Leaderboard

Popular Content

Showing content with the highest reputation on 10/26/24 in Posts

-

4 points

-

The material of the tweezers isn't important, it's how you grip the balance that is. You can adjust the screws without a pair of tweezers holding the balance still, but it is a bit risky. The shockproof will give a bit, but the last thing you want is to hear that noise no watchmaker wants to hear. That 'SNAP'; you know the one I mean. When you hear that, you know you're in trouble. Also, it might be an idea for a first go to take the balance out of the movement and place the balance on a balance tack that has a supporting table for the balance. You can then hold the balance from the sides with your finger and thumb whilst turning the screws equally. That is probably the hardest part in getting the screws to turn evenly and not put it out of poise. You'll know if you have when it goes on the timegrapher in vertical positions. This will give you a feel of the Microstella screws without the risk. Once you feel confident, put the balance back in the movement and finish the last bit off in situ, using the tweezers this time. The trick is to relax, which is hard to do and the more you see your hand shake the more you're telling yourself to relax and the more pressure you're putting yourself under. Eventually muscle memory will take over and it'll be like an out of body experience of watching yourself adjusting the screws to perfection. There will be no more worry, only confidence in what you are doing. I found a vid I did a while ago on a 2135, so made a GIF. The hand with the supporting tweezers is resting on a block just out of shot, so my hand is totally steady. Here's a link to my cloud where the original video is, but it won't be there for long. https://drive.google.com/file/d/1CJUCz846vvgf6uUNIK7m9CWL7j5fxjSW/view?usp=sharing3 points

-

3 points

-

I just checked through the list of North Sea fish, there is a swordfish -> https://en.wikipedia.org/wiki/List_of_fishes_of_the_North_Sea ... and the leopard spotted gobby.. I think I met her in the Dock Ferry bar back in the eighties.2 points

-

Yes, I've tried with the invisible springs, I can't see the wood for the trees, nor the hairspring.2 points

-

just read the original thread, we never got to the bottom of what happened there... i thought your terminology was off. Can we start again as to what has been done up to now its those new non visible ones rich, they're an absolute bugger to regulate.2 points

-

Just reading it made me more scared than any event around Halloween ever did! This is probably the most important tip: Allow yourself to relax as much as possible. Holding your hand in the air and thinking you can keep it still is doomed to failure. Another possibility might be to put the balance on a clean staking block, put the roller table in a hole just big enough, and then hold the balance with tweezers. That's what I do when adjusting the collet position. That was a tip I got from @nickelsilver some years ago: "For everyday work, from the smallest ladies' movements to the marine chronometers, I set the balance with the cock on a bench block so the roller table is in a hole, balance on the block. Lift up the cock and move it over not flipping it, just moving laterally, until I can see the slot in the hairspring collet, get in there and adjust (for tiny watches this is usually with an oiler, larger, a small screwdriver). I hold a balance arm of the rim with tweezers while moving the collet. Go back in the watch and check on the machine." Now downloaded to my Onedrive for future use and as a reminder. Many thanks Jon, much appreciated!2 points

-

To add to what OH has provided, if you are buying from Europe it will likely be 220-240V 50Hz same as here in the UK. North American or Japanese machines are more usually 110V 60Hz and would likely need either a transformer or replacement motor. By the nature of these machines being vintage personally I would rewire as a matter of course, insulation deteriates over time and a lot of the older machines were not necessarily earthed properly or indeed at all. Tom2 points

