Leaderboard

Popular Content

Showing content with the highest reputation on 10/31/24 in all areas

-

Guy’s, I know we like to go off on tangents for a post or two but lubricant discussion has its own forum section dedicated to those arguments, this thread is meant to be discussing favourite yootoobers. thanks Tom4 points

-

Four Weeks later, it finally looks finished, Luming the dial went well, the finish is a bit too goldy was hoping for more of a brown. Looks great compared to how it started though, the hairline cracks in the dial cleaned out well. Now to find a new watch to work on (Before I decide to have a second go at the lume).4 points

-

https://www.bonhams.com/auction/29154/lot/35/grana-a-rare-stainless-steel-manual-wind-military-issue-wristwatch-with-promethium-p-dial-dirty-dozen-circa-1945/ …perhaps this watch?3 points

-

3 points

-

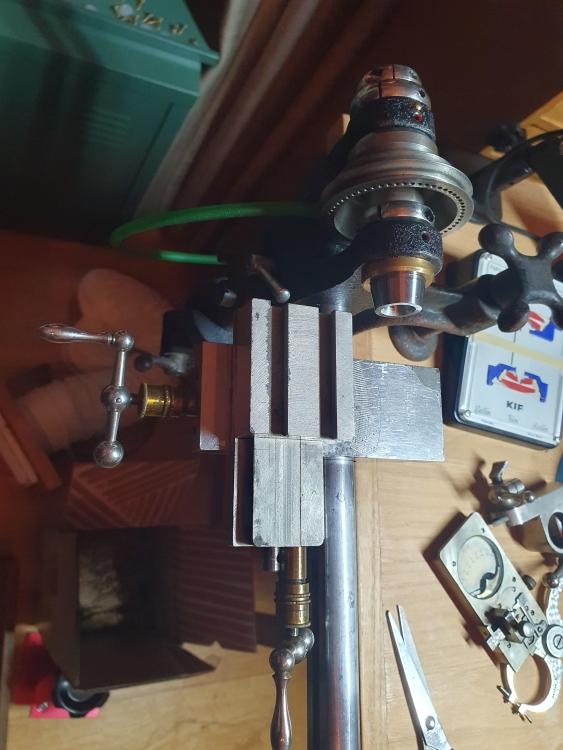

Just bought this great old tool (lathe?)and now finally will be able to make the bezel I have needed for about a year now for my big old 65mm pocket watch. Just love these old tools. No idea how old it is but it must be 100 years or more. Tomorrow I’ll show you a nice old set of pliers - with teeth! For making the right size hole in pocket watch hands.(round or square). I finally found a great old watch maker 4th generation who is teaching me all sorts of tricks including using my lathe to drill out and re pin balance staffs. My next visit we’re going to make one from scratch. At last somebody to lead me!He also let me have a few of his grandfathers tools this one , the pliers and a great full set of Lorch 8mm collets for my star. More to come when I get home cheers Jules P.S hope IBIS doesn’t mind me setting up and checking my tools on their work desk in the room…2 points

-

I'm saying 5 jewels, because that is the minimum it is likely to be, but it *may* be seven. I haven't explored it any further. There is a good chance however that the lower balance hole is a bushing, with perhaps a steel cap. It might, of course be a jewel and cap jewel. I'll find out when I get a chance to strip and clean it. What makes me suspect that it is only five jewels is the fact that I have found similar Lonville (Langendorf) seven jewel movement pictures online, but they are stamped 7 Jewel like this example. My suspicion is that if it were 7 jewel, it would say so. Lonville was part of the Langendorf Watch Company, a well respected Swiss watch making company. They traded for exactly 100 years from 1873. They used several brand names including Lanco, Larex and Lancyl.2 points

