Leaderboard

Popular Content

Showing content with the highest reputation on 10/29/24 in all areas

-

6 points

-

3 points

-

3 points

-

Yes, the thing in the pin vice usually is the original staff and it is there for reference. There are different approaches here. Some people prefer to use the original staff for reference and do everything to prevent it from damage. Others count on drawings and measurements and use for reference dedicated calipers that hold the size needed for the current operation. Such caliper I made for that lathe - one turn of the wheel there moves the pointer to 0.5mm and the wheel is graduated like in micrometers. I needed this as I normally work on cross-slide lathes and count only on the wheels graduation for the staff sizes in height. I usually destroy the original staff when removing it off the rim and thou it still can be measured, I measure what i need before the removing and don't care if it gets lost or destroyed. Often the watches that come to me are with staffs that for sure are not original, so I have learned how to do reverse-engineering of the sizes needed and don't care much to preserve for measurements what is in the watch3 points

-

Nope, not a bad price for a 17 jewel Waltham with an apparently intact balance. But the deeper you get, the more money you will lay out for vintage specialty tools and that's where the fun is.2 points

-

2 points

-

2 points

-

So if you really want to you can break the cock and jewel setting down to these 4 pieces, the regulator arms remove quite easily with a sharp knife under the beat arm then the setting can also be prised out from the cock with the same sharp knife. Thats about as far as you'll get and tbh i dont think you need to go any further the US should flush it out, so I'll try that. But for interest there does look like a fine seam that will split the jewels holder in two and yes the jewels are seperate....a holed and a cap...the cap is a tad wider as usual. Lets give it a blast in the US and see how it comes out...this one is grubby as hell and the jewel hole is block...so a little poking around is required to free up the crap. To summarise....dont bother stripping it down even to the 4 parts unless you're really fussed about it, just blast it in a USM. Let us know about your outcome with it please. Yes it comes apart Andy..... to 4 pieces I'll flush it, and then try split the jewel holder, 99.9 % sure it wont survive, the equaliser is ready and waiting to take over when it goes pear shaped2 points

-

I've seen similar Lonville watches with a Langendorf movement. And in the USA there were brands Lonville and also Stratford which had six jewel Langendorf movements, presumably to lower import costs. The lower balance cap on those is polished steel set in brass instead of a ruby jewel. The plates were very rough, with lots machine swarf and jagged milling, and the plating very thin & corrosion-prone. You may have some fun!2 points

-

1 point

-

Pivot looks fine along with the jewel and hand so looks like you've been lucky.1 point

-

1 point

-

Great observations gpraceman! I agree that when it comes to jewel work I turn to a Seitz or Horia tool since that is what they are primarily designed for. But if you only had the one tool, the 18R set can do a lot for you. It takes time to find tools that are in good condition and complete. I used my 18R until I was lucky enough to find a Seitz tool that was in decent shape with all the bits. I still have the 18R jeweling option available as a backup. Claudio, You should have the two balance staff removers as mentioned, along with the two stakes that go with those removers. K&D sold them to owners of older sets as a separate kit which you can often find on ebay. One of the staff removers in the first set was from one of these kits. (The kit is the blue box, which is missing one of the holders). One caveat: Sometimes you need to cut out the old staff using a lathe instead of this tool, or you risk warping the balance. The sub punches were available in the Deluxe version of the 18R, but were also sold separately. You are buying a used staking set so it is very unlikely all the pieces are original or even there. Try and find a set that is the most complete and in good shape, and later you will find stakes or another staking tool that is incomplete that you can use to supplement your set. You don't need to get an 18R, just find a staking set you are happy with in functionality and appearance and that fits your financial situation. I gave a small set of 20 stakes and base to someone starting out in watchmaking and it was all he needed at that point in time. I did not inherit a completely original set. My dad acquired stakes and stumps along the way, and so did I. Several of those stakes and stumps have moved to a different set since I don't use them as often (like working on cylinder balance staffs and making oil sinks). To be honest, there are a lot of stakes I never use. Good luck, take your time, enjoy the journey!1 point

-

Hello Frank, I’ll leave the hole ‘plugged’ with the steel rivet and will only remove it if somehow it works loose in future. It is very firm at the moment. I admit my timegrapher was set to the default 52 degrees and the watch was only running for a few minutes before I decided to let down the mainspring. I must look up the lift angle for this movement- the H7 variant of cal 52.1 point

