Leaderboard

Popular Content

Showing content with the highest reputation on 10/17/24 in all areas

-

Today its the turn of this Tissot 2030 powered early quartz Limit International to enjoy a little of the Autumn sunshine. I've shown this one before, but it is a bit of a personal favourite, with its spectacular blue dial. It came with the original box, instructions and "hair puller" steel band. Currently I have it on a quick release navy blue soft suede strap and I must admit I'm pretty enamoured with it. I should wear it a lot more. The Tissot 2030 (from around 1977) has a rather unique setting mechanism, which confuses anybody who is used to the more conventional method, hence they are often listed as not working, spares or repair or whatever. They generally work just fine if you take the time to read the instructions. More details about the Tissot 2030 calibre here -> https://www.crazywatches.pl/tissot-seastar-2030-quartz-19773 points

-

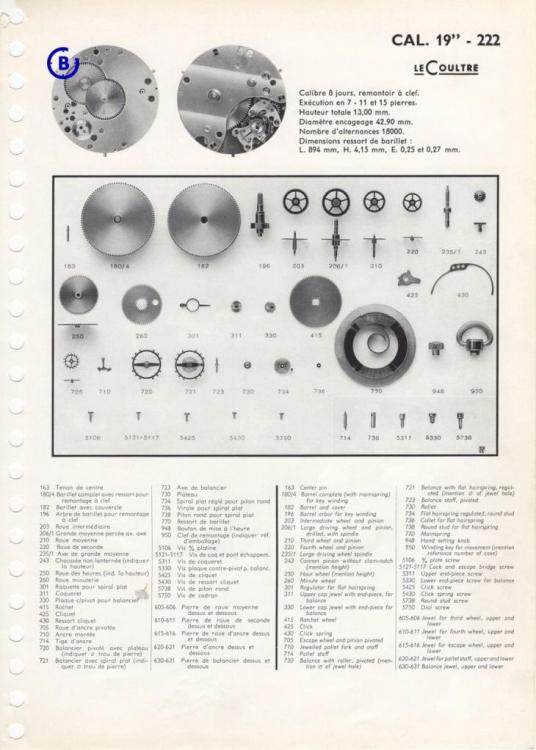

Digging around it seems to be on the cal. 222 base, I also saw one marked 228 with the same bridge layout. Didn't see a staff for it anywhere, but you never know- it's worth calling and asking at material houses sometimes. Jules Borel list the staff as compatible between 201,202,206,207,208, 19.41 and 22R movements.3 points

-

2 points

-

If it's a metal case then to make it safe it should have an earth connection. That way if anything shorts to the case it goes to earth and not via you should you touch it.2 points

-

Dial feet soldering has a very steep learning curve and you'll probably end up destroying your first dial. But once you got the hang of it, it's really satisfying. But not all dials can be soldered. Only brass dials will solder nicely. Some modern dials are made of aluminium and that can never be soldered. So, glue dots, glued dial feet repair kits and plain rubber cement are still viable methods.2 points