-

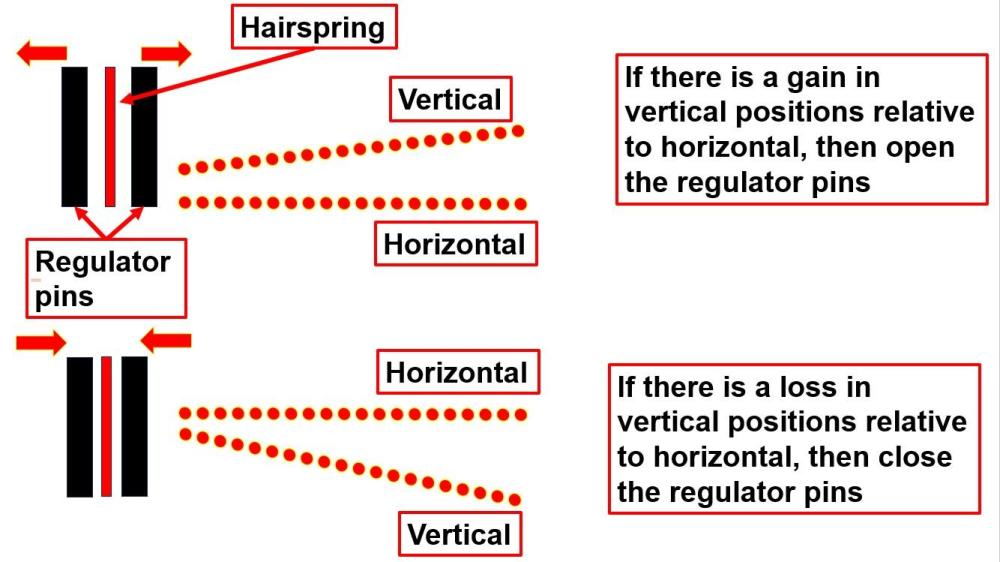

I guess 'the industry' would not use it if there were no benefits or it caused problems - it's not cheap. Many companies have banned Rodico as it leaves a residue. So any problem with epilame and they would stop using it? Where could it wear off and contaminate the oil? I know some like ETA seem to treat most of the movement. I use it on pallet + cap jewels and escape wheel. I run the balance for a few minutes so that it wears away (from the centre of the pallet jewels and escape wheel teeth) before oiling. It makes oiling the cap jewels easier. So, in this case, I don't see where it could wear away and cause problems. You would need to run them for a number of years !2 points

