Leaderboard

Popular Content

Showing content with the highest reputation on 10/18/24 in Posts

-

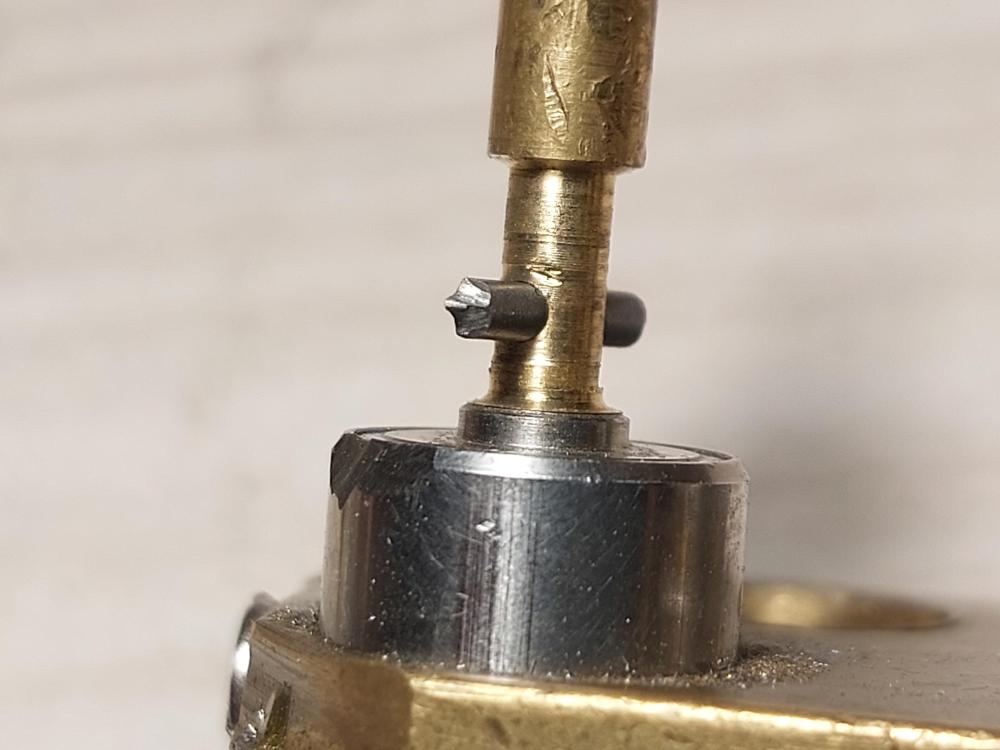

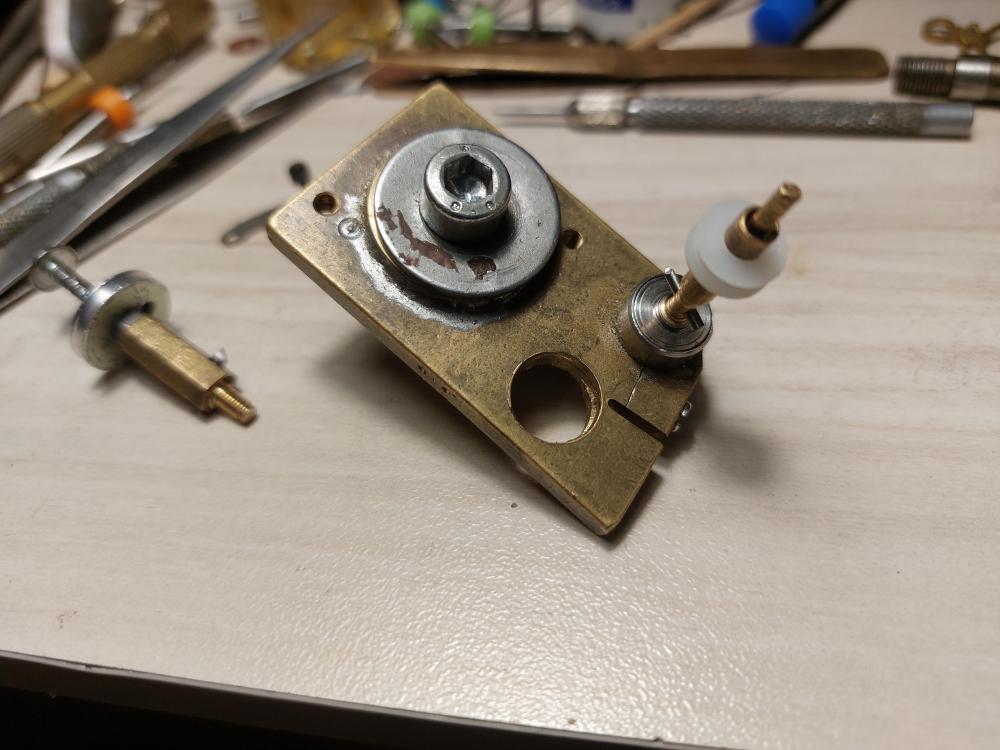

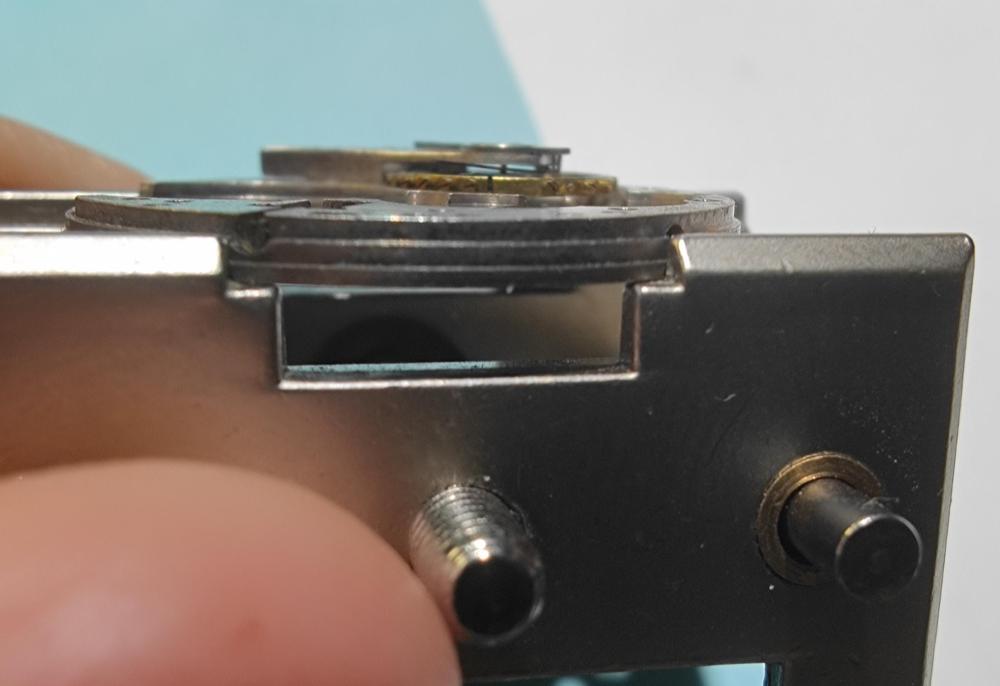

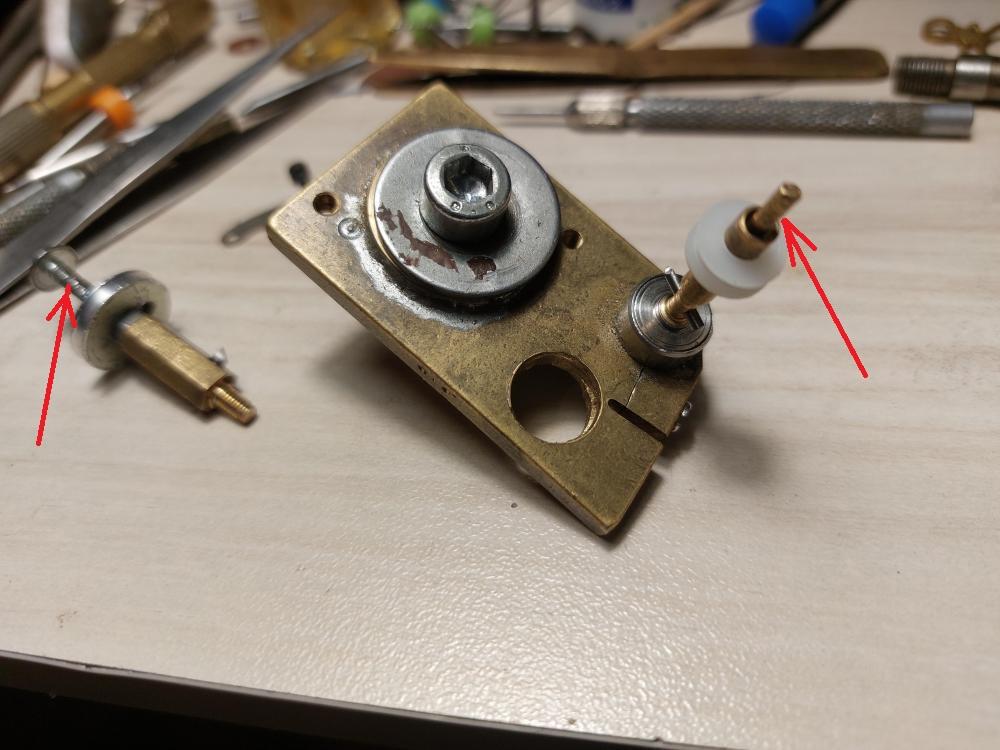

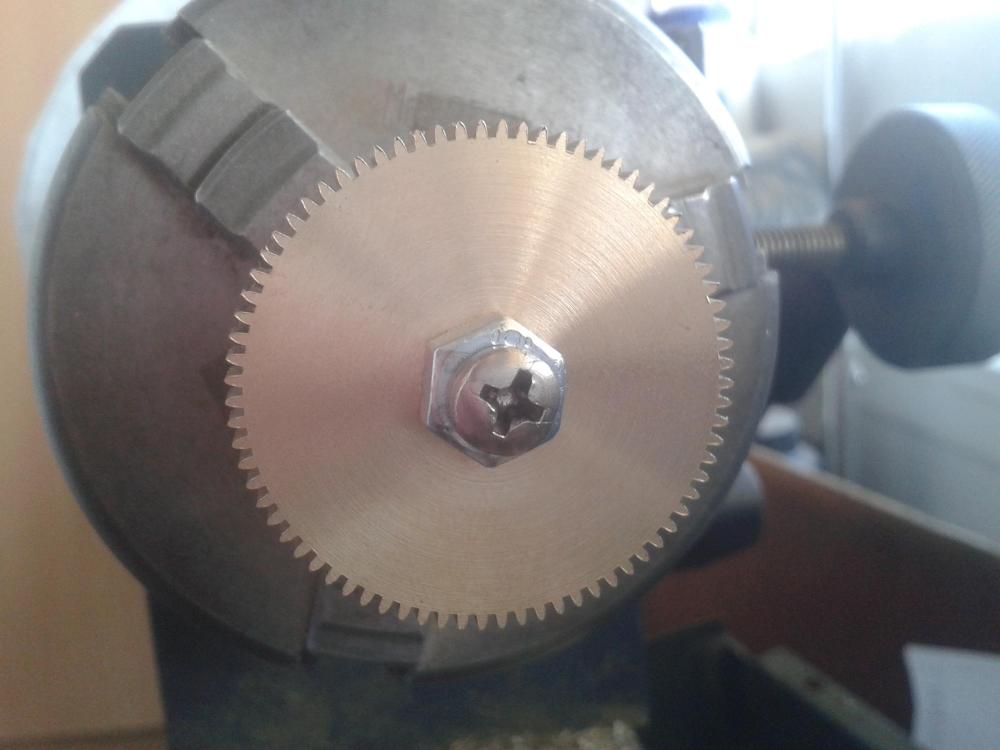

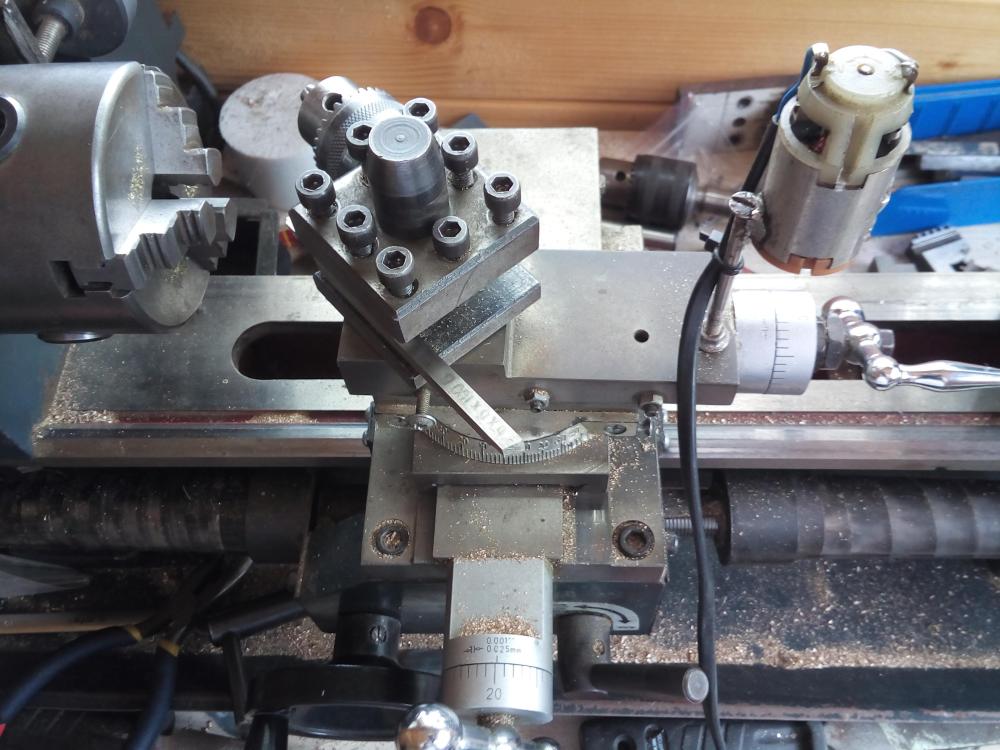

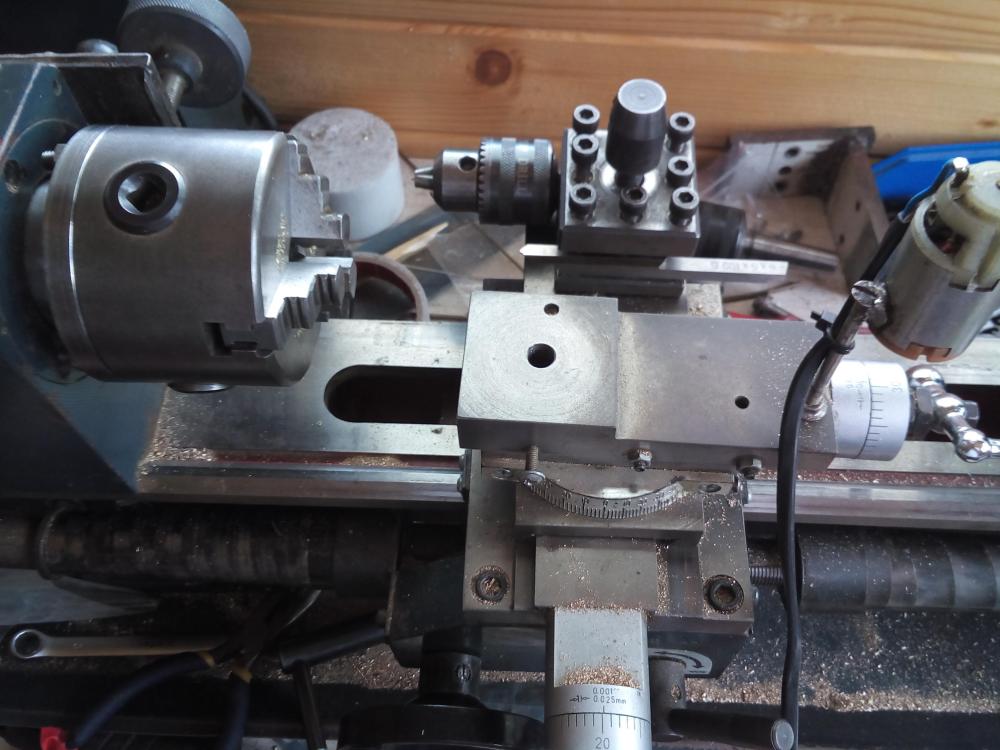

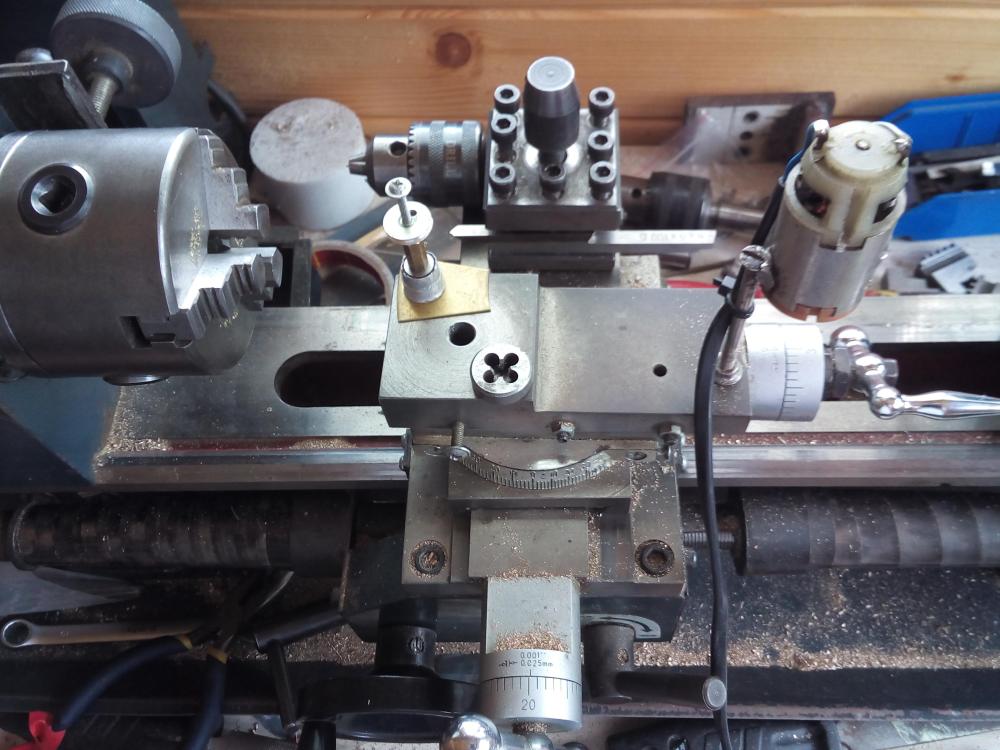

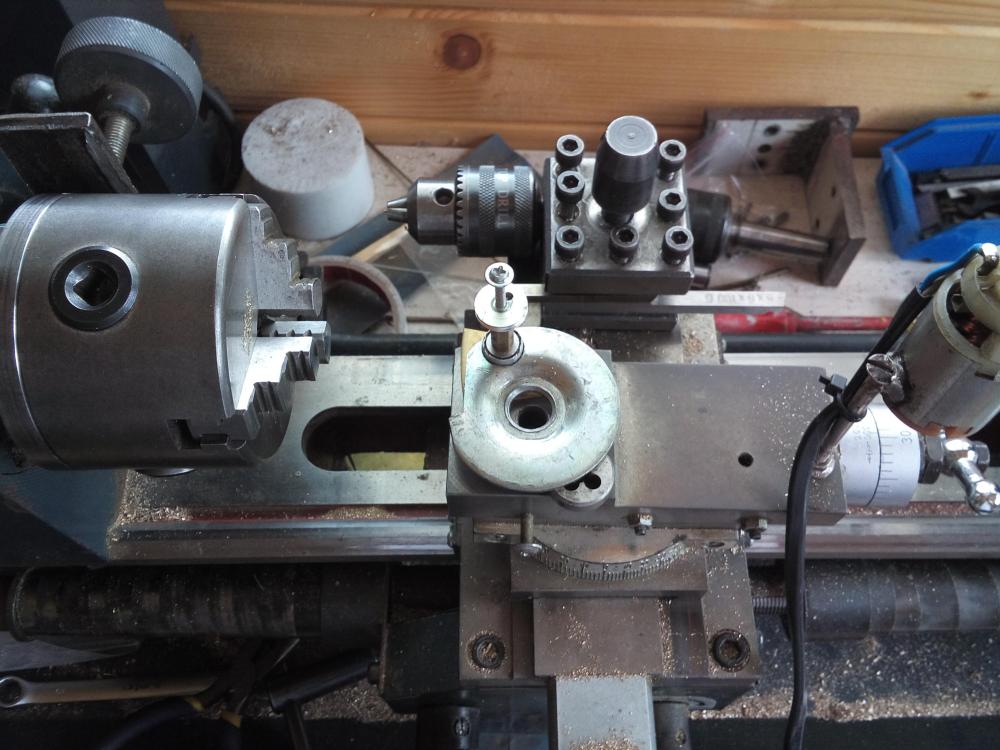