-

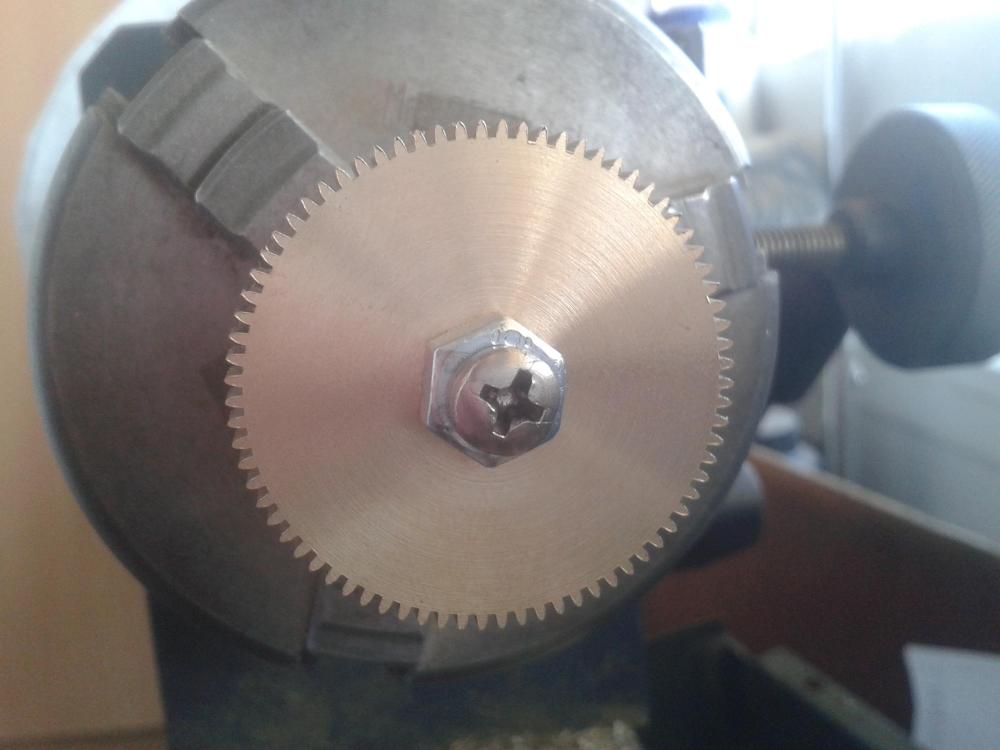

Some important things. Making brass gears with fly cutter is a piece of cake. You can make the cutter of HSS, even of tool steel, and it will cut many wheels without significant wear. The cutter itself is easy to form, as the hardened steel is easy ground by dremel tool with small carborund disks (dental separators). The cutter needs high speed (RPM) and doesn't overheat. But, cutting gears of steel is another thing. Only special steels can cut steel, even soft steel. Hardened tool steel cutter, even HSS one, will not cut more than the half of this wheel before getting complitelly dull. And sharpening of fly cutters is possible only in limited cases of cutter design, and sharpening in the middle of cutting process is not wanted as the teeth may get not equal in different parts of the wheel. Lo RPM and lubrication needed in order to avoid overheating and damage of the cutter. On other hand, if cutter is made of tungsten carbide, it cuts easy soft steel and even possible to cut hardened and annealed to blue. Cutting such ratchet wheel of soft steel is easy and high RPM are used, even with no need of lubrication. The main problem here is forming the carbide cutter. Only diamond grinding tools work here, so such small diamond disks needed and some practice to learn how to form the cutter. Once the cutter is formed, then the wheel cutting is easy. Will try to show how I form the cutters I will show the design of the milling attachments I use on my lathe. The construction is simple and easy to reproduce, it is based on using a double row ball bearing from the head block of a computer hard drive. I must search for some old pictures and make some new ones, so give me a little time. There are some videos in my Youtube channel that may help to understand the way the attachment works, will give the links to them.2 points

-

It is clearly seen here that the side wall of the barrel is broken, thus no wonder if the barrel is distorter when the lid is put in place. You need to replace the barrel, so now is the time to make one. The answer to the 'interference' question is simple: decrease the lid diameter until it snap fits well to the barrel, or increase the diameter of the place in the barrel until the lid snap fits well in it.1 point

-

1 point

-

My point was that I wouldn't expect a dial finisher to want to be bothered just fitting feet.1 point

-

usually companies that refinished dials can replace dial feet I suppose it depends upon where you are on the planet. I used to know somebody that a Swatch group account because they were selling one of the Swatch group products. Then that also sent a watchmaker to the school and once you do that and they complete the basic watch rule class that's like half a week or week or something then they can access the complete database. I strive or what the official term is so not authorized Swatch group there Swatch group something and then yes they can order movement parts. But typically nobody's going to order a component for you there are going to want to in the case of a dial probably service the entire watch. This is because if you were to change something like a dial in the watch didn't run then you might be unhappy and want your money back or something so typically it's all or nothing.1 point

-

Hi Ibrahim, Welcome to the WRT forum and good luck with your journey in horology .1 point

-

Well today marks a special event, a personal horological milestone, a wrong has been righted .... righted? Well you may be asking what could this grand announcement be, the event in question is that a Timex has been on my wrist for the first time, that I can remember anyway. I proudly present this rather well worn 1971 Timex Viscount with the M32 movement ... if my googling skills are up to scratch! Ok, so I finished this last night and have been giving it a test run all day, was 10 seconds fast when I set it and it's still 10 seconds fast. As previously mentioned I had one hell of a battle getting the escape and pallet back in, the source of my stress was the setting lever spring hampering one of the posts I'd left loose from locating back in it's hole, once I'd noticed that and one last struggle and miraculously without causing damage, I made it through. The rotor with way too much play tightened up perfectly with a few gentle taps with a stake to the pivot rivet at the back of the rotor, nod to JerseyMo for that, thanks. The beat error was off the scale, all set up nicely thanks to the mark on the balance. Wasn't expecting good readings but was very surprised with the good end result. The movement holder is now vacant and this next watch has been waiting patiently. Anyone got any information on this? I can find nothing on the watch and very little on the movement.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. If there is anything we can help you with don’t be afraid to ask. Nice clear photos can help a lot.1 point