-

2 points

-

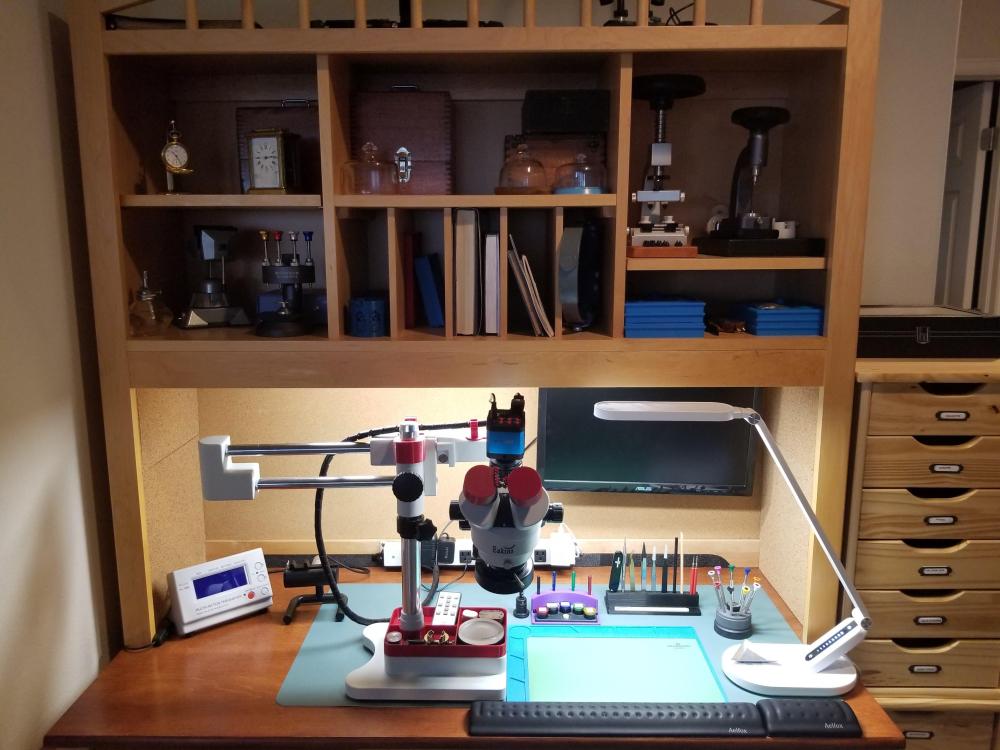

My setup has continued to evolve. Not ideal, I know, but it works well for the tight real estate that I have. Added an optical microscope. Takes up a lot of space, but so much nicer than using a loupe or magnifying visor. Better on my back, for sure. Added two sets of drawers for projects, parts and tools. Keeps me better organized. I now use the desk drawers for tools and supplies that I more commonly need. The hutch and drawer units are handy to store all of the tools that I have been acquiring. The computer wrist rests help corral parts. I plugged up the gap between the hutch and desk with some foam, where some parts liked flying to. I also added some cork board to the sides of the hutch for a bit of parts ping abatement. There's only one part (a screw) that pinged away that I haven't been able to find, even with the big magnet wand that I keep off to the left of the desk. Lighting is still something that I want a better solution for. The microscope gets in the way of a portable desk light. I did buy a unit with two adjustable lights for the times that the microscope ring light provides too much glare for photography, but it's awkward to use and isn't as bright as I'd like. I keep my ultrasonic cleaner and watch cleaning machine down in my basement.2 points

-

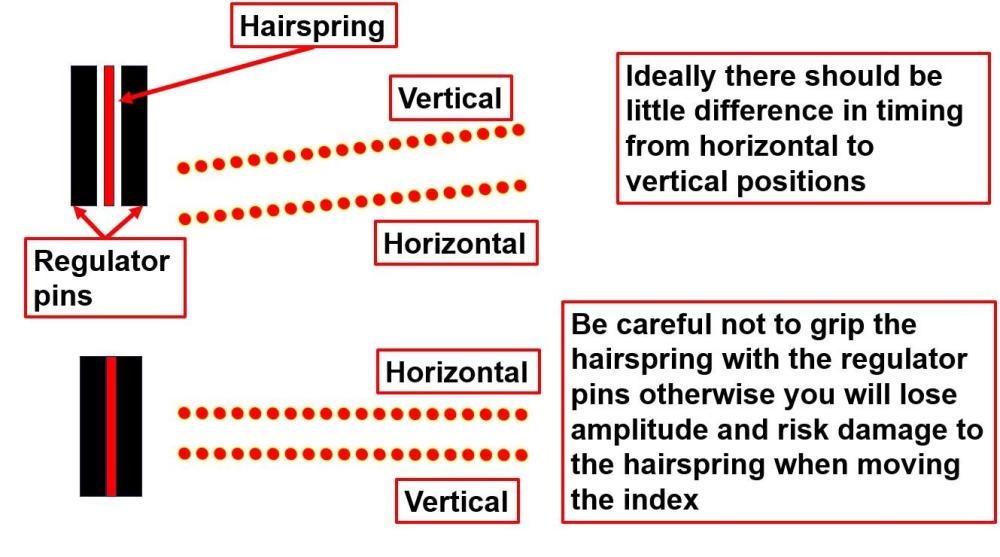

A Vostok (1975 inscription on the back) with 2209 inside, a nice gentle dial patina, Cyrillic printing, perfect hands and numerals. I did the restoration about 18 months ago but the 2nd wheel hand setting friction was too low and it would occasionally lose a minute on the wrist. I didn't have the confidence or time between projects to pull the part out and tighten it until yesterday, thinking I didn't have the right tools to separate the friction pinion from the 2nd wheel. Of course I had them. 10min job and now it's perfect. It runs +2/260/0.0 on the original spiral mainspring.2 points