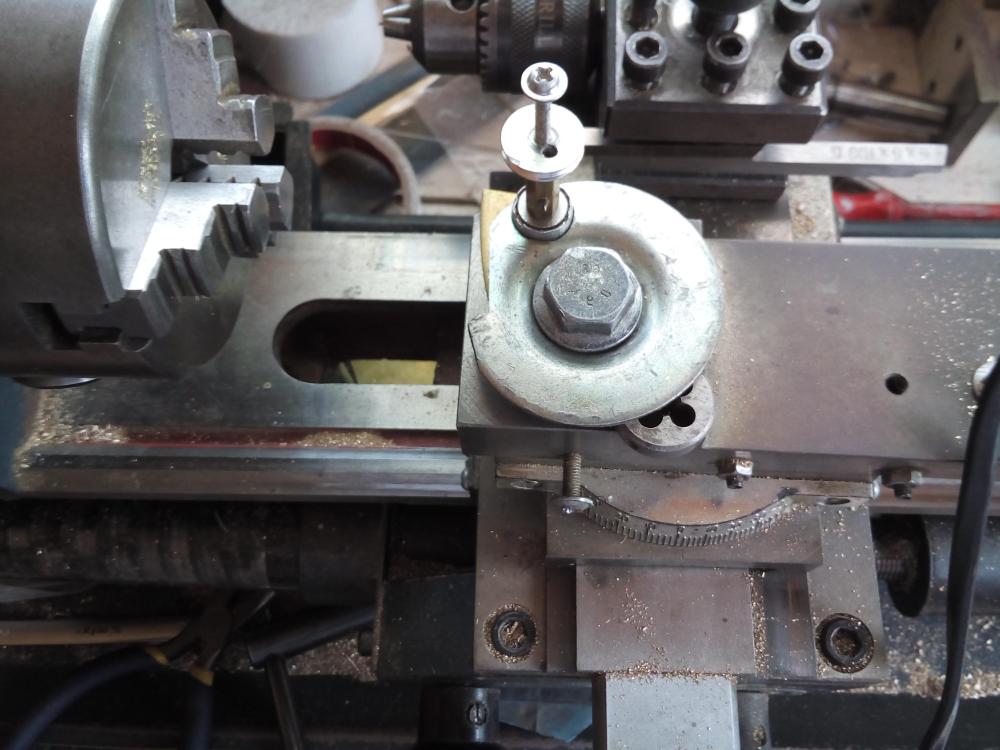

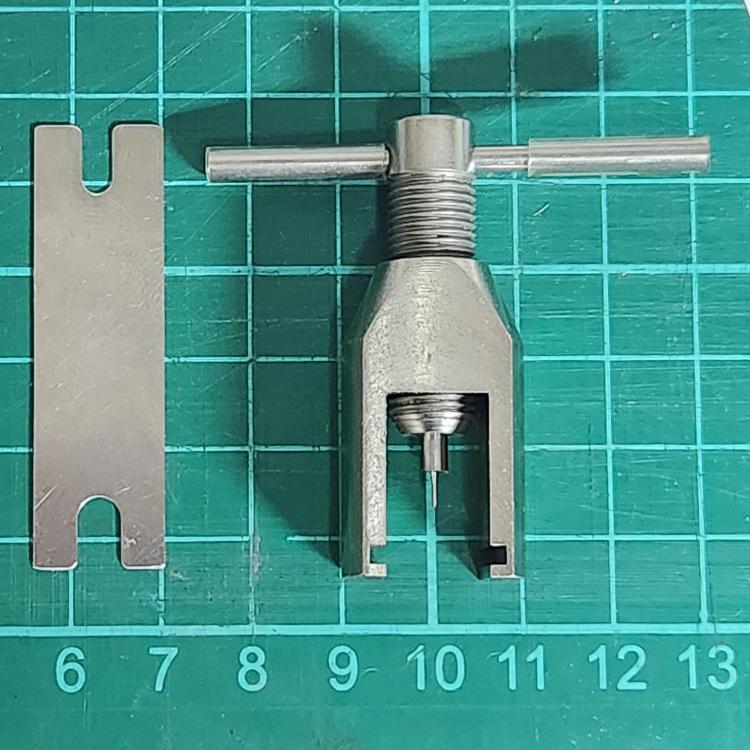

Hi Rich, The brass plate is for regulating the height of the cutter, like shimming. The die is to keep the big washer horizontal. Indexing is ... see this video, the index is shown in the end. Here is REV 2.0. The design is similar, but the height can be adjusted by shifting up/down when the small screw is loosen. There is a big double bearing that lets the whole brass plate rotate when this is needed in order the cutter to be able to follow templates. The tool bit is held by tightening the long steel screw, just like in chandelier terminal. This particular bit is not carbide, but yes, a carbide one will look just the same. And yes, I shape them with diamond disks, diamond files and patience. But the gravers that we use for lathe cutters are to big, this is the only problem with them. There are carbide Chinese drill bits with tail 3.17mm, the tail is not carbide. The small sizes carbide tips has something like tail, which is 1.2mm in diam. and about 2mm length. I make the carbide cutters for small wheel modules out of them. Will show pictures... Actually, when cutting small gears like the ratchet wheel You need, there is no impact on the lathe bearings. The revolutions of the cutter are big and the shavings are very fine. I can't say nothing about the milling machine, but no problem to use the lathe as a device for small gears cutting.3 points