-

1 point

-

I checked out your youtube. You're very resourceful! I might have to steal the idea you have on your homemade lathe having the length indicator on the back side. That would make turning balance staffs much easier. I also want to make a pin vice holder to have the reference staff near the chuck so I have a constant reference.1 point

-

1 point

-

1 point

-

I must admit, that until a couple of years ago, if I came across a Limit watch in a lot, with no hesitation it would be discarded into the junk pile and never thought of again. That is until I came across one and happened to notice that it had made in GDR on the dial, and was 36j automatic. Proceded to remove the caseback to see what was going on in there. Inside, a wonderful Glashutte spezimatic. I will wear it soon and put some pictures up. Needless to say that Limit watches are now firmly on my radar, I had no idea Tissot also supplied movements, I do have another with Swiss FHF movement. Fine looking watch there Andy1 point

-

Just an update on my Atmos project. I've disassembled the clock, cleaned and only oiled the mainspring, mainspring pivots and 2nd wheel pivots. Checked poise and beat error of pendulum. Straightened bends in the pallet fork and poised it. Checked and adjusted clearance of pallet fork and guard pin. But the clock still refuses to run. The only thing I haven't addressed is a bent banking pin. There have been so many discussions on this forum advising to leave banking pins alone that I was hesitant to straighten it. I spent almost an hour observing the escapement last night and have come to the conclusion that the bent banking pin is preventing the unlocking of the entry pallet. It is unlikely that a high-end movement like this JLC would need the banking pins to be bent. So I went for it and straightened it. The entry pallet now unlocks properly. I have left it to see if it would run overnight. That banking pin couldn't have bent on its own. ( I know I have gremlins in my house, as @oldhippy says...) But I think this was a deliberate sabotage by an unscrupulous clockmaker who probably wanted to charge an arm and a leg for servicing the clock and when the owner refused, he bent the banking pin to give the next clockmaker a hard time. What do you guys think?1 point

-

sometimes watch companies are really good at hiding that they made the movement. Then of course sometimes really good at not putting markings on the movement. I once found the Le Coultre under one of the bridges a place where you normally wouldn't think about looking to find it. then one of the ways helpful when looking for a balance staff is if you have the dimensions. Usually the cross reference sources will list dimensions and even if you can't find your model number you may find that one of their other staff may be of the right dimension as they don't always fully cross-reference everything. Or basically you're lucky you use the same staff in another one of their clocks1 point

-

So from the number and description I presume this is your watch taken from an eBay listing. My suggestion would be to find a decent watch repair guy as refitting dial feet shouldn't be a problem. Edit Looks like this is yours with the blue dial. And this is possibly the dial you're looking for. https://www.ebay.com/itm/285404259041?_skw=tissot&itmmeta=01JABH16X3AGXG671B3R3AD143&hash=item42736b62e1:g:JSYAAOSwi-5j1oYs1 point

-

It could be the photo but the case engraving doesn't look that crisp compared to this one. https://bulangandsons.eu/products/cartier-tank-must-61008-burgundydial-boxandpapers-w28661 point

-

1 point

-

1 point

-

Hello all, I do have a microstella tool, but I've never dared to use it.... but I'd like to try. The thing that worries me the most is to hold the balance with tweezers (while doing the adjustment). The rationale is to do this to prevent putting stress on the balance pivots, but I'm scared that holding the balance will cause stress and possibly bend the pivots.. or do you think that's an exaggerated worry? This looks very nice in terms of amplitude, delta and beat error. Congrats! But, of course, the average rate is now the debate.1 point

-

Actually, there is no matter if the barrel is eccentric or the lid. The idea is to make a lid that will compensate for the eccentricity of the barrel, no mater how big it is. Making a lid is much more simple than making a barrel. OP, so You need to make new lid. The idea is to turn one with the same sizes, but with no hole. The new lid must firmly snap in place on the barrel. You must do on the lid's periphery the same cut place as on the old lid and remember to put the lid on the barrel in only one and the same position - with the cut place to cover the hole for the chain hook in the barrel. Then, You need to grasp a big rod in the lathe and turn it's face to look like this The 'pivot on the top must fit the hole of the barrel. Then You fix the barrel (with the new lid placed) with shellac on the face of the rod as shown here. The rod here is in red, the barrel is green and the lid is yellow. The idea is the down side of the barrel to lay well on the face so it will rotate true. If there is some axial wobble of the cylindrical part of the barrel, it is no important at all. Then, the lid has to be drilled and the hole enlarged to fit the arbor pivot.1 point

