-not-genuine-flat-gaskets-pkg-of-3-individual-sizes-to-fit-rolex-replacement-for-29-287-105-click-to-see-case-numbers @mikepilk Have you got the old gasket along with the back to take measurements?1 point

-

1 point

-

Same here, but I don't really need it. The values in those documents are specifications; instructions within that organisation, defining hard and fast targets which the service centres have to achieve. They are by definition company- and movement-specific (although inevitably generic to a large degree). What we are talking about here is a rule of thumb, an indicative value which gives you some useful initial information about the "health" of the movement. In isolation it is practically worthless, and it isn't a target in itself, but if you aren't seeing it, then you it should give you pause for thought. I'm struggling to understand why you can happily work to these values as targets, but not accept 270 degrees as a reference point or initial indicator. Essentially, they are bound together and dependent on one-another. Usually, the vertical positions will have lower amplitude than the horizontal ones. The difference will usually be at least 20 degrees but could be as much as 50 degrees. After 24 hours the amplitude will also have fallen, which will also be a loss of around 20 to 50 degrees. So how can you achieve a minimum 200 degrees vertical, if you don't start somewhere around 270 horizontal on a full wind? Incidentally, do you understand why 200 degrees is set as the minimum amplitude for vertical positions after 24 hours? One big reason is the sensitivity to heavy spots on the balance. At exactly 220 degrees, poising errors do not affect timing. Below 200 degrees, the effect of poising errors increases rapidly. So keeping amplitude above 200 degrees for all positions over 24 hours makes a significant contribution to good timekeeping, even if the balance assembly is not perfectly poised. It's a shame you got so hung up on it back then, but don't let that stop you from using it to your advantage from now on. Interesting that you omitted the part of the quote which made clear that he's talking about an exception! What about some documentation to which you do have access? What books do you have? De Carle's Practical Watch Repairing and Gazely's Watch and Clock Making and Repairing both mention the importance of at least 3/4 turns of the balance (in one direction, i.e. 270 degrees) on a full wind. This was back in the day before timing machines, so it was easier to visualise fractions of a rotation than degrees. Jendritzski's The Swiss Watch Repairer's Manual is more modern, but again you can find him talking about the importance of 270 degrees horizontal (and enlighteningly, the 220 degrees vertical). Maybe you have some different books, but most of the "general introduction to watchmaking" works will probably mention it.1 point

-

I think your new mainspring is stronger than the original. What size spring did you put in?1 point

-

Yes the PZ5072 should be original but be careful where you buy from and ideally you want to see it in it's Omega packet. https://www.passionchrono.com/en/omega-136-0020-verre-glass-pz50721 point

-

My advice will be to check for overbanking in DD position. Amplitude readings... Learn to see amplitude by observing the balance, what is seen on timegrapher is not always relevant. Of course, it may be some kind of hairspring problem, but may be just stronger mainspring. There is difference DU/dd, which needs investigation.1 point

-

This is super helpful! I have been pursuing the ebay seller to consider shipping to me in India but she is very reluctant. If that doesn’t work then I will order the Zodiac 10 part and keep my fingers crossed for fit. Thank you so much AndyGsi and Manskirtbrew, I wouldn’t have figured this out without your help. This forum never disappoints!1 point

-

Mostly fear, as I haven't actually got my hands on some cleaning solutions you guys have, bad results though in ultrasonic with all solutions in my disposal. Wonder if my cheap ultrasonic has to do with shellac loss. Rgds1 point

-

1 point

-

the problem sometimes with photography and my reading skills are I'm not 100% sure what your case number is? In other words 62? Like maybe 6267 or 6287 which by the way both exist which would be a problem? So you can go to this website http://cgi.julesborel.com/ and in the search box enter it in what I have below ome CS#62 you'll notice that I'm only doing a partial number is I didn't know the rest and that is helpful in that it gives us a nice big list so you have both numbers to pick from. When you click on the number you'll get a list of parts which will give you the crystal number then somewhere out there will be generic crystals but with a case like this the crystal is key it really is important to have the right crystal in other words I would try to stay with the original mega crystal. You'll notice that the crystal itself as the inside ring that's the other problem with generic crystals it has to be shaped correctly. Then if you can only find a white crystalline other was a white metal ring you can take the ring out of this one providing it hasn't been damaged and swap with the other one so that gives you another option for a crystal1 point

-

This discussion has expanded beyond my initial query, which is fine. For balance wheel, I've taken to mounting it on the main plate, removing the jewels (and closing the springs) then into the machine in its own compartment in the basket. Is that ok? The jewels I do in one dip.1 point

-

We need picture of what is inside the barrel. From what You describe, the conclusion is that the barrel arbor is somehow stuck in the barrel. What the pallet fork does is to block the movement of the wheel train. But it is part of it's normal function and the train doesn't need to rotate to allow for ratchet wheel rotation, unless the spring is already wound to the end.1 point

-

now that it's out for future reference can you give us a picture of the case without the movement so everybody can see the locking ring. then a picture of the back side of the movement so people can see the locking tabs on the movement themselves. probably warped because somebody was trying to pry their movement out not recognizing that its locked in place with the ring.1 point

-

One thing you can do if you remove the spring is to place it on the upturned cock, centering the collet over the jewel, and observe where the regulator pins are in relation to the coils. Now you can form the curve over that coil (or between two), sort of a built-in guide. When you're happy with the curve, most of the final adjustment should be right near the stud- and you can check this with the spring off as well.1 point

-

I don't really see many Seikos (like 1 every 3 or 4 years?) but they seem to be known for running lower than 270 amplitude. Likewise, I might have worked on one Russian movement years ago. But for other stuff, regardless of age, I do go for a healthy 270 horizontal. I am doing this for paying customers though. If I am under, I will figure out a way to get it up (and 99 times out of 100 a new mainspring isn't the answer). That often entails adjusting the escapement, which I do very frequently. There are exceptions; for example I had a nice little Piaget 9P in last week, which hit 255 or so horizontal. However, it only dropped to 240 in vertical, and had a 15 second delta over 6 positions, going to 20s at 24h and amplitude staying above 200. So I let it go at that.1 point

-

Yes, thou shall not worship the holy timegraph machine but in my experience praezis alert is quite correct. If you are working on a quality movement in fair condition and don’t see the magic amplitude number it may be telling you something is amiss… Something amazing happened to me in my watch journey- as I learned to discover more defects and faults and my skills improved at correcting them and I learned a few tips and tricks to easily improve amplitude…amazingly! the quality and condition of my movements improved AND when they don’t meet or exceed the magic number I almost always discover a reason why. Sometimes the reason is ‘because this is a Seiko’. More often it’s because there’s something I missed or something I could improve… …In conclusion: take the number as a hint…1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Once again, a short lived victory. I used a little blob of Rodico to hold the setting lever in place while I clipped it in from the other side of the movement. I immediately forgot about the Rodico and started winding the movement until I noticed it felt funny. Yes, I wound the Rodico into the whole train, the riveted wheel on the plate, and looks like onto the barrel arbor and inside the barrel. Which means I have to strip the movement back down to the plate, take out all 43 of the cap jewels, and start the whole cleaning process over again. SIGH0 points