-

3 points

-

Wow Nev, i looks like it just shouldn't work , i tried to understand what the brass plate and die was for under the base of the cutter....just packing lol. How are you indexing the chuck please ? Fascinates me how you just bolt bits and pieces of anything together....and manufacture. If we ever reach armaggedon, I'm coming to Bulgaria to find you3 points

-

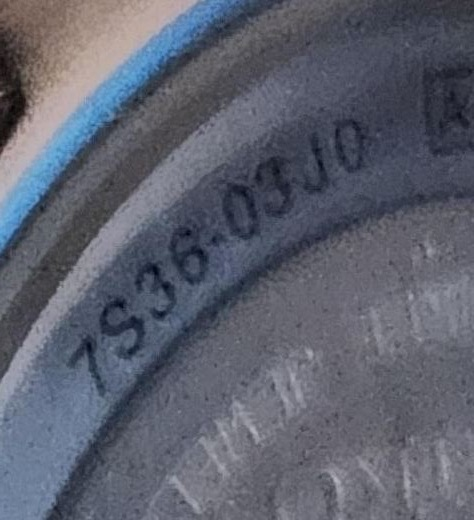

ideally you should resist from DIY alternatives to gaskets for watches. Fortunately gaskets are used in lots of watches so if you go to a variety of watch material houses they will actually have gaskets. Then if you're doing lots of watches really even have a gasket assortments. Then if you have a watch like perhaps Seiko for instance there is typically a caseback number on the back of the case. This is where typically have a four digit number which is the movement number and then it separator fall by the actual caseback number. Then for a variety of sources you might be lucky and looked up the part numbers so for instance at the link below you can enter in a case number and if you can't get your case number to come up usually if you have some of the numbers removes like the last three for instance you are likely end up with a grouping of cases that are similar if you're lucky. Because the other unfortunate problem with caseback numbers is it also depends upon where the watch was supposed to be sold and depending upon like in the US if it's an out of country watch we might not have a listing at all but we might have a listing that's a similar watch that was sold in this country if were lucky. http://cgi.julesborel.com/ so we do get a listing we just don't get a complete listing unfortunately http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK_CS^7S36-03J0 the other thing of interest to do is to take the caseback number 7S36-03J0 and just search on eBay for which you get a lot of watches and miscellaneous casing parts. then if you not finding what you desire which I'm not need to go to the Internet and find this now we know your caseback number and a heck of a lot of other numbers to. https://www.theseikoguy.com/watches/7S36-03J0/ so basically to avoid complications and problems always best to say with the original gasket.2 points

-

2 points

-

There was a conversation about this a while ago, unfortunately I have forgotten the answer. Something to do with ebouches and helping with alignment (of what? ) for the finishers.2 points

-

2 points

-

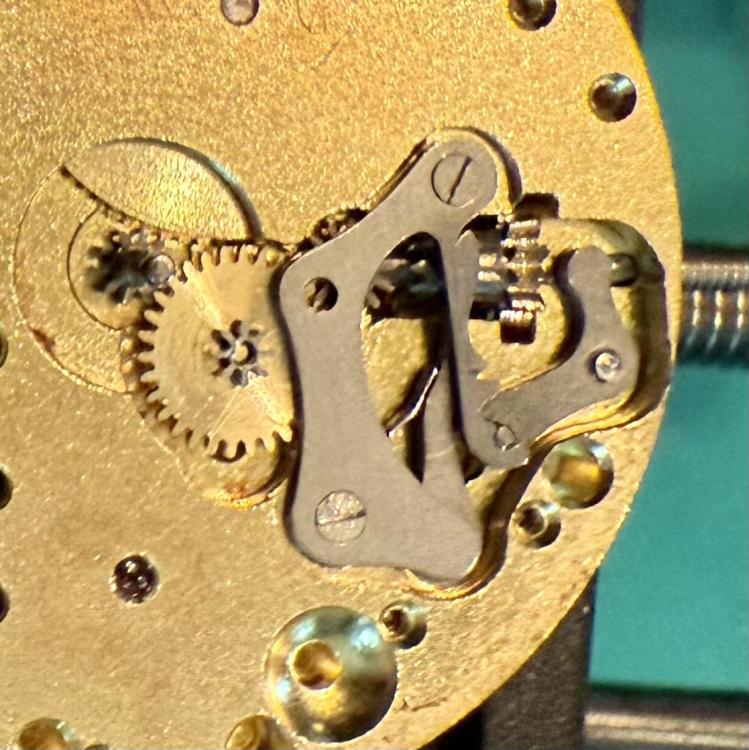

The new part is in. It's an Omega part listed as a compatible and I'm not going to worry about the the finish. The bridge screws have a similar straight grain and assuming they're the original screws this replacement is just fine with me... ...this is a bad design, though. The detent takes nearly all the forces of the keyless. In addition to the high risk of breaking the spring when removing the winding stem, the cups for the post on the setting lever are quite deep. There's a definitive pull which is a good feel when it works but it gets hung up a bit on occasion. I'm considering softening the depth with a file or some lapping film. Also the detent part of the bridge takes vertical pressure from the yoke. I put a touch of grease on the top of the yoke and it has rubbed across the top surface with contact. Loosening the bridge slightly seems to make things worse and misaligned. If anyone has suggestions on how to reduce the stress...2 points