-

1 point

-

this is a bit peculiar for several reasons? First when I was in school I was taught to reassemble the basics of the keyless parts first. As you have a calendar you do not install this until much later on. But you can't get the stem and its associated components in first as you really going to need them. Then when you put the gear train together makes it a lot easier to wind the watch rather than the screw head which is not a good method especially on the Swiss watches. Seiko some Seiko's cannot be wound from the crown as are an automatic watch only the air ratchet wheel screw head is specifically designed that you can wind the watch. A lot of times with Swiss watches the screw head will break off. Then you have the other problem of how to let the power off where it's much easier to have a stem and crown versus trying to break the screw head off letting the power off. if you remove the pallet fork what happens?1 point

-

Making a Printed Circuit Board watch dial. Hackaday link to their related article -> https://hackaday.com/2024/08/26/turns-out-a-pcb-makes-a-nice-watch-dial/1 point

-

I would like to share a check list made up by a master watchmaker. I take no credit for it, only think it would be helpful for us hobbyists. Here it is! CHECK LIST I decided to write up what is called a 16 point check that is meant to be a guide to steps required to service a watch this is slightly bias towards a wrist watch but very relevant to pocket watches also: This is a guide and not the definitive answer after going through it a few times add you own additional tests and observations. This is of course for a basic time only non-automatic or any with additional features, I also leave out things like demagnetizing, actual cleaning procedures, a good chunk of common sense needs to be applied also as I say its meant as a good starting point to a correct disciplined procedure, This is version 1 may add or edit/delete later. Check number 1 a Check the winding to see if the mainspring is broken. b Check to see if the setting bridge or sleeve is broken by pulling the stem out and testing the proper snap of stem. A broken setting bridge/sleeve is easily detected c. The balance wheel should be oscillated to see that it is true and the balance pivots should be checked by looking through the upper jewel to see that there is not a flash on the pivot. d. The hairspring should be checked to see that it is not damaged. e Check setting of hands f. The watch should be looked over in every respect, paying particular attention to any rust spots that may appear on any part of the movement. When rust is evident around the stem or setting mechanism, it is most important to remove the dial and hands in order to check this mechanism to see if the rust is very extensive. Check Number 2 a. Examine each part as it is being removed from the movement. b. Check for rust on every part. c. Check every pivot to see that it is not damaged or bent. d. Check the jewels in the watch, to see that there are no cracked jewels. e. Check pallet stones to see that they are not chipped or damaged. f. When removing barrel cap, make sure that it snaps off only after sufficient pressure has been applied to it. g. In the examination of each part, a close check is not made at this time as many of the parts will not be clean enough for that purpose. a much closer check will be made on the parts as each part is handled in the assembly of the watch Check Number 3 a. Upon completion of cleaning and parts removed from the basket into the assembly tray, each part should be checked over with the use of a watchmaker’s loupe special attention should be paid to the jewels, because if there is gum oil still remaining on the jewels, the cleaning job was not done satisfactory . It is also worthwhile at this time to examine the pivots. If the jewels are clean, and the pinion leaves are clean, it is almost certain that the cleaning operation was performed effectively. Check Number 4 a. Examine the condition of the mainspring. b. Check the width, strength and length of the mainspring. c.. If correct, replace mainspring using correct mainspring winding tool, not by hand d. Check the lubrication of the mainspring if required e. Check the fit of the mainspring around barrel arbor. f. check the mainspring end for proper shape to catch in barrel. g. Check the snap of the cap on barrel and replace in correct position h. Check the end shake and side shake of barrel arbor is it also sometime recommended to do this without mainspring fitted to test for free run and end shake i. Check the cleanliness of the barrel and barrel teeth. j. Check the oiling of the barrel arbor after the cap is on. k. Check the condition of the barrel teeth to see if they are bent or worn. Check Number 5 a. Jewel holes must be cleaned with peg wood if necessary. b. Jewels must be checked for chips or cracks. c. Check the train wheel pivots for rust, polish, cuts and straightness. d. Check the pinions for rust’, pits and polish. e. Check the pivots for pitting check that clean pith wood is being used. f. Check plates for tarnish, fingerprints, and polish jewel settings. g. Assemble time train and check end shake and side shake. h. Check wheels for trueness arid upright. i. Lift each wheel with tweezers to check for end shake and to see if each wheel is free enough to fall back to its original position. j. Spin train to see that is spins freely, in dial up, dial down and a vertical position. Check Number 6 a. Replace barrel and barrel bridge and check the oiling of the barrel arbor upper and lower bearing. b. Check oiling of crown wheel. c. Replace ratchet wheel. d. Note: do not oil remainder of movement until after kick-back is checked or cap jewels are present oil those now e. Wind watch slightly to check kick-back and recoil. This check should be made in dial up and dial down positions. If the watch does not have kick¬back, this indicates that the train is not as free as it should be. First, however, before checking into the train itself to determine if there is some frictional error, it would be worthwhile to examine the mainspring around the barrel arbor. Many times the loose fit of the mainspring around the arbor will prevent kick-back from occurring within the train. In such instances, the arbor is simply slipped in the mainspring instead of the train receiving the reversal torque, that normally occurs. If the barrel is found to be satisfactory, then the train. should be checked to see if the trouble can be located. first, the train should be examined carefully to see if each wheel is free, and if no trouble can be found, then it is advisable to remove the