-

I was thinking that if I had the skill (I don't) the part that would be handy to be able to make would be the 'tips' or whatever they are called that are shaped specifically for the Jubilee and Oyster links, then you could (maybe?) use them on bracelets that have a different shape than those.1 point

-

1 point

-

I actually got a similar idea from Nev, he had an adjustable depth marker for his lathe. I'm using this cheap 3rd hand tool. If you're into turning, you're probably into other hobbies as well, and might have one lying around. It works great for quick reference instead of holding the vice in one hand and trying to mark out our length with the other.1 point

-

Yeah sorry, this goes on the other side of the lathe when turning. Its holding a balance staff and I just slide it out of the way after I make reference. Its similar to a height marking gauge if you're a machinist.1 point

-

I fell down this rabbit hole after buying a 2409 amphibian and discovering an issue with the keyless works. Research suggested it should be simple enough to address and, well you can guess the rest. I believe, having read a number of your service notes on Vostoks and put into a epub to read on my tablet, that you started on them for the same reason: relatively inexpensive and the understanding that, in theory, all the parts are interchangeable in the 24xx series. Re. Third wheel and canon pinion: My conclusion was the same as yours, to make room for the calendar wheel. The hands won't fit if the calendar complication is in place. With regard to my question on the balance assembly, I haven't faced an issue previously with fitting the balance cock on the 2409's and 2414A's I've looked at, though admittedly that's about four of each. However when trying a balance assembly from three or so other Vostoks on a 2416b the pins were very tight going into the main plate. Similarly when trying the assembly from the 2409 on the 2414a I was salvaging from. It may well be coincidence. The 2416b I'm working on came without a balance assembly, and I'm not taking apart another just to check balance assemblies. I got this one to prep myself for working on the others. The other reason I wondered about the balance assembly being different is I've tried two and the rates are slow. My thinking was that if there's no known difference in assemblies, then it's obviously something else which I've got to find out, but I should ask just in case there is. By the by; I put the arbor from the old mainspring barrel in the new barrel with spring. Seems to work. If the actual mainspring is also different.....1 point

-

1 point

-

1 point

-

If the barrel is brass and the rivet steel, you could perhaps dissolve it with alum. When enough material is gone is should drop out.1 point

-

Valuable information! And it makes sense, I suppose, to make some extra room for the 2414 calendar wheel!? By the way, it's fantastic to see an update in this thread, which I started many years ago and thought was dead! I didn't know this. Can you elaborate on this thread? It would be great, and I'm sure future readers would appreciate it.1 point

-

My advice will be to leave the rivet as is, may be just carefully file the outside if it protrudes and is not smooth.1 point

-

1 point

-

Wow!! What a great forum. Waking up early morning loaded with many good answers to my question. It feels very inspiring to continue with the movement. Thank you all!!!!1 point

-

If it's non removable how would you replace the regulator?1 point

-

Apologies for the late comeback, my memory is terrible these days, I'll drag that spring out while i remember and see what i can help you with. You're in uk i assume you mentioned 50 quid in your intro. 50 quid to change a 2 quid battery, i need to set up shop i can see the spring for the date ring in your photo ? Is this one that you've modified ? Was the original one missing ? This is the spring, pretty basic shepherd's crook, let me know what you're looking for.......and if you say a busty blonde.....then its too late i already have the perfect match And no its not Sam Fox that we keep seeing in the lingerie ads at the top, mine is far better.1 point

-

This i simple. The escape wheel bearings position is not important. The straight line needed where the impulse pin must be is balance bearings - pallet fork bearings.1 point

-

Yes, the ultrasonic is your best friend in this situation. Whatever you do, DO NOT peg that hole. Thls is a non-removable jewel setting. The 3 notches are to allow the cleaning fluid to penetrate and wash out any debris. This is the first time I've seen it being used for a balance jewel. It does not offer any shock resistance to the balance pivots. It's normally used for the escape wheel and pallet fork jewels.1 point