-

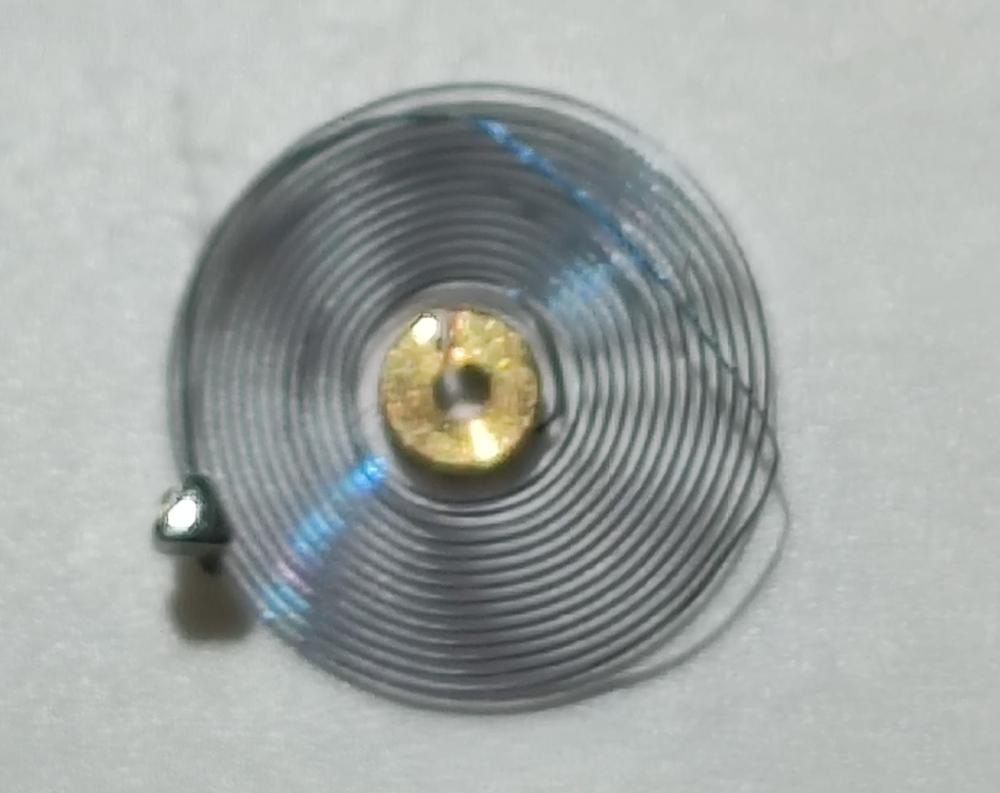

Bit of an update. I have managed to get the hairspring into a reasonable shape. I managed to distort the spring right at the collet when initially taking it from the balance. It was really stuck in place and I ended up having to twist it off with a craft knife. My hand levers just wouldn't quite get underneath it and I slipped and bent the hairspring when levering it up. I nearly gave up at that point and ordered the new balance complete but I figured 'why not keep trying until you really mangle it?' I held the collet down and stroked the hairspring where it came of the collet until I got it untwisted, laying flat and mostly central. I then layed it loosely on the upturned balance cock and had a look at the layout. It looked like the outer curve of the overcoil which runs through the regulating pins needed to be in line with where the next inner coil should be. I gripped the overcoil where the sharp bend needed to be and stroked it to the necessary angle. I then worked along the outer curve to get it where I wanted it. The stud had a further sharp bend but I wasn't sure whether that was required or not. At this point I tried placing it on the upturned balance cock with the stud in position. This showed me that I was far off and the curve needed to come right in over the next flat coil. Off it came again and I remade the sharp bend to bring the overcoil back closer to the centre. First attempt This time, when I installed it in the balance cock it looked a lot better. I played with the hairspring where it came out of the stud and I thought it was worth trying it installed on the balance in the main plate to see what the overall shape looked like. Second attempt With the balance back installed, I had to play around with the depth of the stud but this got the overcoil located vertically so it isn't touching either the balance cock or the spring. The main coils of the hairspring still has a bit of a lean to it. I think this is where it comes off the collet so I will probably have a go at trying to get that flat. The overcoil also seems to be slightly high compared to the balance cock. It doesn't touch anywhere since it actually dives down back to the main coils before coming near the balance cock. When spun up with a fine paint brush the balance oscillates quite well and the hairspring seems to 'breath' without touching anything. I can't tell if the hairspring is having too much of an effect on how free the balance is as I still haven't cleaned the jewels so it's still a little sticky. I will take the hairspring off the balance cock again and run the cock through my normal cleaning cycle along with the rest of the movement. Not going to take a risk with the 100 year old shellac in the ultrasonic.2 points

-

unfortunately there a way more watches then there are service guides. Even for Seiko they don't currently have or conveniently have PDFs for everything they've ever made it. So yes there are service guides out there are just not for everything. so basically unlike other things in the world like automobiles where you can probably find quite a few manuals for every car in existence watch repair has a lot of nothing available.2 points

-

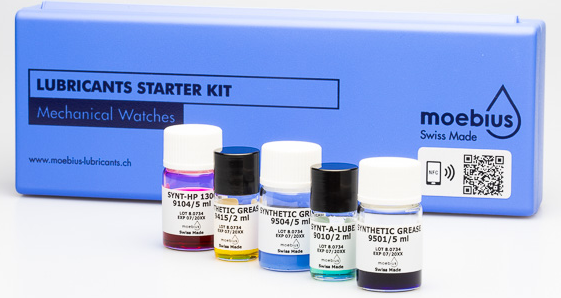

realistically you'd be very happy if you didn't find the starters kit as people usually like to complain about the cost of lubrication and a starters kit may not actually have what you really want and it would be expensive anyway. but starter kits do exist for instance at the link below scroll down the page and you will find a starter kit for mechanical and another for quartz watches. Then the problem with starter kits are you would have to go through in figure out the cost of all individual oils as to whether you're getting a savings by purchasing all is a kit and does it actually have what you want or not. I'm in a skip over that is everybody has a different opinion and mine of course would be different than what's in the kits. So my looking at what they have one of the problems I see is the HP 1300 comes in 5 mL which is a lot of oil. Oh and then technically the oil expires but as a hobbyist is not collecting money personally wouldn't worry about the expiring date of. It is nice though that it's there in case you buy something off of eBay that doesn't have expiring date that tells you was made a long time ago and maybe it's not really what you want have. But still 5 mL is a heck of a lot of oil it's quite amazing how slowly you go through the oil in a way. Then they have grease 9504 which I really like which I think replaces 9501 which they also have. So as I said you'd have to evaluate your needs as to whether you really need the rest of them for the most part are good. So in any case of the first link is scroll down and there's the description of the kit. You can download a PDF but I've already done that and attached the message. Then at the second link because cousins didn't seem to have the kit there is the kit. It's only the first one I found conceivably other people have it also but it does give your price and you can evaluate whether it's really what you want or not. https://www.moebius-lubricants.ch/en/products/specialities https://www.ofrei.com/page246.html I think you really need to take the watch out of the case and evaluate the situation where you can see things better. then it's always nice if you can give us a model number I did notice one on the case but this watch comes in either in three different variations a, B and C but the case number doesn't indicate family can give you a version which is probably the most common. blue-starterkit-ts-eng_0.pdf Seiko 7S26A & 7S36A.pdf2 points