train wheels from the watch and replace each wheel in the watch individually and to check the spin of each wheel. If each wheel spins freely, this indicates that the pivots and the jewels are in good condition and that one need not look further for defects or faults in those areas. Next, place two wheels at a time in the watch and check the spin of the wheels. Thus, any error of improper depthing or a badly formed tooth on a wheel or pinion will be detected. It is simply a process of elimination in order to locate the particular trouble, and of course, proper corrective measures must be taken to correct an error when one is found. Check Number 7 a. Oil all the train jewels in the watch, and at this point it is advisable to oil also the balance jewels. b. Check to see that there is a ring of oil around each train pivot and that the jewels are not over-oiled or under-oiled. c. Check the jewels that have caps to see that the globule of oil has been formed properly between the flat cap and curved hole jewel and no keyhole shape if so remove re clean jewels and check seating the re oil and repeat check for perfect ring. Check Number 8 a. Oil stem properly. b. Oil friction parts of setting. c. Oil wolf teeth of clutch wheel and winding pinion. d. Oil clutch wheel groove. e. Oil points on setting lever that contact the setting bridge or the clutch lever. f. Never oil dial train. Note: ‘dial train means all wheels following center wheel staff. g. Seek expert advice on some types of intermediate wheels connecting clutch at setting positions that require oil. Check Number 9 a. Check condition of pallet arbor pivots. b. Check for chipped or loose stones, shellac or gummed oil on pallet stones. c. Check guard pin for straightness and proper shape. d. Check polish of pallet arbor, pivots and fork slot. e. Check end shake of pallet fork. f. Check height of pallet stones in conjunction with escape wheel teeth. g. Check matching stones. h Check drop lock i. Inside and outside drop. j. Draw. k. Hang-up of stones on escape wheel teeth. Check Number 10 a. Check tightness of roller jewel in roller table - uprightness of roller jewel. b. Check the height of the balance wheel in conjunction with the fork bridge and the center wheel. c. Check the clearances. d. Check the height of the guard pin in relation to safety roller. e. Check the proper length of roller jewel and fit of roller jewel to fork slot. f. Check the guard clearance. g. Check the corner clearance. h. Check the jewel pin shake. i. Check the guard test, j. Check the corner test. Check Number 11. a. Check the hairspring in-the-flat. b. Check the hairspring in-the-round. c. Check the quadrant of the hairspring to see that it is formed properly between the regulator pins and stud d. Check for beat of the watch by equalizing the force to receiving and discharge pallets. e. Check for the collet wobble. f. Check for trueness of the balance wheel, and for the flash of the balance pivots g. Check for trueness of roller table. Check Number 12 a. Place the watch on the timing machine and take a rate in the dial down position, then turn the movement over to dial up position and take a rate. There are three things that should be observed from the rate that was taken: 1. Dial up should indicate the same time as dial down. 2. Observe the closeness of the lines to determine if the watch is in perfect beat. 3. Observe how the watch is running in reference to the time error over a 24-hour period. b. Adjust the mean time rate of the watch so that the dial up and dial down positions will record on time. Do not move the regulator more than one degree in adjusting the mean time rate. Any other alteration must be made by adjusting mean time screws or by adding or removing weight from the balance wheel in such a manner as not to affect poise, static or dynamic,. c. If the rates in dial up arid dial down are found to be different from one another, then this indicates a mechanical error in the watch which must be traced out before proceeding. d. If the watch is found to be out-of-beat, then of course, it should be put r in proper beat at this time. We might emphasize that if the watch was put in proper beat in accordance with the proper procedure at the bench, then an out-of-beat condition or minimal amount would not be indicated on the timing machine. e. When the above conditions have been satisfied, the next step would be to take a rate in positions and errors corrected. If everything has proved to be satisfactory, the watch should be tested for isochronal test be made on the timing machine, which consists of re-testing at different winding levels and rate in the dial up position. Check Number 13 a. Check for proper lubrication of cannon pinion on center post. b. When replacing the cannon pinion, be sure that the leaves of the cannon pinion do not come down on top of the minute wheel teeth so as to bend the teeth of the minute wheel. c. Check tightness of. cannon pinion d. Check to see that cannon pinion does not ride up when watch is being set. and smooth consistent operation. Check Number 14 a Make sure that the hands are fitted securely to the parts to which they are attached b. Make sure that the hands are adjusted so that there is equal space between the hands and the hands are set as close to the dial as possible. c. Check to be sure that the hands are shaped to the contour of the dial. d. Check to see that\ the hands are positioned so that they are synchronized with one another. Check Number 15 a. If there is no case for the movement, simply disregard this check and proceed with the next check, number 16. b. Check for proper snap/screw back of the case. c. Check for the clearance of the hands under the crystal. d. Check the crystal to see that it is securely fitted into the case. e. Check to see that the crown is next to the stem and reasonably close to the case. f. Check for tightness of movement in case. g. Check the spring bars to see that proper spring bars are used for the particular type of case so that the band is held securely to the case. h. Check the lug holes to see that they have not been worn badly by the spring bars to a point where the hole may break through and allow the spring bar to come out of place. Check Number 16 a. Set the watch on time with a master clock. b. Let the watch run for a period of 24 hours and check the error in the time repeat in several positions. c. Allow the watch to run until it completely runs down and check the length of run. The watch should run a minimum of 30 hours, preferably 40 hours, if it is in “A. I have no answers to any of the steps since I didn't make this up. Maybe Mark might.1 point