-

1 point

-

1 point

-

1 point

-

Can you confirm what you mean by bezel insert? The only true way I've found with a crown is sealed in original packet.1 point

-

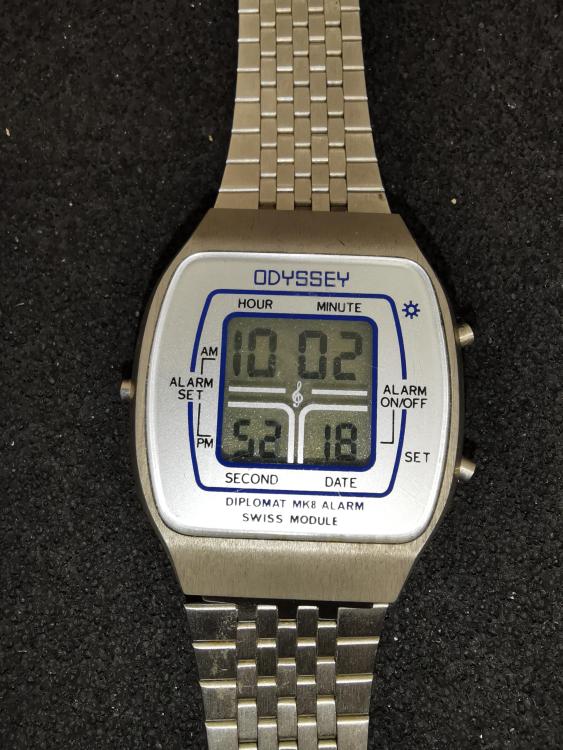

As the title suggests, I have introduced myself a while ago but have been inactive since, I'm about to ask for some advice from the military experts so it's only right that I introduce myself properly first. My love of watches has grown from my passion for 80s casios, when all the other cool kids had the fancy marlins, I had to make do with the embarrassing petrol station omac. I now have a large collection now to make up for time lost. In the process of collecting the digitals, one or two japanese mechanicals would be included which just got put to the side. Some years ago I thought I'd have a go at getting one sorted, it was a orient chronoace with a heavily corroded movement, over time and waiting for the right spares I managed to get it going, and is still going today. I now have just as many mechanical watches as the digitals, mainly japanese but also swiss, german, russian, french. I am by no means an expert, am constantly learning and I am confident to service, source spares and carry out hobbiest level repairs, and yes, I've got plenty of movements in various states of repair waiting for the correct spares. Now dear moderator, please forgive the waffle, I'll outline my query to the forum if you could direct me to the correct thread, this is my first ever venture into any forum so be gentle. I know you guys like pictures so I'll have a go... I have recently acquired what I believe to be a dirty dozen watch and possibly the hard to find grana, the watch I have has a P dial, now I know that this is a reference to the lume, but I can't find any other images of a www grana with a P dial. Does this signify a re dial or is it a later issue. The other question is, if it is a genuine www grana, do I service it and try and polish out the scratches on the crystal or leave it as it is. The watch does run for about 30 seconds but the jewels are gummed up and does need servicing. Greatful for any advice1 point

-

That's an amazing find and a beautiful looking watch. Good luck with the auction...1 point

-

1 point

-

what I was curious about was if you look at the dial side plate can you see the scribe marks were somebody hand laid out the wheels? It would give us an indication as to whether this was mass-produced or whether it was basically hand assembled.1 point