-

Ref, your first pic, a screw to winder module had come loose and is somewhere inside the gear works. Jax case back remover tool is almost universal for opening case back. Important: Once you spot the screw, should be careful/ patient taking it out, specially if its near the hairspring. Removing the rotor helps and must be done without letting it move, cuz the screw might be stuck right underneath it . I don't think your watch needs a service as it looks new. How long has it been in use? Rgds2 points

-

Yes, I should have been more clear: that video still was from someone else's Youtube disassembly video. I also was very careful to photo every spring I saw, since the movement had roughly 40 of them, and didn't have a photo of that one, which makes me believe it wasn't there to begin with. The keyless works seems to work fine without it, so it's possible that whoever was in here before me scratching up every flat surface launched it into space and didn't put it back. That said, I did check my cleaning fluids. And all of my baskets, twice. And the inside of my food dehydrator high-precision, custom made, watch parts dryer. Also ran my magnets around the floor. Astonishingly, McCaw Company saved me the effort of making a spring by having one in stock! Hopefully I'll get this thing off my bench in 2024 (famous last words).2 points

-

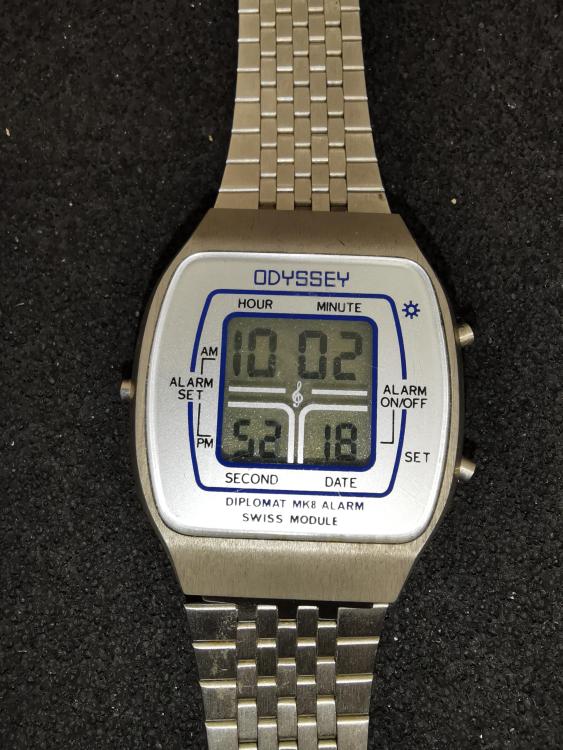

Lovely watch. I assume it has the appropriate stampings on the case back?1 point

-

Right above the word Japan is a hole that says "push". Push in there with a sharp tweezers point while gently pulling out the crown to release the stem. Then it looks like there is another "push" to release the lower crown & stem. Usually the crowns should be pulled out to the setting position before removal. After this though, it is unclear how the pushers are captured so be cautious when dropping the movement out that you don't lose springs or internal parts of the pushers.1 point

-

I suspect they are minute markers, as Richard suggests, when the watchmaker has finished the ebouche, before fitting a dial, fit a minute hand and leave running for a while, if happy with the accuracy then final finishing and casing up .... maybe?1 point

-

1 point

-

Yes please! With your Rev 2.0, is the toolbit held in place in a simular way (long steel screw that's not showing in the pictures) or is it tapered? Great that I will be able to use my little lathe. I'll start putting something together as soon as possible and keep you posted.1 point

-

Sorry but i can't find any reference to the 6309-523A ever having a metal strap, only a leather one.1 point

-

This company is serious and reliable, existing in 3rd generation, I know them personally. They are supplying wholesalers worldwide - they won‘t deal with small consumer‘s orders. But they have a shop in Mumbai, you can go there and even buy a single tool - if you happen to be nearby . Frank1 point

-

one of the problems that makes things really confusing and watch repair is time? Not timekeeping of the watch but time of? Watch repair spans a considerable quantity of time with technical documentation and recommendations for lubrication cleaning etc. spending a lot of time. So depending upon document you look at recommendations change with time but for anyone not paying attention to the evolution the whole thing becomes a big confusing mess. Then of course we have the different thoughts that the various watch companies have on things like lubrication. Plus the bonus of lubrication rules don't come with all of the information using epilam to keep the oil from spreading and you get a technical documentation recommending the and Wales that failed to disclose that you're supposed use epilam to keep them from spreading. So basically we never quite get all the documentation in one place and its spans too much time which makes for confusions. Occasionally people make references to automobile repair but the problem is in watch repair we don't have as many people as we do people trying to repair the automobiles so there's less people writing service guides for every single watch which typically almost never happens. Whereas you can find literally hundreds of books on various automobiles1 point

-

That a 6309-523A but if the strap works for you then OK, although it doesn't look the easiest to get the pins out.1 point

-

There's no way I'd spend that sort of money sent by bank transfer with an unknown company in India.1 point

-

thinking about quantity is of lubrication I have a predefined search at the link below. All sorts of interesting documents to download with number 40 covering lubrication. It's very good for the quantities of lubrication you may not necessarily want to follow their suggestions though for lubrication. As each the watch companies will have variations. that's unfortunately the watch companies don't like us as there are considerably more working instructions and you see but they're unavailable. Plus you'll notice how paranoid Swatch group is as these ones every single corner of every single pages watermarked with where it came from. Which is why typically anyone who has access will not share it online because knows what Swatch group would do if they found your document floating around in the wilds. Then the other problem with technical documentation is it was often times scanned solely for the parts list and it's missing all the technical. So often times you'll find something on the website here and there will be no technical because it was never scanned. https://www.cousinsuk.com/document/search?SearchString=working1 point

-

…winders were one of the first big $$$ purchases. I began with common swiss movements and found many old steel mainsprings or broken ends. I could have done without the winders and just purchased new springs. Also, despite the risk of damage, hand winding really isn’t that difficult….1 point

-

All advice here are solid , yet as a begginer you wouldn't want to tear the movement down more than you can clean & safely put back, neither uncase the movement nor spray anything, as any of the above puts the paint on dial plate in harmsway. Just touching the dial with clean finger, leaves a progressively worsening mark on the paint. Good luck.1 point

-

1 point

-

I agree with @Nucejoe. There is a screw missing. Probably it's this which is jamming the rotor. You definitely need to remove the back, and you may need to remove the rotor to free it. Go slowly and ask before doing something you are unsure of.1 point

-

Do you suspect water ingress ? If so i would want to start some disassembly to discover the extent. If you are contemplating spraying some kind of release agent to loosen things up without taking anything apart...personally i wouldn't, you might be tempted to use an amount of force to encourage the process and as Joe has pointed out something other than rust or dried up lubricant may be jamming the autoworks.1 point