-

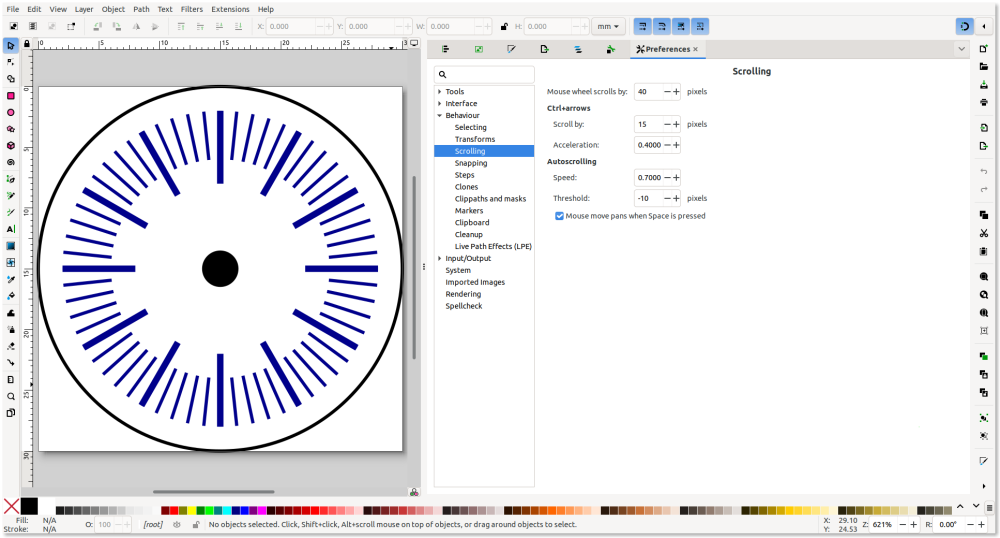

I feel I should call this post "Artificial Intelligence creates a watch dial." I present possibly the worlds first AI generated python code to produce an SVG graphic for a 30mm watch dial. First... I went to ChatGPT and asked it the following question. It responded with the following code... def generate_svg_watch_dial_with_markers(diameter, num_minutes_markers, num_hours_markers, hole_radius): svg_content = f'<svg width="{diameter}mm" height="{diameter}mm" xmlns="http://www.w3.org/2000/svg">\n' # Draw white circle for watch dial svg_content += f'<circle cx="{diameter/2}mm" cy="{diameter/2}mm" r="{diameter/2}mm" fill="white" stroke="black" stroke-width="1"/>\n' # Draw markers for minutes for i in range(num_minutes_markers): angle = i * (360 / num_minutes_markers) x1 = diameter / 2 + (diameter / 2 - 2) * math.cos(math.radians(angle)) y1 = diameter / 2 + (diameter / 2 - 2) * math.sin(math.radians(angle)) x2 = diameter / 2 + (diameter / 2 - 6) * math.cos(math.radians(angle)) y2 = diameter / 2 + (diameter / 2 - 6) * math.sin(math.radians(angle)) svg_content += f'<line x1="{x1}mm" y1="{y1}mm" x2="{x2}mm" y2="{y2}mm" style="stroke:darkblue;stroke-width:1"/>\n' # Draw markers for hours for i in range(num_hours_markers): angle = i * (360 / num_hours_markers) x1 = diameter / 2 + (diameter / 2 - 2) * math.cos(math.radians(angle)) y1 = diameter / 2 + (diameter / 2 - 2) * math.sin(math.radians(angle)) x2 = diameter / 2 + (diameter / 2 - 8) * math.cos(math.radians(angle)) y2 = diameter / 2 + (diameter / 2 - 8) * math.sin(math.radians(angle)) svg_content += f'<line x1="{x1}mm" y1="{y1}mm" x2="{x2}mm" y2="{y2}mm" style="stroke:darkblue;stroke-width:2"/>\n' # Draw solid black circle in the center svg_content += f'<circle cx="{diameter/2}mm" cy="{diameter/2}mm" r="{hole_radius}mm" fill="black"/>\n' svg_content += '</svg>' return svg_content import math # Diameter of watch dial in mm DIAMETER_MM = 30 # Number of minute and hour markers NUM_MINUTES_MARKERS = 60 NUM_HOURS_MARKERS = 12 # Radius of hole in the center in mm HOLE_RADIUS_MM = 1.5 svg_code = generate_svg_watch_dial_with_markers(DIAMETER_MM, NUM_MINUTES_MARKERS, NUM_HOURS_MARKERS, HOLE_RADIUS_MM) print(svg_code) I saved this as 30mmWatchDial.py Next a ran the code (using python of course). python 30mmWatchDial.py >30mmWatchDial.svg ... and here is the result displayed in Inkscape. Here is a png of the .svg .. and the .svg saved as a .svg.rtf is attached to the bottom of this post. Save it as .svg and you can open it in Inkscape. Some things to bear in mind when playing with this idea. The free version of ChatGPT can only write short snippets of code, so don't try to get too fancy or you will get incomplete results. Image generating AI will produce arguably more interesting watch dials, like the one below, but they wont be in SVG format. ChatGPT is available here -> https://chat.openai.com/ DeepAI image generator is here -> https://deepai.org/machine-learning-model/text2img Have fun. 30mmWatchDial.svg.rtf Just for fun, here is another AI generated watch. Spooky stuff.1 point

-

1 point

-

1 point

-

I'm behind you all the way, Mo. I've learnt so much from you through the years. Your experience and insight on all things Timex are priceless! The only movements that I thought were unrepairable were those cheap plastic quartz movements with plastic rivets that were ultrasonically welded. But I've been proven wrong when I saw a video from a 3rd world country, where the rivets were cut off, movement disassembled and cleaned and reassembled, then sealed with a few drops of glue. Just because our affluence affords us to dispose of a $10 movement, it does not allow us to ridicule and insult others who would undertake the repair.1 point

-

thanks, I can't leave until everyone owns a vintage Timex or those elusive rivets are found!1 point

-