-

It's a glorious autumn morning here in Lancashire, out with the doggo, Maximus Lupus, and to assist with my life endeavours of punctuality, I present this rather fine and classy looking 1967 Timex marlin. So this is only the second Timex I have ever worked on, so I'd thought to try an experiment, actually it's more of a brazen cheat and shoddy corner cutting but experiment sounds way better. I expect we all do a bit of research when working on something different, and with Timex movements this dunk and swish approach seemed to be acceptable, although I appreciate it's more for the movements that are rivited, so thought I'd give it a go. I gave the movement far more than a dunk and swish, stripped off all the external components, everything soaked in isopropanol overnight, scrubbed all reachable areas with a brush then two twenty minute stints, in isopropanol, on a 40 degree setting in the ultrasonic. Well it looked the part after all that, re assembled,oiled, given full wind and ..... well it ran, but very poorly, kind of like a fuel starved austin allegro. Released the spring tension and that was enough to tell me to start again and do it properly, the spring didn't unwind smoothly at all, speeding then slowing, that spring had to come out. Once stripped, also now got the opportunity to properly inspect the components, found the pins on the pallet not nice and smooth but pitted with a rough looking surface. I acquired, some years ago, a large box full of movements components and scraps, primarily as a source of screws. I had no idea until recently that a lot of the bits were from Timex movements, well that was fortunate, decent replacement pallet, setting lever and screw, crown and stem, all now sorted, the only thing I had to pinch from another watch was the second hand. Now the movement running much better and an acceptable if somewhat untidy readout on the timegrapher, amplitude could do with improvement but suspect just need to allow the oil to work around the escape. The case cleaned up very well and the crystal, which is glass on this one, not too badly scratched. Very comfortable on the wrist, I'll give it a good weeks outing and see how it peforms. Whilst researching this watch, it would appear that timex did a re issue of this very model, check out the price tag on the Timex website: And of course, given the opportunity I'm compelled to give you a side by side pucture of marlins, so for any digital fans, here's a treat, the rare and extremely hard to find W550. And just one more closing thought, shouldn't a waterproof Timex from Dundee be the Timex mackerel, or the Timex mullet. I know it's not quite as appealing as the Timex marlin, but there aint no marlins off our shores.2 points

-

This can be made and it is not a problem. Get hold of one of these mags and look at the adds and you will find clockmakers who make parts. http://www.clocksmagazine.com/ The reason I missed this is because the heading didn't mention clock. Brass pinion wire is too soft.2 points

-

2 points

-

1 point

-

My name is Maximus Decimus Meridius commander of the armies of the North, father to a murdered son, husband to a murdered wife. I will have my vengeance in this life or the next....erm..coff...coff.. apologies lost track for a moment....nice looking Timex.1 point

-

1 point

-

for terminology your ending up with two separate things that ideally both have to be done possibly. vintage wood main vintage wiring and vintage wiring as a problem of not being safe for variety of reasons. So anything vintage with electricity the wiring needs to be verified that it's still functionally correct and not going to burn your house down for instance. So typically people rewire a functional machine to make sure the wiring is suitable. So basically it's not so much the wire itself it's the insulation disintegrates so that needs to be dealt with which would be called rewired. then just to make sure I get my numbers right quick search and I got the link below. As you can see the power coming out of wherever it comes out of is different depending upon where you live. So in the US it's considered to be 220 V at 60 cycles.in the United Kingdom it's 230 V at 50 cycles. fortunately if you look at most of Europe 230 and other places 120 so yes a lot of equipment can be rewired because it was designed to work in either location. His wife you look at modern power supplies for all of our electronic stuff they will usually say between 100 and some voltage as there designed to have just about everything. Oh and purchasing a vintage cleaning machines or for that matter new cleaning machines whoever packages up and ships to you should be aware of cleaning machines in general are heavy and glass does not like to be bumped by heavy objects. As a really interesting video on YouTube or someone purchased a brand-new Elma machine and Elma didn't seem to grasp anymore or at the time failed to grasp that they didn't package their jars appropriately and they came disintegrated and the machine of course was damaged. Which wouldn't happen if things were properly packaged. As a brings up the problem of vintage machines were they ideally should almost send the jars separate from the machine to keep the jars from disintegrating. https://www.generatorsource.com/Voltages_and_Hz_by_Country.aspx1 point

-

these need to match up, i did something similar when i started , used a cannon pinion from a calibre family, the detent was off and pushed the pinion tight onto the plate, took me ages to find the issue.1 point