-

How about giving the whole assembly a good bath in ultrasonic?1 point

-

1 point

-

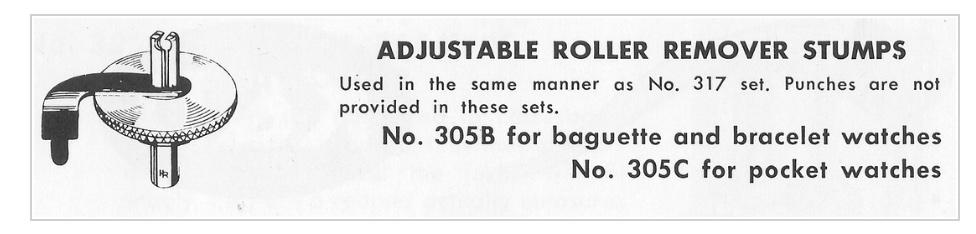

Hi Claudio, I have the first one you mentioned (K&D Inverto 18R) but a slightly older model (since the depthing gauge on this one looks newer). The piece you mentioned that is missing on the 305b and 305c roller table stumps is a black metal strap that goes around the stump and hangs over the edge and would be held in the two empty holes on in the box. When used on the tool, they would fall into the die hole on the main surface of the tool (I usually put it in the hole in the middle). It holds the stump stable, while you tighten the knurled part under it to close the jaws together. Not a showstopper, as you could easily make something to do this. The inverto models are great because you can put stakes upside down in the tool, not just coming down from the top. That gives you a crazy combination of stumps options available to you. The other one you showed (model 17) does not have the depthing guage. It is still a good staking tool, but you would need a Seitz or Horia jeweling tool to complement it, which is totally fine. Not a bad route to go. You would also possibly look for additional stakes & stumps that were not available in the 17 set, but keep in mind some stumps and stakes are really not used much anymore. If money is not an issue, I would go with your first choice, it looks like it is in good shape. I do not see any blockages, but as previously suggested definitely ask if there are any blockages and if everything is still in alignment. Are any of the stakes or stumps broken or blocked? Are there any bad rust spots? Does the knob on the back of the unit work smoothly and lock the base in place? Get the book "The Watchmakers' Staking Tool" by George G. Lucchina and Archie B. Perkins to help understand how to use all the stakes. And here are a few useful links to on Staking Tools https://kanddinverto.weebly.com https://tadelstein.com/Cross-over-punches.pdf https://tadelstein.com/Staking Tools and How to Use Them 1910 - 163p BW - S.pdf Good Luck!1 point

-

Looks worth the gamble. Looking forward to seeing what you got. Here's my latest gamble. A Lonville pocket watch in a gunmetal case. I too have absolutely no idea what lies inside. Possibly a Langendorf. Possibly a 7 jewel cylinder movement. Possibly a small lump of coal inside and a note to Santa Clause. Time will tell. Lonville watches seem to still be around (or perhaps they have been brought back to life). https://lonville.com/1 point

-

Hi SiZi, It looks from what You show the movement should work, but it doesn't. So the reason must be found... You videos are informative, but it would be better if You don't blow so strongly air on the balance as to make it spin really fast. No, it is not needed. Now I have to wait looking at the videos for the balance to calm down almost all the time, and then what I need to see happens very fast on the end of video or is missed at all. Can You record a video where the movement is assembled and tries to work? I don't need initial amplitude more than 180 and what I really need is to see how fast and how exactly the balance will come to a stop and in what exact position it will stop, plus position of the pallet fork1 point

-

I have an A1 clone and it has been working out well for me. I did have an issue with the fine needle tip being bent initially. I pressed the tip gently against a case cushion to coax it back straight. No instructions, but it wasn't hard to figure out how to adjust and use it. I needed a 180 clockwise turn on the adjustment screw (not sure if clockwise or counterclockwise really matters) to get the correct size droplet. I put the tip carefully into pithwood before each application to make sure there is not any extra oil left on the tip from the last application. I have seen one YouTuber using an auto oiler with HP 1300. Not sure who nor which model auto oiler.1 point