-

I placed another order with them for a crown and did end up getting the crown, they were very slow to respond to emails or ship it. Shipping was egregious ($13 to ship a crown). I don't see myself ordering from them again. Just in case, the email they used was *****@*****.tld.1 point

-

1 point

-

It is clearly seen here that the side wall of the barrel is broken, thus no wonder if the barrel is distorter when the lid is put in place. You need to replace the barrel, so now is the time to make one. The answer to the 'interference' question is simple: decrease the lid diameter until it snap fits well to the barrel, or increase the diameter of the place in the barrel until the lid snap fits well in it.1 point

-

1 point

-

Just had a look, and hat's off to you mbwatch, 1080 stamped there, also a seperate 7 or 1 all on its own, just visible 9 o clock. No makers mark, just assumed that the 3559 on the bridge was the movement. I'll get it stripped down for cleaning, maybe some more clues await.1 point

-

usually companies that refinished dials can replace dial feet I suppose it depends upon where you are on the planet. I used to know somebody that a Swatch group account because they were selling one of the Swatch group products. Then that also sent a watchmaker to the school and once you do that and they complete the basic watch rule class that's like half a week or week or something then they can access the complete database. I strive or what the official term is so not authorized Swatch group there Swatch group something and then yes they can order movement parts. But typically nobody's going to order a component for you there are going to want to in the case of a dial probably service the entire watch. This is because if you were to change something like a dial in the watch didn't run then you might be unhappy and want your money back or something so typically it's all or nothing.1 point

-

1 point

-

Just find a little bigger screw (in diameter) and screw it in the hole, making this way new thread in the hole. Screw it with forvard-reverse movements and put some oil.1 point

-

You could be right - it's annoying that Christian's pics show the keyless, less the setting lever spring. If you can only get a part with graining, I guess you could sand it smooth ?1 point

-

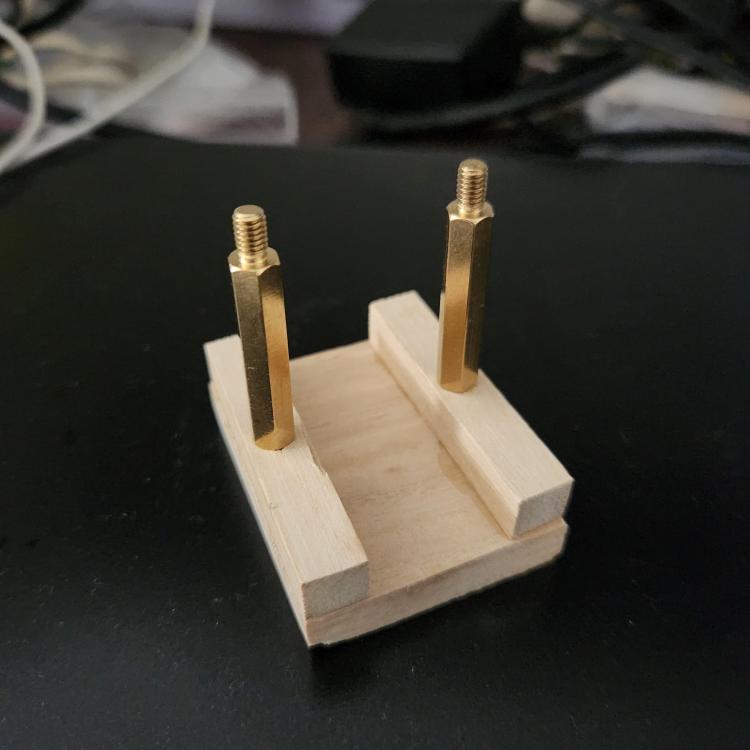

I modified a cheap gear puller from AliExpress and made a hand remover for the Atmos clock. It worked perfectly and removed the minute hand easily. The hour hand a little stubborn and took a bit of persuasion to loosen it. After the hand was removed, I found scratch marks on the hour wheel. So, someone has been in this clock before. I also made a movement holder from bits I had around the house. I'll probably remove the movement tonight.1 point

-

Just cased up my latest watch - a Longines 12.68ZS from 1953. I'm a big fan of Longines and couldn't resist this one. The dial is gorgeous, and near perfect condition. As expected from Longines, it's running beautifully. The balance even has mean time screws. Most of the watches I buy, I do up and re-sell on ebay to fund the next one. But this one is a definite keeper.1 point

-

Been a few weeks since anyone posted. Heres 25 candidates for the 10:10 club. 25 watches £203.00. I have a few favourites. The Nivada on my wrist, bit small at 30mm but its a lovely little bumper automatic. The Doxa, cant wait to get to this, the Cyma is a nice size, Citizen Eagle 7, Leonidas GSTP. Mickey Mouse Timex.1 point

-

Got this wonderful 1971 $8 eBay find running. Other than a broken mainspring and a crack in the crystal, it just needed a good clean up. It did have a beat error problem, but I got it adjusted to a 0.6ms BE, a 260° and positional error of +/-30s. Not bad for essentially a novelty watch probably not expected to make it much past the '70s. I think the hardest part was fitting the pallet fork without jewels. Those holes are TINY! That brass plating was 10 kinds of awful so I just polished it off for now. I might nickel plate it. Or 24k rose gold, for such an elegant timepiece.1 point

-

Five and a half years later I can confirm that a bit of silicon grease on the rubber seal makes a huge difference!1 point

-

As I say to my students, 'Just because it's on YouTube doesn't make it the truth!' @semmyroundelIf you're in or near London I teach watchmaking courses for complete beginners to the seasoned horologist. You might be interested to learn the correct way, rather than the steep learning curve of YouTube videos. Check out my website: https://www.jonthewatch.co.uk/ Instagram: https://www.instagram.com/jonthewatch/1 point

-

Having received and tested the "Bergeon 6400 for various shapes", I can now confirm that it indeed works with various shapes (maximum width 45 mm). It feels like a really solid tool and it works very well. Expensive yes, but I can confirm that it does its job. Lifting the old crystal off and setting the new the crystal in on the Poljot was a job made very easy and fast with this tool. The only thing I'm not perfectly happy with is that the arms that grab the crystal are pretty hard to push all the way out to 45 mm. It feels like the inner diameter of the rubber seal is too narrow. Perhaps a bit of silicon on the rubber seal might make it a bit smoother!? Then again, it's not every day we need to lift a crystal that large. As already discussed, the needs for a crystal lift are limited. Nevertheless I'm happy to have one in my "arsenal of tools".1 point