-

It’ll probably remain an unknown but for ten pounds it’s running nicely and has a nice silver case nice emblem, I’ll keep it around for a bit. Thanks for all the help. Heres another which I have cleaned up and running. It says Brevet which I understand is patent but it doesn’t have a patent number for me to look up the maker. Nice two faced chronograph working well now. I saw one similar on eBay but they didn’t have any more information than I do. It’s nice and chunky!1 point

-

Unless I'm going crazy, which is likely, where is the spring?1 point

-

It's a generic late 1800s Swiss movement; there were vast quantities made by numerous makers; unless the movement itself has a makers name, they are generally unidentifiable. I believe the cross may be just a mark showing it's swiss made? The case may have the sellers name - cases were often interchangeable and case and movement put together by the seller (or now the ebay seller). I can't comment on that case, I am not familiar with hallmarks etc. In essence, the quality & finish of the dial are a large part of the movement value (assuming it runs OK), and type / quality / materials of the case, and how good condition it is in, make up the rest. Unless one is fully identifiable to a maker, and rare or unusually good, they are not often particularly valuable, typically £20 - £200 depending on condition and, a if buyer seeing something that stands out to them. Examples of similar movements: https://www.ebay.com.my/itm/314734246508 https://www.ebay.co.uk/itm/3044895304811 point

-

Coming back to this, I've now been able to compare the 6458 to a couple of their larger siblings the 7548. The two 7548s also have the ball captive in the case, but protruding much more than on the 6458. Reluctant to do anything irreverable to the case, I decded to try this: That's the ball from a ballpoint pen sitting on top of the original. Seems to work pretty well.1 point

-

The old Bergeon catalog lists it as for "removing and holding seconds hands". There's the 14a which has a sliding lock on the side as well.1 point

-

Just found this on google. There are a few on here I'm sure will be able to help you more than me. This is googles answer If the input range includes 230 which is the common UK voltage as well as the 120 which is common in the US then it will work. It also needs to work on both 50 and 60 Hz to work in the US and UK1 point

-

Without checking on this movement i didn't know H , just a mention that top and bottom cap stones can vary o vsome watches... no I'm pretty sure that wouldn't change any heights more to do with how the shock system works. Having a bit of a list for OPs gives them a few things to look at before coming back, its always nice when they do to say " ive found the problem...it was ...........1 point

-

Something new to learn every day. I didn't know this existed! Available in brass as well. Well worth a try I would say.1 point

-

Hey, this may mean two things. 1. You turned the cap stones over in their respective settings, so which way are they facing now ? Or more probably you mean you swithched top and bottom with one an other.....top and bottom cap stones can be of different thicknesses...so i would switch them back for now until you know for definite that they were the wrong way round before you switched them. So dial down runs and dial up stops, something is increasing the friction in this position and you just need to find out what that is. Be it excess endshake in the escapement causing interactions to fail , such as the pallet fork gaurd finger and impulse pin, hairspring touching something...are all the trainside pivots clean and ok ?..in particular..the escape, the pallet fork and balance, are the endstones ok for these as well ?1 point