-

1 point

-

The video and the photo you posted above; these are both with the escape wheel removed, is that right? Did you change anything else since this morning? Your description of how the train comes gently to rest sounds good. Post a video to be sure. In the latest video above, it looks like the balance is swinging freely, and coming to rest gradually with the impulse jewel on the line through the pivot centres, exactly as it should do. So we can rule out the interference between impulse jewel and horns etc. which I was speculating about earlier. You don't need to adjust the stud carrier. The watch is in beat. I read through your post from this morning over again. I think I misunderstood it. You describe the fork resting against one the banking pins, to one side or the other, but not in the middle. If you had all the train wheels installed and power in the mainspring, then this is exactly what is supposed to happen. This how the escapement works! Would you mind defining your problem again? Give us as much information as possible about the conditions and how the problem manifests itself. Your videos are helping a lot. Don't be afraid to start recording earlier and stop later.1 point

-

As already mentioned, if it's about centered it will be ok and not be the cause of the watch stopping. You mentioned that the escapewheel comes to a gentle stop. That is nice, but no guarantee. You also seem to have some doubts about the pallet fork's "snap". Sometimes an escapewheel spins great when the train is not under "load", but with some wind and the pallet fork preventing the wheels from spinning, other factors come into play. There was a post on this forum very recently where the train of a desk clock of some type spun great when free, but not under load. In the end it turned out one of the wheels had a broken pivot.. Just saying, don't assume the pallet fork or balance are now the only 2 options left.1 point

-

Got this one arriving today. An Elgin jump hour watch with an Elgin 717 movement. I had been itching for a jump hour watch with a nice movement in it. Most I've seen have a cheap pin pallet movement. This one is 17 jeweled. Not currently running and missing the crystal. Getting the minute wheel off may be interesting. Looks like there is a special tool to do so. https://www.crazywatches.pl/elgin-717-golfball-direct-read-jump-hour-19571 point

-

A1 clone arriving in the post. This doesn't fill me with confidence. I'd seen someone mention them somewhere in the topic of budget items that are good so I thought I'd take a chance.1 point

-

Hi @ClaudioCavalli, where are you based? US, Europe...? The ones you picked are on the expensive side, but also very nice, I think. Especially if you're in Europe, also look for Boley staking sets. They're excellent. The diameter of their stakes is 4.7mm, which is still the most common diameter and you can order replacement stakes, e.g. from CousinsUK. Boley sets can go for 300-400 around here (in Europe). There are also other bands, like Favourite. The one in your first link also includes reamers. And maybe even pushers for jewelling (is there a micrometer adapter??) -- but it doesn't have pump-pushers, which makes it inferior to a dedicated jewelling set like Horia/Seitz. In terms of the actual punches/stumps, first and second link seem roughly the same. Feel free to post more links you find and we can help you choose.1 point

-

Always when buying second hand make sure that the punches are not blocked and the same goes for the main tool. You do not want to buy one were the main tool has been dropped.1 point

-

Thank you very much I appreciate it. I’m starting to get a feel for this1 point

-

So you didn't find this on Cousins looking under parts for the ETA 2375. As @RichardHarris123 said, the amplitude may or may not be related to the mainspring. Depending where you are in the world there are numerous places for parts in general. https://www.watchmaterial.com/eta-2375-2381-2384-automatic-mainspring-self-lubricating/ Edit What bridle did the original have? Was it a separate one? What was it you actually got from timeparts?1 point

-

these need to match up, i did something similar when i started , used a cannon pinion from a calibre family, the detent was off and pushed the pinion tight onto the plate, took me ages to find the issue.1 point

-

I found a differences with the centre wheel and canon pinion on a 2409 and 2414A when I tried using the centre wheel from a 2409 in a 2414A. They look identical, but the notch for the canon pinion is obviously slightly higher up the shaft on one. The canon pinions differ by 0.5 mm in height. The canon pinion in the 2414A is 2.5mm tall, the one in the 2409 2.0mm tall. The height of the centre wheel for both is 3.6mm. The canon pinion for the 2414A won't work with the centre wheel from the 2409.1 point

-

Does this have the same movement? https://www.ebay.co.uk/itm/1563003840661 point

-

Actually, as the wheel is big, it is possible to repivot it without special tools. Just good hand drill needed and proper drill bit of the correct size, close to the pivot size. If needed, I will explain how and show some pictures. Well, this statement brought all of us to delusion. It appears now that the train was blocked by the wheel with broken pivot1 point

-

I wondered if superglue had been used somewhere and the off-gassing had caused the effect to the crystal.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)