-

1 point

-

1 point

-

Agree! I don't mind a detour now and then, on the contrary. However, when the thread changes shape completely, it's better to start a new thread or post in an existing thread and then link to it so those interested can jump over there. So, please follow our much-appreciated moderator @tomh207's suggestion!1 point

-

The lathe can be situated with the head to the right or the left. Convention is to have it to the left; but that slide is built to use with it to the right. If you put the head to the left, the crank on the left side of the slide will be crashing into it.1 point

-

1 point

-

Couldn't it be welded? Other than the general concept, I know little about welding but I know thin plate can be welded.1 point

-

1 point

-

The slide is for use with the headstock on the right, and may also have reversed threads on the advance (some Lorch do, some don't). I don't think it can be switched for use with the headstock on the left. For me that would be a no-go. As you are in the U.S., I would keep my eyes open for a WW style lathe, perferably with a collet holding tailstock. Levin, Derbyshire, and Marshall (not their Peerless line) are all very nice machines. You might find a Paulson, which was made by Boley-Leinen, also excellent, as well as Boley. Lorch made a WW style, the KD50, but they are very sought after.1 point

-

unfortunately in watch repair it's the painful lessons we remember. finding spare parts for vintage watches is always going to be a challenge. Then a unidentified watch makes things even more challenging. If you cannot find one you could always regulated and use a small amount of glue to hold it in place. Not ideal but you may not be of a find one right away I don't suppose we can have a picture of the dial side without the dial just because I'm curious about something.1 point

-

my eyes didn't catch that, that's definitely a tougher task, hopefully a donor can be sought....1 point

-

Wow, i remember Dixions electical local outlets, thats going back a way. I seem to think they are still a company online. I use a similar idea at work....wood effect plastics for doors windows and kitchens...any light scratches become unnoticeable with a quick wipe over with WD.1 point

-

Clean bezel! I've noticed that the seconds hand on this model comes in both one that is fully painted red with a normal lume 'lollipop' like yours and one like mine that is not painted red but has a red 'lollipop'. I would have though that one is just an aftermarket addition but I've now seen enough of both that I assume at some point they switched form one to the other.1 point