-

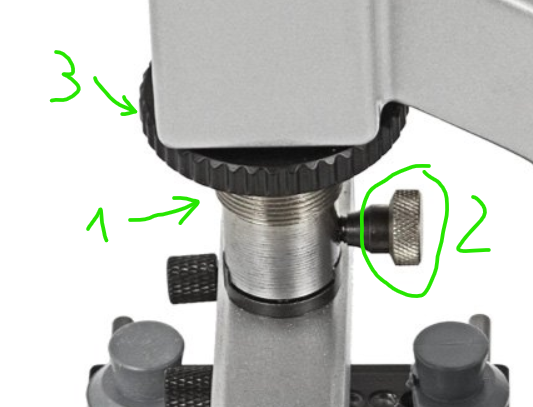

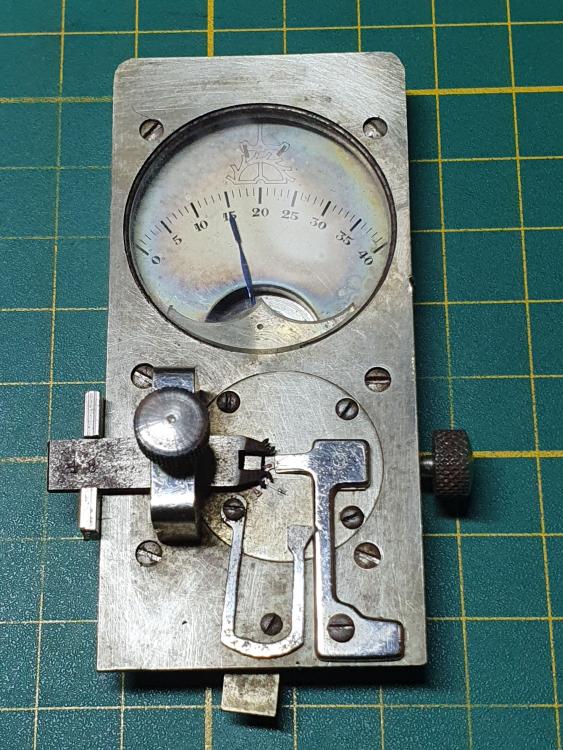

Back to my original post . I got the tool. It allows you to very accurately set the jewels of a pallet fork to the same depth as those of a "standard", but only one jewel at a time. You place the pallet fork (upside down) that is your "standard" and turn the knob on the right side which moves the hammer-shaped arm, which then pushes against the pallet fork, causing the jewel to push against a stud that then makes the pointer move to a random value. After that you do not turn the knob anymore. The device is then set to the entry or exit jewel of your "standard". You can now place another pallet fork of the same type of movement and adjust its entry or exit jewel until the pointer indicates the "standard" value you set. Nice device, but only useful perhaps if you have a kind of production situation where you want to set the pallet forks of multiple identical movements to a "standard". Not something I expect to do. This tool won't replace my copper coin .1 point

-

Actually, as the wheel is big, it is possible to repivot it without special tools. Just good hand drill needed and proper drill bit of the correct size, close to the pivot size. If needed, I will explain how and show some pictures. Well, this statement brought all of us to delusion. It appears now that the train was blocked by the wheel with broken pivot1 point

-

Limit International produced a lot of interesting watches, and used a lot of different suppliers. I don't think you could claim they were ever "high end", but they did make some very attractive watches. They are still around, in one form or another, but like quite a few watch companies, their current offerings are a bit of a mixed bag of "Smart" watches and rebadged, mainly Chinese, mid range mass produced stuff. Their older stuff is always worth looking at as there are some real gems.1 point

-

I must admit, that until a couple of years ago, if I came across a Limit watch in a lot, with no hesitation it would be discarded into the junk pile and never thought of again. That is until I came across one and happened to notice that it had made in GDR on the dial, and was 36j automatic. Proceded to remove the caseback to see what was going on in there. Inside, a wonderful Glashutte spezimatic. I will wear it soon and put some pictures up. Needless to say that Limit watches are now firmly on my radar, I had no idea Tissot also supplied movements, I do have another with Swiss FHF movement. Fine looking watch there Andy1 point

-

Yes, it says "Key of Watch" on one side and "Ling Hui No 5788" on the other side. In the meantime, I've also tested it on two watches and it worked perfectly. All the accessories are also well-aligned/centered.1 point

-

Yes, it was clear: You are happy. My new one looks like yours. I'm also happy with the new one1 point

-

Hello all, I'm happy to report that the new case opening tool from Vevor is much better. The lateral play is minimal and feels just right. Funnily, it doesn't look like the one on their website. Literally none of these three points (from the pic on their website) actually applies (except Point 2 - it is metal, but a different colour): It looks, however, much like the one posted by @Malocchio Here are two photos: From the initial inspection, I'm very content. I'm glad to have sent back the other one, which was inferior to this one.1 point

-

Did you replace the whole balance assembly or the balance and hairspring or just the hairspring alone? What movement is this?1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)