Qualified with $10 of course. Recently, I had a solid gold ladies watch with a bad ETA movement. Battery leaked. It was a fairly rare movement thus the ones I found were expensive: $75. The movement arrived and was not working. Soooo, I decided to see if I could get the old movement working. Not in my right mind (left mind for this task!), I did service the movement. It was not as hard as I thought it would be. Anyway, it worked. However, I was also able to get the NOS movement working as well.1 point

-

I've done a single one of those, and it was extremely challenging for me. So much so that I couldn't get myself to do another one. Those tiny, tiny cap jewel springs for the escape wheel and the 3rd wheel (if I remember correctly) must have been designed by a sadistic Japanese WWII veteran1 point

-

Are we discussing movement prices cheap disposable movements? For instance Ronda movements A well-recognized Swiss brand let's look at prices. So let's look at the link quality watches at quality prices versus Timex garbage at cheap prices oh wait I'm confused look at all the movements for less than $25 in fact see quite a few movements at nine dollars? https://www.stsupply.com/watch-parts/movements/ronda-movements.html Here's one So we have a Swiss product quality Swiss product and how do we know it's a quality product because at the link below you can download the technical information including the complete a colorful service guide. Although who in their right mind would service a quartz watch that could be replaced for less than $10? https://www.ronda.ch/en/productfinder/caliber/505 Now we have another problem Timex is easier to make fun of because they make their movements for the most part. Occasionally in the past when they didn't have specific movements they will purchase from other companies or they just will purchase the entire other company to get their movements. It makes it a lot easier to point at the target because one target. What happens to these quality Rhonda movements what watches expensive Swiss watches have these movements in them? I suppose you could argue that the expensive Swiss watch isn't as profitable as the Timex watch because maybe the Swiss spend more money making the cases the bands and other components to justify selling a watch for several hundred dollars with a nine dollar movement inside. Oh and I think somewhere somebody was commenting about the price of Rolex suggesting that their greedy versus Timex. Except Rolex is a nonprofit company they're not in it to make money at least isn't that what a nonprofit company is for? Then just a reminder for everybody this is a watch repair discussion group. So personally for somebody starting out I always recommend a clone of a 6497 because it's relatively cheap. It's also a brand-new its typically running. I think it's good for people to see what a running watch looks like if they would pay attention. In other words what does a running watch really look like what does the balance wheel look like when it's oscillating what is a flat hairspring look like. Plus the all-important test if you disassemble a running watch and put it back together is it still running? Who can you blame if it's not running after you disassemble and put it back together. Versus working on broken watches were they have no experience and the outcome of successful repair is unknown. Or working on any non-jeweled watch pin levers in particular which can be repaired the same as the Timex but they represent challenges that I think newbies should avoid. The same as newbies should avoid trying to repair a watch until they grasp what the watch actually is. Plus unless they like expensive lessons should avoid quality name brand Swiss in particular like Omega or Rolex to start with. Not that either those companies rip us off on the cost of spare parts that they won't sell us anyway.1 point