-

1 point

-

1 point

-

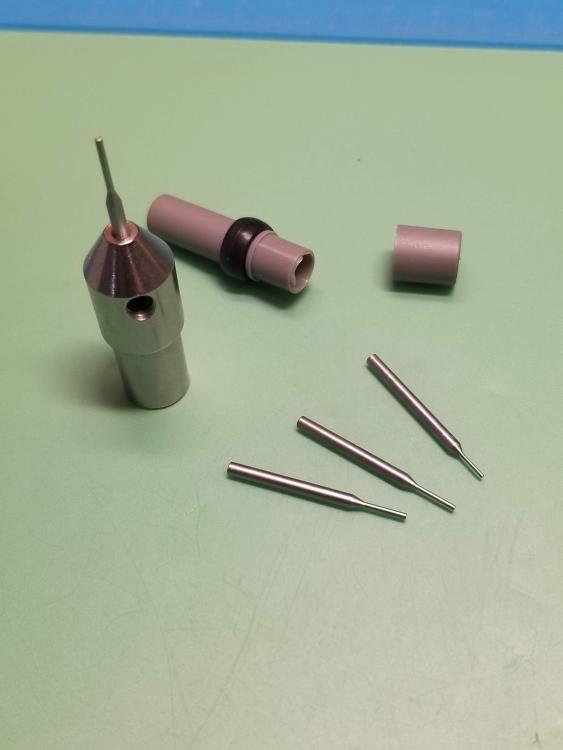

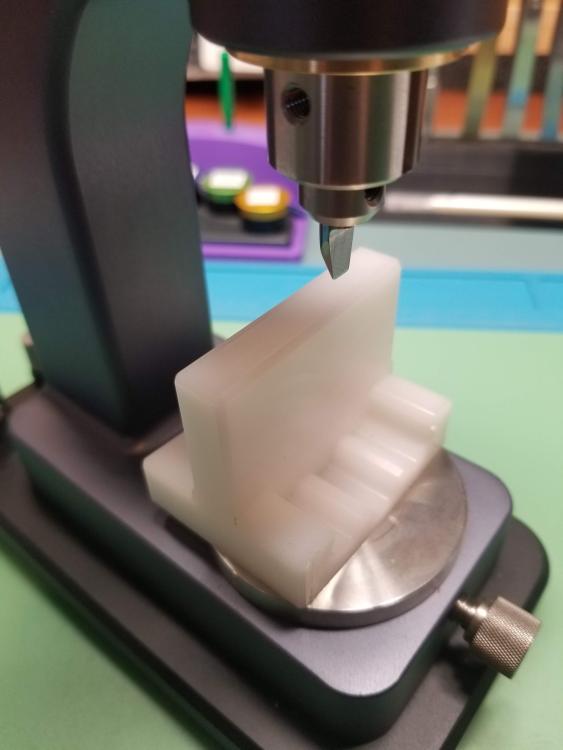

I think my journey for a good crystal press is over. I just got the press shown below and am liking it so far. Far better than the other two cheaper Chinese ones that I have tried. It is solidly built. Can also be used to open snap on casebacks and adjusting metal band links, so it is a 3-in-1 tool. I had the problem opening up a Waltham wristwatch with a caseback knife and this opened it up no problem. What I don't like about it is that you need an Allen wrench to change out the upper bit. Maybe I can change out that grub screw for a knurled head screw. Also, the handle turns opposite of what I expected. Counter-clockwise to lower and clockwise to raise. I'll get used to it. It did not come with the crystal press dies, but those are pretty inexpensive to get a set of nylon or aluminum ones. https://www.aliexpress.us/item/3256806922669039.html Started with one like this. Ended up getting it for free, as I had to repair it. https://www.aliexpress.us/item/3256806885195604.html Then tried this one. Was certainly better than the first, but sold it when I thought that I was getting a vintage Robur press (press only) that ended up getting lost in the mail. https://www.aliexpress.us/item/3256805690261587.html As a crystal press: As a caseback opener: To adjust watch band links: Bit storage:1 point

-

Lesson 33. ETA 955.422 Assembly.pdf You might find this lesson I wrote helpful. Unfortunately, I converted it into a PDF to post so it won't show the video of fitting the keyless work. Here's a link to my cloud storage where you'll find the PowerPoint presentation https://docs.google.com/presentation/d/1_OPys8CnqdprxOvnHL2QTTFR802jjFW1/edit?usp=sharing&ouid=107902587627140904870&rtpof=true&sd=true It won't be there for long, so download it to refer back to1 point