-

We can't point the finger at just one company, I'm sure most watch brands in their day have cut corners to compete, you choose a customer market that you want, so you aim to get that market, business is business. A brief glimpse of Swatch's antics over the years shows real planned greed rearing its ugly head. There's probably not many that have decent ethics if anybody can name one, and many more that hide behind them. From the videos I've watched they brought affordability and reliability to an important aspect of everyday life. It would certainly be a shame to lose a valuable member that has vast experience and knowledge in such a unique design. JerseyMo's passion of Timex obviously shows, for that reason alone we cant let you leave.1 point

-

Hi like Jersey Mo I take the timex as another step on the evouloution of the watch industry, people like them and wear them and buy them, why. What is the basic function of a watch. To tell the time. And if the timex watches do that then that’s a success. The fact that they are still being made, worn and sold all over the world . So what’s with the snobbery regarding which is the best brand. You buy a watch it’s a personal choice. I have about 30 watches and as many clocks but I wear a Lorus Quartz, it tells me the time ,day date and it glows in the dark and it’s dependable. Timex are very much in the same vein practical. Would your Rolex, or any other Swiss watch still tick after an afternoon working with a Jack hammer breaking concrete ,probably not but a Timex would. In conclusion I respect JersyMo’s attachment and expertise he has built up through great patience and his knowledge of the brand. So let’s kick the SNOBBERY into touch we all have our own opinions some best kept to our selves. I would agree with the comments regarding they are not the best starter movement to work on as the construction differs from the many watches you will come across in the course of watch repair. But there are many cheap working watches to be had to practise on preferably pocket watches as the bits are larger and easier to handle. My 10 pence worth.1 point

-

yes, how can I continue now that the truth has come out that Timex is the evil empire of the watch industry! Oh wait just a minute. So when Rolex creates a product that sells for 35K ( those are the cheap ones too) and only can be afforded by a small percentage of the world population "that's not greed" ? I thought companies were in business to generate funds, create jobs, support economies and all that good stuff the politicians argue about? What am I missing here? I ain't missing nothing. In fact have a look at these NOS beauties I picked up a few weeks back. All from 1967.1 point

-

That's an interesting quote up above then yes everybody gets to have a point of view it still interesting plus not entirely technically correct. One of the amusements is dunking in lighter fluid Is a lot of eBay sellers do that with the watches there selling. Because then they can sell their watch as running at least for a few seconds. Then quite a few people on this group dunk their watches in lighter fluid rather than investing in proper cleaning fluids. The first link is to the history of the Timex watch company unfortunately it doesn't cover there Unethical business plans and how evil they are I wonder where we would find that history? The image is rather interesting because that's an advertisement by the Bulova watch company. They are attempting to sell a watch probably quite successfully. Comparing their well-made seven jewel versus the evil Timex company watch. Except where exactly did that seven jewel watch come from? I recognize the movement number we've discussed it before. So that Caravelle movement is really a Bulova movement. Which is really equivalent to a citizen movement basically they're all the same watch it's a Japanese movement. Then yes I remember that because we discussed that watch for servicing issues before So just for reference as I found one link to a discussion I know there's more. Now as we got a nice Bulova advertisement image about some advertising from the scoundrels at Timex? Do a search for Timex keeps on ticking on YouTube I picked out a couple for you. https://www.heddels.com/2019/08/cheap-tick-history-timex-watches/ Bulova 11DP (Citizen 0241) http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Bulova_11DP http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Citizen_0241 https://17jewels.info/movements/c/citizen/citizen-0201/ http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Citizen_02411 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.85ffb614e22e1624ce832b1513d723df.jpg)