-

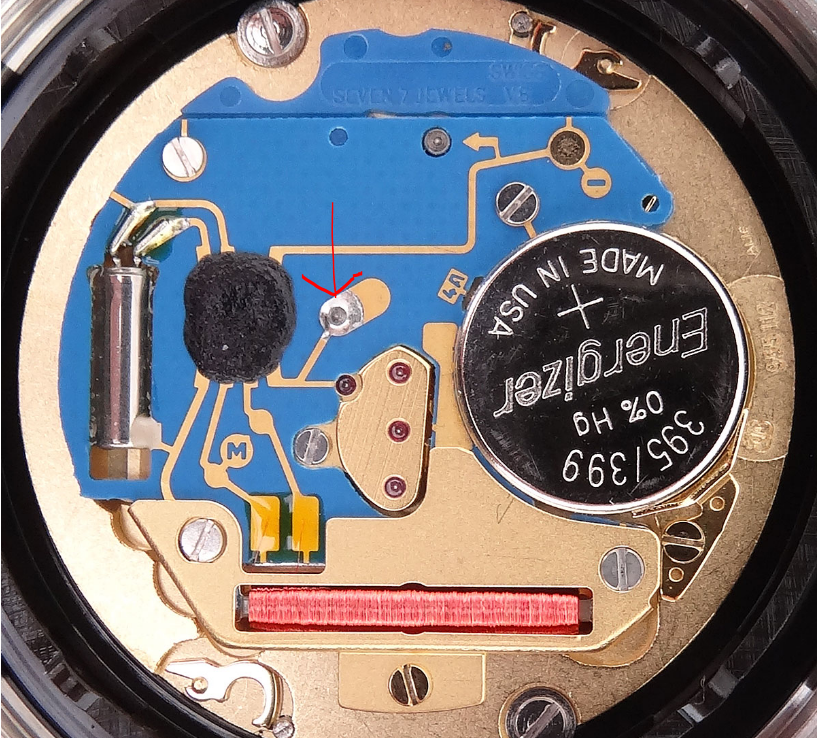

I just serviced a few of these movements. I honestly would remove all of the keyless works and start again. In my experience, trying to finagle and move spring loaded parts usually takes more time than just starting over. you can use rodico on the on the movement side to hold the setting lever pin in, but it usually isn't necessary. A side note on this movement, one I recently serviced would not pulse or run, but when removing the circuit and coil from the plate, those would generate a pulse. This pin on the underside was grounding out on the plate below, so I had to file a bit away to stop that. Something I hadn't come across before.1 point

-

That's a great looking watch. Maybe this forum wasn't such a good idea for me, I'm now on the lookout for a Longines and a Caravelle .... I want one, 70s watches that can be used as a bludgeon are right up my street. Got some time to kill here at work, it's got busy, that means quiet for me, so whilst I wait for things to quieten down a bit, and provide some light reading whilst you're killing time reading through the posts, I'll share what I'm sporting on my wrist this morning. Well it should be the Timex, it's time isn't up yet, but I've had to call in a substitute. The watch is doing really well and time keeping spot on, but I just wasn't diggin the strap, it was busy digging into me, so it's sat on the side forming the strap around some pipe lagging. So I thought I'd go back to where it all started for me with mechanical watches. This Orient chronoace with the 21 jewel 42940 movement. Probably not the wisest choice for a first movement, but it was available, came with a lot of digitals. This movement was rusty! If I ever come by a watch as bad as this was again, it won't be getting sorted, I'll be looking for a donor. But as a keen new starter, soldiered on, slowly assembled as replacement components arrived, and eventually ended up with a working watch, I was pleased. I should probably strip and service again now that I've got a lot more experience under my belt, but it's running fine. It did dawn on me though whilst I was getting this up and running again that it's never had a ride on the timegrapher. Amplitude was ok, just ok, running way too fast, throttled down accordingly and the beat error 0.1! I can only assume that was good before the rust set in and miraculously I didn't mess it up. The rust damage had creeped around onto the dial, clearly visible are the areas that I learned that watch dials don't like being cleaned. My first success, I wear with pride.1 point

-

1 point

-

as you're going to the meetings you could always email headquarters and see if it's in their library. They do have a really nice library with a lot of books.1 point

-

1 point

-

You would never clean a barrel assembled. Back in the dark days when there was a surplus of watchmakers and they were all cutting each other's throats, there were cheats like a final rinse that "lubricated the movement" (which was cleaned assembled). "Better" watchmakers would remove the balance jewels, the barrel bridge, take out the barrel and open it but leave the spring in. I worked in a trade shop like that in the 90s when I was in school... Didn't have any comebacks, but I would actually disassemble the whole movement contrary to my orders: we weren't to remove the balance jewels in that place, or do anything beyond pulling and opening the barrel. With the barrel open, there's at least a chance for the cleaning fluids to get out; closed, no way. Obviously cleaning the barrel with the spring in is just a dumb idea, period. Honestly better not to clean it at all, leave it closed, and add some lube to the arbor.1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)